Abstract

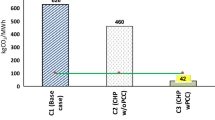

Emission of carbon dioxide from fossil fuel-fired thermal power plants is a major concern for energy providers all around the world. In this context, carbon capture from thermal power plants and the energy penalty incurred in the process are important issues. The present work reports on a detailed analysis of gas-fired power plant layouts with in-built carbon capture, i.e. the flue gas from these power plants contains mainly carbon dioxide and water vapour. Four layouts, two of which are based on pressurized oxyfuel combustion and two on chemical looping combustion (CLC), have been considered. Based on detailed mass balance, energy and thermodynamic analyses of the power plant layouts, the net efficiencies for each plant have been computed. After accounting for thermodynamic irreversibilities and CO2 compression to 110 bar, these have been found to vary between 31 and 52 % for the four plants. Despite the technological maturity of oxyfuel combustion, it is concluded that CLC-based plants would be future-ready in the sense that they can readily accommodate CCS with only 2 % loss in overall thermal efficiency for CO2 capture.

Similar content being viewed by others

Abbreviations

- ASU:

-

Air separation unit

- CLC:

-

Chemical looping combustion

- CC:

-

Combined cycle

- SMOC:

-

Steam-moderated oxyfuel combustion

- CLCSC:

-

Chemical looping combustion steam cycle

- HRSG:

-

Heat recovery steam generator

- LP:

-

Low pressure

- MP:

-

Medium pressure

- HP:

-

High pressure

- AR:

-

Air reactor

- FR:

-

Fuel reactor

- \(M_{\text{Air in}}\) :

-

Mass of air entering air reactor per unit time, kg/s

- \(M_{\text{Dep air}}\) :

-

Mass of depleted air leaving air reactor per unit time, kg/s

- \(M_{{{\text{MeO}}_{x} }}\) :

-

Mass of oxygenated metal oxide per unit time, kg/s

- \(M_{{{\text{MeO}}_{x - 1} }}\) :

-

Mass of reduced metal/metal oxide per unit time, kg/s

- \(M_{\text{Fuel in}}\) :

-

Mass of fuel entering fuel reactor per unit time, kg/s

- M Exhaust :

-

Mass of exhaust leaving fuel reactor per unit time, kg/s

- T :

-

Temperature at any point, °C

- \(Q_{\text{Air in}}\) :

-

Thermal energy flow in air entering the air reactor, kW

- \(Q_{\text{Depleted air}}\) :

-

Thermal energy flow in oxygen-depleted air, kW

- Q MeOx :

-

Thermal energy flow in oxygenated metal oxide, kW

- Q Me :

-

Thermal energy flow in reduced form of metal oxide, kW

- Q Ox :

-

Thermal energy produced by metal oxidation reaction, kW

- \(Q_{\text{Extract}}\) :

-

Thermal energy extracted from air reactor by cooling fluid, kW

- \(Q_{\text{Fuel in}}\) :

-

Thermal energy flow in fuel entering the air reactor, kW

- Q Red :

-

Heat produced by metal reduction reaction, kW

- MeO:

-

Oxygenated metal oxide

- Me:

-

Reduced form of metal oxide

- e :

-

Electrical (related to power, as in MWe)

- Ox:

-

Oxidation

- Red:

-

Reduction

- x, x − 1:

-

Oxidized and reduced states of O2 carrier, respectively

- th:

-

Thermal (related to power, as in MWth)

References

Abad A, Adánez J, García-Labiano F, Diego LFD, Gayán P, Celaya J (2007) Mapping of the range of operational conditions for Cu-, Fe-, and Ni-based oxygen carriers in chemical-looping combustion. Chem Eng Sci 62:533–549

Adanez J, Garcia-Labiano F, Diego LFD, Gayan P, Celaya J, Abad A (2006) Nickel–copper oxygen carriers to reach zero CO and H2 emissions in chemical-looping combustion. Ind Eng Chem Res 45:2617–2625

Adanez J, Abad A, Garcia-Labiano F, Gayan P, Diego LFD (2012) Progress in chemical-looping combustion and reforming technologies. Prog Energy Combust Sci 38:215–282

Barin I (1989) Thermochemical data of pure substances, part II, 4th edn. Hemisphere Publishing Corporation, New York

Basavaraj RJ, Jayanti S (2015) Syngas-fueled, chemical-looping combustion-based power plant lay-out for clean energy generation. Clean Technol Environ Policy 17:237–247

Basavaraja RJ, Jayanti S (2015) Viability of fuel switching of a gas-fired power plant operating in chemical-looping combustion. Energy. doi:10.1016/j.energy.2014.12.027

Baukal CE Jr (2013) Oxygen-enhanced combustion, 2nd edn. CRC Press, Boca Raton

Benjamin MFD, Tan RR, Razon LF (2014) A methodology for criticality analysis in integrated energy systems. Clean Technol Environ Policy. doi:10.1007/s10098-014-0846-0

Brandvoll O, Bolland O (2004) Inherent CO2 capture by using chemical looping combustion in a natural gas fired power cycle. J Eng Gas Turbines Power 126:316–321

Buhre BJP, Elliott LK, Sheng CD, Gupta RP, Wall TF (2005) Oxy-fuel combustion technology for coal-fired power generation. Prog Energy Combust Sci 31:283–307

Costa RC, Sodré JR (2010) Hydrous ethanol vs. gasoline-ethanol blend: engine performance and emissions. Fuel 89:287–293

Davison J, Thambimuthu K (2009) An overview of technologies and costs for carbon dioxide capture in power plants. Proc I Mech E Part A 223:201–212

Ditaranto M, Hals J (2006) Combustion instabilities in sudden expansion oxy–fuel flames. Combust Flame 146:493–512

El-Wakil MM (2010) Power plant technology, 3rd edn. Tata McGraw Hill, New Delhi

Erlach B, Schmidt M, Tsatsaronis G (2011) Comparison of carbon capture IGCC with pre-combustion decarbonisation and with chemical-looping combustion. Energy 36:3804–3815

Faizal M, Saidur R, Mekhilef S, Hepbasli A, Mahbubul IM (2014) Energy, economic, and environmental analysis of a flat-plate solar collector operated with SiO2 nanofluid. Clean Technol and Environ Policy. doi:10.1007/s10098-014-0870-0

Finkenrath M (2011) Cost and performance of carbon dioxide capture from power generation. International Energy Agency, Paris

Garcia-Labiano F, Adanez J, Diego LFD, Gayan P, Abad A (2006) of pressure on the behavior of copper-, iron-, and nickel-based oxygen carriers for chemical-looping combustion. Energy Fuels 1(10):26–33

Gräbner M, Von Morstein O, Rappold D, Günster W, Beysel G, Meyer B (2010) Constructability study on a German reference IGCC power plant with and without CO2-capture for hard coal and lignite. Energy Convers and Manag 51:2179–2187

Gutiérrez-Arriaga CG, Serna-González M, Ponce-Ortega JM, El-Halwagi MM (2013) Multi-objective optimization of steam power plants for sustainable generation of electricity. Clean Technol and Environ Policy 15:551–566

Hetland J (2009) Assessment of pre-combustion decarbonisation schemes for polygeneration from fossil fuels. Clean Technol Environ Policy 11(1):37–48

Huang Y, Liu L, Ma XM, Pan XF (2014) Abatement technology investment and emissions trading system: a case of coal-fired power industry of Shenzhen. China. Clean Technol and Environ Policy. doi:10.1007/s10098-014-0854-0

IEA (2013) Key world energy statistics. International Energy Agency, Paris

IPCC (2013) Climate change 2013: the physical science basis. Contribution of working group I to the fifth assessment report of the intergovernmental panel on climate change, IPCC, Cambridge University Press, New York, USA

Ishida M, Zheng D, Akehata T (1987) Evaluation of a chemical-looping combustion power-generation system by graphic exergy analysis. Energy 2:147–154

Jayanti S, Saravanan V, Sivaji S (2012) Assessment of retrofitting possibility of an Indian pulverized coal boiler for operation with Indian coals in oxy-coal combustion mode with CO2 sequestration. Proc I Mech E Part A 226:1003–1013

Jenni KE, Baker ED, Nemet JF (2013) Expert elicitations of energy penalties for carbon capture technologies. Int J Greenh Gas Control 12:136–145

Jin H, Ishida M (2001) Reactivity study on a novel hydrogen fueled chemical-looping combustion. Int J Hydrogen Energy 26:889–894

Johansson EÃ, Mattisson T, Lyngfelt A, Thunman H (2006) Combustion of syngas and natural gas in a 300 W chemical-looping combustor. Chem Eng Res Design 2:819–827

Kanniche M, Gros-Bonnivard R, Jaud P, Valle-Marcos Amann J-M, Bouallou C (2010) Pre-combustion, post-combustion and oxy-combustion in thermal power plant for CO2 capture. Appl Therm Eng 30:53–62

Kehlhofer RH (1999) Combined cycle gas and steam turbine power plants, 2nd edn. Penn Well, Oklahoma

Knacke O, Kubaschewski O, Hesselmann K (1991) Thermochemical properties of inorganic substances, 2nd edn. Springer, Berlin

Kvamsdal HM, Jordal K, Bolland O (2007) A quantitative comparison of gas turbine cycles with CO2 capture. Energy 32:10–24

Lee JC, Lee HH, Joo YJ, Lee CH, Oh M (2014) Process simulation and thermodynamic analysis of an IGCC (integrated gasification combined cycle) plant with an entrained coal gasifier. Energy 64:58–68

Maruta K, Abe K, Hasegawa S, Maruyama S, Sato J (2007) Extinction characteristics of CH4/CO2 versus O2/CO2counterflow non-premixed flames at elevated pressures up to 0.7 MPa. Proc Combust Inst 31:1223–1230

Mousavian SM, Mansouri MT (2011) Conceptual feasibility study of retrofitting coal-fired power plant with oxy-coal combustion. Proc I Mech E Part A 225:689–700

Naqvi R (2006) Analysis of natural gas-fired power cycles with chemical looping combustion for CO2 capture. Doctoral Thesis, Norwegian University of Science and Technology

Nayef G, Redhouane H (2010) Principles of chemical engineering processes. CRC Press, New York

Ng KS, Zhang N, Sadhukhan J (2012) Decarbonised coal energy system advancement through CO2 utilisation and polygeneration. Clean Technol Environ Policy 14:443–451

Prabhakar SVRK, Elder M (2009) Biofuels and resource use efficiency in developing Asia: back to basics. Appl Energy 86:S30–S36

Prabu V, Jayanti S (2012) Integration of underground coal gasification with a solid oxide fuel cell system for clean coal utilization. Int J Hydrogen Energy 37:1677–1688

Rackley SA (2010) Carbon capture and sequestration. Butterworth-Heinemann, Burlington

Sadeghinezhad E, Kazi SN, Badarudin A, Oon CS, Zubir MNM, Mehrali M (2013) A comprehensive review of bio-diesel as alternative fuel for compression ignition engines. Renew Sustain Energy Rev 28:410–424

Sadeghinezhad E, Kazi SN, Badarudin A, Togun H, Zubir MNM, Oon CS, Gharehkhani S (2014a) Sustainability and environmental impact of ethanol as a biofuel. Rev Chem Eng 30(1):51–72

Sadeghinezhad E, Kazi SN, Sadeghinejad F, Badarudin A, Mehrali M, Sadri R, Reza Safaei M (2014b) A comprehensive literature review of bio-fuel performance in internal combustion engine and relevant costs involvement. Renew Sustain Energy Rev 30:29–44

Seepana S, Jayanti S (2012) Optimized enriched CO2 recycle oxy-fuel combustion for high ash coals. Fuel 102:32–39

Siefert NS, Litster S (2013) Exergy and economic analyses of advanced IGCC-CCS and IGFC-CCS power plants. Appl Energy 107:315–328

Sivaji S, Jayanti S (2009) Flame structure and NO generation in oxyfuel combustion at high pressures. Energy Convers Manag 50(4):1116–1123

Sivaji S, Jayanti S (2010) Steam-moderated oxy-fuel combustion (SMOC). Energy Convers Manag 51(10):1981–1988

Ströhle J, Orth M, Epple B (2014) Design and operation of a 1MWth chemical looping plant. Appl Energy 113:1490–1495

Tan Y, Croiset E, Douglas MA, Thambimuthu KV (2006) Combustion characteristics of coal in a mixture of oxygen and recycled flue gas. Fuel 85:507–512

Theodoros D, Athanasios IP, Panos S (2014) Optimum synthesis of solvent-based post-combustion CO2 capture flowsheets through a generalized modeling framework. Clean Technol Environ Policy 16:1363–1380

Wall TF (2007) Combustion processes for carbon capture. Proc Combust Inst 31:31–47

Wang B, Zhang N, Hwang SW, Kim J-K (2013) Process integration of solid oxide fuel cells with process utility systems. Clean Technol Environ Policy 15:801–815

Wolf J (2004) CO2 mitigation in advanced power cycles-chemical looping combustion and steam-based gasification. Doctoral Thesis, Royal Institute of Technology

Wunning JA, Wunning JG (1997) Flameless oxidation to reduce thermal NO reduction. Prog Energy Combust Sci 23:81–94

www.engineering-solutions.airliquide.com/en/about-us-global-engineering-and-construction-solutions/technologies-air-liquide-lurgi-cryo-zimmer/cryogenics-technologies-air-separation-units.html. Accessed 24 Aug 2014

www.linde-engineering.com/internet.global.lindeengineering.global/en/images/AS.B1EN%201113%20-%20%26AA_History_.layout19_4353.pdf. Accessed 24 Aug 2014

Xiao R, Song QL, Zhang SA, Zheng WG, Yang YC (2010) Pressurized chemical-looping combustion of Chinese bituminous coal: cyclic performance and characterization of iron ore-based oxygen carrier. Energy Fuels 24:1449–1463

Xiao R, Chen LY, Saha C, Zhang S, Bhattacharya S (2012) Pressurized chemical-looping combustion of coal using an iron ore as oxygen carrier in a pilot-scale unit. Int J Greenh Gas control 10:363–373

Zheng M, Shen L, Feng X (2014) In situ gasification chemical looping combustion of a coal using the binary oxygen carrier natural anhydrite ore and natural iron ore. Energy Convers Manag 83:270–283

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Basavaraja, R.J., Jayanti, S. Comparative analysis of four gas-fired, carbon capture-enabled power plant layouts. Clean Techn Environ Policy 17, 2143–2156 (2015). https://doi.org/10.1007/s10098-015-0936-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-015-0936-7