Abstract

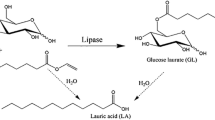

Erythorbic acid, a stereoisomer of L-ascorbic acid, has been extensively used as an antioxidant but cannot be applied to lipid-based foods due to its poor lipophilicity. For this reason, synthesis of erythorbyl laurate (6-O-lauroyl-erythorbate) was achieved in acetonitrile using an immobilized lipase from Candida antarctica as a biocatalyst to increase its lipophilicity. Response surface methodology was used to optimize the erythorbyl laurate synthesis conditions in terms of enzyme content (1,000–5,000 propyl laurate unit, PLU), molar ratio of lauric acid to erythorbic acid (5–25), and reaction temperature (25–65°C). The central composite experimental results showed the conditions for maximum molar conversion yield were as follows: enzyme content, 2,994 PLU; lauric acid to erythorbic acid molar ratio, 24.23; and reaction temperature, 53.03°C. The maximum molar conversion yield reached 77.81%, which was in agreement with the predicted value (76.92%). The erythorbyl laurate was purified and identified by Fourier transform-infrared spectroscopy (FT-IR). This research could help to develop an economical method of synthesizing erythorbyl laurate for use as a novel foodgrade emulsifier with antioxidative activity.

Similar content being viewed by others

References

Sherwin ER. Antioxidants for food fats and oils. J. Am. Oil Chem. Soc. 49: 468–472 (1972)

Kochhar SP, Rossell JB. Detection, estimation, and evaluation of antioxidants in food systems. pp. 19–64. In: Food Antioxidants. Hudson BJF (ed). Elsevier, New York, NY, USA (1990)

Pratt DE, Hudson BJF. Natural antioxidants not exploited commercially. pp. 171–191. In: Food Antioxidants. Hudson BJF (ed). Elsevier, New York, NY, USA (1990)

Shahidi F, Janitha PK, Wanasundara PD. Phenolic antioxidants. Crit. Rev. Food Sci. 32: 67–103 (1992)

Schuler P. Natural antioxidants exploited commercially. pp. 99–170. In: Food Antioxidants. Hudson BJF (ed). Elsevier, New York, NY, USA (1990)

Wang XY, Seib PA, Ra KS. L-Ascorbic acid and its 2-phosphorylated derivatives in selected foods: Vitamin C fortification and antioxidant properties. J. Food Sci. 60: 1295–1300 (1995)

Chang S-W, Yang C-J, Chen F-Y, Akoh CC, Shieh C-J. Optimized synthesis of lipase-catalyzed L-ascorbyl laurate by Novozym® 435. J. Mol. Catal. B-Enzym. 56: 7–12 (2009)

Humeau C, Girardin M, Coulon D, Miclo A. Synthesis of 6-Opalmitoyl L-ascorbic acid catalyzed by Candida antartica lipase. Biotechnol. Lett. 17: 1091–1094 (1995)

Kuwabara K, Watanabe Y, Adachi S, Nakanishi K, Matsuno R. Continuous production of acyl L-ascorbates using a packed-bed reactor with immobilized lipase. J. Am. Oil Chem. Soc. 80: 895–899 (2003)

Karmee SK. Biocatalytic synthesis of ascorbyl esters and their biotechnological applications. Appl. Microbiol. Biot. 81: 1013–1022 (2009)

Burham H, Rasheed RAGA, Noor NM, Badruddin S, Sidek H. Enzymatic synthesis of palm-based ascorbyl esters. J. Mol. Catal. BEnzym. 58: 153–157 (2009)

Bradoo S, Saxena RK, Gupta R. High yields of ascorbyl palmitate by thermostable lipase-mediated esterification. J. Am. Oil Chem. Soc. 76: 1291–1295 (1999)

Swern D, Stirton AJ, Turer J, Wells PA. Fatty acid monoesters of Lascorbic acid and D-isoascorbic acid. J. Am. Oil Chem. Soc. 20: 224–226 (1943)

Fidler MC, Davidsson L, Zeder C, Hurrell RF. Erythorbic acid is a potent enhancer of nonheme-iron absorption. Am. J. Clin. Nutr. 79: 99–102 (2004)

Park K-M, Lee DE, Sung H, Lee J, Chang P-S. Lipase-catalyzed synthesis of erythorbyl laurate in acetonitrile. Food Chem. 129: 59–63 (2011)

Song Q-X, Wei D-Z. Study of vitamin C ester synthesis by immobilized lipase from Candida sp. J. Mol. Catal. B-Enzym. 18: 261–266 (2002)

Myers RH, Montgomery DC, Anderson-Cook CM. Response Surface Methodology: Process and Product Optimization Using Designed Experiments. John Wiley & Sons, Hoboken, NJ, USA (2009)

Box GEP, Wilson KB. On the experimental attainment of optimum conditions. J. Roy. Stat. Soc. B Met. 13: 1–45 (1951)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, D.E., Park, K.M., Choi, S.J. et al. Optimal production and structural characterization of erythorbyl laurate obtained through lipase-catalyzed esterification. Food Sci Biotechnol 21, 1209–1215 (2012). https://doi.org/10.1007/s10068-012-0158-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-012-0158-2