Abstract

This study explores the compression deformation characteristics of compacted loess after different wetting–drying (WD) cycles, by tracking microstructure changes by scanning electron microscope (SEM), laser particle size analyzer, Fourier transform infrared spectroscopy (FTIR), and nuclear magnetic resonance (NMR). Experimental results show that, as the number of wetting–drying cycles increases, the compression deformation of the compacted loess upon mechanical loading increases and the yield stress decreases. The first wetting–drying cycle causes the largest change in terms of mechanical response. As long as the number of wetting–drying cycles increases, their effect is less significant. Microstructural analyses have been exploited to interpret the evolution of the mechanical properties at the laboratory scale. With the increase in the number of wetting–drying cycles, FTIR results showed that the functional group strength gradually decreased, implying a reduction of the cementation strength between the particles of the compacted material. SEM images showed that the contacts among loess aggregates (composed by particles) varied from “face to face” to “point to point.” NMR results demonstrated that the total and inter-aggregate pores volume increased, while the intra-aggregate pores volume decreased upon wetting–drying cycling. The microstructure investigation allowed understanding the major role played by cementation strength, aggregate contact type, and pore size distribution on the compression behavior of compacted loess after wetting–drying cycles.

Similar content being viewed by others

References

Ahmed S, Lovell CW Jr, Diamond S (1974) Pore sizes and strength of compacted clay. J Geotech Eng Div 100(4):407–425

Arthur E, Schjønning P, Moldrup P et al (2013) Density and permeability of a loess soil: long-term organic matter effect and the response to compressive stress. Geoderma 193–194:236–245. https://doi.org/10.1016/j.geoderma.2012.09.001

ASTM (2006) Annual book of ASTM standards. ASTM International, West Conshohocken, PA

ASTM. D2974-07a (2007) Standard test methods for moisture, ash, and organic matter of peat and other organic soils; ASTM International: West Conshohocken, PA

Azizi A, Musso G, Jommi C (2020) Effects of repeated hydraulic loads on microstructure and hydraulic behaviour of a compacted clayey silt. Can Geotech J 57:100–114. https://doi.org/10.1139/cgj-2018-0505

Bai X (1992) Microstructural deformation of clay. University of Glasgow

Chen H, Wang J (2014) Regression analyses for the minimum intensity-duration conditions of continuous rainfall for mudflows triggering in Yan’an, northern Shaanxi (China). Bull Eng Geol Environ 73:917–928. https://doi.org/10.1007/s10064-013-0567-3

Costabel S, Yaramanci U (2013) Estimation of water retention parameters from nuclear magnetic resonance relaxation time distributions. Water Resour Res 49:2068–2079. https://doi.org/10.1002/wrcr.20207

Dathe A, Eins S, Niemeyer J, Gerold G (2001) The surface fractal dimension of the soil–pore interface as measured by image analysis. Geoderma 103:203–229. https://doi.org/10.1016/S0016-7061(01)00077-5

Delage P, Pellerin FM (1984) Influence de la lyophilisation sur la structure d’une argile sensible du Québec. Clay Miner 19(2):151–160

Della Vecchia G, Dieudonné AC, Jommi C, Charlier R (2015) Accounting for evolving pore size distribution in water retention models for compacted clays. Int J Numer Anal Meth Geomech 39(7):702–723

Fang XW, Shen CN (2013) Quantitative analysis of microstructure characteristics of Pucheng loess in Shaanxi province. Chin J Rock Mech Eng 32:1917–1925

Hong ZS, Yin J, Cui YJ (2010) Compression behaviour of reconstituted soils at high initial water contents. Géotechnique 60:691–700. https://doi.org/10.1680/geot.09.P.059

Houston SL, Houston WN, Zapata CE, Lawrence C (2001) Geotechnical engineering practice for collapsible soils. In: Toll DG (ed) Unsaturated Soil Concepts and Their Application in Geotechnical Practice. Springer, Netherlands, Dordrecht, pp 333–355

Hu Z, Cheng YZ (2017) Effectiveness of non-suction controlled method of wetting-drying cycles for unsaturated compacted loess material. KEM 748:346–349. https://doi.org/10.4028/www.scientific.net/KEM.748.346

Huang CQ, Wang MN, Tan WF et al (2018) Hydroxy-interlayered minerals in the Holocene paleosol on the southernmost Loess Plateau, China. Appl Clay Sci 153:70–77. https://doi.org/10.1016/j.clay.2017.12.007

Kleinberg RL (1996) Utility of NMR T2 distributions, connection with capillary pressure, clay effect, and determination of the surface relaxivity parameter ρ2. Magn Reson Imaging 14:761–767. https://doi.org/10.1016/S0730-725X(96)00161-0

Kleinberg RL, Flaum C, Griffin DD et al (2003) Deep sea NMR: Methane hydrate growth habit in porous media and its relationship to hydraulic permeability, deposit accumulation, and submarine slope stability: DEEP SEA NMR. J Geophys Res. https://doi.org/10.1029/2003JB002389

Kong L, Sayem HM, Tian H (2018) Influence of drying–wetting cycles on soil-water characteristic curve of undisturbed granite residual soils and microstructure mechanism by nuclear magnetic resonance (NMR) spin-spin relaxation time (T2) relaxometry. Can Geotech J 55:208–216. https://doi.org/10.1139/cgj-2016-0614

Li G, Wang F, Ma W, et al (2018) Variations in strength and deformation of compacted loess exposed to wetting-drying and freeze-thaw cycles. Cold Regions Science and Technology 151:159–167. https://doi.org/10.1016/j.coldregions.2018.03.021

Li P, Vanapalli S, Li T (2016) Review of collapse triggering mechanism of collapsible soils due to wetting. J Rock Mech Geotech Eng 8:256–274. https://doi.org/10.1016/j.jrmge.2015.12.002

Li XA, Li L, Song Y et al (2019) Characterization of the mechanisms underlying loess collapsibility for land-creation project in Shaanxi Province, China—a study from a micro perspective. Eng Geol 249:77–88. https://doi.org/10.1016/j.enggeo.2018.12.024

Liu YF (2016) Spatial and temporal variation of different precipitation type in the Loess Plateau area. Sci Geograph Sin 36(8):1227–1233

Lu H, Li J, Wang W, Wang C (2015) Cracking and water seepage of Xiashu loess used as landfill cover under wetting–drying cycles. Environ Earth Sci 74:7441–7450. https://doi.org/10.1007/s12665-015-4729-4

Lv Q, Wang S, Wang D, Wu Z (2014) Water stability mechanism of silicification grouted loess. Bull Eng Geol Environ 73:1025–1035. https://doi.org/10.1007/s10064-014-0646-0

Ma F, Yang J, Bai X (2017) Water sensitivity and microstructure of compacted loess. Transp Geotech 11:41–56. https://doi.org/10.1016/j.trgeo.2017.03.003

Ma T, Wei C, Yao C, Yi P (2020) Microstructural evolution of expansive clay during drying–wetting cycle. Acta Geotech 15:2355–2366. https://doi.org/10.1007/s11440-020-00938-4

Mao YC, Li GY, Lei JX et al (2013) Experimental study on the effects of wetting-drying cycles of compacted loess. AMR 831:326–330. https://doi.org/10.4028/www.scientific.net/AMR.831.326

Mariri M, Ziaie Moayed R, Kordnaeij A (2019) Stress–strain behavior of loess soil stabilized with cement, zeolite, and recycled polyester fiber. J Mater Civ Eng 31:04019291. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002952

Meng J, Li X-A (2019) Effects of carbonate on the structure and properties of loess and the corresponding mechanism: an experimental study of the Malan loess, Xi’an area, China. Bull Eng Geol Environ 78:4965–4976. https://doi.org/10.1007/s10064-018-01457-z

Mu QY, Dong H, Liao HJ et al (2020) Water-retention curves of loess under wetting−drying cycles. Géotech Lett 10:135–140. https://doi.org/10.1680/jgele.19.00025

Musso G, Azizi A, Jommi C (2020) A microstructure-based elastoplastic model to describe the behaviour of a compacted clayey silt in isotropic and triaxial compression. Can Geotech J 57(7):1025–1043

National standards of People’s Republic of China (1999) Standard for soil Test Methods (GB/TS0123-99). China Planning Press, Beijing

Ni W, Yuan K, Lü X, Yuan Z (2020) Comparison and quantitative analysis of microstructure parameters between original loess and remoulded loess under different wetting-drying cycles. Sci Rep 10:5547. https://doi.org/10.1038/s41598-020-62571-1

Nicolli HB, Bundschuh J, García JW et al (2010) Sources and controls for the mobility of arsenic in oxidizing groundwaters from loess-type sediments in arid/semi-arid dry climates—evidence from the Chaco-Pampean plain (Argentina). Water Res 44:5589–5604. https://doi.org/10.1016/j.watres.2010.09.029

Ono S, Sawano K, Kazama M (2020) Assessing the degree of slaking deterioration of rock materials by focusing on grain refinement. In: Duc Long P, Dung NT (eds) Geotechnics for Sustainable Infrastructure Development. Springer Singapore, Singapore, pp 1107–1112

Pinyol N, Vaunat J, Alonso EE (2007) A constitutive model for soft clayey rocks that includes weathering effects. Géotechnique 57:137–151. https://doi.org/10.1680/geot.2007.57.2.137

Qi J, Ma W, Song C (2008) Influence of freeze–thaw on engineering properties of a silty soil. Cold Reg Sci Technol 53:397–404. https://doi.org/10.1016/j.coldregions.2007.05.010

Romero E, Della Vecchia G, Jommi C (2011) An insight into the water retention properties of compacted clayey soils. Géotechnique 61:313–328. https://doi.org/10.1680/geot.2011.61.4.313

Romero E, Simms PH (2008) Microstructure investigation in unsaturated soils: a review with special attention to contribution of mercury intrusion porosimetry and environmental scanning electron microscopy. Geotech Geol Eng 26(6):705–727

Rosone M, Ferrari A, Celauro C (2018) On the hydro-mechanical behaviour of a lime-treated embankment during wetting and drying cycles. Geomech Energy Environ 14:48–60. https://doi.org/10.1016/j.gete.2017.11.001

Rost KT (2001) Late Holocene loess deposits and dust accumulation in the alpine meadow belt of the Wutai Shan, China. Quatern Int 76–77:85–92. https://doi.org/10.1016/S1040-6182(00)00092-6

Russ JC (1992) Characterizing and modelling fractal surfaces. J Comput Assisted Micro 4:73–126

Shao X, Zhang H, Tan Y (2018) Collapse behavior and microstructural alteration of remolded loess under graded wetting tests. Eng Geol 233:11–22. https://doi.org/10.1016/j.enggeo.2017.11.025

Shi H, Shao M (2000) Soil and water loss from the Loess Plateau in China. J Arid Environ 45:9–20. https://doi.org/10.1006/jare.1999.0618

Sun D, Bloemendal J, Rea DK et al (2004) Bimodal grain-size distribution of Chinese loess, and its palaeoclimatic implications. Catena 55:325–340. https://doi.org/10.1016/S0341-8162(03)00109-7

Sun H, Mašín D, Najser J et al (2020) Fractal characteristics of pore structure of compacted bentonite studied by ESEM and MIP methods. Acta Geotech 15:1655–1671. https://doi.org/10.1007/s11440-019-00857-z

Tian H, Wei C, Wei H et al (2014) An NMR-based analysis of soil–water characteristics. Appl Magn Reson 45:49–61. https://doi.org/10.1007/s00723-013-0496-0

Vandenberghe J (2013) Grain size of fine-grained windblown sediment: a powerful proxy for process identification. Earth Sci Rev 121:18–30. https://doi.org/10.1016/j.earscirev.2013.03.001

Vasava HB, Gupta A, Arora R, BhabaniS D (2019) Assessment of soil texture from spectral reflectance data of bulk soil samples and their dry-sieved aggregate size fractions. Geoderma 337:914–926. https://doi.org/10.1016/j.geoderma.2018.11.004

Wang F, Li G, Ma W et al (2020a) Effect of repeated wetting-drying-freezing-thawing cycles on the mechanic properties and pore characteristics of compacted loess. Adv Civ Eng 2020:1–8. https://doi.org/10.1155/2020/8839347

Wang G, Ye W, Lv Y (2019a) Loess geoheritage and geohazard protective measures at Luochuan Loess National Geopark in NW China. Geoheritage 11:1089–1100. https://doi.org/10.1007/s12371-019-00354-5

Wang HB, Zhou B, Wu SR et al (2011) Characteristic analysis of large-scale loess landslides: a case study in Baoji City of Loess Plateau of Northwest China. Nat Hazards Earth Syst Sci 11:1829–1837. https://doi.org/10.5194/nhess-11-1829-2011

Wang JD, Li P, Ma Y et al (2020b) Change in pore-size distribution of collapsible loess due to loading and inundating. Acta Geotech 15:1081–1094. https://doi.org/10.1007/s11440-019-00815-9

Wang JD, Li P, Ma Y, Vanapalli SK (2019b) Evolution of pore-size distribution of intact loess and remolded loess due to consolidation. J Soils Sediments 19:1226–1238. https://doi.org/10.1007/s11368-018-2136-7

Yao W, Li C, Zhan H et al (2020a) Multiscale study of physical and mechanical properties of sandstone in Three Gorges Reservoir region subjected to cyclic wetting–drying of Yangtze River water. Rock Mech Rock Eng 53:2215–2231. https://doi.org/10.1007/s00603-019-02037-7

Yao Z, Chen Z, Fang X et al (2020b) Elastoplastic damage seepage–consolidation coupled model of unsaturated undisturbed loess and its application. Acta Geotech 15:1637–1653. https://doi.org/10.1007/s11440-019-00873-z

Yu B, Liu G, Liu Q et al (2019) Seasonal variation of deep soil moisture under different land uses on the semi-arid Loess Plateau of China. J Soils Sediments 19:1179–1189. https://doi.org/10.1007/s11368-018-2119-8

Zhang D, Wang J, Chen C, Wang S (2020) The compression and collapse behaviour of intact loess in suction-monitored triaxial apparatus. Acta Geotech 15:529–548. https://doi.org/10.1007/s11440-019-00829-3

Zhang, W., Guo, A., Lin, C. (2019). Effects of cyclic freeze and thaw on engineering properties of compacted loess and lime-stabilized loess. Journal of materials in civil engineering, 31(9), 04019205. https://doi.org/10.1016/j.trgeo.2019.100279

Zhang X, Mavroulidou M, Gunn MJ (2017) A study of the water retention curve of lime-treated London Clay. Acta Geotech 12:23–45. https://doi.org/10.1007/s11440-015-0432-6

Zhu Y, Luo P, Zhang S, Sun B (2020) Spatiotemporal analysis of hydrological variations and their impacts on vegetation in semiarid areas from multiple satellite data. Remote Sens 12:4177. https://doi.org/10.3390/rs12244177

Acknowledgements

The authors gratefully acknowledge the China Postdoctoral Science Foundation (Grant no. 2019T120873 and Grant no. 2018M631117), Postdoctoral Research Project in Shaanxi Province (Grant no. 2018BSHGZZHQYXMZZ26), the Key Program of the National Natural Science Foundation of China (Grant no. 41931285), and the key research and development program of Shaanxi Province (Grant no. 2019ZDLSF05-07).

Author information

Authors and Affiliations

Contributions

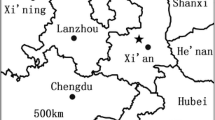

Wankui Ni and Xiangfei Lü designed research; Kangze Yuan performed all experiments and analyzed the data; Yongpeng Nie, Haiman Wang, Lan Li, and Kangze Yuan calculated the pore distribution of loess samples. Kangze Yuan and Xiangfei Lü wrote the paper. Gabriele Della Vecchia revised the manuscript. The map data in Fig. 1 was provided by the Data Center for Resources and Environmental Science, Chinese Academy of Science (RESDC) (http://www.resdc.cn). All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

This article does not contain any studies with human participants and/or animals. Informed consent was obtained from all individual participants included in the study.

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yuan, K., Ni, W., Lü, X. et al. Influence of wetting–drying cycles on the compression behavior of a compacted loess from microstructure analysis. Bull Eng Geol Environ 81, 348 (2022). https://doi.org/10.1007/s10064-022-02854-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10064-022-02854-1