Abstract

The laser-beam powder bed fusion process for metals, commonly abbreviated as PBF-LB/M, is a widely used process for the additive manufacturing of parts. Numerical simulations are useful to identify optimal process parameters for different materials and to obtain detailed insights into process dynamics. The present work uses a single-phase incompressible Smoothed Particle Hydrodynamics (SPH) scheme to model PBF-LB/M which was found to reduce the required computational time and significantly stabilize the partially violent flow in the melt pool in comparison to a weakly compressible SPH approach. The laser-material interaction is realistically modelled by means of a ray tracing method. An approach to model the effective thermal coductivity of the powder bed is proposed. Excellent agreement between the simulation results and experimental X-ray analyses of the transition from conduction melting mode to keyhole mode including geometric properties of the vapor depression zone was found. These results prove the usability of SPH as a high precision simulation tool for PBF-LB/M.

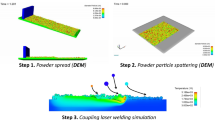

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Additive manufacturing (AM) processes are on the rise in many industries, where they compete with established manufacturing processes such as casting. The decision to replace established processes with new AM processes is not trivial. A detailed comparison between established manufacturing processes and potential AM processes is required for an economic and technological consideration. Manufacturing times, production costs, waste volumes, process reliability, CO\(_2\) footprint, and part properties must be considered. The information and data required for the evaluation can be obtained by experiments and can be significantly supplemented by detailed numerical simulations.

In laser-beam powder bed fusion for metals (PBF-LB/M), a subgroup of additive manufacturing processes, the layer-by-layer deposited powder is locally fused in a solidifying laser induced melt pool. The dynamics of the melt pool depend on various physical properties, some of which are temperature-dependent, such as laser absorptance and reflectance, surface tension, viscosity, heat capacity, thermal conductivity, and gas-phase recoil pressure. A suitable method for modelling the diverse physics of the melt pool is the Smoothed Particle Hydrodynamics (SPH) method. In particular, SPH can effortlessly account for the strong deformations of the melting powder particles. The data on the temperature-dependent material properties, required for the SPH simulations, are obtained by thermophysical measurements or by thermodynamic calculations. A major advantage of numerical simulations compared to experimental investigations is the very detailed insights into the PBF-LB/M process. The simulations help to reveal correlations between material properties and process parameters on the one hand and properties of the resulting part on the other hand. Such correlations help in the application-specific optimization of process parameters.

Laser-based additive manufacturing processes have been mainly modelled using mesh-based simulation approaches such as the Lattice Boltzmann Method [1, 2], the Finite Volume Method using a Volume-of-Fluid model [3, 4] or a hybrid Finite Volume-Finite Element approach utilizing arbitrary Lagrangian–Eulerian techniques [5, 6]. Yet, the present study makes use of the mesh-free SPH method for the following reasons. In SPH, the discretization nodes move with the material, making it easier to track free surfaces and interfaces, which is crucial in laser powder bed fusion where melting and solidification occur. In SPH, there is no numerical diffusion error, which can be a significant issue in Eulerian simulations. SPH can track the history of material points, which is important in laser powder bed fusion where the thermal history affects the final part properties. Mesh-based methods require remeshing for large deformations, which can be cumbersome, while SPH can handle large deformations without the need for remeshing. A challenge for the SPH method is its computational intensity, which can be a disadvantage for large-scale or high-resolution simulations. SPH can have difficulties with accurately representing velocity boundary conditions, which is, however, not a necessity for PBF-LB/M process simulations.

The SPH method has been used for various laser-based processes. Using a pulsed-laser, micro-cutting and drilling of stainless steel for a medical applications were simulated with the SPH method by Muhammad et al. [7]. They found good agreement between the simulation and experimental data concerning the penetration depth. Alshaer et al. [8] modelled pulsed-laser ablation of aluminium using the SPH method. The predictions of the ablation depth in dependence of process parameters were in good agreement with previously reported experimental data. Hu and Eberhard [9] applied a thermomechanically coupled scheme to model conduction mode laser welding of aluminium and iron. The effects of laser process parameters on weld dimensions were studied. The SPH method was also used by Trautmann et al. [10] to model tungsten inert gas welding. The predicted weld pool shape corresponds well to experimental findings.

PBF-LB/M processes were also simulated by using the SPH method. One of the first SPH simulations of PBF-LB/M processes were carried out by Russell et al. [11]. They report that SPH is advantageous in modelling different states of matter. However, simulating surface tension forces was computationally demanding and further development efforts are needed to reduce computational time. Blank et al. [12] used an incompressible SPH scheme to study the melting and capillary dynamics of an arbitrarily shaped particle and agglomerating spheres. Fürstenau et al. [13] reported an SPH implementation on a graphics processing unit which was used to achieve a particularly fine spatial resolution when simulating individual laser tracks. Their findings that laser power and scan speed have non-linear influences on process quality were presented in virtual process maps. Qiu et al. [14] studied the influence of laser power on melt pool dimensions and temperature. A novel stabilization scheme for the liquid–gas interface was developed by Meier et al. [15] and applied to model melt pool dynamics in PBF-LB/M. SPH was also used to model both PBF-LB/M and direct metal deposition including the rigid body dynamics of powder particles [16]. In order to reduce the computational effort, a multi-resolution scheme for PBF-LB/M was developed by Afrasiabi et al. [17] and refined by Lüthi et al. [18]. Fuchs et al. [19] presented a versatile framework to model phase transitions as well as coupled microfluid-powder dynamics in additive manufacturing processes using SPH. [20] studied the influence of the linear energy density, i.e., laser power over scan speed, on the size and shape of the melt pool. Zöller et al. [21] investigated balling effects during PBF-LB/M of Inconel 718. They identified a mechanism causing balling due to capillary forces in the melt pool neck region. In all above discussed publications, laser irradiation was modelled either as an effective local heat source or approximations of the Lambert-Beer law were used.

A ray tracing scheme in combination with an SPH material model had been used by Shah et al. [22] to model laser drilling of metals yielding a very good agreement with experimentally observed cavity shapes. Cummins et al. [23] used ray tracing to model the heat input in SPH process simulations of PBF-LB/M aiming at the prediction of microstructural properties in a Ti6Al4V alloy. Lin et al. [24] proposed a ray tracing scheme for SPH to model irradiation of powder beds using a stationary or moving laser source. They find good quantitative agreement with experiments in terms of melt pool and gas capillary dimensions.

The thermal conductivity within a powder bed is significantly smaller than in fully dense material [25]. This phenomenon was modelled in the context of SPH by Shah and Volkov [26, 27] using different thermal conductivities for the powder particles and the background medium, respectively. Furthermore, the contact thermal conductance between particles was considered explicitly.

The novelty of our work with respect to existing literature is twofold. On the one hand, the combination of a computationally efficient incompressible single-phase SPH scheme with a ray tracing laser model is presented. On the other hand, a simple method to obtain a realistic powder bed thermal conductivity is proposed. The central research question is how accurate the modelling approach is in predicting the transition from conduction to keyhole melting mode in PBF-LB/M. All simulations presented in this work were carried out with the SimPARTIX simulation software developed at the Fraunhofer IWM [28].

The rest of the paper is organised as follows. We discuss firstly the underlying physics in Sect. 2.1 and present the respective SPH discretization in Sect. 2.2. In Sect. 3.1, we introduce a novel approach to calibrate the powder bed thermal conductivity. The weakly compressible and the incompressible SPH approach applied to PBF-LB/M are compared in Sect. 3.2. High fidelity simulations of single laser melting tracks including experimental validations of the transition between conduction and keyhole melting modes are presented and discussed in Sect. 3.3. The results and findings are summarized in Sect. 4 and we further provide a perspective on future work relevant for PBF-LB/M simulations.

2 Methods

2.1 Physics of the process

2.1.1 Laser irradiation

Laser beams in PBF-LB/M can have different intensity distributions. The intensity of the laser beam is often normally distributed (Gaussian profile) or uniformly distributed (top-hat profile) around the centre of the laser spot as illustrated in Fig. 1.

For a Gaussian profile, we used the following laser intensity distribution given by a Gaussian caustic:

where P is the laser power, w is the characteristic spot size, and the time-dependent spot centre coordinate is defined by \(x_0\) and \(y_0\). An estimated laser spot diameter is often given by 4w for the Gaussian distribution which means that approximately \({86.5}\,{\%}\) of the total power is located within the estimated laser spot area.

The laser beam interaction with the powder material can be modelled by different methods and we used two different methods depicted in Fig. 2.

The first model is a continuous laser model. For a laser beam passing through material, the laser beam energy is transferred to the material according to the Lambert-Beer law

where \({\tilde{z}}\) is the laser propagation coordinate and a is the attenuation coefficient, i.e., the inverse optical penetration depth. Due to the large attenuation coefficient of metals, the absorption occurs in immediate vicinity of the surface. In a second, more realistic approach, the intensity distribution is spatially discretized by individual rays with an intensity corresponding to their initial position within the laser beam. The propagation of the discretized laser rays is tracked by a ray tracing (RT) algorithm that allows to model the reflection and refraction of a ray hitting a material surface, exemplarily illustrated in Fig. 3. For differing refractive indices \(n_A\) and \(n_B\) of two bordering phases or materials A and B, respectively, the incident ray is split into a reflected and refracted ray. The reflection angle is equal to the incident angle \(\alpha _A\) measured to the normal surface vector. For the refractive angle \(\alpha _B\), Snell’s law is evaluated, i.e.,

In some cases, a total reflection of the incident ray occurs if the condition

is fulfilled, i.e., a refracted ray does not occur.

The intensities of the reflected ray, \(I_\text {reflected}\), and refracted ray, \(I_\text {refracted}\), are calculated as shares of the incident ray intensity, \(I_\text {incident}\), according to the Fresnel equations:

where the share S reads

Note that the attenuation is typically very large in case of metallic materials leading to complete absorption of the refracted ray close to the gas-metal interface. RT significantly increases the accuracy of the simulation at additional computational cost. The RT calculations require roughly one third of the total computational effort for PBF-LB/M simulations as presented in this work.

2.1.2 Energy balance

Using the thermal energy density H, the ratio of thermal energy to unit mass, we can write the energy balance equation as

The terms on the right-hand side of Eq. (7) describe from left to right contributions from heat conduction, viscous heating, Stefan-Boltzmann radiation, convective heat transfer, evaporation cooling, and absorbed laser radiation, respectively. Note that some authors use the enthalpy \(L_\text {v} + c(T_\text {v} - T)\) instead of only the latent heat \(L_\text {v}\) in the evaporation term in Eq. (7) [15]. However, we found that using only the latent heat already yields a rather good approximation as it contributes to most of the evaporation heat loss. The various variables represent the density \(\rho\), the temperature T, the thermal conductivity k, the dynamic viscosity \(\mu\), the heat transfer coefficient f, the emissivity \(\varepsilon\), the Stefan-Boltzmann constant \(\sigma _\text {B}\), the building chamber temperature \(T_\text {b}\), and the latent heat of evaporation \(L_\text {v}\). \({\dot{n}}_\text {v}\) is the mass evaporation rate per area approximated by the Hertz-Knudsen model,

where M is the molar mass, R is the universal gas constant, and \(P_\text {v}\) is the vapor pressure approximated by the Clausius–Clapeyron equation [8],

where \(P_0\) is the atmospheric pressure. Equation (8) models the statistical evaporation from the liquid phase in the presence of a Knudsen layer and is thus limited by the liquidus and the vaporization temperature. The rate of strain tensor is defined by \({{\mathbb {E}}} = (\nabla {{\textbf {v}}} + (\nabla {{\textbf {v}}})^{\text {T}})/2\), where \({{\textbf {v}}}\) is the velocity. Stefan-Boltzmann radiation, heat transfer, and evaporation cooling are thermal boundary conditions which act at the material surface. These boundary conditions are discretized as volumetric sinks in a later section and require therefore the multiplication with a delta function \(\delta _\text {s}\) in Eq. (7) to model accurately the spatial location of the surface.

The melting and evaporation phase transitions, illustrated in Fig. 4, are considered by the following relationships between temperature and thermal energy density [29]:

The temperatures in Fig. 4 and Eq. (10) are the vaporization temperature \(T_\text {v}\), condensation temperature \(T_\text {c}\), liquidus temperature \(T_\text {l}\), and solidus temperature \(T_\text {s}\). The corresponding thermal energy densities \(H_\text {v}\), \(H_\text {c}\), \(H_\text {l}\), and \(H_\text {s}\) are

\(c_\text {s}\) is the specific heat capacity below and c is the specific heat capacity above the solidus temperature. The latent heat of melting and evaporation is defined as \(L_\text {m}\) and \(L_\text {v}\), respectively.

2.1.3 Momentum balance

The Navier–Stokes momentum equation describes the fluid velocity changes in time and space:

The contributions of pressure gradient, viscous dissipation, surface tension, recoil pressure, natural convection and gravity are represented in the terms on the right-hand side of Eq. (15) from left to right. The various quantities are the pressure P, the surface tension \(\sigma\), the curvature \(\kappa\), the surface unit normal vector \(\textbf{n}\), the Nabla operator along the surface \(\nabla _\text {s}\), the coefficient of linear thermal expansion \(\eta\), the gravitational acceleration \(\textbf{g}\), and the number of spatial dimensions d. The surface tension is typically dependent on the temperature. The recoil pressure model acts only on the fluid if the temperature is above vaporization temperature \(T_\text {v}\), which is expressed by means of the Heaviside step function \({\mathcal {H}}\) in Eq. (15). The Boussinesq approximation is often expressed using the volumetric thermal expansion coefficient. However, we are using the linear thermal expansion coefficient and, thus, have to multiply by the number of spatial dimensions. The momentum equation is only solved if the local temperature is above the solidus temperature \(T>T_\text {s}\). Otherwise, the material is considered spatially fixed.

The flow is assumed to be either compressible,

or incompressible,

Eq. (16) is required, if thermal expansion shall be included in the simulation. A comparison between the compressible and incompressible approach is presented in Sect. 3.2.

2.2 SPH discretization

2.2.1 Kernel function

Powder material and building chamber are discretized using SPH particles which are initially placed on a simple square (2D) or cubic grid (3D) with particle spacing \(\Delta x\). Interpolation of any quantity A at the position \(\textbf{r}\) is achieved by a weighted sum over the contributions \(A(\textbf{r}_j)\) of all neighboring particles j at positions \(\textbf{r}_j\) with masses \(m_j\) and densities \(\rho _j\) within a range related to the smoothing length h,

where W(r, h) is a kernel function. See Fig. 5 for a visualization of the neighboring particles within the interaction domain of a given particle. The particle mass is related to the rest density \(\rho _0\) via \(m_j=\rho _0 (\Delta x)^d\) where d represents the dimensions (\(d = 2\) or \(d = 3\) for 2D or 3D, respectively).

is the quintic C2 Wendland kernel [30] with \(\zeta =r/h\). The normalization factor is \(\nu =7/(4\pi )\) for \(d=2\) and \(\nu =21/(16\pi )\) for \(d=3\).

A smoothed approximation of a field quantity at the position of particle i is obtained by evaluating Eq. (18) so that

where the shortened expressions \(A_j = A(\textbf{r}_j)\), \(W_{ij} = W(|\textbf{r}_{ij}|, h)\), and \(\textbf{r}_{ij} = \textbf{r}_i-\textbf{r}_j\) are used.

In order to discretize the physical equations in the SPH scheme, spatial gradients of field quantities can be expressed as

The gradient \(\nabla W_{ij}\) of the kernel function is given by

In comparison to the canonical formulation given by Eq. (21), the expressions

and

show numerical advantages [31] and are used in the remainder of this work.

2.2.2 Surface description

Several physical phenomena involved in the laser powder bed fusion process occur at the material surface. For the mathematical description of these phenomena, a surface delta function \(\delta _\text {S}\), a surface unit normal vector \(\textbf{n}\), a surface curvature \(\kappa\), and a gradient operating along the surface \(\nabla _\text {S}\) are defined and described in this section.

The present formulation uses previously introduced ideas [32,33,34]. Crucial is the identification of the surface which can be accomplished by using the renormalization tensor \({\mathbb {L}}\). The inverse renormalization tensor for a particle i is given by

The minimum eigenvalue \(\lambda _i\) of \({\mathbb {L}}_i^{-1}\) describes a scalar field which is 1 inside the material and approaches 0 at the surface [32]. The gradient of the \(\lambda\) field for particle i, corrected by the renormalization tensor, is given by

It follows then for the surface unit normal vector:

Depending on their \(\lambda _i\) value and geometrical considerations, particles are categorized as immediate surface particles (the very first layer of particles at the surface), surface region particles (first or second layer of particles), or as particles deeper within the material. Special treatment is given to isolated particles to avoid numerical artifacts. Details of this categorization can be found in Bierwisch [35]. All below listed equations in this section apply only to surface region particles.

The surface delta function is defined as

where \(a_\lambda\) and \(b_\lambda\) are numerical normalization parameters which depend on the choice of the kernel function. For the quintic Wendland kernel the values \(a_\lambda = 1.324\) and \(b_\lambda = -0.108\) should be used in 2D while \(a_\lambda = 1.328\) and \(b_\lambda = -0.174\) should be used in 3D. Equation (28) with the appropriate choices for \(a_\lambda\) and \(b_\lambda\) ensures that a spatial line integral over the surface delta function yields unity. Further explanations regarding the surface delta function and determination of the aforementioned parameters can be found in Bierwisch [35].

The local curvature of the surface is calculated by using an approach proposed by [33], i.e.,

An upper limit for the curvature is given by the smoothing length:

2.2.3 Momentum balance

The Navier–Stokes momentum balance Eq. (15) is expressed as an acceleration for each SPH particle i,

where \(\textbf{f}_i\) corresponds to the sum of all acceleration contributions excluding the pressure gradient.

The Laplacian applied to each component of the velocity vector gives

where \(\textbf{v}_{ij} = \textbf{v}_i - \textbf{v}_j\) is the relative velocity vector.

The temperature gradient is required to include thermo-capillary effects [36]. A corrected gradient formulation [37] is used for this purpose:

2.2.3.1 Weakly compressible SPH

Equation (31) can be solved in combination with (16) using the weakly compressible SPH (WCSPH) approach. The pressure gradient term is then expressed as

The pressure \(P_i\) is related to the density \(\rho _i\) using Tait’s equation of state,

where s is the numerical speed of sound and \(\gamma = 7\) is the dimensionless isentropic exponent. The mass balance, Eq. (16), is discretized as

Time integration in the WCSPH approach is based on the velocity Verlet scheme [38]. The density propagation for a time step \(\Delta t\) is given by

The velocity and position are propagated by

and

respectively.

2.2.3.2 Incompressible SPH

Alternatively to the weakly compressible SPH method, Eq. (31) can be solved in combination with Eq. (17) using the incompressible SPH (ISPH) approach. This scheme applies an implicit solution procedure and is, therefore, often faster than WCSPH. The ISPH scheme does not modify the density and hence, \(\rho _i = \rho _0\) is always true. The present ISPH approach largely follows the predictor-corrector scheme given in Chow et al. [39].

The velocity is predicted by using all acceleration contributions except the pressure gradient, i.e.,

The pressure \(P_i\) is then computed by solving the pressure Poisson equation (PPE),

which is implicitly formulated as a linear system of equations

In addition to Eq. (42), two extra cases for particles at a free surface or particles close to solid boundaries must be considered. For free surface particles, the surface pressure

is based on the surface tension and surface recoil given as first and second term on the right-hand side, respectively. The linear system of equations of the PPE is modified for the rows of surface particles i as

where \(\beta _i\) is a smoothing function which is 0 at the surface and transitions to 1 within the material. This modification provides a Dirichlet boundary condition at the free surface. Consequently, the surface tension and surface recoil terms are not included in \(\textbf{f}_i\).

In order to satisfy a Neumann boundary condition at the wall, the system of equations (42) must be modified for each row of a fluid particle i which has fixed particles in its neighborhood by

and for each row of a wall particle i which has fluid particles in its neighborhood by

The full step velocity is obtained by the corrector step

using

The position after a full time step is obtained by

The linear system of equations (42) is solved using a biconjugate gradient stabilized method (BiCGStab) with a diagonal preconditioner.

2.2.4 Energy balance

The energy balance equation Eq. (7) is discretized in the form

The first term on the right-hand side describes thermal diffusion and is calculated by an approach suggested in Cleary [40]. The specific thermal energy is propagated in time by

Thermal boundary conditions can be set at the substrate, i.e., the base material on which powder is deposited. A thermal boundary condition can have either a specified constant temperature or a transient temperature profile. For the latter boundary condition, the transient temperature profile can be deduced from an analytical solution describing the heating of a half-space (i.e., only material at coordinates \(z<0\) exists) with a punctiform power source moving along the xy-plane at constant velocity.

2.2.5 Laser ray tracing

A laser source is discretized into N rays separated by equidistant spacing at the initialization of the ray tracing algorithm. According to Eq. (1), an initial intensity is assigned to each discretized ray based on its initial position. Besides the initial ray position \(\textbf{p}_k\) and intensity \(I_k\) of each ray with index k, an initial normalized direction \(\textbf{s}_k\), corresponding to focal properties of the laser beam, is determined. After initialization, the recursive Algorithm 1 propagates each ray by a propagation length \(\Delta p\) until the ray collides with a surface or material interface. During the collision, the ray can be split into two rays, a refracted and reflected ray, as described in Sect. 2.1.1. Thereafter, the algorithm starts anew for each ray with initialization values determined from the optical interaction laws described in Sect. 2.1.1 and in Algorithm 1.

2.2.6 Time step

The time step must allow to model the fastest physical mechanism within the simulation. The competing mechanisms are inertia, surface tension, viscous diffusion, and thermal diffusion. Conditions for the respective time steps, which ensure stable simulations, are provided by [41,42,43,44] resulting in

where \(f_\text {max}\) is the magnitude of the maximum particle acceleration. For WCSPH, sound propagation [45] needs to be considered as well,

It is usually suggested to choose the numerical speed of sound s about 10 times greater than the maximum particle velocity in the simulation [46].

2.2.7 Numerical stabilization

A particle shifting technique is used to homogenize the particle distribution [34, 47]. The position shifting for a particle i is defined as

where

The shifting contribution \(\Delta \textbf{r}_i^\text {PST}\) is added to the right-hand side of Eq. (39) or Eq. (49), respectively.

A similar method which penalizes inhomogeneous particle distributions is used in the ISPH approach by adding the density relaxation term

to \(b_i\) in Eq. (42). The non-relaxed density is calculated as

The XSPH scheme [41] is used to smooth the velocity field by adding the velocity correction,

3 Results and discussion

3.1 Powder thermal conductivity

The powder bed, which is molten by the laser, consists of spherical particles with a defined size distribution. Each powder particle is discretized as a group of SPH particles. The mean powder particle diameter is typically six times larger than the SPH particle spacing \(\Delta x\). The thermal conductivity within a solid material \(k_\text {solid}\) is orders of magnitude larger than the thermal conductivity within a powder bed \(k_\text {bulk}\) of the same material. Considering this effect, the thermal conductivity k between SPH particle groups discretizing different powder particles in Eq. (50) is scaled down in comparison to the conductivity within a powder particle. Let \(k_\text {inter}\) be the thermal conductivity between different powder particles and \(k_\text {intra} = k_\text {solid}\) be the conductivity within a powder particle. As soon as two powder particles fuse with each other during the melting process, the contact conductivity \(k_\text {inter}\) takes the same value as the internal conductivity \(k_\text {intra}\) of a powder particle.

In order to match the conductivity of a real powder bed, a calibration setup, such as in Fig. 6a, is used where each powder particle can be identified by its distinct color. Figure 6b shows a corresponding surface reconstruction. The calibration simulation is carried out by keeping the temperature of the left vertical plate constant while applying a constant heat flux \({\dot{Q}}\) at the right vertical plate [35]. The simulation domain is periodic in the other two spatial directions. The particles are not allowed to move while the energy equation is solved until a steady state is reached as shown exemplarily in Fig. 6c.

The powder volume fraction \(\phi\) and the thermal conductivity scaling \(k_\text {inter} / k_\text {intra}\) are systematically varied. Figure 7 shows a stationary temperature profile as well as a fitted constant temperature gradient \(\text {d}T/\text {d}x\) for a powder volume fraction of \(\phi = 0.494\) and a conductivity scaling \(k_\text {inter} / k_\text {intra} = 0.3\). The resulting bulk thermal conductivity is obtained as

Temperature profile according to Fig. 6c and fitted constant temperature gradient

An overview of the simulation results is provided in Table 1. It can be observed that the normalized powder bed conductivity \(k_\text {bulk} / k_\text {solid}\) decreases strongly with a decreasing volume fraction \(\phi\) for a constant contact conductivity scaling \(k_\text {inter} / k_\text {intra}\). Furthermore, the relation between the contact conductivity scaling and the normalized powder bed conductivity is non-linear. An inverse simulation strategy allows to reproduce an experimentally measured powder bed conductivity in the numerical simulations. The simulation of \({100}\,{{\textrm{ms}}}\) real time requires about \({20}\,{\textrm{min}}\) of wall time on 28 computing cores.

3.2 Comparison of WCSPH and ISPH

The advantages of the ISPH methodology over WCSPH are demonstrated by comparing two dimensional PBF-LB/M simulations. A layer of randomly distributed powder particles with the thickness of approximately two diameters is molten by a laser beam. The mean diameter of the logarithmically normally distributed particle sizes is \({50}\,{\mu {\textrm{m}}}\). The setup is similar to that described in [11]. The here-used material model for the powder particles and the dense substrate below the deposited powder particles corresponds to the nickel-based alloy Inconel 718 [48]. The continuous Lambert-Beer model, Eq. (2), is used for the laser attenuation along the vertical axis instead of the ray tracing method and the chosen intensity distribution of the laser spot is a top-hat profile. The beam energy absorption and subsequent energy conversion to thermal energy when penetrating SPH particles is defined by an absorptance ratio. Reflection of the laser is not considered in simulations presented in this section.

Figure 8 shows simulations with a laser moving from left to right at three different time steps for three configurations each: Firstly, WCSPH with a speed of sound of \(s = {100}\,{\textrm{m}}\,{{\textrm{s}}^{-1}}\). Secondly, WCSPH with a speed of sound of \(s = {1000}\,{\textrm{m}}\,{{\textrm{s}}^{-1}}\), and thirdly, ISPH. The simulation domain has a length of \({1}\,{{\textrm{mm}}}\). After \({130}\,{\mu {\textrm{s}}}\), the results of the different simulations are barely distinguishable. After \({160}\,{\mu {\textrm{s}}}\), slight differences at the front and rear of the melt pools with regard to their shapes are observed. For WCSPH using \(s ={100}\,{\textrm{m}}\,{{\textrm{s}}^{-1}}\), first instabilities in terms of single spattering SPH particles are observed. With increased time at around \({200}\,{\mu {\textrm{s}}}\), a significant increase in SPH particle spatter is found. For an increased speed of sound, \(s = {1000}\,{\textrm{m}}\,{{\textrm{s}}^{-1}}\), WCSPH shows spattering instabilities only after \({200}\,{\mu {\textrm{s}}}\). Furthermore, the differences in the melt pool shape between both WCSPH simulations of varied speed of sound and the ISPH simulation become more apparent with increasing simulation time. The predictive quality of ISPH laser melting simulations will be discussed in Sect. 3.3.

Comparison of WCSPH simulations using speeds of sound \(s ={100}\,{\textrm{m}}\,{{\textrm{s}}^{-1}}\) and \(s ={1000}\,{\textrm{m}}\,{{\textrm{s}}^{-1}}\), respectively, with an ISPH simulation. The position of the laser beam is indicated by the dark red area. The columns refer to the time after the start of laser irradiation. The temperature of the Inconel 718 material is color-coded. Regions with instabilities are highlighted by zoom insets

The source of the instabilities in the WCSPH simulations is traced back to a rather violent flow field at the melt pool surface. Figure 9 shows the spatial distribution of the strain rate defined as \(\sqrt{2\,{\mathbb {E}}:{\mathbb {E}}}\). For the WCSPH simulations large strain rates with pronounced local variance appear at the melt pool surface. This locally violent flow is most probably a numerical artefact caused by the inadequate handling of the recoil pressure and Marangoni shear stress at the surface in case of the explicit WCSPH scheme. The implicit solution procedure of the ISPH scheme does not suffer from this instability.

Same as Fig. 8 but with color-coded rate of strain. Note the large and non-smooth rate of strain at the melt pool surface in case of the WCSPH simulations

The ISPH scheme needs on average 5 BiCGStab iterations to converge to a residual smaller than \(10^{-3}\). The implicit solution step contributes to about \({20}\,{\%}\) of the total computational effort. One advantage of the ISPH variant is the absence of the time step criterion related to numerical speed of sound, Eq. (53). As a consequency the ISPH simulations can typically use a significantly larger time step than the WCSPH simulations and, thus, require less wall time to be completed. The limiting physics for the time step in ISPH is typically the surface tension when using a discretization in the order of microns and metal alloy material parameters. Table 2 summarizes the performance comparison between ISPH and WCSPH simulations for the 2D case of the present section. The simulation of \({5}\,{{\textrm{ms}}}\) real time requires \({6}\,{\textrm{h}}\) of wall time on 28 computing cores using the ISPH method. Table 3 contains the respective summary for the 3D case shown in Sect. 3.3. The gain in execution time of the ISPH approach is mainly caused by the increased time step.

3D PBF-LB/M simulation of a single melt track in Ti6Al4V. The times are measured relative to the start of laser irradiation. The laser creates a \({1}\,{{\textrm{mm}}}\) track and is switched off after \({667}\,{\mu {\textrm{s}}}\). The rows for each point in time are an SPH particle representation with color-coded temperature (top) as well as surface reconstructions of the temperature (center) and the molten region (bottom), respectively. The simulation domain is clipped along the plane of symmetry for a better visualization of the melt pool

In summary, the use of the ISPH method leads to both more stable and much faster simulations in the studied examples. In the remainder of this work, only results of ISPH simulations are shown.

3.3 Melt track simulation

The shape of the melt pool during powder bed fusion depends on the laser parameters and the thermophysical material properties. It can be rather elongated along the direction of the laser’s motion or its depth can be increased.

Figure 10 shows a single PBF-LB/M laser track simulated by ISPH. The fully dense substrate extends \({1.5}\,{{\textrm{mm}}}\) along the direction of laser motion and \({0.4}\,{{\textrm{mm}}}\) into the other perpendicular directions. On top of the dense substrate is a powder layer of \({60}\,{\mu {\textrm{m}}}\) thickness. The powder has a log-normal size distribution with a median diameter of \({30}\,{\mu {\textrm{m}}}\) and a standard deviation of the underlying normal distribution of 0.2. The powder volume fraction is about 0.5. The titanium alloy Ti6Al4V is chosen as material. An overview of all material properties is given in Table 4. The SPH particle spacing is \(\Delta x = {5}\,{\mu {\textrm{m}}}\) and the adaptive time step varies between \(\Delta t = {50}\,{\textrm{ns}}\) and \(\Delta t = {100}\,{\textrm{ns}}\) during the simulation. The number of SPH particles is about \(2 \times 10^6\). The simulation of about \({1}\,{{\textrm{ms}}}\) real time requires \({24}\,{\textrm{h}}\) of wall time on 25 computing cores.

It is desirable that the melt pool covers at least partially the previously melted and re-solidified powder layer to ensure good bonding. For the simulation shown in Fig. 10, a Gaussian laser intensity distribution according to Eq. (1) with a spot diameter of \(4w = {95}\,{\mu {\textrm{m}}}\) is used. The laser power is \(P = {416}\,{\textrm{W}}\) and the laser scan speed is \({1.5}\,{\textrm{m}}\,{{\textrm{s}}^{-1}}\), which are typical values from industrial applications. The ray tracing scheme is used in this example. A melt track of \({1}\,{{\textrm{mm}}}\) length is created in the powder bed. The melt pool reaches its maximum depth after roughly \({100}\,{\mu {\textrm{s}}}\) and remains constant in its dimensions when following suit the laser motion. It can be observed that the molten region (dark gray in the lower images in Fig. 10) reach sufficiently deep into the dense substrate indicating flawless fusion. Furthermore, a stationary melt pool is established without significant ejection of spatter indicating that the used process parameters lead to stable powder bed fusion behavior.

Powder bed thermal conductivity scaling with \(k_\text {inter} / k_\text {intra} = 0.1\) as described in Sect. 3.1 is used for the 3D melt track simulations. The influence of the scaling is shown in Fig. 11. Here, \(V_\text {molten}(t)\) denotes the amount of molten material volume at time t for the case of conductivity scaling while \({\tilde{V}}_\text {molten}(t)\) represents the case without this scaling. It is observed that the molten volume is increased by up to \({30}\,{\%}\) if no conductivity scaling is used compared to simulations using conductivity scaling. An explanation for this observation is that the reduced heat conduction through the powder bed traps the heat in a localized region. This effect should be considered to model the melt pool accurately.

If the material becomes locally sufficiently hot, a gas phase transition may occur at the melt pool surface. Due to the volume expansion and the resulting gas pressure, the melt pool deepens significantly and the so-called keyhole mode occurs. If, however, the gas transition is avoided and the melt pool is shallow, one speaks of the heat conduction mode. The transition between these two regimes depends on the change in the locally introduced area energy density which is defined as the laser power divided by the product of laser spot diameter and laser scan speed. Our SPH method has been validated by capturing accurately the transition between heat conduction mode and keyhole mode. We compared therefore the simulation results to experimental findings in the literature [50].

The left column in Fig. 12 depicts experimentally obtained X-ray images of the vapor depression during PBF-LB/M of Ti6Al4V under variation of laser power and scan speed. The direction of view is perpendicular to the melt track. The laser spot diameter is \({95}\,{\mu {\textrm{m}}}\). The area energy densities used in the experiments vary only from \({2.4}\,{\mathrm{J\, mm}}^{-2}\) to \({6.3}\,{\mathrm{J\, mm}}^{-2}\). Yet, the differences in the morphology of the vapor depression are significant.

Left: X-ray images of the vapor depression in the PBF-LB/M process using Ti6Al4V powder while varying the laser power and scan speed; adopted from [50]. Right: Snapshots from corresponding SPH simulations. The fuzzy layer above the vapor depression is the powder bed. The laser moves from left to right. The area energy densities are \({6.3}\,{\mathrm{J\, mm}}^{-2}\), \({2.9}\,{\mathrm{J\, mm}}^{-2}\), \({3.6}\,{\mathrm{J\, mm}}^{-2}\), and \({2.4}\,{\mathrm{J\, mm}}^{-2}\) from top to bottom

At the highest area energy density of \({6.3}\,{\mathrm{J\, mm}}^{-2}\) (laser power of \({416}\,{\textrm{W}}\) and scan speed of \({0.7}\,{\textrm{m}}\,{{\textrm{s}}^{-1}}\)), shown in the first row of Fig. 12, a deep keyhole, which is slightly tilted to the right in the direction of the advancing laser, is formed. Close to the bottom of the keyhole, the depression shows its largest extent in the longitudinal direction while tapering in upward direction and eventually widening towards the surface. In contrast, the vapor depression in the second row (laser power of \({416}\,{\textrm{W}}\) and scan speed of \({1.5}\,{\textrm{m}}\,{{\textrm{s}}^{-1}}\)) leads to laterally much larger but shallower melt pool dimensions. The front of the vapor depression is less inclined with respect to the horizontal axis than in the case of the keyhole mode. Towards the rear end of the melt pool, the vapor depression is even shallower than at the front. This is an example for the conduction mode. For a laser power of \({208}\,{\textrm{W}}\) and a scan speed of \({0.6}\,{\textrm{m}}\,{{\textrm{s}}^{-1}}\), a narrow, tilted depression, which resembles the first case but on a smaller length scale, is formed. Note that the area energy density in the third row is larger than in the second row while the volume of the vapor depression is much smaller. Presented in the last row of Fig. 12, a laser power of \({208}\,{\textrm{W}}\) and scan speed of \({0.9}\,{\textrm{m}}\,{{\textrm{s}}^{-1}}\) lead to the lowest area energy density and to a small vapor depression of hemispherical shape.

Complementary to the experiments, our SPH simulations, using the same laser parameters as the experiments, are depicted in the right column of Fig. 12. The simulations yield very similar morphologies of the vapor depression compared to the respective experiments. All the above-described features are also found in the simulations. The shape features and spatial dimensions of the vapor depressions are very similar to the experimentally observed characteristics. These results show that the transition between keyhole mode and heat conduction mode can be quantitatively predicted by the SPH method.

The relation between the inclination of the front of the vapor depression and the depth of the depression was analyzed in [50]. For quantification of the inclination of the melt pool front, the depth of depression was plotted against the tangent of the tilt angle \(\theta\) for variations in spot diameter, power, and scan speed. The geometrical melt pool properties are illustrated in the inset of Fig. 13. An angle of \({90}^{\circ }\) corresponds to a vertical front. For a smaller angle, the inclination is shallower. If the depth of the depression is normalized by the spot diameter, all experimental data points fall on a straight line passing through the origin with a slope of about 0.6 as shown in Fig. 13. The SPH simulation results collapse similar to the experimental findings when non-dimensionalized. A simple theory predicts a slope of 1.0 [51]. In comparison to the simple theory, the SPH simulations provide a much better approximation to reality. The simulations are able to describe the slope to depth ratio of the vapor depression with satisfactory accuracy.

Universal relation between normalized vapor depression depth and tangent of the front keyhole tilt angle observed in experiments and SPH simulations. Inset: Definition of the melt pool vapor depression and the front keyhole tilt angle \(\theta\) adopted from [50]

4 Conclusion

We used the SPH method to model the laser-beam powder bed fusion process for metals. The key findings can be summarized in the following points:

-

Attention should be paid to the description of the thermal conductivity between powder particles prior to melting. A generic approach might overestimate the inter-particle conductivity and, thus, overestimate the amount of molten material.

-

Incompressible SPH is superior to weakly compressible SPH in terms of performance when using a single-phase scheme without the need to explicitly model the gas phase.

-

It is possible to predict the transition between the conduction and the keyhole melting mode as a function of laser process parameters.

-

The shape of the laser vapor depression can be modelled in good quantitative agreement with experiments.

Future work should address further improvements regarding the computational efficiency to allow for sophisticated multilayer simulations in three dimensions. Furthermore, including both rigid body powder dynamics and laser ray tracing could possibly lead to an even more realistic process model.

Data availability

No datasets were generated or analysed during the current study.

References

Körner, C., Attar, A., Heinl, P.: Mesoscopic simulation of selective beam melting processes. J. Mater. Process. Technol. 2110(6), 978–987 (2011). https://doi.org/10.1016/j.jmatprotec.2010.12.016

Körner, C., Bauereiß, A., Attar, E.: Fundamental consolidation mechanisms during selective beam melting of powders. Modell. Simul. Mater. Sci. Eng. 210(8), 085011 (2013). https://doi.org/10.1088/0965-0393/21/8/085011

Otto, A., Koch, H., Leitz, K.-H., Schmidt, M.: Numerical simulations—a versatile approach for better understanding dynamics in laser material processing. Phys. Proc. 12, 11–20 (2011). https://doi.org/10.1016/j.phpro.2011.03.003

Zenz, C., Buttazzoni, M., Florian, T., Crespo Armijos, K.E., Gómez Vázquez, R., Liedl, G., Otto, A.: A compressible multiphase mass-of-fluid model for the simulation of laser-based manufacturing processes. Comput. Fluids 268, 106109 (2024). https://doi.org/10.1016/j.compfluid.2023.106109

Khairallah, S.A., Anderson, A.: Mesoscopic simulation model of selective laser melting of stainless steel powder. J. Mater. Process. Technol. 2140(11), 2627–2636 (2014). https://doi.org/10.1016/j.jmatprotec.2014.06.001

Khairallah, S.A., Anderson, A.T., Rubenchik, A., King, W.E.: Laser powder-bed fusion additive manufacturing: physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 108, 36–45 (2016). https://doi.org/10.1016/j.actamat.2016.02.014

Muhammad, N., Rogers, B.D., Li, L.: Understanding the behaviour of pulsed laser dry and wet micromachining processes by multi-phase smoothed particle hydrodynamics (SPH) modelling. J. Phys. D Appl. Phys. 460(9), 095101 (2013). https://doi.org/10.1088/0022-3727/46/9/095101

Alshaer, A.W., Rogers, B.D., Li, L.: Smoothed Particle Hydrodynamics (SPH) modelling of transient heat transfer in pulsed laser ablation of Al and associated free-surface problems. Comput. Mater. Sci. 127, 161–179 (2017). https://doi.org/10.1016/j.commatsci.2016.09.004

Hu, H., Eberhard, P.: Thermomechanically coupled conduction mode laser welding simulations using smoothed particle hydrodynamics. Comput. Part. Mech. 40(4), 473–486 (2017). https://doi.org/10.1007/s40571-016-0140-5

Trautmann, M., Hertel, M., Füssel, U.: Numerical simulation of TIG weld pool dynamics using smoothed particle hydrodynamics. Int. J. Heat Mass Transf. 115, 842–853 (2017). https://doi.org/10.1016/j.ijheatmasstransfer.2017.08.060

Russell, M.A., Souto-Iglesias, A., Zohdi, T.I.: Numerical simulation of laser fusion additive manufacturing processes using the SPH method. Comput. Methods Appl. Mech. Eng. 341, 163–187 (2018). https://doi.org/10.1016/j.cma.2018.06.033

Blank, M., Nair, P., Pöschel, T.: Capillary viscous flow and melting dynamics: coupled simulations for additive manufacturing applications. Int. J. Heat Mass Transf. 131, 1232–1246 (2019). https://doi.org/10.1016/j.ijheatmasstransfer.2018.11.154

Fürstenau, J.-P., Wessels, H., Weißenfels, C., Wriggers, P.: Generating virtual process maps of SLM using powder-scale SPH simulations. Comput. Part. Mech. 70(4), 655–677 (2020). https://doi.org/10.1007/s40571-019-00296-3

Qiu, Y., Niu, X., Song, T., Shen, M., Li, W., Xu, W.: Three-dimensional numerical simulation of selective laser melting process based on SPH method. J. Manuf. Process. 71, 224–236 (2021). https://doi.org/10.1016/j.jmapro.2021.09.018

Meier, C., Fuchs, S.L., Hart, A.J., Wall, W.A.: A novel smoothed particle hydrodynamics formulation for thermo-capillary phase change problems with focus on metal additive manufacturing melt pool modeling. Comput. Methods Appl. Mech. Eng. 381, 113812 (2021). https://doi.org/10.1016/j.cma.2021.113812

Dao, M.H., Lou, J.: Simulations of laser assisted additive manufacturing by smoothed particle hydrodynamics. Comput. Methods Appl. Mech. Eng. 373, 113491 (2021). https://doi.org/10.1016/j.cma.2020.113491

Afrasiabi, M., Lüthi, C., Bambach, M., Wegener, K.: Multi-resolution SPH simulation of a laser powder bed fusion additive manufacturing process. Appl. Sci. 110(7), 2962 (2021). https://doi.org/10.3390/app11072962

Lüthi, C., Afrasiabi, M., Bambach, M.: An adaptive smoothed particle hydrodynamics (SPH) scheme for efficient melt pool simulations in additive manufacturing. Comput. Math. Appl. 139, 7–27 (2023). https://doi.org/10.1016/j.camwa.2023.03.003

Fuchs, S.L., Praegla, P.M., Cyron, C.J., Wall, W.A., Meier, C.: A versatile SPH modeling framework for coupled microfluid-powder dynamics in additive manufacturing: binder jetting, material jetting, directed energy deposition and powder bed fusion. Eng. Comput. 380(6), 4853–4877 (2022). https://doi.org/10.1007/s00366-022-01724-4

Afrasiabi, M., Keller, D., Lüthi, C., Bambach, M., Wegener, K.: Effect of process parameters on melt pool geometry in laser powder bed fusion of metals: a numerical investigation. Proc. CIRP 113, 378–384 (2022). https://doi.org/10.1016/j.procir.2022.09.187

Zöller, C., Adams, N.A., Adami, S.: Numerical investigation of balling defects in laser-based powder bed fusion of metals with Inconel 718. Addit. Manuf. 73, 103658 (2023). https://doi.org/10.1016/j.addma.2023.103658

Shah, D., Volkov, A.N.: Simulations of deep drilling of metals by continuous wave lasers using combined smoothed particle hydrodynamics and ray-tracing methods. Appl. Phys. A 126, 82 (2020). https://doi.org/10.1007/s00339-019-3202-8

Cummins, S., Cleary, P.W., Delaney, G., Phua, A., Sinnott, M., Gunasegaram, D., Davies, C.: A coupled DEM/SPH computational model to simulate microstructure evolution in Ti-6Al-4V laser powder bed fusion processes. Metals (2021). https://doi.org/10.3390/met11060858

Lin, Y., Lüthi, C., Afrasiabi, M., Bambach, M.: Enhanced heat source modeling in particle-based laser manufacturing simulations with ray tracing. Int. J. Heat Mass Transf. 214, 124378 (2023). https://doi.org/10.1016/j.ijheatmasstransfer.2023.124378

Wei, L.C., Ehrlich, L.E., Powell-Palm, M.J., Montgomery, C., Beuth, J., Malen, J.A.: Thermal conductivity of metal powders for powder bed additive manufacturing. Addit. Manuf. 21, 201–208 (2018). https://doi.org/10.1016/j.addma.2018.02.002

Shah, D., Volkov, A.N.: Calculation of effective thermal conductivity of powder bed systems using smoothed particle hydrodynamics method. Proceedings of the Sixteenth Annual Early Career Technical Conference, (2016)

Shah, D., Volkov, A.N.: Numerical simulations of thermal transport in random porous materials and powder systems using the smoothed particle hydrodynamics method. Int. Mech. Eng. Congr. Expos. 58356, V002T02A019 (2017)

SimPARTIX. Available online: https://www.simpartix.com, 2024. (accessed on 26 February 2024)

Körner, C., Attar, E., Heinl, P.: Mesoscopic simulation of selective beam melting processes. J. Mater. Process. Technol. 2110(6), 978–987 (2011). https://doi.org/10.1016/j.jmatprotec.2010.12.016

Wendland, H.: Piecewise polynomial, positive definite and compactly supported radial functions of minimal degree. Adv. Comput. Math. 4, 389–396 (1995). https://doi.org/10.1007/BF02123482

Price, D.J.: Smoothed particle hydrodynamics and magnetohydrodynamics. J. Comput. Phys. 2310(3), 759–794 (2012). https://doi.org/10.1016/j.jcp.2010.12.011

Marrone, S., Colagrossi, A., Le Touzé, D., Graziani, G.: Fast free-surface detection and level-set function definition in SPH solvers. J. Comput. Phys. 2290(10), 3652–3663 (2010). https://doi.org/10.1016/j.jcp.2010.01.019

Hirschler, M., Oger, G., Nieken, U., Le Touzé, D.: Modeling of droplet collisions using Smoothed Particle Hydrodynamics. Int. J. Multiph. Flow 95, 175–187 (2017). https://doi.org/10.1016/j.ijmultiphaseflow.2017.06.002

Sun, P.N., Colagrossi, A., Marrone, S., Zhang, A.M.: The δ plus-SPH model: simple procedures for a further improvement of the SPH scheme. Comput. Methods Appl. Mech. Eng. 315, 25–49 (2017). https://doi.org/10.1016/j.cma.2016.10.028

Bierwisch, C.: Consistent thermo-capillarity and thermal boundary conditions for single-phase smoothed particle hydrodynamics. Materials (Basel, Switzerland) 140(16), 4530 (2021). https://doi.org/10.3390/ma14164530

Tong, M., Browne, D.J.: An incompressible multi-phase smoothed particle hydrodynamics (SPH) method for modelling thermocapillary flow. Int. J. Heat Mass Transf. 73, 284–292 (2014). https://doi.org/10.1016/j.ijheatmasstransfer.2014.01.064

Bonet, J., Lok, T.-S.L.: Variational and momentum preservation aspects of Smooth Particle Hydrodynamic formulations. Comput. Methods Appl. Mech. Eng. 1800(1), 97–115 (1999). https://doi.org/10.1016/S0045-7825(99)00051-1

Swope, W.C., Andersen, H.C., Berens, P.H., Wilson, K.R.: A computer simulation method for the calculation of equilibrium constants for the formation of physical clusters of molecules: Application to small water clusters. J. Chem. Phys. 760(1), 637–649 (1982). https://doi.org/10.1063/1.442716

Chow, A.D., Rogers, B.D., Lind, S.J., Stansby, P.K.: Incompressible SPH (ISPH) with fast Poisson solver on a GPU. Comput. Phys. Commun. 226, 81–103 (2018). https://doi.org/10.1016/j.cpc.2018.01.005

Cleary, P.W.: Modelling confined multi-material heat and mass flows using SPH. Appl. Math. Model. 220(12), 981–993 (1998). https://doi.org/10.1016/S0307-904X(98)10031-8

Monaghan, J.J.: Smoothed particle hydrodynamics. Ann. Rev. Astron. Astrophys. 300(1), 543–574 (1992). https://doi.org/10.1146/annurev.aa.30.090192.002551

Morris, J.P.: Simulating surface tension with smoothed particle hydrodynamics. Int. J. Numer. Meth. Fluids 330(3), 333–353 (2000). https://doi.org/10.1002/1097-0363(20000615)33:3<333::AID-FLD11>3.0.CO;2-7

Morris, J.P., Fox, P.J., Zhu, Y.: Modeling low Reynolds number incompressible flows using SPH. J. Comput. Phys. 1360(1), 214–226 (1997). https://doi.org/10.1006/jcph.1997.5776

Cleary, P.W., Monaghan, J.J.: Conduction modelling using smoothed particle hydrodynamics. J. Comput. Phys. 1480(1), 227–264 (1999). https://doi.org/10.1006/jcph.1998.6118

Courant, R., Friedrichs, K., Lewy, H.: Über die partiellen Differenzengleichungen der mathematischen Physik. Math. Ann. 100, 32–74 (1928). https://doi.org/10.1007/BF01448839

Monaghan, J.J.: Smoothed particle hydrodynamics. Rep. Prog. Phys. 680(8), 1703–1759 (2005). https://doi.org/10.1088/0034-4885/68/8/r01

Lind, S.J., Xu, R., Stansby, P.K., Rogers, B.D.: Incompressible smoothed particle hydrodynamics for free-surface flows: a generalised diffusion-based algorithm for stability and validations for impulsive flows and propagating waves. J. Comput. Phys. 2310(4), 1499–1523 (2012). https://doi.org/10.1016/j.jcp.2011.10.027

Cao, L., Yuan, X.: Study on the numerical simulation of the SLM molten pool dynamic behavior of a nickel-based superalloy on the workpiece scale. Materials (Basel, Switzerland) (2019). https://doi.org/10.3390/ma12142272

Bayat, M., Thanki, A., Mohanty, S., Witvrouw, A., Yang, S., Thorborg, J., Tiedje, N.S., Hattel, J.H.: Keyhole-induced porosities in Laser-based Powder Bed Fusion (L-PBF) of Ti6Al4V: high-fidelity modelling and experimental validation. Addit. Manuf. 30, 100835 (2019). https://doi.org/10.1016/j.addma.2019.100835

Cunningham, R., Zhao, C., Parab, N., Kantzos, C., Pauza, J., Fezzaa, K., Sun, T., Rollett, A.D.: Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed x-ray imaging. Science (New York, N.Y.) 3630(6429), 849–852 (2019). https://doi.org/10.1126/science.aav4687

Fabbro, R., Chouf, K.: Keyhole modeling during laser welding. J. Appl. Phys. 870(9), 4075–4083 (2000). https://doi.org/10.1063/1.373033

Acknowledgements

We gratefully acknowledge financial support by the European Commission under grant no. 760173 (MarketPlace) within the Horizon 2020 program, by the German Research Foundation under grant no. BI 1859/2-2 within the priority program 2122, by the Federal Ministry for Economic Affairs and Climate Action based on a resolution of the German Bundestag within IGF project no. 21470 N and by Fraunhofer Internal Programs under Grant MAVO HAlUr.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

All authors developed the method and implemented the software; C.B. carried out the numerical simulations; C.B. wrote the main manuscript text; C.B. and B.D. prepared the figures; all authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bierwisch, C., Dietemann, B. & Najuch, T. Particle-based modelling of laser powder bed fusion of metals with emphasis on the melting mode transition. Granular Matter 26, 71 (2024). https://doi.org/10.1007/s10035-024-01442-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-024-01442-2