Abstract

The effects of water on the behaviour of granular materials can be significant. Besides capillary bridges, several other chemo-hydro-mechanical processes can affect the response of hydro-sensitive granular assemblies, when water sorption critically alters the individual particles properties (i.e., swelling, deterioration of mechanical properties). It is very common to find such materials in food and pharmaceutical industries, where water sorption can often lead to important resources waste while processing or storing the product. It is therefore necessary to understand the phenomena that affect the material’s functionality, often related to particle agglomeration and degradation. However, despite the relevance of the problem, our knowledge about these phenomena is still relatively poor. With this study we aim to explore the link between water content increase and particle, contacts and assembly scale phenomena. Simultaneous neutron and X-ray tomography allows us to investigate respectively the water uptake and microstructure evolution of two couscous assemblies exposed to high relative humidity while subjected to constant stress, a configuration chosen to simulate the conditions in an industrial silo-storage. We acquire a data-set of images, from which we follow and quantify the variations of water content distribution and the resulting volumetric response of thousands of particles through bespoke algorithms. Despite the abundance of water provided, we observe spatial gradients in water content distribution and consequently in particle swelling. We find that the relation between these two variables can be described as (quasi-)linear. The contact area growth also seems to follow a similar trend.

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The presence of water significantly affects the behaviour of granular media. Their response strongly depends on whether the system is in dry, saturated or partially saturated conditions. This problem has been thoroughly investigated for assemblies of impermeable particles (e.g., sands) [1]. However, there exist many granular materials whose individual particles are hydro-sensitive, meaning that their morphology and mechanical properties vary based on the water content. Clear examples of such materials can be found in food or pharmaceutical industry, e.g., cereals, pharmaceutical powders, flour, tablets, pasta and couscous. These are all hygroscopic, i.e., they can adsorb water molecules from the outer environment. Notably, industries are interested in maintaining constant product properties. Water sorption during processing or storage can alter them, an issue that can lead to severe product or financial loss, sometimes reported to be up to 50% [2].

In spite of the practical relevance of the problem, very little is know about the underlying phenomena that originate at the molecular level, which in turn affect the particle-, assembly- and macroscopic-scale behaviour.

The inherent chemical composition of food stuff or pharmaceutical excipients often endows the material to be in disequilibrium with the external environment (a difference in “water activity”) [3, 4]. In this case, the molecular matrix can adsorb large amount of water [5], which in turn causes structural changes and also induces the glass transition phenomenon that specifically involves the amorphous fraction of the material [4, 6]. The material can swell (often due to the dilation of starch molecules) but it can also shift from a “glassy” to a less viscous state, which causes a significant deterioration of mechanical properties.

Naturally, these processes affect the particle properties and make them hydro-sensitive. Several studies were carried out to evaluate the effects of water content on shape and mechanical properties of individual particles. Swelling is one of the common phenomena observed when exposing such materials to water. Rice and wheat grains [7, 8], lentil seeds [9], microcrystalline cellulose granules [10], couscous [11,12,13,14] are just some examples of the numerous materials that were found to dilate when increasing water content. Besides the effect on the morphology, water strongly influences also mechanical properties. For example, strength and stiffness of wheat kernels decreased more than 10% when increasing water content [15, 16]. Similar results were found for rice grains [17, 18], which also developed fissures upon wetting and drying cycles [19]. The tensile strength of microcrystalline cellulose tablets decreased for higher water contents according to a study by Shi et al. [10].

These phenomena are not necessarily deleterious by themselves. However, as particles continuously interact with each other, they can agglomerate. Bridges are formed either by material solution accumulated on the contact regions which dries or when a viscous flow occurs between particles (i.e., sintering) [20,21,22,23]. Relatively high stresses can also enhance the agglomeration and thus decrease the flowing properties of the material [6].

As a whole, these processes can lead to caking, a phenomenon in which granular media loose their free flowing properties due to formation of lumps. To prevent this kind of problems is of high interest for the industry [6, 23,24,25], therefore studies have also focused on the bulk/product scale effects of water uptake. As the material picks up water, the caking strength is generally found to be higher and its flowability lower [26,27,28,29]. Studies have also showed how the process is not uniform, even for relatively homogeneous testing conditions [29] and it is therefore necessary to take into account heterogeneities to properly model, simulate or predict the behaviour of any hydro-sensitive material.

Altogether, a large number of studies focused on the interaction of water with such materials, and the effects on their properties. However, our knowledge of the problem is still insufficient, either because of its complexity or the impracticality of finding standard references for such a broad class of materials. A few review papers summarised experimental and numerical research related to the caking phenomenon, and they often concluded that it is necessary to investigate and understand the link between particle-scale phenomena and bulk response [23,24,25]. Nevertheless, few studies aimed to describe the multi-scale response of hydro-sensitive particles. For instance, Wahl et al. [30] investigated optically the bridge formation between two particles of urea prills (a fertiliser) and quantified its mechanical resistance. The Authors then implemented a model describing the particles interaction and predicted numerically the uniaxial strength of the assembly. Haider et al. [31] examined the effect of temperature on the contact formation, morphology and compressive-tensile strength between maize starch particles. In a recent study [14], we investigated by means of X-ray tomography the effects of high relative humidity (RH) on the microstructure of a couscous sample subjected to constant stress. We observed the swelling of thousands of particles as they sorbed water and quantified their volume change (up to 20%) as well as the volume change of the whole sample. We found a dilation-compaction behaviour as a result of the particle swelling and deterioration of mechanical properties. Moreover, we found a strong correlation between the inter-particle contact areas growth and the applied boundary conditions (e.g., loading direction and injection point).

With the experimental study presented in this paper we aim to expand our previous work, specifically focusing on the correlation between microstructural changes and water content distribution, a feature that was not possible to capture by means of X-ray tomography only. For this reason, we couple the technique with neutron tomography. The two are highly complementary thanks to the different way in which the beams interact with matter [32, 33]. X-rays interact with the electron cloud of atoms, whereas neutrons interact with nuclei. Of particular interest for this study is the different attenuation of hydrogen atoms, which are basically transparent to X-rays and quite the opposite to neutrons, which as a consequence allows the detection of water. For these reasons, neutron + X-ray tomography is a technique that has been used in several experimental studies to observe the hydro-mechanics of different processes, as detailed in recent reviews [33, 34]. Recent inspiring examples related to our work are the studies by Stavropoulou et al. [35] and Sleiman et al. [36]. In the former, the Authors measured the water absorption by a sample of Callovo-Oxfordian claystone and the following microstructural evolution. Via image analysis, the deformation of reference sub-volumes (deduced from X-ray images) was correlated to the local increase of water (from neutrons). In the latter, the drying of concrete samples due to increasing temperature and the resulting cracks opening were investigated.

This paper presents the results of two experimental campaigns similar to the one of our previous study [14]. We again expose samples of couscous particles to high RH air, while subjected to zero radial strain (oedometric) conditions. This time, instead of using only X-ray tomography, we continuously acquire 5D (neutron + X-ray + time) images, where X-rays provides data about the sample microstructure, while the contrast of neutron images provides information about the water content variation as the molecular matrix of the particles entraps water. Following bespoke algorithms, we measure from X-ray tomography images the volumetric response at the particle- and sample-scale, and correlate them to the water content, which we deduce and quantify from neutron tomography. Finally, we correlate the swelling of particles and the increase of inter-particle contact areas to the water content increase, and to the overall assembly response.

The paper is structured as follows: Sect. 2 describes the material, experimental procedure, set-ups and instruments used in this study. Section 3 presents the results we obtained through image analysis. Using the algorithms developed for our previous study [14], we analyse the volumetric response of the samples during the two experiments. Then, Sect. 3.3 introduces the procedure specifically developed to assess and quantify the water content distribution, which is then correlated to the microstructural changes of the couscous assembly.

2 Experimental study

2.1 Material choice: couscous, a hydro-sensitive granular medium

Besides its low cost, and commonness, couscous presents several of the phenomena that characterise hydro-sensitive granular materials. When in contact with water its particles can in fact swell, undergo deterioration of mechanical properties, and agglomerate. At the same time, couscous particles do not present some of the more complex phenomena typical of other hydro-sensitive particles, such as peeling or particle breakage (for sufficiently low stresses) – all phenomena that would make the quantification of some microstructural properties studied here cumbersome. Finally, the average particles diameter of fine couscous is \(\approx \,0.85\,{\rm {mm}}\), a size compatible to the imaging set-up used here: the neutron and X-ray tomograph “NeXT” at the Institut Laue-Langevin (see Sects. 2.2 and 2.2.3).

2.2 Experimental procedure

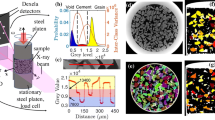

a Sketch of the experiments at NeXT: the samples of couscous are placed in an oedometric cell (sketch on the left, side view) and subjected to a constant vertical stress (dead load). Meanwhile, a flow of high RH air is injected by means of a peristaltic pump from the bottom. Neutron and X-ray tomographies are acquired placing the set-up on a rotation stage (sketch in the middle, top view). b Vertical slices of the X-ray (top row) and neutron tomographies (bottom row) at representative states, highlighting the overall processes

The particles are subjected to oedometric conditions (no radial displacement) to emulate typical conditions found in storage silos. They are poured in a rigid cylindrical cell, thus, vertical displacement is allowed, and the constant stress applied simulates the action played by the self weight of material stored above. We subject the sample to a flow of high RH air, to study typical phenomena in hydro-sensitive materials exposed to humidity. The air is injected from the bottom of the cell by means of a peristaltic pump, which in turn is connected to a RH control chamber. The environment in this chamber is controlled with a saturated saline solution of potassium sulphate (\({\hbox {K}_{2}\hbox {SO}_{4}} + {\hbox {H}_{2}\hbox {O}}\)), which produces rather constant RH in its environment (95–97% for a range of temperatures between 20 and 25 °C [37, 38]). At the bottom and top of the sample two high porosity stones maintain the sample in position and uniformly apply the stress and the humidity.

This paper presents the results of two experimental campaigns:

-

CCRH97-01;Footnote 1

-

CCRH97-02.

Both performed at the NeXT beamline at the Institute Laue Langevin (ILL) in Grenoble (France) [39], they are analogous experiment to one in our previous study [14], in which only X-ray tomographies were acquired. These allowed the characterisation of the effects of high RH on the microstructure of a couscous particles assembly. Nonetheless the water content in the particles could not be quantified then, because of the low attenuation (and thus visibility) of water to X-rays. For this reason, in this study we also acquire simultaneous neutron tomographies, to capture the water uptake process and its spatial distribution. A sketch of the experimental set-up and of the process as revealed by the tomographies is presented in Fig. 1.

2.2.1 CCRH97-01: experimental procedure

To subject the sample to the desired experimental conditions, we use the same oedometer as in our previous study, except for the material of the cell, fabricated here in PTFE (Teflon) and not PEEK to improve its neutron transparency. However, a first preliminary test, although successful, shows us that the high natural hydrogen content of couscous particles causes a strong beam hardening in the neutron tomographies over the \(16 \,{\rm {mm}}\) diameter of the sample [40]. The significant amount of scattering spuriously increases the apparent attenuation of the outermost particles. While this artefact can be partly remediated during the reconstruction, it increases the error margin in the estimation of water content. To diminish the influence of this artefact, the cell internal diameter is reduced to \(13 \, {\rm {mm}}\) by inserting a PTFE sleeve of about \(17 \,{\rm {mm}}\) height in the main cylindrical cell, above the bottom porous stone. \(1.77 \, {\rm {g}}\) of couscous particles are then poured in the reduced cell. A smaller porous stones is placed on top (of diameter lower than the “sleeve”) and the piston applying the dead load above it. The diameter reduction means an increase of the applied stress to \(35\,{\rm {kPa}}\) (to be compared to \(25 \, {\rm {kPa}}\) for the previous study [14]). Some particles trapped on top of the PTFE sleeve, i.e., between the upper porous stone and the cell wall, might have partly reduced the load actually transmitted to the sample, also due to the expected particle swelling. Air of 95–97% RH is injected at \(0.02 \, {\rm {L/min}}\) for about \(49.5 \, {\rm {h}}\). The final mass of the sample is \(1.91 \, {\rm {g}}\), corresponding to an 8% mass increase.

2.2.2 CCRH97-02: experimental procedure

This second campaign’s goal is to acquire higher resolution images (see Sect. 2.2.3) to further investigate the processes occurring at the particle scale, but it aims at a reduction of the beam hardening effect. For this reason, a smaller oedometric set-up is designed and fabricated (internal diameter of \(7\,{\rm {mm}}\)) improving on the previous design. The new cell is in aluminium, because the PTFE would not be stiff enough. The initial mass of the sample is \(0.31\,{\rm {g}}\), and, to be consistent with the conditions of CCRH97-01, the dead load applies a vertical stress of \(35\,{\rm {kPa}}\). High RH air is produced in the same manner as for CCRH97-01 (Sect. 2.2.1), and the flow rate is initially set to \(0.02\,{\rm {L/min}}\) for 48 hours, indicatively matching the duration of the other test. The flux is then increased to \(\approx \,0.2\,{\rm {L/min}}\), to resolve suspected infiltration of lower RH air from the outer environment due to small defects of the cell. The final mass of the sample is \(0.38\,{\rm {g}}\). The water content variation is then around \(22\%\). This is a noticeable increase of mass, higher than \(\approx \,19\%\) reported in previous studies on the sorption isotherms of durum semolina [41]. We suspect that small droplets, perhaps accumulating at the porous stone, are accidentally pushed trough the sample by the increase in flow in the later stages of the test. These possible variations in water content are part of the reasons why the addition of neutron imaging is indispensable to correlate the directly measured water content increase in the particles to their strain.

2.2.3 Neutron and X-ray tomographies

During both campaigns, neutron and X-ray tomographies of the sample are continuously acquired.

The cold neutron source at NeXT provides a quasi-parallel beam. The neutrons are detected with high resolution detectors adopting infinity-corrected optics [39]. The X-ray source is operated at \(100{\rm{ kV}}\) and \(60\,{\upmu \rm{A}}\) for CCRH97-01. For CCRH97-02, the parameters are initially set to \(140\,{\rm {kV}}\) and \(200\,{\upmu \rm{A}}\) to better penetrate the aluminium cell. After 28 h these settings are decreased to \(120\,{\rm {kV}}\) and \(68\,{\upmu \rm {A}}\), to further reduce the cross talk between the two radiations, without effective loss of resolution for the X-ray tomographiesFootnote 2.

In the CCRH97-01 campaign each tomography comprises 992 projections. Each X-ray projection is the result of the average of 8 individual frames and is acquired at \(1.8\,{\rm {Hz}}\), without binning. The neutron projections are averaged 3 times and acquired at \(0.67\,{\rm {Hz}}\), as obtained through a \( 122 {\text{ mm}} \) Heliflex lens combined a \(50\,{\rm {mm}}\) lens, in binning 2, yielding a pixel size of \(32\, {\upmu \rm {m}}\). A \(20\, {\upmu \rm {m}}\) thick Gadolinium Oxysulfides scintillator is used. With an estimated \(9\,{\rm {mm}}\) average sample-detector distance, and pinhole of \(30\,{\rm {mm}}\) at \(10\,{\rm {m}}\), this yields an estimated \(27\, {\upmu \rm {m}}\) neutron penumbra, compatible with the pixel size and the desired resolution. This results in the simultaneous acquisitions lasting around \(1.24\,{\rm {h}}\). In total, 38 tomographies are acquired. The voxel-size for both X-ray and neutron images is \(32\,{\upmu \rm {m}}\).

Tomographies are also acquired continuously during the CCRH97-02 experiment. Each one of them comprised 1200 projections. An X-ray projection is acquired initially averaging 27 acquisition at \(9\,{\rm {Hz}}\). After the aforementioned decrease of the X-rays power (at scan #27), the average and frame-rate are reduced to 7 and \(2.3\,{\rm {Hz}}\), respectively. Each neutron projection averages 3 acquisitions obtained at \(1\,{\rm {Hz}}\), in binning 2, throughout the entire test, as obtained through a \(55\,{\rm {mm}}\) Heliflex lens combined with a \(50\,{\rm {mm}}\) lens, in binning 2, yielding a pixel size of \(14\, \upmu {\rm {m}}\). A \(10\, \upmu {\rm {m}}\) thick Gadolinium Oxysulfides scintillator is used. With an estimated \(4.5\,{\rm {mm}}\) average sample-detector distance, and pinhole of \(30\,{\rm {mm}}\) at \(10\,{\rm {m}}\), this yields an estimated \(13.5\, \upmu {\rm {m}}\) neutron penumbra, compatible with the (binned) pixel size and the desired true resolution. A single tomography then lasts \(1.02\,{\rm {h}}\). We acquire in total 60 bi-modal tomographies. The voxel-size of the X-ray and neutron images is respectively \(25\, \upmu {\rm {m}}\) and \(14\, \upmu {\rm {m}}\).

In both the experimental campaigns, we take an initial tomography of the “dry” reference sample configuration (counted among the total number of scans) and only then the peristaltic pump is turned on exposing the particles to humid air.

As the experiments go on for 2-3 days, we occasionally interrupt the scanning procedure to re-calibrate the detectors.

Finally, tomographies are reconstructed with the Feldkamp filtered back projection [42] algorithm, as implemented in the X-Act software (RX-Solutions, Annecy, France). Examples of the reconstruction process are shown in Fig. 1b.

In Table 1 we summarise the experimental conditions of the two campaigns and the imaging parameters.

3 Image analysis: methods and results

In this Section we present the image analysis methods proposed in this work as well as the processes quantified thanks to them. The analyses are performed with the open source software for image analysis spam [43].

3.1 Multi-modal registration and segmentation

Joint histogram built with the X-ray (red) and the neutron (blue) gray-value histograms of the tomography of the reference configuration of CCRH97-01. Two peaks can be observed, corresponding to two phases: void/air at low gray-values and solid/particles(+sorbed water) at higher gray-values. This joint histogram is employed in the MMR algorithm to register the two tomographies (color figure online)

Firstly, we perform multi-modal registration (MMR, i.e., align the two tomography modalities) at each time-step. This method was proposed in Tudisco et al. [44] and implemented in spam [45]. With this algorithm each neutron tomography is aligned to its corresponding X-ray one, to have a coherent coordinate system between them. This operation requires firstly a “map” of correspondences between the X-ray and neutron gray-values, i.e., the joint histogram. Figure 2 reports a representative joint histogram combining X-ray (red) and neutron (blue) gray-value distributions. The two peaks correspond to the two phases in the system: void/air peak and solid/particles(+water). The algorithm describes the joint histogram with a Gaussian mixture model, which is then employed to perform a generalised digital volume correlation (DVC) between images acquired with the two modalities [44, 45]. This allows us to align the tomographies across the test with sub-voxel accuracy, while also segmenting them, i.e., classifying each voxel as either void or particle.

This step is crucial for the following analyses, especially at the particle scale. Combining the MMR segmentation and thresholding of the X-ray image, the sample solid fraction alone is extracted as a binary image. From it the distance map is computed, and the local maxima are used as flooding point for the watershed algorithm [46, 47]. Over- and under-segmentation issues are resolved with the dedicated algorithms [43].

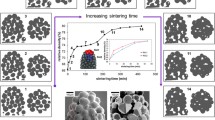

Once the particles are separated we can assign to each a unique number (a process named “labelling”). We find that 3013 and 527 particles comprise at the end the CCRH97-01 and CCRH97-02 samples and the average particle diameter equal to \(0.86 \pm 0.13\,{\rm {mm}}\) and \(0.88 \pm 0.12\,{\rm {mm}}\). The 3D renderings are shown in Fig. 3a and b.

3.2 Volumetric response

Volumetric strain \(\varepsilon _{V}\) at both sample and particle scale (with standard deviation) of CCRH97-01 (green) and CCRH97-02 (orange) as a function of the injected air volume. High RH air is injected into the system, particles uptake water and swell. These two processes affect the overall sample volumetric strain \(\varepsilon _{V,s}\), which increases as the particles are able to lift the dead load. In CCRH97-02, a compaction stage is observed too. The particles become softer with high water content, which causes an overall shortening of the sample (color figure online)

Relation between the particle \(\bar{\varepsilon }_{V, p}\) and sample \(\varepsilon _{V, s}\) volumetric responses for the two experimental campaigns presented here (green and orange) and the one in Vego et al. [14] (gray line). The evolution of porosity in all three tests is shown here with dashed lines for comparison (color figure online)

We analyse the volumetric response at the assembly and individual particles scale following the procedure proposed in our previous work [14]. It should be noted that we use the X-rays images for this and the contact measurement presented later in Sect. 3.3, because of their lower noise (see Fig. 1b).

The sample’s deformation is measured via DVC between the reference X-ray image and the sequential ones. Specifically, a global, non-rigid registration is performed, as implemented in spam. Among the outputs, the operation returns the gradient tensor F between the reference and the deformed configuration, which allows the computation of the sample’s volumetric strain is then computed as: \(\varepsilon _{V,s}=det(F)-1\). Because of the selected boundary conditions, i.e., no radial strain, no substantial difference is observed when measuring the sample’s deformation using this approach or from the relative displacement of particles.

Measuring the particle-scale volumetric strain requires relatively high resolution images, made possible by a combination of the NeXT beamline specifications, the choice of the material as well as of the geometry of the cell, as detailed above. From the labelled image of the reference configuration, we perform Discrete Digital Volume Correlation (DDVC), as proposed by Hall et al., [48]. We isolate a sub-volume for each particle and perform DVC on it to measure displacement. To track the particles, the rigid displacements measured from the DDVC is used to move the initial particle labels to their updated position, which then is used as a “seed” for a new watershed algorithm so as to assign the same label to a particle throughout the test. The particles’ volumetric strain is then directly measured from the variation in volume of each labelled particle with respect to the reference configuration. It should be noted that its evolution is essentially the same when measured as detailed here or from the overall volume variation of the sample's solid fraction.

The volumetric strain of the sample and the distribution of particles for CCRH97-01 as a function of the injected air volume are shown in dark green in Fig. 4, with solid and dashed line, respectively. Initially the assembly increases in volume until it reaches a constant value (\(\varepsilon _{V,s}=\,1.7\%\) after injecting \(\approx \,34\,{\rm {L}}\)). Meanwhile, the particles (dashed line, arithmetic mean along with the standard deviation value) swell monotonically throughout the entire test, up to \(10\%\) from their initial size, despite the plateau in overall sample dilation (i.e., the particles cannot further lift the dead load). The sample porosity decreases from \(48\%\) to \(44\%\) throughout the experiment (see Fig. 5). The particle swelling appears to plateau, suggesting an asymptotic value would be reached also for individual particles, at the equilibrium with the external environment.

For CCRH97-02 the same procedure is performed. Figure 4 shows the sample and arithmetic average particle volumetric strain, with orange solid and dashed line, respectively. As mentioned in Sect. 2.2.2, after 48 hours we increase the air flow rate, to study its effect and to compensate a suspected infiltration of lower RH air. The evolution of the curves after this change supports the hypothesis. Before the increase in flow, dilation at the sample and particle scale are lower than for CCRH97-01 (and previous experiments, see Vego et al., [14]). Once the flow rate is increased (a change highlighted with a cross symbol in Fig. 4) the particle swelling rate increases significantly. The sample CCRH97-02 also dilates up to 1%, but, as the particles become more deformable, it compacts down to \(-3.5\%\) of the initial volume. The bulk porosity is initially 47% and it decreases down to 44% at the time-step corresponding to the dilation peak. At the end of the test, the porosity is 34%, as reported in Fig. 5.

In order to make a consistent comparison between the different experimental campaigns, in Fig. 5 is reported the volumetric strain at the sample scale \(\varepsilon _{V, s}\) as a function of the arithmetic average particle volumetric strain \({\bar{\varepsilon }}_{V, p}\). The response in CCRH97-01 (green) and CCRH97-02 (orange) are similar. Initially, both samples dilate because of particle swelling. The curve of CCRH97-01 stops when the experiment is interrupted (end of available beamtime), while CCRH97-02 shows the ensuing compaction stage. This competition between swelling and reduction of mechanical properties is also observed in our previous study [14], here reported with a gray line (in which the stress applied was \(25\,{\rm {kPa}}\) and not 35).

The presence or absence of a compaction stage in the volumetric response is linked to the eventual water content increase. In CCRH97-01 the mass gain is \(\approx \,8\%\) the sample’s initial mass, while in CCRH97-02 \(\approx \,22\%\). The experiments are performed on the same material and at similar environment conditions (temperature and RH), therefore the initial water content can be assumed equivalent in both. We can conclude that the compaction stage is observed only in CCRH97-02, because of the (much) higher water content, which sensibly decreases the mechanical properties of the particles.

Concerning the volumetric response at the sample scale, the differences in peak dilation between the experiments can be explained because of the particles trapped between the porous stone and the PTFE cell (see Sect. 2.2.1), the friction between the particles and the walls, vertical stress, or even a small difference in initial water content.

Figure 5 also reports the evolution of porosity during the experimental campaigns. The void space decreases monotonically in all three cases because of particle swelling, even during the dilation stage. Moreover, the softening of the particles and the consequent sample compaction can accelerate the porosity decrease. Finally, it should be noticed that the curves are essentially parallel, indicating a consistent response between the three tests, with a discrepancy only in the initial porosity value, which can be the result of sample preparation, the sample size, different boundary conditions, and couscous batch.

3.3 Water content and its effect on the microstructure

In these experiments, the driving process is the evolving water content in the particles, which originates due to a difference in water activity between the couscous molecules and the high RH air, which in turn alters the particle-scale properties, and thus the sample-scale structure.

Neutron tomography is performed precisely to gather information about the water distribution in the sample. The multi-modal registration procedure in Sect. 3.1, combined with the DDVC in Sect. 3.2 allows us to follow each particle in the neutron tomographies. The average neutron attenuation of each of these particles can be assumed to be the result of the combination of water sorption, increasing their neutron opacity, and particle swelling (reducing it, since the same amount of material, net of the water sorption, would be spread across more voxels). To be able to quantify water content from the neutron attenuation, while neglecting the possible reduction of gray-value because of dilation, we take the global attenuation of each particle \(\psi _{p}\) (thus the integral of its neutron attenuation values, whose variation we can assume to depend on water sorption), which we simply computed as:

where N is the total number of voxels belonging to the particle and \(\mu _{ne, n}\) the gray-value of the \(n^{th}\) voxel.

It is possible then to investigate the presence of heterogeneities in attenuation across the sample. The mechanisms that can lead to these heterogeneities are multiple. For instance, the water concentration can gradually decrease as water molecules are entrapped by the particles, as suggested by a former study by Brockbank et al. [29]. The presence of heterogeneities can also be attributed to a small air pressure gradient that is generated as the injected air flows through the sample [49], which in turn affects the water activity of the material and the maximum adsorption [50], even with overabundance of water molecules. Ultimately, the stress to which particles are subjected could also affect their sorption capacity.

In this study, we investigate the evolution of vertical gradients, i.e., from inlet to outlet. As observed in our previous study [14] with similar boundary conditions, the radial variation in volumetric strain is found to be modest, while it is significant along the vertical direction. We therefore study the average particle attenuation \(\bar{\psi _{p}}(h)\) at a given height h. More than the overall attenuation of a particle, which is the product of the natural hydrogen content of the initial skeleton plus the sorbed water, we are interested in its evolution with time, caused by water sorption:

where \(\psi _{h,0}\) is the hydrogen profile of the reference configuration, assumed to be homogeneous across the sample. It must be noted that the slices close to the porous stones are excluded from this analysis. The interaction of the porous stones (denser than couscous) with the X-ray conic beam creates inevitable artefacts that affect the particles’ volume measurement. Since we can measure the overall water uptake of the sample (by measuring its mass at the beginning \(m_{0}\) and at end of the test \(m_{f}\)) we can calibrate the correspondence between the measured change in attenuation and normalised change in water content. Assuming a linear relationship between the two, the coefficient linking them is evaluated as:

where \(\int _{h=0}^{H}\Delta {\bar{\psi }}_{h}dh(t=t_f)\) is the integral over the sample height H of \(\Delta {\bar{\psi }}_{h}\) at the end of the test \((t=t_f)\) and thus the overall change in attenuation of the particles comprising the sample.

Thanks to \(\alpha\) it is possible to convert the vertical profiles of variation of attenuation \(\Delta {\bar{\psi }}_{h}(t)\) directly to water uptake profiles \(\omega _{h}(t)\) as:

It is of interest to compare these \(\omega _{h}(t)\) directly to volumetric strain profiles \(\varepsilon _{v,h}(t)\), which can be simply computed as the average particle volumetric strain at a given height. It must be noted that later in the article, we use \(\omega\) to describe the “water content”, even though we measure the change in mass with respect to the initial configuration and not to the actual dry mass of the sample.

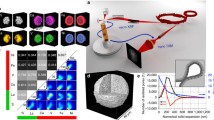

Vertical profiles of a water content (as deduced from neutrons), and b volumetric strain (from X-rays), for CCRH97-01. The profiles—and their linear fits—indicate a vertical gradient, where particles closer to the air injection point (\(h/H\rightarrow 0\)) sorb a higher amount of water then the ones at the top (\(h/H\rightarrow 1\)). A coherent evolution of the volumetric strain (swelling) profiles is observed

Vertical profiles of a water content (as deduced from neutrons), and b volumetric strain (from X-rays), for CCRH97-02. The experiment can be split in two parts: before and after the flow rate increase (black line). The profiles—and their linear fits—in the first stage do not show a significant increase in water content or swelling, and only a modest vertical gradient. In the second stage (higher flow rate), water uptake and swelling accelerate significantly and the particles at the bottom uptake water up to 30–35 % of their initial mass. Interestingly, the swelling gradient remains less pronounced (color figure online)

Figures 6 and 7 present these profiles for the CCRH07-01 and CCRH97-02 experiments. The increase of particle water content and particle volumetric strain distributions are shown along the (normalised) height of the sample h/H (where \(h/H=1\) indicates the top of the sample). For visualisation purposes, we interpolate the data with a straight line.

The water content increases monotonically during the CCRH97-01 experiment (Fig. 6a), with an increasing vertical gradient. Particles closer to the injection point uptake in fact more water than the particles at the top of the sample. By the end of the test, the bottom particles pick up \(\approx \,10\%\) of their initial mass in water, while top particles only \(6\%\). This vertical gradient evolves along the test. At the beginning the profiles’ slope indicates higher sorption rate in the lower regions of the sample. However, the difference in water content between lower an upper regions reduces by the end of the test, when the particles are reaching their sorption capacity. Conversely, the particle volumetric strain profiles (Fig. 6b) evolve coherently to \(\omega _{h}\) confirming that swelling is strongly linked to water content increase.

To interpret CCRH97-02, we split the analysis of this experiment in two: before and after the injection speed increase. Figure 7a shows the water content distribution profiles, while Fig. 7b presents the volumetric strain profiles. The two phases of the test are divided by a black line. In the early stages of the test, we observe no significant increase of water content and no major particle swelling. These results support the hypothesis of an infiltration of lower RH air in the oedometric cell or leakage from it (Sect. 2.2.2). The variations in particle swelling and (thus) volumetric expansion are modest. After we increase the flow rate the process accelerates. The water sorption increases significantly, and a strong vertical gradient can be observed, with particles closer to the injection point sorbing \(35\%\) of their initial mass in water, and particles on the top of the sample sorbing less than half of that. In the CCRH97-02 test the increase of water content is exceptionally high when compared to the previous experiment to other studies performed on durum wheat products by Erbaş et al., [41], who recorded an increase of water content of about \(19\%\) for semolina and farina at 20 °C. In our case, if we assume an initial dry based water content of \(8\%\) (a reasonable value for \(\approx 40-45\%\) RH), then the final average would be equal to \(32.4\%\), a water content far higher than the one expected from former tests. For this reason, we presume infiltration of liquid droplets during the experiment. In support of this hypothesis we observe that, while the volumetric expansion also significantly accelerates, the swelling vertical gradient remains modest, hinting possibly at a temporal delay between the water sorption process and the particle dilation. The delay could be caused by the gelatinous barrier that forms when couscous particles are exposed to liquid water [13].

Once the water content distribution and the volumetric strain of the particles are assessed, it is possible to investigate their relative evolution. Figure 8 presents the average values of particle volumetric strain \(\bar{\varepsilon }_{V, p}\) and average particle water content \(\bar{\omega }_{p}\) (obtained from the respective \(\varepsilon _{V, h}\) and \(\omega _{h}\) profiles) along with their respective standard deviation at different time-steps.Footnote 3 The green solid line corresponds to the CCRH97-01 experiment, which shows a bi-linear trend. Initially, even a small increase of water content of \(2-3\%\) causes a \(6\%\) swelling. For higher water contents, the swelling slows down (approaching a plateau as shown in Fig. 4).

The equivalent analysis is performed for the CCRH97-02 sample, but dividing the sample in a top and in a bottom region. As shown by 7a, the water content distribution gradient is not constant along the height of the sample, but rather there is a significant variation at \(h/H \approx 0.4\). Hence, in Fig. 8, the results from the upper region are shown with a solid orange line, while the results of the lower region with a dashed one. Once again, for rather low water content variations, we observe a significant increase of volume. However, in later stages of the experiment (after the flow rate increase), a different behaviour emerges in the upper and the lower region. While the top particles, having lower water content, follow the response of CCRH97-01, the lower ones swell similarly despite their higher water content. For particularly high amounts in water, the swelling behaviour is still directly proportional to water content, albeit at higher values, there is a delay between the two. In a previous work [13] on individual, submerged particles studied optically, it was observed that, while particles can dilate up to \(400\%\), the rate of expansion progressively slows down. This is caused by the appearance of a gelatinous layer which hinders the water diffusion to the inner layers of the particle. This diffusion-controlled delay could justify the previous results and the loss of linearity between water content and volumetric expansion.

The discontinuity point (or inclination change) could coincide with the saturation of the outer layers of particles and thus the change in regime. However, we cannot confirm this interpretation directly from the images, because of the internal porosity of particles and the relatively high blur on their edges in neutron images. The applied vertical stress or the particle-wall friction could further influence the particle swelling versus water content relationship. More generally, in the images acquired during the two experimental campaigns, no intra-granular water content gradient is observed within individual particles. This suggests that the process is homogeneous at least at the spatial and temporal resolution adopted and for the accuracy of the method – while we cannot exclude that the intra-granular radial gradient plays a role, it does not appear to be a dominant phenomenon in these boundary conditions.

a Evolution of the median contact area variation \(\widetilde{\Delta A}\) as a function of average particle water content \(\bar{\omega }_{p}\) and b representative statistical distributions of \(\Delta A\) measured in both the experiments. The analysis is performed both considering only the contacts existing since the beginning of the test (dashed line) and for all the contacts (solid line). In both experiments, the distribution of contact area variation \(\Delta A\) can be described with a skew normal distribution, whose parameters are reported in Table 2, which broadens at higher water contents

The growth of inter-particle contacts is one of the key factors governing the macrospically observed agglomeration and thus loss of functionality. The presence and area of the contacts are detected as in our previous study [14]. Thanks to neutron tomography and the related \(\bar{\omega }_{p}\) measurements presented previously, in this study we focus on the effect of the water content variation onto the median contact area variation \(\widetilde{\Delta A}\), i.e., the median of all the contact area variations, defined as:

where i and j are any pair of the contacting particles, \(A_{ij}\) is the contact area at that specific time-step and \(A_{ij,0}\) the initial one.

Naturally, the number of detected contacts increases with particle swelling and the eventual sample compaction [14]. We therefore define two different sets of contacts. The first set refers to all the contacts detected throughout the experiment. The second one is a subset of the previous, including only the contacts that are identified since the reference configuration, and is named here as “preserved contacts”. Figure 9 presents the \(\widetilde{\Delta A}\) evolution for both groups and both the experiments. The relation between contact area variation and water content can be described as (quasi-)linear, similarly to what we observe in the particle volumetric strain versus water content relation (Fig. 8).

During the test, new contacts are generated, and their contact area is generally quite small. Therefore, these “generated” contacts affect the \(\widetilde{\Delta A}\) rate of increase. In this case the discontinuity evidently coincides with the start of the macroscopic volumetric compaction (Sect. 3.2). As expected, the final \(\widetilde{\Delta A}\) value is higher for preserved contacts areas, since they are generally larger than newly generated ones. The “error zones” are not reported in Fig. 9a since the distributions of contact areas are inherently broad, due to the irregular shape of the particles and because of their (re)arrangements. Figure 9b shows the distribution of all contact areas at representative water content levels and for both the experiments. These can be interpolated with skew normal distributions, of which the shape, location, and scale parameters are reported in Table 2. The distributions broaden at higher water contents, as the swelling of particles and the possible sample compaction induce the growth of existing areas of contact and the generation of new contacts. Moreover, these distributions are comparable between the experiments, suggesting a coherent process and a reliable image analysis procedure.

4 Conclusions and perspectives

In this article we present the results of two experimental campaigns performed on couscous assemblies exposed to high RH, in order to activate the phenomena characterising it as hydro-sensitive. We acquire images with simultaneous neutron and X-ray tomography, from which we quantify the microstructural changes (swelling, contact areas) of thousands of particles driven by the water uptake, as well as the dilation-compaction competition at the sample scale. We observe the presence of sorption and swelling gradients despite the more than sufficient amount of water molecules provided to the system by the high RH air flow. We presume that the heterogeneities are caused by the location of air injection point, the decrease of water concentration due to sorption, air pressure drops from inlet to outlet that influence the material’s water activity, and possibly stress gradients. A quasi-linear relation can describe the evolution of particle volumetric strain and contact area variation with respect to the water content increase, although the loss of mechanical properties enhances the trend of the latter. The swelling might be delayed for particularly high water contents, which we think is induced when the particle’s external layers are saturated. Altogether, these experiments constitute a unique data-set, which is, to our knowledge, the first attempt to determine the water content of individual particles and correlate it to the particle scale phenomena of hydro-sensitive granular materials. The bespoke developed algorithms combine information from X-ray and neutron images, from which we measure strains and assess the water distribution and their variation with time.

In the future it would be beneficial to further investigate in detail different aspects of the phenomena underlying caking, which is ultimately the final problem to solve in industry. A more accurate control of the initial experimental conditions would help improve the study of the relation between microstructure and water content. The water state (bound or unbound) could be investigated with techniques like Nuclear Magnetic Resonance and thus explain the delay we observe for relatively high water contents. It would be of great importance to study the interaction of particles to understand and quantify how the contact network affects the agglomeration/caking strength. Finally, the problem could be described by analytical models where variables take into account particle scale properties. The process could be then simulated numerically to investigate the role of variables that cannot be measured experimentally and to predict the material’s behaviour.

Data availability

The raw neutron radiography and X-ray tomography data-sets are available according to ILL data policy at: https://doi.ill.fr/10.5291/ILL-DATA.UGA-121 and https://doi.ill.fr/10.5291/ILL-DATA.1-05-90.

Notes

’CC’ stands for couscous, ’RH’ for relative humidity, ’97’ for the relative humidity level in percentage applied during the test.

While the cross-talk between the two was modest, small fluctuations could be observed along time as the X-ray source warmed up. To minimise this possible source of incertitude on the neutron data, the X-ray flux was reduced after verifying that the image quality was comparable. This variation in parameters is not expected to affect the measurements reported in Sect. 3.

We only report the water content standard deviation, as the volumetric strain one was much lower thanks to the accuracy of the measurements on X-ray images in this study.

References

Fredlund, D.G., Rahardjo, H.: Soil Mechanics for Unsaturated Soils. John Wiley & Sons (1993)

Rathore, A.S., Winkle, H.: Quality by design for biopharmaceuticals. Nat. Biotechnol. 27(1), 26–34 (2009)

Lewicki, P.P.: Raoult’s law based food water sorption isotherm. J. Food Eng. 43(1), 31–40 (2000)

Schmidt, S.J.: Water and solids mobility in foods. Adv Food Nutr. Res. 48, 1–101 (2004)

Damodaran, S., Parkin, K.: Fennema’s Food Chemistry, 5th edn. CRC Press (2017)

Aguilera, J., del Valle, J., Karel, M.: Caking phenomena in amorphous food powders. Trends Food Sci. Technol. 6(5), 149–155 (1995)

Morita, T., Singh, R.P.: Physical and thermal properties of short-grain rough rice. Trans. ASAE 22(3), 630–0636 (1979)

Tabatabaeefar, A.: Moisture-dependent physical properties of wheat. Int. Agrophys. 17(4), 207–211 (2003)

Amin, M., Hossain, M., Roy, K.: Effects of moisture content on some physical properties of lentil seeds. J. Food Eng. 65(1), 83–87 (2004)

Shi, L., Feng, Y., Sun, C.C.: Initial moisture content in raw material can profoundly influence high shear wet granulation process. Int. J. Pharm. 416(1), 43–48 (2011)

Abecassis, J., Cuq, B., Boggini, G., Namoune, H.: Other traditional durum-derived products. In: Durum Wheat Chemistry and Technology, pp. 177–199. Springer, Berlin (2012)

Bellocq, B., Ruiz, T., Cuq, B.: Contribution of cooking and drying to the structure of couscous grains made from durum wheat semolina. Cereal Chem. 95(5), 646–659 (2018)

De Richter, S.K., Gaudel, N., Gaiani, C., Pascot, A., Ferrari, M., Jenny, M.: Swelling of couscous grains under saturated conditions. J. Food Eng. 319, 110910 (2022)

Vego, I., Tengattini, A., Andò, E., Lenoir, N., Viggiani, G.: Effect of high relative humidity on a network of a water-sensitive particles (couscous) as revealed by in-situ x-ray tomography. Soft Matter 18(25), 4747–4755 (2022)

Glenn, G., Younce, F., Pitts, M.: Fundamental physical properties characterizing the hardness of wheat endosperm. J. Cereal Sci. 13(2), 179–194 (1991)

Figueroa, J., Hernández, Z., Véles, M., Rayas-Duarte, P., Martínez-Flores, H., Ponce-García, N.: Evaluation of degree of elasticity and other mechanical properties of wheat kernels. Cereal Chem. 88(1), 12–18 (2011)

Kamst, G., Bonazzi, C., Vasseur, J., Bimbenet, J.: Effect of deformation rate and moisture content on the mechanical properties of rice grains. Trans. ASAE 45(1), 145 (2002)

Cao, W., Nishiyama, Y., Koide, S.: Physicochemical, mechanical and thermal properties of brown rice grain with various moisture contents. Int. J. Food Sci. Technol. 39(9), 899–906 (2004)

Sharma, A.D., Kunze, O.R.: Post-drying fissure developments in rough rice. Trans. ASAE 25(2), 465–0468 (1982)

Siddiqui, I., Yiu, S., Jones, J., Kalab, M.: Mucilage in yellow mustard (Brassica hirta) seeds. Food Struct. 5(1), 17 (1986)

Bika, D., Tardos, G., Panmai, S., Farber, L., Michaels, J.: Strength and morphology of solid bridges in dry granules of pharmaceutical powders. Powder Technol. 150(2), 104–116 (2005)

Palzer, S.: The effect of glass transition on the desired and undesired agglomeration of amorphous food powders. Chem. Eng. Sci. 60(14), 3959–3968 (2005)

Zafar, U., Vivacqua, V., Calvert, G., Ghadiri, M., Cleaver, J.S.: A review of bulk powder caking. Powder Technol. 313, 389–401 (2017)

Fitzpatrick, J.J., Ahrné, L.: Food powder handling and processing: industry problems, knowledge barriers and research opportunities. Chem. Eng. Process. 44(2), 209–214 (2005)

Carpin, M., Bertelsen, H., Bech, J., Jeantet, R., Risbo, J., Schuck, P.: Caking of lactose: a critical review. Trends Food Sci. Technol. 53, 1–12 (2016)

Fitzpatrick, J., Hodnett, M., Twomey, M., Cerqueira, P., O’flynn, J., Roos, Y.: Glass transition and the flowability and caking of powders containing amorphous lactose. Powder Technol. 178(2), 119–128 (2007)

Lumay, G., Traina, K., Boschini, F., Delaval, V., Rescaglio, A., Cloots, R., Vandewalle, N.: Effect of relative air humidity on the flowability of lactose powders. J. Drug Deliv. Sci. Technol. 35, 207–212 (2016)

Juarez-Enriquez, E., Olivas, G., Zamudio-Flores, P., Ortega-Rivas, E., Perez-Vega, S., Sepulveda, D.: Effect of water content on the flowability of hygroscopic powders. J. Food Eng. 205, 12–17 (2017)

Brockbank, K., Armstrong, B., Clayton, J.: Measurement and quantification of caking in excipients and food products with emphasis on the non-homogeneous interaction with ambient moisture. Particuology 56, 75–83 (2021)

Wahl, M., Bröckel, U., Brendel, L., Feise, H., Weigl, B., Röck, M., Schwedes, J.: Understanding powder caking: predicting caking strength from individual particle contacts. Powder Technol. 188(2), 147–152 (2008)

Haider, C.I., Hounslow, M.J., Salman, A.D., Althaus, T.O., Niederreiter, G., Palzer, S.: Influence of environmental conditions on caking mechanisms in individual amorphous food particle contacts. AIChE J. 60(8), 2774–2787 (2014)

Peter, O.: Neutronen-durchleuchtung. Zeitschrift für Naturforschung A 1(10), 557–559 (1946)

Tengattini, A., Lenoir, N., Ando, E., Viggiani, G.: Neutron imaging for geomechanics: a review. Geomech. Energy Environ. 27, 100206 (2021)

Kardjilov, N., Manke, I., Woracek, R., Hilger, A., Banhart, J.: Advances in neutron imaging. Mater. Today 21(6), 652–672 (2018)

Stavropoulou, E., Andò, E., Roubin, E., Lenoir, N., Tengattini, A., Briffaut, M., Bésuelle, P.: Dynamics of water absorption in Callovo-Oxfordian Claystone revealed with multimodal x-ray and neutron tomography. Front. Earth Sci. 8, 6 (2020)

Sleiman, H.C., Tengattini, A., Briffaut, M., Huet, B., Dal Pont, S.: Simultaneous X-ray and neutron 4d tomographic study of drying-driven hydro-mechanical behavior of cement-based materials at moderate temperatures. Cem. Concr. Res. 147, 106503 (2021)

Winston, P.W., Bates, D.H.: Saturated solutions for the control of humidity in biological research. Ecology 41(1), 232–237 (1960)

Greenspan, L.: Humidity fixed points of binary saturated aqueous solutions. J. Res. Natl. Bur. Stand. 81(1), 89–96 (1977)

Tengattini, A., Lenoir, N., Andò, E., Giroud, B., Atkins, D., Beaucour, J., Viggiani, G.: Next-grenoble, the neutron and X-ray tomograph in grenoble. Nucl. Instrum. Methods Phys. Res. Sect. A 968, 163939 (2020)

Barrett, J.F., Keat, N.: Artifacts in ct: recognition and avoidance. Radiographics 24(6), 1679–1691 (2004)

Erbaş, M., Ertugay, M.F., Certel, M.: Moisture adsorption behaviour of semolina and farina. J. Food Eng. 69(2), 191–198 (2005)

Feldkamp, L.A., Davis, L.C., Kress, J.W.: Practical cone-beam algorithm. Josa a 1(6), 612–619 (1984)

Stamati, O., Andò, E., Roubin, E., Cailletaud, R., Wiebicke, M., Pinzon, G., Couture, C., Hurley, R.C., Caulk, R., Caillerie, D., et al.: Spam: software for practical analysis of materials. J. Open Sour. Softw. 5(51), 2286 (2020)

Tudisco, E., Jailin, C., Mendoza, A., Tengattini, A., Andò, E., Hall, S.A., Viggiani, G., Hild, F., Roux, S.: An extension of digital volume correlation for multimodality image registration. Meas. Sci. Technol. 28(9), 095401 (2017)

Roubin, E., Ando, E., Roux, S.: The colours of concrete as seen by X-rays and neutrons. Cement Concr. Compos. 104, 103336 (2019)

Beucher, S.: Use of watersheds in contour detection. In: Proceedings of the International Workshop on Image Processing, CCETT, (1979)

Beucher, S.: Watersheds of functions and picture segmentation. In ICASSP’82. IEEE International Conference on Acoustics, Speech, and Signal Processing, vol. 7, pp. 1928–1931, IEEE, (1982)

Hall, S.A., Bornert, M., Desrues, J., Pannier, Y., Lenoir, N., Viggiani, G., Bésuelle, P.: Discrete and continuum analysis of localised deformation in sand using X-ray \(\upmu\)CT and volumetric digital image correlation. Géotechnique 60(5), 315–322 (2010)

Carman, P.C.: Fluid flow through granular beds. Chem. Eng. Res. Des. 75, S32–S48 (1997)

He, J., Ng, K., Yap, C., Saha, B.: Effect of pressure on the adsorption rate for gasoline vapor on pitch-based activated carbon. J. Chem. Eng. Data 54(5), 1504–1509 (2009)

Acknowledgements

The authors want to acknowledge the Institut Laue-Langevin, Grenoble, France for the allocated time at the NeXT-Grenoble beam-line. We gratefully acknowledge Kalvin Buckely for the technical support and the fabrication of the experimental set-up. We thankfully acknowledge Edward Andò for the insight on the the image analysis approach. We sincerely thank the reviewers for their constructive feedback and the helpful comments. This project has received funding from the European Unions Horizon 2020 research and innovation program under the Marie Skłodowska-Curie Grant agreement No. 812638 (CALIPER). We also wish to thank the Joint Research Unit NI-Matters for the support and the allocated beamtime.

Author information

Authors and Affiliations

Contributions

Conceptualization: IV, AT; Data Curation: IV; Formal analysis and investigation: IV, AT; Funding acquisition: GV; Methodology: IV, AT, NL; Resources: AT, NL; Software: IV, AT; Supervision: AT, GV; Validation: AT, GV; Writing - original draft preparation: IV, AT; Writing - review and editing: GV.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Vego, I., Tengattini, A., Lenoir, N. et al. The influence of water sorption on the microstructure of a hydro-sensitive granular material (couscous) deduced from simultaneous neutron and X-ray tomography. Granular Matter 25, 65 (2023). https://doi.org/10.1007/s10035-023-01356-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-023-01356-5