Abstract

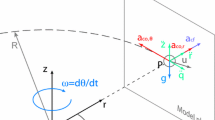

The unique behavior of a bed of monodispersed dry granular matter confined in a rotating vertical cylinder has been investigated using DEM. At a constant rotational speed, the concave free surface shape exhibits an apparent similarity with the hydrodynamic counterpart of the same problem; but there are some unique differences arising from the particulate nature of the medium. In the rotating granular bed, the free surface profile is independent of the density and the size of the particles, but the local gradient of the free surface is not independent of the rotational speed. The results of a simulated experiment exhibit excellent matching with the free surface profiles obtained computationally and thus establish the efficacy of DEM in simulating the rigid body rotation of a particulate medium. However, the simulation results strongly suggest that though globally the bed behavior resembles solid body rotation, locally, the motion of the particles and their distribution is influenced by the discrete nature of the medium.

Graphical abstract

Similar content being viewed by others

References

Andreotti B, Forterre Y, Pouliquen O.P.: Granular Media: Between Fluid and Solid. (2013)

Nott, K.R.P.R.: An introduction to Granular Flow. Cambride University Press (2008)

Jaeger, H.M., Nagel, S.R., Behringer, R.P.: The physics of granular materials. Phys. Today 49, 32–38 (1996). https://doi.org/10.1063/1.881494

Pouliquen, O.: Flows of dense granular media. Annu. Rev. Fluid Mech. 40, 1–24 (2008). https://doi.org/10.1146/annurev.fluid.40.111406.102142

Duran, J., Behringer, R.P.: Sands, powders, and grains: an introduction to the physics of granular materials. Phys. Today. 54, 63 (2001)

Ottino, J.M., Khakhar, D.V.: Mixing and segregation of granular materials. Annu. Rev. Fluid Mech 32(5), 55–91 (2000)

Rapaport, D.C.: Radial and axial segregation of granular matter in a rotating cylinder: a simulation study. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 75, 1–11 (2007). https://doi.org/10.1103/PhysRevE.75.031301

Gray, J.M.N.T.: Particle segregation in dense granular flows. Annu. Rev. Fluid Mech. 50, 407–433 (2018). https://doi.org/10.1146/annurev-fluid-122316-045201

Delannay, R., Valance, A., Mangeney, A., Roche, O., Richard, P.: Granular and particle-laden flows: from laboratory experiments to field observations. J. Phys. D. Appl. Phys. (2017). https://doi.org/10.1088/1361-6463/50/5/053001

Chanson, H., Jarny, S., Coussot, P.: Dam break wave of thixotropic fluid. J. Hydraul. Eng. 132, 280–293 (2006). https://doi.org/10.1061/(ASCE)0733-9429(2006)132:3(280)

Corwin, E.I., Jaeger, H.M., Nagel, S.R.: Structural signature of jamming in granular media. Nature 435, 1075–1078 (2005). https://doi.org/10.1038/nature03698

Jop, P., Forterre, Y., Pouliquen, O.: A constitutive law for dense granular flows. Nature 441, 727–730 (2006). https://doi.org/10.1038/nature04801

Pouliquen, O.: Flows of dense granular media. Annu. Rev. Fluid Mech. 2008(40), 1–24 (2008). https://doi.org/10.1146/annurev.fluid.40.111406.102142

Weinhart, T., Hartkamp, R., Thornton, A.R., Luding, S.: Coarse-grained local and objective continuum description of three-dimensional granular flows down an inclined surface. Phys. Fluids. 25, 1–44 (2013). https://doi.org/10.1063/1.4812809

Cundall, P.A., Strack, O.D.L.: A discrete numerical model for granular assemblies (1979)

Coetzee, C.J.: Review: calibration of the discrete element method (2017)

O’Sullivan, C.: Particle-based discrete element modeling: geomechanics perspective. Int. J. Geomech. 11, 449–464 (2011). https://doi.org/10.1061/(asce)gm.1943-5622.0000024

Govender, I.: Granular flows in rotating drums: a rheological perspective. Miner. Eng. 92, 168–175 (2016). https://doi.org/10.1016/j.mineng.2016.03.021

Arntz, M.M.H.D.: Modeling of particle segregation in a rotating drum (2010)

Combarros, M., Feise, H.J., Zetzener, H., Kwade, A.: Segregation of particulate solids: experiments and DEM simulations. Particuology. 12, 25–32 (2014). https://doi.org/10.1016/j.partic.2013.04.005

Ottino, J.M., Khakhar, D.: V: M Ixing and S Egregation of G Ranular. Annu. Rev. Fluid Mech. 32, 55–91 (2000)

Clément, E., Rajchenbach, J., Duran, J.: Mixing of a granular material in a bidimensional rotating drum. EPL 30, 7–12 (1995). https://doi.org/10.1209/0295-5075/30/1/002

D’Ortona, U., Thomas, N., Lueptow, R.M.: Recirculation cells for granular flow in cylindrical rotating tumblers. Phys. Rev. E. 97, 1–13 (2018). https://doi.org/10.1103/PhysRevE.97.052904

Xiao, Y.L., Specht, E., Mellmann, J.: Experimental study of the lower and upper angles of repose of granular materials in rotating drums. Powder Technol. 154, 125–131 (2005). https://doi.org/10.1016/j.powtec.2005.04.040

Gray, J.M.N.T.: Granular flow in partially filled slowly rotating drums. J. Fluid Mech. 441, 1–29 (2001). https://doi.org/10.1017/S0022112001004736

Hajra, S.K., Khakhar, D.V.: Radial mixing of granular materials in a rotating cylinder: experimental determination of particle self-diffusivity. Phys. Fluids. (2005). https://doi.org/10.1063/1.1825331

Khakhar, D.V., McCarthy, J.J., Shinbrot, T., Ottino, J.M.: Transverse flow and mixing of granular materials in a rotating cylinder. Phys. Fluids. 9, 31–43 (1997). https://doi.org/10.1063/1.869172

Venier, C.M., Damián, S.M., Bertone, S.E., Puccini, G.D., Risso, J.M., Nigro, N.M.: Discrete and continuum approaches for modeling solids motion inside a rotating drum at different regimes. Appl. Sci. 11, 1–20 (2021). https://doi.org/10.3390/app112110090

Liu, Y., Gonzalez, M., Wassgren, C.: Modeling granular material blending in a rotating drum using a finite element method and advection-diffusion equation multiscale model. AIChE J. 64, 3277–3292 (2018). https://doi.org/10.1002/aic.16179

Cleary, P.W.: Predicting charge motion , power draw , segregation and wear in ball mills using discrete element methods. Miner. Eng. 1061–1080 (1998)

Utili, S., Zhao, T., Houlsby, G.T.: 3D DEM investigation of granular column collapse: evaluation of debris motion and its destructive power. Eng. Geol. 186, 3–16 (2015). https://doi.org/10.1016/j.enggeo.2014.08.018

Mellmann, J.: The transverse motion of solids in rotating cylinders-forms of motion and transition behavior. Powder Technol. 118, 251–270 (2001). https://doi.org/10.1016/S0032-5910(00)00402-2

Cross, M.: The transverse motion of solids moving through rotary kilns. Powder Technol. 22, 187–190 (1979). https://doi.org/10.1016/0032-5910(79)80025-X

Boateng, A.A., Barr, P.V.: Modelling of particle mixing and segregation in the transverse plane of a rotary kiln. Chem. Eng. Sci. 51, 4167–4181 (1996). https://doi.org/10.1016/0009-2509(96)00250-3

Henein, H., Brimacombe, J.K., Watkinson, A.P.: Experimental study of transverse bed motion in rotary kilns. Metall. Trans. B. 14, 191–205 (1983). https://doi.org/10.1007/BF02661016

Metcalfe, G., Shinbrot, T., McCarthy, J.J., Ottino, J.M.: Avalanche mixing of granular solids. Nature 374, 39–41 (1995). https://doi.org/10.1038/374039a0

Lehmberg, J., Hela, M., Schugerl, K.: Transverse mixing and heat transfer in horizontal rotary drunl reactors. Powder Technol. 18, 149–163 (1977)

Vavrek, M.E., Baxter, G.W.: Surface shape of a spinning bucket of sand. Phys. Rev. E. 50, 3 (1994). https://doi.org/10.1103/PhysRevE.50.R3353

Bouchaud, J.-P., Cates, M.E., Prakash, J.R., Edwards, S.F.: A model for the dynamics of sandpile surfaces. J. Phys. I(4), 1383–1410 (1994). https://doi.org/10.1051/JP1:1994195

Mehta, A., Luck, J.M., Needs~, R.J.: Dynamics of sandpiles: physical mechanisms, coupled stochastic equations, and alternative universality classes. Phys. Rev. E. 53, (1996)

Yoon, S., Eom, B.H., Lee, J., Yu, I.: Circular kinks on the surface of granular material rotated in a tilted spinning bucket. Phys. Rev. Lett. 82, 4639–4642 (1999). https://doi.org/10.1103/PhysRevLett.82.4639

Lee, C.H., Huang, Z., Yu, M.L.: Collapse of submerged granular columns in loose packing: Experiment and two-phase flow simulation. Phys. Fluids. (2018). https://doi.org/10.1063/1.5050994

Goddard, J.D.: Continuum modeling of granular media. Appl. Mech. Rev. (2014). https://doi.org/10.1115/1.4026242

Breard, E.C.P., Dufek, J., Roche, O.: Continuum modeling of pressure-balanced and fluidized granular flows in 2-D: comparison with glass bead experiments and implications for concentrated pyroclastic density currents. J. Geophys. Res. Solid Earth. 124, 5557–5583 (2019). https://doi.org/10.1029/2018JB016874

Sperl, M.: Experiments on corn pressure in silo cells - translation and comment of Janssen’s paper from 1895. Granul. Matter. 8, 59–65 (2006). https://doi.org/10.1007/s10035-005-0224-z

Landry, J.W., Grest, G.S., Silbert, L.E., Plimpton, S.J.: Confined granular packings: structure, stress, and forces. Phys. Rev. E Stat. Phys. Plasmas Fluids Relat. Interdiscip. Top. 67, 9 (2003). https://doi.org/10.1103/PhysRevE.67.041303

Matuttis, H.G., Luding, S., Herrmann, H.J.: Discrete element simulations of dense packings and heaps made of spherical and non-spherical particles. Powder Technol. 109, 278–292 (2000). https://doi.org/10.1016/S0032-5910(99)00243-0

Burman, B.C., Cundall, P.A., Strack, O.D.L.: A discrete numerical model for granular assemblies. Geotechnique 30, 331–336 (1980). https://doi.org/10.1680/geot.1980.30.3.331

Elyashiv, H., Bookman, R., Siemann, L., Brink, U.T., Huhn, K.: Numerical characterization of cohesive and non-cohesive ‘sediments’ under different consolidation states using 3d dem triaxial experiments. Processes 8, 1–24 (2020). https://doi.org/10.3390/pr8101252

Kermani, E., Qiu, T., Li, T.: Simulation of collapse of granular columns using the discrete element method. Int. J. Geomech. (2015). https://doi.org/10.1061/(ASCE)GM.1943-5622.0000467

Mindlin, R.D.: Compliance of elastic bodies in contact. J. Appl. Mech. 16, 259–268 (2021). https://doi.org/10.1115/1.4009973

Mindlin, R.D., Deresiewicz, H.: Elastic spheres in contact under varying oblique forces. J. Appl. Mech. 20, 327–344 (2021). https://doi.org/10.1115/1.4010702

Kumar, R., Patel, C.M., Jana, A.K., Gopireddy, S.R.: Prediction of hopper discharge rate using combined discrete element method and artificial neural network. Adv. Powder Technol. 29, 2822–2834 (2018). https://doi.org/10.1016/j.apt.2018.08.002

O’Sullivan, C.: Particulate Discrete Element Modelling. (2014)

Kloss, C., Goniva, C.: LIGGGHTS - open source discrete element simulations of granular materials based on lammps. Suppl. Proc. Mater. Fabr. Prop. Charact. Model. 2, 781–788 (2011). https://doi.org/10.1002/9781118062142.ch94

Barrios, G.K.P., Carvalho, R.M.D., Kwade, A., Marcelo, L.: Contact parameter estimation for DEM simulation of iron ore pellet handling. Powder Technol. 248, 84–93 (2013). https://doi.org/10.1016/j.powtec.2013.01.063

Kerswell, R.R.: Dam break with Coulomb friction: A model for granular slumping? Phys. Fluids. 17, 1–16 (2005). https://doi.org/10.1063/1.1870592

Lacaze, L., Phillips, J.C., Kerswell, R.R.: Planar collapse of a granular column: Experiments and discrete element simulations. Phys. Fluids. (2008). https://doi.org/10.1063/1.2929375

Staron, L., Hinch, E.J.: Study of the collapse of granular columns using two-dimensional discrete-grain simulation. J. Fluid Mech. 545, 1–27 (2005). https://doi.org/10.1017/S0022112005006415

Çengel, Y.A., Cimbala, J.M.: Fluid Mechanics A Fundamental Approach. (2018)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, A., Das, P.K. The unique dynamics of a bed of dry granular material in a vertical cylinder rotating at a constant speed. Granular Matter 25, 29 (2023). https://doi.org/10.1007/s10035-023-01319-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-023-01319-w