Abstract

The maximum shear modulus (Gmax) is a key material characteristic that is incorporated in advanced soil constitutive models. Numerous experimental studies have been conducted to describe the effects of particle sizes and packing characteristics on Gmax. However, most of these studies were conducted on quartz-based sands. A review of the literature revealed that few studies have described the effects of grain size distribution (GSD) on Gmax in calcareous sands. Therefore, bender element (BE) tests were performed on calcareous sands with different mean grain sizes (d50), uniformity coefficients (Cu), and void ratios to obtain Gmax. The BE results revealed that the Gmax of calcareous sand increases slightly with increasing d50 but decreases significantly with increasing Cu. A modified model of Gmax incorporating the effects Cu and d50 was therefore developed for calcareous sand. Moreover, microscopic observations of pore size distributions (PSD) obtained from nuclear magnetic resonance (NMR) tests were presented to demonstrate the effect of GSD on PSD and its correlation with Gmax. The NMR results revealed that the interaggregate pore structure proportion and uniformity of the PSD decreased significantly with increasing Cu but increased slightly with increasing d50. The underlying mechanism for the effect of GSD on Gmax was related to its substantial impact on microstructure. The significant decrease in Gmax with increasing Cu can be attributed to the remarkable reduction in the ratio of the interaggregate void ratio to the intraaggregate void ratio. Additionally, Gmax was enhanced as the heterogeneity of the microporosity structure distribution decreased.

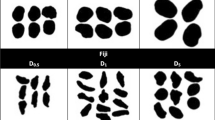

Graphic abstract

Similar content being viewed by others

Data availability statement

All data and models generated or used during the study appear in the published article.

Abbreviations

- G max :

-

Small strain shear modulus

- d 50 :

-

Mean grain size

- C u :

-

Uniformity coefficient

- e :

-

Void ratio

- e t :

-

Target void ratio after consolidation

- e c :

-

Actual void ratio after consolidation

- A, n :

-

Model parameters in Eq. (1)

- pʹ:

-

Mean effective stress

- p a :

-

A standard atmospheric pressure

- S v :

-

Percentage passing

- R, R max :

-

Pore size and maximum pore size

- D a :

-

Fractal dimension

- ζ :

-

Ratio of interaggregate void ratio to intraaggregate void ratio

References

Hardin, B.O., Black, W.L.: Sand stiffness under various triaxial stresses. J. Soil Mech. Found. Div. 92(2), 27–42 (1966). https://doi.org/10.1061/JSFEAQ.0000865

Burland, J.: Ninth Laurits Bjerrum Memorial Lecture: “Small is beautiful”—the stiffness of soils at small strains. Can Geotech J. 26, 499–516 (1989). https://doi.org/10.1139/t89-064

Zhang, S., Cheng, X.: Small-strain shear moduli modeling of sand: a nonequilibrium thermodynamic approach, including an application to Leighton Buzzard sand. Granular Matter 21(3), 68 (2019). https://doi.org/10.1007/s10035-019-0917-3

Kong, G., Li, H., Yang, G., Cao, Z.: Investigation on shear modulus and damping ratio of transparent soils with different pore fluids. Granular Matter 20(1), 8 (2018). https://doi.org/10.1007/s10035-017-0779-5

Hardin, B., Drnevich, V.: Shear modulus and damping in soil: Measurement and parameter effects. Soils Mech Found Div 98, 603–624 (1972). https://doi.org/10.1061/JSFEAQ.0001756

Seed, H., Wong, R., Idriss, I., Tokimatsu, K.: Moduli and damping factors for dynamic analyses of cohesionless soils. J. Geotech. Eng. (1986). https://doi.org/10.1061/(ASCE)0733-9410(1986)112:11(1016)

Santamarina, J., Cascante, G.: Stress anisotropy and wave propagation: a micromechanical view. Can Geotech J. 33, 770–782 (2011). https://doi.org/10.1139/t96-102-323

Jovičić, V., Coop, M.R., Simić, M.: Objective criteria for determining Gmax from bender element tests. Géotechnique. 46(2), 357–362 (1996). https://doi.org/10.1680/geot.1996.46.2.357

Salgado, R., Bandini, P., Karim, A.: Shear strength and stiffness of silty sand. J Geotech Geoenviron. 126(5), 451–462 (2000). https://doi.org/10.1061/(ASCE)1090-0241(2000)126:5(451)

Lings, M.L., Greening, P.D.: A novel bender/extender element for soil testing. Géotechnique. 51(8), 713–717 (2001). https://doi.org/10.1680/geot.2001.51.8.713

Qiu, T., Huang, Y., Guadalupe-Torres, Y., Baxter, C.D.P., Fox, P.J.: Effective soil density for small-strain shear waves in saturated granular materials. J Geotech Geoenviron. 141(9), 04015036 (2015). https://doi.org/10.1061/(ASCE)GT.1943-5606.0001334

Sun, Y., Shen, Y., Chen, C.: A grading parameter for evaluating the grading-dependence of the shear stiffness of granular aggregates. Particuology. (2017). https://doi.org/10.1016/j.partic.2017.05.006

Goudarzy, M., König, D., Schanz, T.: Small strain stiffness of granular materials containing fines. Soil Found. 56, 1–32 (2016). https://doi.org/10.1016/j.sandf.2016.08.002

Goudarzy, M., König, D., Schanz, T.: Interpretation of small and intermediate strain characteristics of Hostun sand for various stress states. Soil Found. 58(6), 1526–1537 (2018). https://doi.org/10.1016/j.sandf.2018.09.002

Goudarzy, M., Magnanimo, V., König, D., Schanz, T.: Anisotropic stress state and small strain stiffness in granular materials: RC experiments and DEM simulations. Meccanica 55, 1869–1883 (2020). https://doi.org/10.1007/s11012-020-01229-8

Goudarzy, M., Rahman, M.M., König, D., Schanz, T.: Influence of nonplastic fines content on maximum shear modulus of granular materials. Soil Found. (2016). https://doi.org/10.1016/j.sandf.2016.11.003

Goudarzy, M., Wichtmann, T.: Influence of particle characteristics on the dynamic characteristics of granular materials. Fachsektionstage Geotechnik, 2 Bodenmechanik-Tagung, Würzburg (2019).

Jamiolkowski, M., Lancellotta, R., Lo Presti, D.: Remarks on the stiffness at small strains of six Italian clays. Developments in Deep Foundations and Ground Improvement Schemes, pp. 197–216 (1995)

Oztoprak, S., Bolton, M.D.: Stiffness of sands through a laboratory test database. Géotechnique. 63(1), 54–70 (2013). https://doi.org/10.1680/geot.10.P.078

Wichtmann, T., Triantafyllidis, T.: Influence of the grain-size distribution curve of quartz sand on the small strain shear modulus Gmax. J Geotech Geoenviron. 135(10), 1404–1418 (2009). https://doi.org/10.1061/(ASCE)GT.1943-5606.0000096

Wichtmann, T., Triantafyllidis, T.: Stiffness and damping of clean quartz sand with various grain-size distribution curves. J Geotech Geoenviron. 140(3), 06013003 (2014). https://doi.org/10.1061/(ASCE)GT.1943-5606.0000977

Sarkar, D., Goudarzy, M., König, D., Wichtmann, T.: Influence of particle shape and size on the threshold fines content and the limit index void ratios of sands containing nonplastic fines. Soil Found. 60(3), 621–633 (2020). https://doi.org/10.1016/j.sandf.2020.02.006

Sarkar, D., König, D., Goudarzy, M.: The influence of particle characteristics on the index void ratios in granular materials. Particuology. 46, 1–13 (2019). https://doi.org/10.1016/j.partic.2018.09.010

Lu, S., Tang, H., Zhang, Y., Gong, W., Wang, L.: Effects of the particle-size distribution on the micro and macro behavior of soils: fractal dimension as an indicator of the spatial variability of a slip zone in a landslide. Bull. Eng. Geol. Environ. 77(2), 665–677 (2018). https://doi.org/10.1007/s10064-017-1028-1

Darendeli, M.: Development of New Family of Normalized Modulus Reduction and Material Damping Curves. PhD Dissertation, Department of Civil Engineering. Austin, Texas: University of Texas. (2001).

Menq, F.Y.: Dynamic properties of sandy and gravelly soils. PhD thesis, University of Texas at Austin, Austin. (2003).

Senetakis, K., Anastasiadis, A., Pitilakis, K.: The small-strain shear modulus and damping ratio of quartz and volcanic sands. Geotech Test J. (2012). https://doi.org/10.1520/GTJ20120073

Liu, X., Yang, J., Wang, G., Chen, L.: Small-strain shear modulus of volcanic granular soil: an experimental investigation. Soil Dyn. Earthq. Eng. 86, 15–24 (2016). https://doi.org/10.1016/j.soildyn.2016.04.005

Yang, J., Gu, X.Q.: Shear stiffness of granular material at small strains: does it depend on grain size? Géotechnique. 63(2), 165–179 (2013). https://doi.org/10.1680/geot.11.P.083

Dutta, T.T., Otsubo, M., Kuwano, R., O’Sullivan, C.: Stress wave velocity in soils: apparent grain-size effect and optimum input frequencies. Geotech Lett. 9(4), 340–347 (2019). https://doi.org/10.1680/jgele.18.00219

Patel, A., Bartake, P., Singh, D.: An empirical relationship for determining shear wave velocity in granular materials accounting for grain morphology. Geotech Test J. (2009). https://doi.org/10.1520/GTJ100796

Hardin, B.O., Kalinski, M.E.: Estimating the shear modulus of gravelly soils. J Geotech Geoenviron. 131(7), 867–875 (2005). https://doi.org/10.1061/(ASCE)1090-0241(2005)131:7(867)

Liu, X., Zou, D., Liu, J., Zheng, B.: Predicting the small strain shear modulus of coarse-grained soils. Soil Dyn Earthq Eng. 141, 106468 (2021). https://doi.org/10.1016/j.soildyn.2020.106468

Liu, D., O’Sullivan, C., Carraro, J.A.H.: Influence of particle size distribution on the proportion of stress-transmitting particles and implications for measures of soil state. J Geotech. Geoenviron. 147(3), 04020182 (2021). https://doi.org/10.1061/(ASCE)GT.1943-5606.0002466

Otsubo, M., Kuwano, R., O’Sullivan, C., Shire, T.: Using geophysical data to quantify stress transmission in gap-graded granular materials. Géotechnique (2021). https://doi.org/10.1680/jgeot.19.P.334

He, S.H., Ding, Z., Xia, T.D., Zhou, W.H., Gan, X.L., Chen, Y.Z., et al.: Long-term behavior and degradation of calcareous sand under cyclic loading. Eng Geol. 276, 105756 (2020). https://doi.org/10.1016/j.enggeo.2020.105756

Coop, M.R., Sorensen, K.K., Freitas, T.B., Georgoutsos, G.: Particle breakage during shearing of a carbonate sand. Géotechnique. 54(3), 157–163 (2004). https://doi.org/10.1680/geot.2004.54.3.157

Ding, Z., He, S.-H., Sun, Y., Xia, T.-D., Zhang, Q.-F.: Comparative study on cyclic behavior of marine calcareous sand and terrigenous siliceous sand for transportation infrastructure applications. Constr Build Mater. 283, 122740 (2021). https://doi.org/10.1016/j.conbuildmat.2021.122740

He, S.-H., Goudarzy, M., Ding, Z., Sun, Y., Xia, T.-D.: The effect of loading frequency on the long-term cyclic behavior of dense calcareous sand. Can Geotech J. (2022). https://doi.org/10.1139/cgj-2021-0333

Jafarian, Y., Javdanian, H., Haddad, A.: Dynamic properties of calcareous and siliceous sands under isotropic and anisotropic stress conditions. Soil Found. 58(1), 172–184 (2018). https://doi.org/10.1016/j.sandf.2017.11.010

Morsy, A.M., Salem, M.A., Elmamlouk, H.H.: Evaluation of dynamic properties of calcareous sands in Egypt at small and medium shear strain ranges. Soil Dyn. Earthq. Eng. 116, 692–708 (2019). https://doi.org/10.1016/j.soildyn.2018.09.030

Shi, J., Haegeman, W., Cnudde, V.: Anisotropic small-strain stiffness of calcareous sand affected by sample preparation, particle characteristic and gradation. Géotechnique. 71(4), 305–319 (2021). https://doi.org/10.1680/jgeot.18.P.348

Jafarian, Y., Javdanian, H.: Small-strain dynamic properties of siliceous-carbonate sand under stress anisotropy. Soil Dyn. Earthq. Eng. 131, 106045 (2020). https://doi.org/10.1016/j.soildyn.2020.106045

Griffiths, F.J., Joshi, R.C.: Change in pore size distribution due to consolidation of clays. Géotechnique. 39(1), 159–167 (1989). https://doi.org/10.1680/geot.1989.39.1.159

Fujikura, Y.: Estimation of permeability for sand and gravel based on pore-size distribution model. J. Mater. Civ. Eng. 31, 04019289 (2019). https://doi.org/10.1061/(ASCE)MT.1943-5533.0002945

Alonso, E.E., Pinyol, N.M., Gens, A.: Compacted soil behavior: initial state, structure and constitutive modeling. Géotechnique. 63(6), 463–478 (2013). https://doi.org/10.1680/geot.11.P.134

Ng, C.W.W., Sadeghi, H., Jafarzadeh, F., Sadeghi, M., Zhou, C., Baghbanrezvan, S.: Effect of microstructure on shear strength and dilatancy of unsaturated loess at high suctions. Can Geotech J. (2019). https://doi.org/10.1139/cgj-2018-0592

Wang, Y.-H., Siu, W.: Structure characteristics and mechanical properties of kaolinite soils. II. Effects of structure on mechanical properties. Can Geotech J. 43, 601–617 (2011). https://doi.org/10.1139/t06-027

Romero, E., Gens, A., Lloret, A.: Water permeability, water retention and microstructure of unsaturated compacted Boom clay. Eng Geol. 54, 117–127 (1999). https://doi.org/10.1016/S0013-7952(99)00067-8

Li, X., Zhang, L.: Characterization of dual-structure pore-size distribution of soil. Can Geotech J. 46, 129–141 (2009). https://doi.org/10.1139/T08-110

Wang, J.-D., Li, P., Ma, Y., Vanapalli, S., Wang, X.: Change in pore-size distribution of collapsible loess due to loading and inundating. Acta Geotech. (2020). https://doi.org/10.1007/s11440-019-00815-9

Delage, P., Lefebvre, G.: Study of the structure of the sensitive Champlain Clay and of its evolution during consolidation. Can Geotech J. 21, 21–35 (1984). https://doi.org/10.1139/t84-003

Lloret, A., Villar, M.V., Sánchez, M., Gens, A., Pintado, X., Alonso, E.E.: Mechanical behavior of heavily compacted bentonite under high suction changes. Géotechnique. 53(1), 27–40 (2003). https://doi.org/10.1680/geot.2003.53.1.27

Feng, S., Xu, Z., Chai, J., Li, Y.: Using pore size distribution and porosity to estimate particle size distribution by nuclear magnetic resonance. Soil Found. 60(4), 1011–1019 (2020). https://doi.org/10.1016/j.sandf.2020.05.006

Minagawa, H., Nishikawa, Y., Ikeda, I., Miyazaki, K., Takahara, N., Sakamoto, Y., et al.: Characterization of sand sediment by pore size distribution and permeability using proton nuclear magnetic resonance measurement. J. Geophys. Res. (2008). https://doi.org/10.1029/2007JB005403

Tian, H., Wei, C., Tan, L.: Effect of freezing-thawing cycles on the microstructure of soils: A two-dimensional NMR relaxation analysis. Cold Reg Sci Technol. (2018). https://doi.org/10.1016/j.coldregions.2018.11.014

Kong, B., Xia, F., Yu, B., Xia, T., Ding, Z.: Pore size changes in marine soft soil under various freezing conditions. J. Mar. Sci. Eng. 8, 170 (2020). https://doi.org/10.3390/jmse8030170

Wang, X., Wu, Y., Cui, J., Zhu, C.-Q., Wang, X.: Shape characteristics of coral sand from the South China sea. J. Mar. Sci. Eng. 8, 803 (2020). https://doi.org/10.3390/jmse8100803

Youn, J.-U., Choo, Y.W., Kim, D.-S.: Measurement of small-strain shear modulus Gmax of dry and saturated sands by bender element, resonant column, and torsional shear tests. Can Geotech J. 45, 1426–1438 (2008). https://doi.org/10.1139/T08-069

Selig, E.T., Ladd, R.S.: Preparing test specimens using undercompaction. Geotech. Test. J. Cold Reg. Sci. Technol. (1978). https://doi.org/10.1520/GTJ10364J

Yang, J., Liu, X.: Shear wave velocity and stiffness of sand: the role of nonplastic fines. Géotechnique. 66(6), 500–514 (2016). https://doi.org/10.1680/jgeot.15.P.205

Liu, X., Zou, D., Liu, J., Zhou, C., Zheng, B.: Experimental study to evaluate the effect of particle size on the small strain shear modulus of coarse-grained soils. Measurement 163, 107954 (2020). https://doi.org/10.1016/j.measurement.2020.107954

Sarkar, D., Goudarzy, M., Wichtmann, T.: Inspection of various grain morphology parameters based on wave velocity measurements on three different granular materials. Soil Dyn. Earthq. Eng. 153, 107071 (2022). https://doi.org/10.1016/j.soildyn.2021.107071

Giang, P.H.H., Van Impe, P.O., Van Impe, W.F., Menge, P., Haegeman, W.: Small-strain shear modulus of calcareous sand and its dependence on particle characteristics and gradation. Soil Dyn. Earthq. Eng. 100, 371–379 (2017). https://doi.org/10.1016/j.soildyn.2017.06.016

Maroof, M.A., Mahboubi, A., Noorzad, A., Safi, Y.: A new approach to particle shape classification of granular materials. Transp Geotech. 22, 100296 (2020). https://doi.org/10.1016/j.trgeo.2019.100296

Blott, S.J., Pye, K.: Particle shape: a review and new methods of characterization and classification. Sedimentology 55(1), 31–63 (2008). https://doi.org/10.1111/j.1365-3091.2007.00892.x

Cox, E.P.: A method of assigning numerical and percentage values to the degree of roundness of sand grains. J. Paleontol. 1, 179–183 (1927)

Li, X., Liu, J., Li, J.: Fractal dimension, particle shape, and particle breakage analysis for calcareous sand. Bull. Eng. Geol. Environ. 81(3), 106 (2022). https://doi.org/10.1007/s10064-022-02585-3

Berrezueta, E., Cuervas-Mons, J., Rodríguez-Rey, Á., Ordóñez-Casado, B.: Representativity of 2D shape parameters for mineral particles in quantitative petrography. Minerals. 9(12), 768 (2019)

Senetakis, K., Madhusudhan, B.N.: Dynamics of potential fill–backfill material at very small strains. Soil Found. 55(5), 1196–1210 (2015). https://doi.org/10.1016/j.sandf.2015.09.019

Sandeep, C.S., Li, S., Senetakis, K.: Scale and surface morphology effects on the micromechanical contact behavior of granular materials. Tribol. Int. 159, 106929 (2021). https://doi.org/10.1016/j.triboint.2021.106929

Liu, Q., Jiang, Y., Wu, Z., He, J.: A Voronoi element based-numerical manifold method (VE-NMM) for investigating micro/macromechanical properties of intact rocks. Eng. Fract. Mech. 199, 71–85 (2018). https://doi.org/10.1016/j.engfracmech.2018.05.010

Reddy, N.S.C., He, H., Senetakis, K.: DEM analysis of small and small-to-medium strain shear modulus of sands. Compt Geotech. 141, 104518 (2022). https://doi.org/10.1016/j.compgeo.2021.104518

Tang, L., Song, Y., Jiang, Z., Jiang, S., Li, Q.: Pore structure and fractal characteristics of distinct thermally mature shales. Energ Fuel. (2019). https://doi.org/10.1021/acs.energyfuels.9b00885

Kuerbis, R., Negussey, D., Vaid, Y.P.: Effect of gradation and fines content on the undrained response of sand. Geotech. Spec. Publ. 21, 330–345 (1988)

Troncoso, J.: Silt content and dynamic behavior of tailing sands. In: Proceedings of 11th ICSMFE, pp. 1311–1314 (1985)

Thevanayagam, S.: Liquefaction potential and undrained fragility of silty soils. In: Proceedings of the 12th world conference earthquake engineering: New Zealand Society of Earthquake Engineering, Wellington, New Zealand (2000)

Rahman, M.M.R.M., Lo, S.R.L.R., Gnanendran, C.T.G.T.: On equivalent granular void ratio and steady state behavior of loose sand with fines. Can Geotech J. 45(10), 1439–1456 (2008). https://doi.org/10.1139/t08-064

Zhou, S., Liu, D., Cai, Y., Yao, Y.: Fractal characterization of pore–fracture in low-rank coals using a low-field NMR relaxation method. Fuel 181, 218–226 (2016). https://doi.org/10.1016/j.fuel.2016.04.119

Li, A., Ding, W., Jiu, K., Wang, Z., Wang, R., He, J.: Investigation of the pore structures and fractal characteristics of marine shale reservoirs using NMR experiments and image analyses: A case study of the Lower Cambrian Niutitang Formation in northern Guizhou Province. South China. Mar. Petrol Geol. (2017). https://doi.org/10.1016/j.marpetgeo.2017.10.019

Hardin, B., Richart, F.E.: Elastic wave velocities in granular soils. J. Mech. Found Div. Proc. Am. Soc. Civ. Eng. SM. 3407, 33–65 (1964). https://doi.org/10.1061/JSFEAQ.0000583

Acknowledgements

This work was financially supported by the Chinese National Natural Science Foundation (Grant No. 51508506), Joint Fund of Zhejiang Provincial Natural Science Foundation (Grant No. LHZ20E080001), Hangzhou Science Technology Plan Project (Grant No. 20172016A06, 20180533B06, 20180533B12, 20191203B44), Scientific Research Cultivation Fund of Zhejiang University City College (J-202112), China Scholarship Council, and Alexander von Humboldt-Stiftung.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing financial interests or personal relationships that could have appeared to affect the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

NMR is a specific physical phenomenon of protons with spin characteristics. The process of returning the magnetization vector to the equilibrium state is called relaxation. According to the relaxation mechanism for low-field NMR, there are three different relaxation mechanisms available for fluids in porous media. Therefore, the relaxation time of the pore fluid can be expressed as follows:

where T2 is the transverse relaxation time of the pore fluid collected by the Carr-Purcell-Meiboom-Gill (CPMG) pulse sequence; T2B is the free transverse relaxation time of the liquid, which is determined by the physical properties of the liquid (such as viscosity and chemical composition); T2S is the transverse relaxation time caused by surface relaxation; and T2D is the transverse relaxation time of pore fluid caused by diffusion under a magnetic field gradient. For water in porous media, the influence of the first and third terms on the equation can be ignored, and surface relaxation plays the main role as follows:

where ρ2 is the surface relaxation coefficient, which is a constant and is not affected by temperature and pressure, and S/V is the ratio between the pore surface area (S) and the pore volume (V), which is related to the pore shape. The shapes of pores in the soil can be approximated as cylindrical tubes. Therefore, Eq. (16) can be written as follows:

where R is the pore size.

Fractal theory is a mathematical method that quantifies the degree of self-similarity, complex geometry and heterogeneity of porous media with fractal dimensions. According to previous studies, the pore structures of porous media exhibit fractal characteristics and can be studied using fractal theory [79, 80]. Fractal theory has been widely used in quantitatively describing and studying the fractal characteristics of PSDs. According to fractal theory, the fractal dimension D in the PSD corresponding to pore size R obtained by NMR can be provided as follows:

Therefore:

where R is the pore size, Rmax is the maximum pore size, D is the fractal dimension, and Sv is the percentage passing.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

He, SH., Goudarzy, M., Ding, Z. et al. Small-strain shear modulus (Gmax) and microscopic pore structure of calcareous sand with different grain size distributions. Granular Matter 24, 112 (2022). https://doi.org/10.1007/s10035-022-01270-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-022-01270-2