Abstract

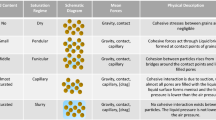

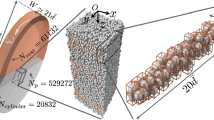

A detailed study on similarities and differences of monodisperse dry and wet dense granular flow down on rough and smooth inclined planes was carried out by discrete element method simulations. Despite implementing a minimal model for capillary bridge cohesive force, all leading regimes of a granular flow, i.e. low-dissipation, high-dissipation, and oscillatory flow, can be developed in wet granular flow, similar to what we knew in the dry one. A smooth and rough based inclined planes as well as different inclination angels were used as parameters to create various flow regimes in dry and wet granular flow. In the oscillatory flow regime, the frequency of velocity profile variation is lower than that of the dry one. The velocity profile of the wet system in the low-dissipation flow regime exhibits an abrupt slope change at shear band bottom. As a measure of particle velocity fluctuations we have studied granular temperature in layers parallel to the inclined base. We found the temperature profile is increasing from the top to bottom, which means the shear band can be considered as a frozen region. By calculation of Radial Distribution Function (RDF) and using the adaptive Common Neighbor Analysis (a-CNA), the evolution of ordered/disordered structures in both dry and wet models is studied. In a wet system in the low-dissipation regime, the shear band exhibits frozen polycrystalline structure and in the bottom slice, in spite of having layered flow in the scale of one granule, we have a low fraction of crystallization. This study gives insightful key differences between wet and dry monodisperese granular flows, specifically the appearance of ordering and presence of crystalizations in different parts of high and low dissipation flow.

Graphic abstract

Similar content being viewed by others

References

Fingerle, A., Roeller, K., Huang, K., Herminghaus, S.: Phase transitions far from equilibrium in wet granular matter. New J. Phys. 10, 053020 (2008). https://doi.org/10.1088/1367-2630/10/5/053020/

Ulrich, S., Aspelmeier, T., Zippelius, A., Roeller, K., Fingerle, A., Herminghaus, S.: Dilute wet granular particles: nonequilibrium dynamics and structure formation. Phys. Rev. E 80, 031306 (2009). https://doi.org/10.1103/PhysRevE.80.031306

Schröter, M., Ulrich, S., Kreft, J., Swift, J.B., Swinney, H.L.: Mechanisms in the size segregation of a binary granular mixture. Phys. Rev. E 74, 011307 (2006). https://doi.org/10.1103/PhysRevE.74.011307

Azéma, E., Radjaï, F.: Internal structure of inertial granular flows. Phys. Rev. Lett. 112, 078001 (2014). https://doi.org/10.1103/PhysRevLett.112.078001

Börzsönyi, T., Stannarius, R.: Granular materials composed of shape-anisotropic grains. Soft Matter 9, 7401 (2013). https://doi.org/10.1039/C3SM50298H

Scheel, M., Seemann, R., Brinkmann, M., Di Michiel, M., Sheppard, A., Breidenbach, B., Herminghaus, S.: Morphological clues to wet granular pile stability. Nat. Mater. 7, 189 (2008). https://doi.org/10.1038/nmat2117

Nan, W., Ghadiri, M., Wang, Y.: Analysis of powder rheometry of FT4: Effect of air flow. Chem. Eng. Sci. 162, 141 (2017). https://doi.org/10.1016/j.ces.2017.01.002

Madadi Najafabadi, A.H., Masoumi, A., Vaez-Allaei, S.M.: Analysis of abrasive damage of iron ore pellets. Powder Technol. 331, 20 (2018). https://doi.org/10.1016/j.powtec.2018.02.030

Baule, A., Morone, F., Herrmann, H.J., Makse, H.A.: Edwards statistical mechanics for jammed granular matter. Rev. Mod. Phys. 90, 015006 (2018). https://doi.org/10.1103/RevModPhys.90.015006

Francois, N., Saadatfar, M., Cruikshank, R., Sheppard, A.: Geometrical frustration in amorphous and partially crystallized packings of spheres. Phys. Rev. Lett. 111, 148001 (2013). https://doi.org/10.1103/PhysRevLett.111.148001

Hanifpour, M., Francois, N., Vaez Allaei, S.M., Senden, T., Saadatfar, M.: Mechanical characterization of partially crystallized sphere packings. Phys. Rev. Lett. 113, 148001 (2014). https://doi.org/10.1103/PhysRevLett.113.148001

Hanifpour, M., Francois, N., Robins, V., Kingston, A., Vaez Allaei, S.M., Saadatfar, M.: Structural and mechanical features of the order-disorder transition in experimental hard-sphere packings. Phys. Rev. E 91, 062202 (2015). https://doi.org/10.1103/PhysRevE.91.062202

Jing, L., Kwok, C.Y., Leung, Y.F., Sobral, Y.D.: Characterization of base roughness for granular chute flows. Phys. Rev. E 94, 052901 (2016). https://doi.org/10.1103/PhysRevE.94.052901

Kumaran, V., Maheshwari, S.: Transition due to base roughness in a dense granular flow down an inclined plane. Phys. Fluids 24, 053302 (2012). https://doi.org/10.1063/1.4710543

Carvente, O., Ruiz-Suárez, J.C.: Self-assembling of dry and cohesive non-Brownian spheres. Phys. Rev. E 78, 011302 (2008). https://doi.org/10.1103/PhysRevE.78.011302

Silbert, L.E., Ertaş, D., Grest, G.S., Halsey, T.C., Levine, D., Plimpton, S.J.: Granular flow down an inclined plane: Bagnold scaling and rheology. Phys. Rev. E 64, 051302 (2001). https://doi.org/10.1103/PhysRevE.64.051302

Brewster, R., Grest, G.S., Landry, J.W., Levine, A.J.: Plug flow and the breakdown of Bagnold scaling in cohesive granular flows. Phys. Rev. E 72, 061301 (2005). https://doi.org/10.1103/PhysRevE.72.061301

Ebrahimnazhad Rahbari, S.H., Vollmer, J., Herminghaus, S., Brinkmann, M.: A response function perspective on yielding of wet granular matter. EPL (Europhysics Letters) 87, 14002 (2009). https://doi.org/10.1209/0295-5075/87/14002

Silbert, L.E., Landry, J.W., Grest, G.S.: Granular flow down a rough inclined plane: transition between thin and thick piles. Phys. Fluids 15, 1 (2003). https://doi.org/10.1063/1.1521719

Delannay, R., Louge, M., Richard, P., Taberlet, N., Valance, A.: Towards a theoretical picture of dense granular flows down inclines. Nat. Mater. 6, 99 (2007). https://doi.org/10.1038/nmat1813

Saingier, G., Deboeuf, S., Lagrée, P.-Y.: On the front shape of an inertial granular flow down a rough incline. Phys. Fluids 28, 053302 (2016). https://doi.org/10.1063/1.4948401

Rognon, P.G., Roux, J.-N., Naaïm, M., Chevoir, F.: Dense flows of cohesive granular materials. J. Fluid Mech. 596, 21–47 (2008). https://doi.org/10.1017/S0022112007009329

Herminghaus, S.: Dynamics of wet granular matter. Adv. Phys. 54, 221 (2005). https://doi.org/10.1080/00018730500167855

Strauch, S., Herminghaus, S.: Wet granular matter: a truly complex fluid. Soft Matter 8, 8271 (2012). https://doi.org/10.1039/C2SM25883H

Richefeu, V., El Youssoufi, M.S., Radjaï, F.: Shear strength properties of wet granular materials. Phys. Rev. E 73, 051304 (2006). https://doi.org/10.1103/PhysRevE.73.051304

Khamseh, S., Roux, J.-N., Chevoir, F.: Flow of wet granular materials: a numerical study. Phys. Rev. E 92, 022201 (2015). https://doi.org/10.1103/PhysRevE.92.022201

Brewster, R., Grest, G.S., Levine, A.J.: Effects of cohesion on the surface angle and velocity profiles of granular material in a rotating drum. Phys. Rev. E 79, 011305 (2009). https://doi.org/10.1103/PhysRevE.79.011305

Chou, S.H., Hsiau, S.S.: Experimental analysis of the dynamic properties of wet granular matter in a rotating drum. Powder Technol. 214, 491 (2011). https://doi.org/10.1016/j.powtec.2011.09.010

Silbert, L.E., Grest, G.S., Plimpton, S.J., Levine, D.: Boundary effects and self-organization in dense granular flows. Phys. Fluids 14, 2637 (2002). https://doi.org/10.1063/1.1487379

de Ryck, A.: Granular flows down inclined channels with a strain-rate dependent friction coefficient: part II—cohesive materials. Granular Matter 10, 361 (2008). https://doi.org/10.1007/s10035-008-0106-2

Ebrahimnazhad-Rahbari, S.H., Khadem-Maaref, M., Seyed-Yaghoubi, S.K.A.: Universal features of the jamming phase diagram of wet granular materials. Phys. Rev. E 88, 042203 (2013). https://doi.org/10.1103/PhysRevE.88.042203

Ebrahimnazhad Rahbari, S.H., Vollmer, J., Herminghaus, S., Brinkmann, M.: Fluidization of wet granulates under shear. Phys. Rev. E 82, 061305 (2010). https://doi.org/10.1103/PhysRevE.82.061305

Ebrahimnazhad Rahbari, S.H., Brinkmann, M., Vollmer, J.: Arrest stress of uniformly sheared wet granular matter. Phys. Rev. E 91, 062201 (2015). https://doi.org/10.1103/PhysRevE.91.062201

Roeller, K., Blaschke, J., Herminghaus, S., Vollmer, J.: Arrest of the flow of wet granular matter. J. Fluid Mech. 738, 407–422 (2014). https://doi.org/10.1017/jfm.2013.587

Ghaboussi, J., Barbosa, R.: Three-dimensional discrete element method for granular materials. Int. J. Numer. Anal. Methods Geomech. 14, 451 (1990). https://doi.org/10.1002/nag.1610140702

Guo, Y., Curtis, J.S.: Discrete element method simulations for complex granular flows. Ann. Rev. Fluid Mech. 47, 21 (2015). https://doi.org/10.1146/annurev-fluid-010814-014644

Luding, S.: Introduction to discrete element methods: basic of contact force models and how to perform the micro-macro transition to continuum theory. Eur. J. Environ. Civ. Eng. 12, 785 (2008). https://doi.org/10.1080/19648189.2008.9693050

Yoshimatsu, R., Araújo, N.A.M., Shinbrot, T., Herrmann, H.J.: Segregation of charged particles under shear. Granular Matter 20, 35 (2018). https://doi.org/10.1007/s10035-018-0806-1

Kloss, C., Goniva, C., Hager, A., Amberger, S., Pirker, S.: Models, algorithms and validation for opensource DEM and CFD-DEM. https://doi.org/10.1504/PCFD.2012.047457; LIGGGHTS- Open Source Discrete Element Method Particle Simulation Software Based on Lammps (2019). http://www.cfdem.com

https://github.com/DiscreteLogarithm/capillary-LAMMPS-LIGGGHTS

Brilliantov, N.V., Spahn, F., Hertzsch, J.-M., Pöschel, T.: Model for collisions in granular gases. Phys. Rev. E 53, 5382 (1996). https://doi.org/10.1103/PhysRevE.53.5382

Zhang, H.P., Makse, H.A.: Jamming transition in emulsions and granular materials. Phys. Rev. E 72, 011301 (2005). https://doi.org/10.1103/PhysRevE.72.011301

Just, S., Toschkoff, G., Funke, A., Djuric, D., Scharrer, G., Khinast, J., Knop, K., Kleinebudde, P.: Experimental analysis of tablet properties for discrete element modeling of an active coating process. AAPS PharmSciTech. 14, 402 (2013). https://doi.org/10.1208/s12249-013-9925-5

Chand, R., Khaskheli, M.A., Qadir, A., Ge, B., Shi, Q.: Discrete particle simulation of radial segregation in horizontally rotating drum: Effects of drum-length and non-rotating end-plates. Phys. A Stat. Mech. Appl. 391, 4590 (2012). https://doi.org/10.1016/j.physa.2012.05.019

Stukowski, A.: Visualization and analysis of atomistic simulation data with OVITO: the Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 18, 015012 (2009). https://doi.org/10.1088/0965-0393/18/1/015012

Schulz, M., Schulz, B.M., Herminghaus, S.: Shear-induced solid-fluid transition in a wet granular medium. Phys. Rev. E 67, 052301 (2003). https://doi.org/10.1103/PhysRevE.67.052301

Becerríl-González, J.J., Peñuñuri, F., Zambrano, M.A., Acosta, C., Carvente, O.: Radial distribution function at the particle-bottom interface in granular self-assembly. J. Phys. Conf. Ser. 792, 012052 (2017). https://doi.org/10.1088/1742-6596/792/1/012052

Jia, T., Zhang, Y., Chen, J.K.: Simulation of granular packing of particles with different size distributions. Comput. Mater. Sci. 51, 172 (2012). https://doi.org/10.1016/j.commatsci.2011.07.044

Stukowski, A.: Structure identification methods for atomistic simulations of crystalline materials. Model. Simul. Mater. Sci. Eng. 20, 045021 (2012). https://doi.org/10.1088/0965-0393/20/4/045021

Honeycutt, J.D., Andersen, H.C.: Molecular dynamics study of melting and freezing of small Lennard-Jones clusters. J. Phys. Chem. 91, 4950 (1987). https://doi.org/10.1021/j100303a014

Jung, J., Gidaspow, D., Gamwo, I.K.: Measurement of two kinds of granular temperatures, stresses, and dispersion in bubbling beds. Ind. Eng. Chem. Res. 44, 1329 (2005). https://doi.org/10.1021/ie0496838

He, Y., Wang, T., Deen, N., van Sint-Annaland, M., Kuipers, H., Wen, D.: Discrete particle modeling of granular temperature distribution in a bubbling fluidized bed. Particuology 10, 428 (2012). https://doi.org/10.1016/j.partic.2012.02.001

Acknowledgement

The authors gratefully acknowledge fruitful discussions with Jürgen Vollmer, Stefan Luding, S. Habib Ebrahimnazhad Rahbari, Tamás Börzsönyi, and Ellák Somfai. We acknowledge the computing resources provided by the Center for High-Performance Computing at the Department of Physics of the University of Tehran.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

The \(k_{n}\), \(k_{t}\), \(\gamma _{n}\), and \(\gamma _{t}\) coefficients are calculated from the material properties according to Table 1, for the Hertz-Mindlin model [16, 41,42,43,44]. In this table Y is Young’s modulus, G is the shear modulus, \(\nu \) is the Poisson ratio, e is the coefficient of restitution, m is the mass and R is the radius of a particle.

Rights and permissions

About this article

Cite this article

Moharamkhani, H., Sepehrinia, R., Taheri, M. et al. Ordered/disordered monodisperse dense granular flow down an inclined plane: dry versus wet media in the capillary bridge regime. Granular Matter 23, 62 (2021). https://doi.org/10.1007/s10035-021-01115-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-021-01115-4