Abstract

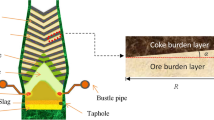

The porosity distribution of burden layers in the blast furnace (BF) plays an important role for the gas distribution and gas–solid two-phase interaction. In this work, the porosity distribution along the radial and vertical directions of the BF throat was studied by the discrete element method combined with some experimental verification. The simulated radial porosity distribution of coke burden layer shows general agreement with experimental findings, which in practice depends on the charging matrix. When a layer of burden moves from the top to the bottom, its structure will become more compact, so the porosity will decrease. However, the changes occur while 4–5 new layers are built on top of the layer in question, after which the porosity stabilized at an equilibrium point. For the full burden bed, the porosity of coke layers is larger than that of ore layers, but both layers have larger porosity than mixed layer formed by sinter charged on coke, especially when the particle size difference between ore and coke is large.

Graphic abstract

Similar content being viewed by others

References

Yu, Y., Saxen, H.: Segregation behavior of particles in a top hopper of a blast furnace. Powder Technol. 262, 233–241 (2014)

Ji, Y., Zhang, S., Yin, Y., Su, X.: Application of the improved the ELM algorithm for prediction of blast furnace gas utilization rate. IFAC-PapersOnLine 51(21), 59–64 (2018). https://doi.org/10.1016/j.ifacol.2018.09.393

Mitra, T., Saxén, H.: Model for fast evaluation of charging programs in the blast furnace. Metall. Mater. Trans. B 45(6), 2382–2394 (2014)

Nag, S., Koranne, V.M.: Development of material trajectory simulation model for blast furnace compact bell-less top. Ironmaking Steelmaking 36(5), 371–378 (2009)

Hattori, M., Iino, B., Shimomura, A., Tsukiji, H., Ariyama, T.: Development of burden distribution simulation model for bell-less top in a large blast furnace and its application. ISIJ Int. 33(10), 1070–1077 (1993)

Radhakrishnan, V.R., Ram, K.M.: Mathematical model for predictive control of the bell-less top charging system of a blast furnace. J. Process Control 11(5), 565–586 (2001)

Shi, L., Zhao, G., Li, M., Ma, X.: A model for burden distribution and gas flow distribution of bell-less top blast furnace with parallel hoppers. Appl. Math. Model. 40(23), 10254–10273 (2016). https://doi.org/10.1016/j.apm.2016.07.024

Park, J.-I., Jung, H.-J., Jo, M.-K., Oh, H.-S., Han, J.-W.: Mathematical modeling of the burden distribution in the blast furnace shaft. Met. Mater. Int. 17(3), 485–496 (2011). https://doi.org/10.1007/s12540-011-0629-7

Ketterhagen, W.R., Curtis, J.S., Wassgren, C.R., Kong, A., Narayan, P.J., Hancock, B.C.: Granular segregation in discharging cylindrical hoppers: a discrete element and experimental study. Chem. Eng. Sci. 62(22), 6423–6439 (2007)

Wu, S., Kou, M., Xu, J., Guo, X., Du, K., Shen, W., Sun, J.: DEM simulation of particle size segregation behavior during charging into and discharging from a Paul-Wurth type hopper. Chem. Eng. Sci. 99, 314–323 (2013). https://doi.org/10.1016/j.ces.2013.06.018

Xu, Y., Xu, J., Liao, Z., Pei, Y., Gao, L., Sun, C., Kou, M., Wen, L.: DEM study on ternary-sized particle segregation during the sinter burden charging process. Powder Technol. 343, 422–435 (2019). https://doi.org/10.1016/j.powtec.2018.11.062

Yu, Y., Saxén, H.: Particle flow and behavior at bell-less charging of the blast furnace. Steel Res. Int. 84(10), 1018–1033 (2013). https://doi.org/10.1002/srin.201300028

Tsotsas, E., Schlünder, E.-U.: Heat transfer in packed beds with fluid flow: remarks on the meaning and the calculation of a heat transfer coefficient at the wall. Chem. Eng. Sci. 45(4), 819–837 (1990)

Mueller, G.E.: Radial void fraction distributions in randomly packed fixed beds of uniformly sized spheres in cylindrical containers. Powder Technol. 72(3), 269–275 (1992)

Al Falahi, F., Al-Dahhan, M.: Experimental investigation of the pebble bed structure by using gamma ray tomography. Nucl. Eng. Des. 310, 231–246 (2016). https://doi.org/10.1016/j.nucengdes.2016.10.009

Khalili, A., Matyka, M., Malek Mohammadi, R., Weise, J., Kuypers, M.M.M.: Porosity variation within a porous bed composed of multisized grains. Powder Technol. 338, 830–835 (2018). https://doi.org/10.1016/j.powtec.2018.07.039

Götz, J., Zick, K., Heinen, C., König, T.: Visualisation of flow processes in packed beds with NMR imaging: determination of the local porosity, velocity vector and local dispersion coefficients. Chem. Eng. Process. 41(7), 611–629 (2002). https://doi.org/10.1016/S0255-2701(01)00185-4

Ouchiyama, N., Tanaka, T.: Porosity of a mass of solid particles having a range of sizes. Ind. Eng. Chem. Fundam. 20(1), 66–71 (1981)

Yu, A.B., Standish, N.: An analytical—parametric theory of the random packing of particles. Powder Technol. 55(3), 171–186 (1988)

Yu, A.B., Zou, R.P.: Modifying the linear packing model for predicting the porosity of nonspherical particle mixtures. Ind. Eng. Chem. Res. 35(10), 3730–3741 (1996)

Yu, A.B., Bridgwater, J., Burbidge, A.: On the modelling of the packing of fine particles. Powder Technol. 92(3), 185–194 (1997)

Gan, J.Q., Yu, A.B., Zhou, Z.Y.: DEM simulation on the packing of fine ellipsoids. Chem. Eng. Sci. 156, 64–76 (2016). https://doi.org/10.1016/j.ces.2016.09.017

Theuerkauf, J., Witt, P., Schwesig, D.: Analysis of particle porosity distribution in fixed beds using the discrete element method. Powder Technol. 165(2), 92–99 (2006). https://doi.org/10.1016/j.powtec.2006.03.022

Li, C., Honeyands, T., O’Dea, D., Moreno-Atanasio, R.: DEM study on size segregation and voidage distribution in green bed formed on iron ore sinter strand. Powder Technol. 356, 778–789 (2019). https://doi.org/10.1016/j.powtec.2019.09.014

Komatsu, T.S., Inagaki, S., Nakagawa, N., Nasuno, S.: Creep motion in a granular pile exhibiting steady surface flow. Phys. Rev. Lett. 86(9), 1757 (2001)

Alizadeh, M., Hassanpour, A., Pasha, M., Ghadiri, M., Bayly, A.: The effect of particle shape on predicted segregation in binary powder mixtures. Powder Technol. 319, 313–322 (2017)

Yu, Y., Saxén, H.: Experimental and DEM study of segregation of ternary size particles in a blast furnace top bunker model. Chem. Eng. Sci. 65(18), 5237–5250 (2010). https://doi.org/10.1016/j.ces.2010.06.025

Maryam, A., Ali, H., Mojtaba, G., Andrew, B.: Experimental evaluation of the effect of particle properties on the segregation of ternary powder mixtures. Powder Technol. 336, 240–254 (2018)

Mitra, T., Saxén, H.: Discrete element simulation of charging and mixed layer formation in the ironmaking blast furnace. Comput. Particle Mech. 3(4), 541–555 (2016). https://doi.org/10.1007/s40571-015-0084-1

Dong, F., Yan, C., Zhou, C.Q.: Mathematical modeling of blast furnace burden distribution with non-uniform descending speed. Appl. Math. Model. 39(23), 7554–7567 (2015)

Hinnelä, J., Saxén, H., Pettersson, F.: Modeling of the blast furnace burden distribution by evolving neural networks. Ind. Eng. Chem. Res. 42(11), 2314–2323 (2003). https://doi.org/10.1021/ie0203779

Chen, J., Akiyama, T., Yagi, J.I.: Effect of burden distribution pattern on gas flow in a packed bed. ISIJ Int. 32(12), 1259–1267 (2007)

Yang, W.J., Zhou, Z.Y., Yu, A.B.: Discrete particle simulation of solid flow in a three-dimensional blast furnace sector model. Chem. Eng. J. 278, 339–352 (2015). https://doi.org/10.1016/j.cej.2014.11.144

Wei, H., Tang, X., Ge, Y., Li, M., Saxén, H., Yu, Y.: Numerical and experimental studies of the effect of iron ore particle shape on repose angle and porosity of a heap. Powder Technol. 353, 526–534 (2019). https://doi.org/10.1016/j.powtec.2019.05.031

Wei, H., Ge, Y., Li, M., Li, Y., Saxén, H., He, Z., Yu, Y.: DEM study of the porosity distribution of pellet sandpile formed by ternary size particles. Powder Technol. 360, 1337–1347 (2020). https://doi.org/10.1016/j.powtec.2019.11.017

Cundall, P.A., Strack, O.D.L.: A discrete numerical mode for granular assemblies. Géotechnique 29(1), 47–65 (1979)

Barrios, G.K.P., De Carvalho, R.M., Kwade, A., Tavares, L.M.: Contact parameter estimation for DEM simulation of iron ore pellet handling. Powder Technol. 248(Complete), 84–93 (2013)

Wei, H., Nie, H., Li, Y., Saxén, H., He, Z., Yu, Y.: Measurement and simulation validation of DEM parameters of pellet, sinter and coke particles. Powder Technol. 364, 593–603 (2020). https://doi.org/10.1016/j.powtec.2020.01.044

Zhou, C.D., Liu, W.S., Wang, X.L., Xu, G.Z.: Technical Manual of Ironmaking Process for Blast Furnaces, vol. 6. Metallurgical Industry Press, Beijing (2002)

Acknowledgements

We gratefully acknowledge financial support from The Program for Professor of Special Appointment (Eastern Scholar) at Shanghai Institutions of Higher Learning (No. TP2015039), National 111 Project (The Program of Introducing Talents of Discipline to University), Grant Award Number: D17002, The Open Project Program of Anhui Province Key Laboratory of Metallurgical Engineering & Resource Recycling (Anhui University of Technology) No: SKF20-01 and Project No: 51974182 supported by NSFC. The discrete element method simulations and analysis were conducted using LIGGGHTS 3.5.0 open source.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wei, H., Ding, W., Li, Y. et al. Porosity distribution of moving burden layers in the blast furnace throat. Granular Matter 23, 10 (2021). https://doi.org/10.1007/s10035-020-01080-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10035-020-01080-4