Abstract

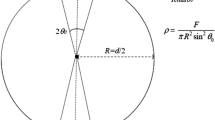

The paper presents an application of Discrete Element Modelling (DEM) in understanding the micro-process parameters of a particle failure under different loading conditions. A composite particle has been modelled using many primary particles to represent a quasi-homogeneous particle. Some of the examples of quasi-homogeneous particles are constituents of tablets, pellets, granules and concrete. These particles can behave differently under identical loading conditions even though they consist of same primary particles and proportions. This is a typical behaviour of such particles which is governed by the imperfections present in the particles. A DEM has been used to model the composite particle consisting of bi-modal distribution (smaller particles—matrices and larger particles—aggregates) of primary particles. The particle has been loaded under single plate compression, double plate compression and normal impact on different types of target. The single plate compression and normal impact experiments have also been performed. Process parameters like, fracture pattern, particle size distribution, liberation degree and new surface generation have been evaluated and compared. The results are applicable in understanding the particle failure under different processing operations like, transportation, handling and comminution. The results are also useful in selecting the better loading method for liberating aggregates from cheaper matrices for recycling.

Similar content being viewed by others

References

Schönert K.: Breakage of spheres and circular discs. Powder Technol. 143–144, 2–18 (2004)

Arbiter N., Harris C.C., Stamboltzis G.A.: Single fracture of brittle spheres. Soc. Min. Eng. AIME Trans. 244, 118–133 (1969)

Kiss L., Schönert K.: Aufschlusszerkleinerung eines zweikomponentigen Modellstoffes unter einzelkornbeanspruchjung durch druck-und prallbeanspruchjung. Aufbereitungs-Technik 30(5), 223–230 (1980)

Khanal M., Schubert W., Tomas J.: DEM simulation of diametrical compression test on particle compounds. Granul. Matter 7, 83–90 (2005)

Gorham D.A., Salman A.D.: The failure of spherical particles under impact. Wear 258, 580–587 (2005)

Tomas J., Schreier M., Gröger T., Ehlers S.: Impact crushing of concrete for, liberation and recycling. Powder Technol. 105, 39–51 (1999)

Thornton C., Yin K.K., Adams M.J.: Numerical simulations of impact fracture and fragmentation of agglomerates. J. Phys. D Appl. Phys. 29, 424–435 (1996)

Mishra B.K., Thornton C.: Impact breakage of a particle agglomerates. Int. J. Min. Process. 61, 225–239 (2001)

Khanal M., Schubert W., Tomas J.: Ball impact and crack propagation simulations of particle compound material. Granul. Matter 5(4), 177–184 (2004)

Antonyuk S., Tomas T., Heinrich S., Mörl L.: Breakage behaviour of spherical granulates by compression. Chem. Eng. Sci. 60, 4031–4044 (2005)

Khanal M., Tomas J.: Effect of target walls on the breakage of composite particles. Chem. Eng. Technol. 31(4), 609–614 (2008)

Particle Flow Code in 2 Dimensions Manual, Version 3.0. Itasca Consulting Group Inc., Minneapolis, US (2002)

Schubert W., Khanal M., Tomas J.: Impact crushing of particle–particle compounds—experiment and simulation. Int. J. Min. Process. 75(1–2), 41–52 (2005)

Khanal M., Schubert W., Tomas J.: Experiment and simulation of breakage of particle compounds under compressive loading. Part. Sci. Technol. 23(4), 387–394 (2005)

Khanal M., Schubert W., Tomas J.: Compression and impact loading experiments of high strength spherical composites. Int. J. Min. Process. 86(1–4), 104–113 (2008)

Subero J., Ning Z., Ghadiri M., Thornton C.: Effect of interface energy on the impact strength of agglomerates. Powder Technol. 105, 66–73 (1999)

Schönert K.: Role of fracture physics in understanding comminution phenomena. Trans. SME AMIE 252, 21–26 (1972)

Yoshikawa H., Sata T.: Measurement of tensile strength of granular brittle materials. Sci. pap. Inst. Phys. Chem. Res. 54(4), 389–393 (1960)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khanal, M., Tomas, J. Application of DEM to evaluate and compare process parameters for a particle failure under different loading conditions. Granular Matter 12, 411–416 (2010). https://doi.org/10.1007/s10035-010-0192-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10035-010-0192-9