Abstract

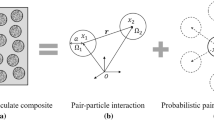

A micromechanical model based on discrete element method (DEM) was employed to investigate the effects of aggregate size and specimen scale on the cracking behavior of asphalt mixture. An algorithm for generating three-dimensional aggregates that can reflect the realistic geometry such as shape, size and fracture surface of aggregate particles was developed using a user-defined procedure coded with FISH language in particle flow code in three-dimensions (PFC3D). The parallel-bond model (PBM), linear contact model (LCM), and slip model(SM), whose sets of micro parameters were obtained by comparing experimental tests with numerical simulation results, were used to characterize the internal contact behavior of asphalt mixture. Digital asphalt mixture specimens were used to simulate the effects of aggregate size and specimen scale on the cracking behavior by the indirect tensile (IDT) test. Some conclusions can be drawn as follows: Both cracks and IDT strength decrease with increasing aggregate size. However, the heterogeneity of contact-force distribution augments with increasing aggregate size, especially with 13.2-16 mm aggregate. The aggregate size of 4.75-9.5 mm dominates in forming skeleton structure for asphalt mixture. The IDT strength decreases and cracks augment with increasing sample scale. The crack growth can be well interpreted from the perspective of energy analysis. The conclusions show that the proposed micromechanical model is suitable for the simulation of crack propagation. This study provides an assistant tool to further study the cracking behavior of particle-reinforced composites material such as asphalt mixture and Portland cement concrete.

Similar content being viewed by others

References

Kim YR. Cohesive Zone Model to Predict Fracture in Bituminous Materials and Asphaltic Pavements: State-of-the-art Review[J]. Int. J. Pavement Eng., 2011, 12(4): 343–356

Yin A, Yang X, Zhang C, et al. Three-dimensional Heterogeneous Fracture Simulation of Asphalt Mixture under Uniaxial Tension with Cohesive Crack Model[J]. Constr. Build. Mater., 2015, (76): 103–117

Potyondy DO, Cundall P A. A Bonded-particle Model for Rock[J]. Int. J. Rock Mech. Mini., 2004, 41(8): 1 329–1 364

Kim YR, Baek C, Underwood B S, et al. Application of Viscoelastic Continuum Damage Model Based Finite Element Analysis to Predict the Fatigue Performance of Asphalt Pavements[J]. KSCE J. Civ. Eng., 2008, 12(2): 109–120

Dai Q, Sadd M, Parameswaran V, et al. Prediction of Damage Behaviors in Asphalt Materials Using a Micromechanical Finiteelement Model and Image Analysis[J]. J. Eng. Mech., 2005, 131(7): 668–677

Abbas AR, Papagiannakis AT, Masad EA. Micromechanical Simulation of Asphaltic Materials Using the Discrete Element Method[C]. In: Proceeding of the Symposium on Mechanics of Flexible Pavements, ASCE, USA, Asphalt Concrete, 2006: 1–11

Abbas AR. Simulating the Deformation Behavior of Hot Mix Asphalt in the Indirect Tension Test[C]. In: Symposium on Pavement Mechanics and Materials, ASCE, USA, Pavement and Materials, 2008: 16–23

Kim H, Buttlar G. Discrete Fracture Modeling of Asphalt Concrete[J]. Int. J. Solids Struct., 2009, 46(13): 2 593–2 604

Chen J, Pan T, Huang X. Discrete Element Modeling of Asphalt Concrete Cracking Using a User-defined Three-dimensional Micromechanical Approach[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2011, 26(6): 1 215–1 221

Pei J, Chang M, Chen S, et al. Numerical Simulation of Indirect Tensile Test for Asphalt Mixture[J]. Journal of Chang’an University- Natural Sci. Ed., 2010, 30(5): 6–10 (in Chinese)

Koyama T, Jing L. Effects of Model Scale and Particle Size on Micromechanical Properties and Failure Processes of Rocks-a Particle Mechanics Approach[J]. Eng. Anal. Bound. Elem., 2007, 31: 458–472

Ngai L, Wong Y, Zhang X. Size Effects on Cracking Behavior of Flawcontaining Specimens under Compressive Loading[J]. Rock Mech. Rock Eng., 2014, 47: 1 921–1 930

Ding X, Zhang L, Zhu H, et al. Effect of Model Scale and Particle Size Distribution on PFC3D Simulation Results[J]. Rock Mech. Rock Eng., 2014, 47: 2 139–2 156

Zhang D, Huang X, Zhao Y. Algorithms for Generating Threedimensional Aggregates and Asphalt Mixture Samples by the Discreteelement Method[J]. J. Comput. Civil Eng., 2013, 27(2): 111–117

Hou S, Zhang D, Huang X, et al. Investigation of Micro-mechanical Response of Asphalt Mixtures by a Three-dimensional Discrete Element Model[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2015, 30(2): 338–343

Itasca Consulting Group. Particle Flow Code in 3 Dimensions[M]. Version 3.1, Minneapolis, MN, 2004

Liu Y, You Z. Visualization and Simulation of Asphalt Concrete with Randomly Generated Three-dimension Models[J]. J. Comput. Civil Eng., 2009, 23(6): 340–347

Zhang D. Research on Morphology of Coarse Aggregates and its Mechanical Performance by Discrete Element Modeling[D]. Nanjing: Southeast University, 2013(in Chinese)

Qiu Y, Yan C, Ai C. Numerical Simulation of Split Test Process for Asphalt Mixture under Heterogeneous State[J]. Journal of Traffic and Transp. Eng., 2009, 9(2): 12–16 (in Chinese)

Chen J, Huang X. Evaluation of Aggregate Skeleton Structure Using the Discrete Element Method[J]. Journal of Southeast University-Natural Sci. Ed., 2012, 42(4): 761–765 (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China (No.51108081)

Rights and permissions

About this article

Cite this article

Liu, W., Gao, Y. & Huang, X. Effects of aggregate size and specimen scale on asphalt mixture cracking using a micromechanical simulation approach. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 32, 1503–1510 (2017). https://doi.org/10.1007/s11595-017-1775-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-017-1775-7