Abstract

This paper considers the problem of the dynamic modelling of macro slip in spherical roller bearings. By revisiting the fundamental physics which drive these systems, potential issues in existing models have been identified. Furthermore, in pure rolling conditions it was found that governing differential equations become “stiff”, requiring the use of implicit methods of time integration. The problem of individual roller macro slip in a wind turbine main bearing is then investigated using a simplified representation of system dynamics. Model results indicate clear links between slip/friction and the operational strategy of the wind turbine, as well as significantly higher frictional effects in the downwind main bearing row. Due to modelling simplifications, these results should not yet be considered conclusive, with further work required.

Zusammenfassung

Dieser Beitrag befasst sich mit dem Problem der Dynamischen Modellierung des Makroschlupfs in Pendelrollenlagern. Durch eine Überprüfung der grundlegenden physikalischen Zusammenhänge, die diese Systeme antreiben, wurden potenzielle Probleme in bestehenden Modellen identifiziert. Darüber hinaus wurde festgestellt, dass die maßgeblichen Differentialgleichungen unter reinen Rollbedingungen „steif“ werden, was den Einsatz impliziter Methoden der Zeitintegration erfordert. Das Problem des Makroschlupfes einzelner Rollen in einem Hauptlager einer Windturbine wird dann anhand einer vereinfachten Darstellung der Systemdynamik untersucht. Die Modellergebnisse zeigen klare Zusammenhänge zwischen Schlupf/Reibung und der Betriebsstrategie der Windkraftanlage sowie deutlich höhere Reibungseffekte in der windabgewandten Hauptlagerreihe. Aufgrund von Vereinfachungen der Modellierung sollten diese Ergebnisse noch nicht als abschließend betrachtet werden; weitere Arbeiten sind erforderlich.

Similar content being viewed by others

Notes

More specifically, \(\mathbf{L}_{\text{CoM}}\) is the angular momentum (relative to \(\mathcal{O})\) of a point mass with mass equal to that of the rigid body, and with position and velocity equal to the body centre-of-mass at each point in time.

An example of such an orbit being that of our tidally-locked moon.

References

Bergua Archeli R, Keller J, Bankestrom O, Dunn M, Guo Y, Key A, Young E (2021) Up-tower investigation of main bearing cage slip and loads. Tech. rep. National Renewable Energy Lab.(NREL), Golden

Brizmer V, Stadler K, van Drogen M, Han B, Matta C, Piras E (2017) The tribological performance of black oxide coating in rolling/sliding contacts. Tribol Trans 60(3):557–574

Crook A (1961) The lubrication of rollers III. A theoretical discussion of friction and the temperatures in the oil film. Philos Trans Royal Soc Lond Ser A Math Phys Sci 254(1040):237–258

Doll G (2022) Surface engineering in wind turbine tribology. Surface and coatings technology, p 128545

Gould B, Greco A (2015) The influence of sliding and contact severity on the generation of white etching cracks. Tribol Lett 60(2):1–13

Gould B, Greco A (2016) Investigating the process of white etching crack initiation in bearing steel. Tribol Lett 62(2):1–14

Greco A, Demas N, Erck R, Gould B, Keller J, Sheng S, Guo Y (2022) Wind turbine drivetrain reliability. Tech. Rep. PR–5000–84029. National Renewable Energy Lab.(NREL), Golden (https://www.nrel.gov/docs/fy23osti/84029.pdf)

Guo Y, Keller J (2020) Validation of combined analytical methods to predict slip in cylindrical roller bearings. Tribol Int 148:106–347

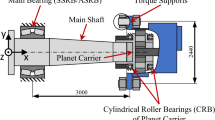

Guo Y, Bankestrom O, Bergua R, Keller J, Dunn M (2021) Investigation of main bearing operating conditions in a three-point mount wind turbine drivetrain. Forsch Ingenieurwes 85(2):405–415

Guo Y, Thomson A, Bergua R, Bankestrom O, Erskine J, Keller J (2022) Acoustic emission measurement of a wind turbine main bearing. Tech. rep. National Renewable Energy Lab.(NREL), Golden

Han Q, Chu F (2015) Nonlinear dynamic model for skidding behavior of angular contact ball bearings. J Sound Vib 354:219–235

Han Q, Li X, Chu F (2018) Skidding behavior of cylindrical roller bearings under time-variable load conditions. Int J Mech Sci 135:203–214

Hart E (2020) Developing a systematic approach to the analysis of time-varying main bearing loads for wind turbines. Wind Energy 23(12):2150–2165

Hart E, Turnbull A, Feuchtwang J, McMillan D, Golysheva E, Elliott R (2019) Wind turbine main-bearing loading and wind field characteristics. Wind Energy 22(11):1534–1547

Hart E, Clarke B, Nicholas G, Kazemi Amiri A, Stirling J, Carroll J, Dwyer-Joyce R, McDonald A, Long H (2020) A review of wind turbine main bearings: design, operation, modelling, damage mechanisms and fault detection. Wind Energy Sci 5(1):105–124

Hart E, de Mello E, Dwyer-Joyce R (2022) Wind turbine main-bearing lubrication–part 1: an introductory review of elastohydrodynamic lubrication theory. Wind Energy Sci 7(3):1021–1042

Hart E, de Mello E, Dwyer-Joyce R (2022) Wind turbine main-bearing lubrication–part 2: Simulation-based results for a double-row spherical roller main bearing in a 1.5 mw wind turbine. Wind Energy Sci 7(4):1533–1550

Jain S, Hunt H (2011) A dynamic model to predict the occurrence of skidding in wind-turbine bearings. J Physics Conf Ser IOP Publ 305:12027

Kotzalas MN, Doll GL (2010) Tribological advancements for reliable wind turbine performance. Philos Trans Royal Soc A: Math Phys Eng Sci 368(1929):4829–4850

Liu Y, Chen Z, Tang L, Zhai W (2021) Skidding dynamic performance of rolling bearing with cage flexibility under accelerating conditions. Mech Syst Signal Process 150:107–257

Masjedi M, Khonsari M (2012) Film thickness and asperity load formulas for line-contact elastohydrodynamic lubrication with provision for surface roughness. J Tribol 134(1):11503

Nejad AR, Keller J, Guo Y, Sheng S, Polinder H, Watson S, Dong J, Qin Z, Ebrahimi A, Schelenz R et al (2022) Wind turbine drivetrains: state-of-the-art technologies and future development trends. Wind Energy Sci 7(1):387–411

Rao A (2006) Dynamics of particles and rigid bodies: a systematic approach. Cambridge University Press, Cambridge

Tu W, Shao Y, Mechefske CK (2012) An analytical model to investigate skidding in rolling element bearings during acceleration. J Mech Sci Technol 26(8):2451–2458

Vaes D, Guo Y, Tesini P, Keller JA (2019) Investigation of roller sliding in wind turbine gearbox high-speed-shaft bearings. Tech. rep. National Renewable Energy Lab.(NREL), Golden

Wanner G, Hairer E (1996) Solving ordinary differential equations II vol 375. Springer, Berlin Heidelberg

Acknowledgements

The authors would like to thank to Dr Tim Rogers (University of Sheffield) for helpful discussions which greatly supported this research. This work forms part of project AMBERS (Advancing Main-BEaRing Science for wind and tidal turbines). Elisha de Mello’s PhD project is funded by the Powertrain Research Hub, co-funded by the Offshore Renewable Energy Catapult. Edward Hart is funded by a Brunel Fellowship from the Royal Commission for the Exhibition of 1851. This work was authored in part by the National Renewable Energy Laboratory, operated by Alliance for Sustainable Energy, LLC, for the U.S. Department of Energy (DOE) under Contract No. DE-AC36-08GO28308. Funding provided by the U.S. Department of Energy Office of Energy Efficiency and Renewable Energy Wind Energy Technologies Office. The views expressed in the article do not necessarily represent the views of the DOE or the U.S. Government. The U.S. Government retains and the publisher, by accepting the article for publication, acknowledges that the U.S. Government retains a nonexclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published form of this work, or allow others to do so, for U.S. Government purposes.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

de Mello, E., Hart, E., Guo, Y. et al. Dynamic modelling of slip in a wind turbine spherical roller main bearing. Forsch Ingenieurwes 87, 297–307 (2023). https://doi.org/10.1007/s10010-023-00652-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-023-00652-z