Abstract

Plastic gears and their numerous applications have become an integral part of industrial practice. In particular, the ability to produce large numbers of gears cost-effectively using injection molding techniques is making a significant contribution to growing market shares. Compared to conventional steel materials, however, the material properties of thermoplastics differ fundamentally. In particular, the high temperature dependence of the material properties and the lower strength pose challenges for designers. Against this background, theoretical and experimental studies on the operating and service life behavior of different thermoplastic materials have been conducted and evaluated. In addition to theoretical investigations on the tooth flank load carrying capacity, comprehensive measurements on temperature behavior were carried out and compared to common methods of temperature calculation for plastic gears. Experimental investigations on the tooth flank load capacity by means of back-to-back tests of different materials and their evaluation show the potential of thermoplastic materials for the application in power transmitting drivetrains. This contribution will give an overview of the performed research work and summarizes main results of these studies.

Zusammenfassung

Kunststoffzahnräder und ihre zahlreichen Anwendungen sind aus der industriellen Praxis nicht mehr wegzudenken. Insbesondere die Möglichkeit, Zahnräder in großen Stückzahlen kostengünstig im Spritzgussverfahren zu produzieren, trägt wesentlich zu deren wachsenden Marktanteilen bei. Im Vergleich zu herkömmlichen Stahlwerkstoffen unterscheiden sich die Materialeigenschaften von Thermoplasten jedoch grundlegend von den von Stahlwerkstoffen bekannten Eigenschaften. Insbesondere die hohe Temperaturabhängigkeit der Materialeigenschaften und die geringere Festigkeit stellen Herausforderungen im Auslegungsprozess von Zahnrädern dar.

Vor diesem Hintergrund wurden theoretische und experimentelle Untersuchungen zum Betriebs- und Lebensdauerverhalten verschiedener thermoplastischer Werkstoffe durchgeführt und ausgewertet. Neben theoretischen Untersuchungen zur Zahnflankentragfähigkeit wurden umfangreiche Messungen zum Temperaturverhalten durchgeführt und mit gängigen Methoden der Temperaturberechnung für Kunststoffzahnräder verglichen. Experimentelle Untersuchungen zur Zahnflankentragfähigkeit verschiedener Werkstoffe und deren Auswertung zeigen das Potenzial von thermoplastischen Werkstoffen für den Einsatz in leistungsübertragenden Antriebssträngen auf. Dieser Beitrag gibt einen Überblick über die durchgeführten Forschungsarbeiten und fasst die wesentlichen Ergebnisse dieser Untersuchungen zusammen.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 State of knowledge

Plastic gears are constantly expanding their areas of application and market share in the field of drive technology. In contrast to the earlier period when drives in domestic products or auxiliary drives were mostly made of plastic, today ever higher performance classes are being achieved, right up to the kilowatt range of modern urban electromobility. The high requirements in terms of reliability and service life frequently require operation with oil lubrication. On the one hand, the use of a lubricant contributes significantly to heat dissipation from the tooth contact and thus to thermal stability. On the other hand, the lubricant film separates the tooth surfaces and substantially decelerates damage due to wear. Due to the strongly temperature-dependent material properties of thermoplastics, knowledge of the occurring tooth temperatures is of decisive importance both in the design of plastic gears and in experimental investigations regarding the generation of strength data. In the 1960s, Hachmann and Strickle [1] have been conducting experimental research on the thermal operating behavior of polyamide gears. They developed a calculation approach for determining the tooth temperature based on a thermal equilibrium between frictional heat generated in the tooth contact and heat dissipated to the outside via the gear-housing surface. This methodology was continuously enhanced and finally adopted in the guideline VDI 2736 [2] for the design and calculation of plastic gears. Equation 1 and 2 show the calculation approach to determine the tooth flank temperature and tooth root/bulk temperature. Apart from the transmitted drive power and the coefficient of friction prevailing in the tooth contact, the lubrication condition and the heat-dissipating surfaces of the housing in particularly affect the calculated tooth temperatures. For the formula symbols, reference is made to the nomenclature.

Further approaches to determine the tooth temperature are proposed by Housz [3] who adapts the flash temperature concept acc. to Blok [4] for nylon gears. The calculation approaches presented so far neglect viscoelastic losses and their influence on the tooth temperature. The effects of viscoelastic losses on the thermal behavior of plastic gears are addressed in the calculation methods acc. to Takanashi & Shoji [5] as well as in the research work presented by Koffi et al. [6]. These approaches, however, are rarely used since the input and material parameters required for the calculation are often not available or only available in insufficient detail. In addition to analytical calculation approaches, an increasing number of numerical calculation models have recently been applied [7,8,9]. This offers the possibility of determining the local temperature distribution on the tooth surface and inside the tooth, taking into account the complex material properties of thermoplastics.

Unlubricated dry running conditions often limit the transferable power due to heating of the gear teeth to the limit of damage by melting. Abrasive wear of the tooth flanks leads to a continuous reduction of the tooth cross-section and thus limits the lifetime. Due to the reduction in wear, fatigue damages such as tooth root breakage and pitting are increasingly emerging in oil-lubricated operation and extended running times [10, 11]. For the calculation of the tooth root load capacity and the tooth flank load capacity, VDI 2736 [2] provides calculation approaches that are strongly based on the principles according to DIN 3990 [12] for metallic gears. The calculation of the tooth flank load carrying capacity is based on the fundamentals of Hertzian pressure at the pitch point. Equation 3 shows the calculation approach for determining the occurring Hertzian pressure during operation.

The resulting Hertzian pressure is compared to a permissible pressure, which is based on a temperature-dependent S‑N-curve that reflects the strength properties of the material in use. Equation 4 and 5 show the calculation approach to determine the permissible flank pressure based on material specific strength values.

The consistent application of this calculation method is contradicted by the fact that no or insufficient strength values are available for a large number of thermoplastic materials. VDI 2736 [2] only contains values for a limited number of thermoplastics.

2 Aim of this work

The aim of this work is the systematic experimental investigation of the operating behavior of oil-lubricated high-performance plastics in the material pairing steel-plastic. For this purpose, temperature measurements are carried out at different tooth positions under varying operating conditions. Furthermore, the occurring damage behavior is characterized and the resulting service life is evaluated. The investigations focus on an unreinforced and a carbon fiber reinforced PEEK material.

3 Test rig set up

All experimental investigations are performed on a modified FZG back-to-back test rig according to [13] with a center distance of a = 91.5 mm. In order to control the tooth temperature the test rig is equipped with an oil lubrication system. The lubricant is injected directly into the gear mesh while the oil level is maintained constant at the shaft center. Heating cartridges and cooling pipes allow controlling the oil temperature at predefined temperature levels. Fig. 1 shows the test gearbox with mounted plastic test gear and steel pinion with the oil sump level at shaft center. To measure the tooth temperatures, the test rig is provided with a corresponding sensor system. Thermal sensors are applied to the plastic gears and the measurement signal is passed via a hollow shaft from the housing to a telemetry system.

Software is used to continuously monitor and record the tooth temperatures during operation. All tests are performed with an ISO VG 100 reference mineral oil (FVA 3 + 4% Anglamol 99) with a sulfur-phosphorus-based additive package. The lubricant main data are shown in Table 1.

4 Test gears

The experimental investigations were carried out in accordance with previous investigations [10, 11, 15] using test gears of a transmission ratio of i = 1.5 at a design size of mn = 3 mm. The detailed specifications of the test gear geometry are documented in Table 2. The plastic gears are molded onto a steel insert. The steel insert is fixed to the test rig shaft by means of a conical adapter. This ensures a reliable shaft-hub connection. Holes distributed evenly around the circumference of the steel insert are filled with plastic during the injection molding process and ensure a sufficiently strong form fit between the plastic and the steel insert. As a result of the injection molding process the plastic gear features a tip edge radius. The detailed design of the plastic gear and the steel insert is shown in Fig. 2.

Design of plastic test gears [16]

All experimental investigations are performed using a case hardened and ground 16MnCr5 steel pinion. The steel pinion is designed with a circular tip relief to prevent premature damage on the plastic gear caused by meshing interference. The tip relief ensures that the sharp-edged tip edge of the steel pinion cannot engage with the dedendum flank area of the plastic gear, which would lead to significant pressure peaks in this area. The use of a tip relief significantly lowers the pressure in the extended area of contact and guarantees that the maximum Hertzian pressure is present in the area of single tooth contact.

The steel pinions reach surface roughness values of Ra ≤ 0.4 µm and gear qualities of Q ≤ 6 according to DIN 3962 [17]. The plastic gears achieve gear qualities of Q ≈ 12. The surface roughness of the plastic gears differs depending on the material. The unreinforced test gears exhibit roughness values of Ra = 0.1 µm, while the carbon fiber reinforced test gears indicate surface roughness values of Ra = 0.6 µm. The roughness of the flanks is evaluated as the mean value of three teeth around the circumference measured in the direction of the involute in the middle of the face width. The main properties of both unreinforced and carbon fiber reinforced PEEK materials are shown in Table 3. The two materials differ fundamentally in their mechanical properties. The addition of carbon fibers increases the Young’s modulus of the reinforced variant significantly by a factor of more than six.

5 Experimental investigation of tooth temperature

To characterize the thermal operating behavior, stage tests are performed on the back-to-back test rig. For this purpose, speed is increased stepwise at constant torque once a thermal steady-state condition is established. The test gears are equipped with PT100 thermal sensors, which are mounted at different positions approximately 1.5 mm below the tooth surface. An additional thermal sensor is located in the middle of the tooth to monitor the tooth bulk temperature. Fig. 3 shows the positions of the thermal sensors. For each measurement only one tooth is equipped with a single thermal sensor.

The measuring tests are carried out up to a maximum wheel speed of n2 = 3000 min−1 at two different torque levels at a constant oil temperature of ϑOil = 80 °C. Fig. 4 and 5 show the measured rise of temperature compared to the oil temperature at different tooth positions at the maximum speed of n2 = 3000 min−1. The temperature increase amounts to only a few K at all measuring positions for both materials investigated. The temperature increase of the bulk temperature is the lowest in all investigated load cases. The temperature increase in the center of the tooth is caused by viscoelastic losses due to tooth deformation and by heat conduction from the tooth surface. The friction in the tooth contact results in heating of the tooth surface. However, due to the effective heat dissipation by the lubricant, the tooth surface heats up only to a minor extent for the operating conditions investigated in this study. The temperature differences between dedendum, pitch point and addendum areas are negligible since they are in the range of measurement accuracy. The transmitted torque has a major influence on tooth warming. As expected, an increase in torque leads to an increase in tooth temperature. However, even for higher torques, the heat can be effectively dissipated from the tooth contact by the lubricant. The measured temperature differences between reinforced and unreinforced material are marginal.

The results of the temperature measurements are compared with the calculated tooth temperatures according to VDI 2736 [2]. To calculate the tooth temperature for oil-lubricated gears, VDI 2736 [2] recommends a coefficient of friction of µ = 0.04. Fig. 6 shows the maximum measured tooth heating in comparison with the heating calculated according to VDI 2736 [2] for the unreinforced variant. The tooth temperatures calculated according to VDI 2736 [2] are significantly higher than the measured tooth temperatures. However, it should be noted that the temperature sensor is not mounted directly on the tooth surface, but approximately 1.5 mm below the tooth surface, and consequently there is a certain temperature gradient towards the surface. Reitschuster [18] investigates the friction behavior of oil-lubricated PEEK disks in a steel-plastic pairing in a two-disk test rig and determines the coefficient of friction for different operating conditions to approximately µ ≈ 0.01. The recalculation of the tooth temperatures according to VDI 2736 [2] with the reduced coefficient of friction results in a significant improvement of the correlation between calculation and measurement.

Comparison of temperature measurement with VDI 2736 [2], Vestakeep 5000G

6 Experimental investigation of flank load carrying capacity

To investigate the damage mechanism and fatigue characteristics, single-stage fatigue tests are carried out in the back-to-back test rig. All load carrying capacity tests performed are carried out at an material temperature of 80 °C and a wheel speed of n2 = 2250 min−1. The test runs are stopped at regular intervals and the condition of the tooth flank and the existing damage progress are documented. Tactile contour scans are performed to determine the tooth profile. In addition, the flank condition is documented photographically.

The torque is kept constant during the entire test run and any torque reductions are compensated. The test run is terminated according to [11] when flank damage reaches 2% of the active flank area of the plastic gear and the test run is considered as a failed specimen (pitting damage). Fig. 7 shows the flank condition of an exemplary unreinforced PEEK gear at the end of test.

The optical form of the generated pittings resemble those observed on steel gears while the pittings occur preferably at positions of high flank pressure and high negative specific sliding speeds as also known from steel gears [11]. The comparison of the tooth profile in new condition and at end of test shows that hardly any profile form deviations due to wear were formed during the test run. The profile form deviation at the mean tooth height is attributed to pitting generation. The photo documentation of the flank condition at the end of the test shows significant damage due to pitting.

Fig. 8 shows the flank condition at the end of an exemplary test run with the carbon fiber reinforced PEEK material. Analogous to the test runs with unreinforced test gears, the test runs were stopped when an area damaged by pitting of 2% was reached. In contrast to the unreinforced variant, significant profile form deviations due to wear and a reduction in the tooth cross-section can be observed for the carbon fiber reinforced variant. The damage caused by abrasive wear is superimposed by large-area pittings. It should be noted that the two tests (unreinforced and carbon fiber reinforced) were performed at identical torque. Under identical test conditions, the unreinforced variant achieves a significantly higher running time until a critical pitting area is reached without any wear occurring, while the reinforced variant is already severely damaged by abrasive wear at an early stage of the test. The recalculation of the wear coefficient averaged from three test runs using the calculation approach according to VDI 2736 [2] considering the reduction in tooth cross section, results in a wear coefficient of kw = 6.5 ∙ 10−6 mm3/Nm for the herein performed tests at oil lubricated conditions.

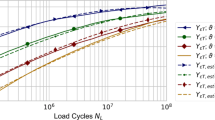

According to VDI 2736 [2], the consideration of wear is of increased relevance especially in dry running conditions. However, it can be shown at this point that the wear coefficient for the carbon fiber reinforced variant is in the range of dry-running plastic gear systems although oil lubrication is applied and that the wear behavior has a significant influence on the service life. At this point, VDI 2736 [2] does not contain wear coefficients for oil-lubricated conditions. The resulting service lifetime of the two investigated thermoplastics is documented in Fig. 9. The flank pressure according to VDI 2736 [2] is calculated taking into consideration the geometry at the test beginning and changes due to wear are not taken into account. It can be shown that the reinforced grade has advantages over the unreinforced grade, especially for short running times and high flank pressures. It must be noted, however, that a comparison of the two materials by flank pressure has only limited meaningfulness: Due to the large differences in the Young’s modulus, the flank pressures in the tooth contact are very different for identical tooth forces. The lower material stiffness of the unreinforced variant leads to greater flattening in the tooth contact and to a reduction in Hertzian pressure for equal tooth load. For this reason, the results of the load carrying capacity tests are shown as a function of the tooth force per tooth width in Fig. 10. This allows the direct comparison of the transmissible tooth force up to damage. It can be shown that the service life of the unreinforced variant is significantly higher in the herein conducted study than the lifetime of the reinforced variant at the same tooth force.

The low running time of the reinforced variant is attributed to severe abrasive wear, which occurs in combination with pitting damage. The abrasive wear of the reinforced variant is attributed on the one hand to the production-related higher flank roughness compared to unreinforced PEEK. Furthermore, due to the higher material stiffness, higher pressures occur in tooth contact and more energy is transmitted over a smaller flank area, which further promotes the development of wear. The addition of fibers and the resulting improvement in mechanical properties can have a positive effect on tooth root load carrying capacity [2]. However, with regard to tooth flank load carrying capacity, the fibers influence the tribological properties in the tooth contact and can lead to a combined occurrence of wear and pitting and an overall reduction in tooth flank load carrying capacity. When selecting a material, therefore, several aspects and a balancing of all requirements must be taken into account. Minor optical changes in the dedendum flank area and profile form deviations of a few micrometers can be observed on the steel pinions after the end of testing. The calculation of the minimum lubricant film thickness acc. to [19] as well as the specific lubricant film thickness of the unreinforced and the fiber-reinforced variant shows significant differences in the present lubrication condition.

The unreinforced plastic gear indicates a minimum lubricant film thickness hmin = 0.39 µm and a specific lubricant film thickness of λ = 1.6 for the herein investigated operating conditions. The fiber reinforced variant, however, exhibits a minimum lubricant film thickness hmin = 0.28 µm and a specific lubricant film thickness of λ = 0.6. Due to the higher roughness and the resulting low specific lubricant film thickness, the carbon fiber reinforced test gears may be more sensitive to wear in operation than the non-reinforced variants of lower roughness.

7 Conclusion

In this study, the thermal operating behavior and tooth flank load capacity of oil-lubricated reinforced and unreinforced PEEK gears were investigated. The measurement of the tooth temperatures at different operating conditions results in a low heating of the plastic gears due to the effective heat dissipation with oil lubrication. Experimental investigations of the load carrying capacity and damage behavior indicate the occurrence of pitting on unreinforced variants. No wear can be observed for unreinforced PEEK. For the fiber reinforced variant, on the other hand, severe flank wear with superimposed pitting formation can be observed. For the fiber reinforced variant, the wear coefficient was determined according to VDI 2736. The achievable service lives were also evaluated and compared. It was found that the positive effects of fiber reinforcement in terms of tooth root load carrying capacity may be accompanied by disadvantages in terms of tooth flank load carrying capacity. For this reason, materials and operating conditions must always be selected holistically, taking into account all influences and transverse influences, in order to achieve the maximum possible service life.

8 Nomenclature

The nomenclature is shown in Table 4.

Change history

13 October 2021

An Erratum to this paper has been published: https://doi.org/10.1007/s10010-021-00559-7

References

Hachmann H, Strickle E (1966) Polyamide als Zahnradwerkstoffe. Konstruktion 18(3):1–19

VDI 2736 Blatt 2 (2014) Thermoplastische Zahnräder – Stirnradgetriebe Tragfähigkeitsberechnung. Beuth, Berlin

Housz AJI (1967) Scuffing as a factor in the design of nylon gears. Wear 10:118–126. https://doi.org/10.1016/0043-1648(67)90083-X

Blok H (1937) Measurement of temperature flashes on gear teeth under E.P. conditions. In: Proceedings of the General Discussion on Lubrication and Lubricants

Takanashi S, Shoji A (1980) On the temperature rise in the teeth of plastic gears

Koffi D, Gauvin R, Yelle H (1985) Heat generation in thermoplastic spur gears. J Mech Transm Autom Des 107:31

Maier E, Ziegltrum A, Lohner T, Stahl K (2017) Charakterization of TEHL contacts of thermoplastic gears. Forsch Ingenieurwes 81:317–324

Doll NP (2015) Modeling thermomechanical behavior of polymer gears. Masterarbeit, University of Wisconsin-Madison

Raghuraman N, Houser D, Wright H (2019) Numerical thermal 3D model to predict the surface and body temperature of spur and helical plastic gears

Hasl C, Illenberger CM, Oster P, Tobie T, Stahl K (2018) Potential of oil-lubricated cylindrical plastic gears. J Adv Mech Des Syst Manuf 12(1). https://doi.org/10.1299/jamdsm.2018jamdsm0016

Illenberger CM, Tobie T, Stahl K (2019) Flank load carrying capacity of oil-lubricated high performance plastic gears. Forsch Ingenieurwes 83:545–552. https://doi.org/10.1007/s10010-019-00332-x

DIN 3990 Teil 1–5 (1987) Tragfähigkeitsrechnung von Stirnrädern. Beuth, Berlin

DIN ISO 14635-1:2006-05: (2006) Zahnräder – FZG-Prüfverfahren – Teil 1: FZG-Prüfverfahren A/8,3/90 zur Bestimmung der relativen Fresstragfähigkeit von Schmierölen. Beuth, Berlin

Schilling M (1985) Ege: Referenzöle – Referenzöle für Wälz- und Gleitlager, Zahnrad- und Kupplungsversuche – Datensammlung für Mineralöle. FVA-Heft, vol 180. Forschungsvereinigung Antriebstechnik e. V. (FVA), Frankfurt a.M.

Hasl C (2019) Zur Zahnfußtragfähigkeit von Kunststoffstirnrädern. Dissertation, Technische Universität München

Hubert T, Bauser M, Hasl C, Tobie T, Stahl K (2015) Load carrying capacity of cylindrical plastic gears—Requirements of injection molded plastic test gears for back-to-back and pulsator testing. In: International Conference on Gears 2015

DIN 3962 Teil 1–3 (1978) Toleranzen für Stirnradverzahnungen. Beuth, Berlin

Reitschuster S, Maier E, Lohner T, Stahl K (2020) Friction and temperature behavior of lubricated thermoplastic polymer contacts. Lubricants 8. https://doi.org/10.3390/lubricants8060067

Myers TG, Hall RW, Savage MD, Gaskell PH (1991) The transition region of elastohydrodynamic lubrication. Royal Soc Phys Eng Sci 432:467–479. https://doi.org/10.1098/rspa.1991.0026

Acknowledgements

The authors would like to thank German Research Foundation (DFG, Deutsche Forschungsgemeinschaft, STA 1198/16-1) for their kind sponsorship of this research project focusing on flank load carrying capacity of thermoplastic gears. Furthermore, we kindly thank Werner Bauser GmbH (Siemensstr. 2, Wehingen, Germany) for the development and manufacturing of the injection molded test gears and Evonik Operations GmbH (Kirschenallee, Darmstadt, Germany) for the sponsorship and support with respect to the PEEK material. On behalf of all authors, the corresponding author states that there is no conflict of interest.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Additional information

The original online version of this article was revised due to a calculation mistake in the calculated lubricant film thicknesses.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Illenberger, C.M., Tobie, T. & Stahl, K. Operating behavior and performance of oil-lubricated plastic gears. Forsch Ingenieurwes 86, 557–565 (2022). https://doi.org/10.1007/s10010-021-00513-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-021-00513-7