Abstract

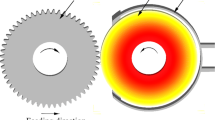

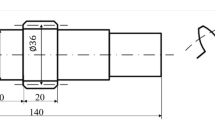

Innovative cold rolling technologies are important future production methods to gain more resource efficiency producing gears. Through current research at the Fraunhofer Institute for Machine Tools and Forming Technology (IWU), it is possible to produce running gears for use in vehicle transmissions by this method.

The paper contends theoretical and experimental investigations on cold rolled gears to determine their properties in detail. The theoretical principles of material anisotropy following cold forming processes as well as the results of investigations on gear teeth are discussed. Different calculation methodologies to compute the efficient elastic behavior of an anisotropic material area are compared by applying them to measurement data of an Electron Backscatter Diffraction (EBSD). Furthermore, methods to simulate the rolling process are described and applied to the investigated gear. It is shown that the production method can have an effect on the elastic material behavior of gear teeth.

Similar content being viewed by others

References

Bräunig J, Burkhardt M, Hensel E, Zumach S, Drossel W‑G, Hieckmann E (2015) Calculation methodology for determining load-dependent transmission error taking into account material anisotropy in gears produced by forming methods. In: International Conference on Gears 2015. VDI, Düsseldorf, p 1461

Druwe T, Lahl M, Milbrandt M (2015) Gear manufacturing by forming technologies. In: 5th ICAFT/22nd SFU 2015, Efficiency in forming technology by integrated approach to process chains Chemnitz. (Presentation)

Bertram A, Glüge R (2015) Solid mechanics. Springer, Cham

Gould PL (2013) Introduction to linear elasticity, 3rd edn. Springer, New York

Voigt W (1887) Theoretische Studie über die Elasticitätsverhältnisse der Krystalle. In: Abhandlungen der Königlichen Gesellschaft der Wissenschaften zu Göttingen, vol 34.

Roos E, Maile K (2008) Werkstoffkunde für Ingenieure, 3rd edn. Springer, Berlin Heidelberg

Gottstein G (2014) Materialwissenschaft und Werkstofftechnik. Physikalische Grundlagen, 3rd edn. Springer, Berlin Heidelberg

Bleck W, Münstermann S (2004) Einflussgrößen auf den Elastizitätsmodul von Stählen für den Fahrzeugbau. FAT Schriftenreihe Nr. 182. Forschungsvereinigung Automobiltechnik e. V., Berlin

Reuss A (1929) Berechnung der Fließgrenze von Mischkristallen auf Grund der Plastizitätsbedingung für Einkristalle. Z Angew Math Mech 9(1):49–58

Lahl M, Druwe T, Hellfritzsch U (2014) Eigenschaftsanalyse bei Verzahnungsherstellung. Eigenschaftsanalyse bei umformintegrierter Prozesskette zur Verzahnungsherstellung. Abschlussbericht des FVA-Forschungsvorhabens Nr. 642 I., FVA Heft 1088, Forschungsvereinigung Antriebstechnik e. V., Chemnitz

Schuster R, Druwe T, Lahl M, Schiller S, Milbrandt M, Popp M, Porstmann S (2013) Simulation of tool load for axial forming process with oscillating feed. In: 6th Forming Technology Forum 2013, Modelling of process chains and interfaces for sheet metal forming Herrsching, 19. - 20. Sept 2013.

Neugebauer R, Hellfritzsch U, Lahl M, Milbrandt M, Schiller S (2013) Gear rolling process. In: Process machine interactions. Springer, Berlin, pp 475–490

Hellfritzsch U, Lahl M, Milbrandt M, Schiller S (2009) Walzprozess und Stirnradverzahnungen. In: Symposium Praxis der Zahnradfertigung Esslingen.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schlecht, B., Ulrich, C. & Bräunig, J. Theoretical and experimental investigations on the influence of the microscopic anisotropic material properties of gear teeth on their macroscopic behavior. Forsch Ingenieurwes 81, 73–82 (2017). https://doi.org/10.1007/s10010-017-0223-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-017-0223-3