Abstract

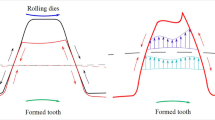

Gear shafts are commonly manufactured by machining of gear teeth and shaft separately. This kind of approach entails quite some problems, such as long processing time, large die, and low production efficiency. To tackle these problems, this paper innovatively proposes a new process of cross wedge rolling (CWR) that is specifically tailored to the manufacturing of gear shafts, with which the shaft and teeth are formed at one go. The finite element model of CWR forming of gear shaft is established to simulate and analyze the CWR forming process. A three-factor and three-level response surface test is designed to optimize the processing parameters, where the friction coefficient, rolling temperature, and die movement speed are chosen as three factors, and inhomogeneous deformation is set as the response. The optimal parameters are obtained as follows: the rolling temperature is 1240 ℃, the speed of the die movement is 336 mm/s, and the friction coefficient is 0.8. This result is subsequently verified by experiments. Further on, the microstructure evolution of the characteristic points of the CWR forming process of gear shaft is analyzed. It is found that the grains at the gear teeth section are continuously refined and grown from the boundary at the early section of deformation, and the final grains grown are much smaller than the original ones. In addition, the grains appear to grow in a short range of time in the process of deformation, but the overall trend is towards refinement. In the shaft section, the evolutions of the grains in the two stepped shaft segments are almost the same; the grain deformation shows cyclic changes; the degree of grain refinement in the shaft is higher than that in the teeth; and the degree of grain refinement in the shaft center is higher than that in the shaft edge. The results of the study provide a theoretical basis for short-process forming of high-performance gear shafts by cross wedge rolling.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article.

References

Pater Z (2000) Theoretical and experimental analysis of cross wedge rolling process. Int J Mach Tool Manu 40(1):49–63

Yuan WS, Huang RG, Zhang K, Li N, Yang XJ, Wang L (2021) Influence of cross wedge rolling process parameters on hollow shaft rolling formation. China Met Form Equip Manuf Technol 56(02):73–78

Yan HJ, Zhang C, Lu HY, Zhang SJ, Zhang JG, Ma SB, Shi XM (2020) Effect of process parameters on thinning and necking of large section multi-step shaft in cross wedge rolling. J Plast Eng 27(9):100–107

Han M, Liu JX, Shi MJ, Chen SF, Zhang SH, Chen M (2023) Research on forming of multi-step TC4 asymmetric axis parts by cross wedge rolling. J Ordnance Equip Eng 44(10):57–64

Yu ZM, Peng WF, Zhang X, Oleksandr M, Titov V (2022) Evolution of microstructure of aluminum alloy hollow shaft in cross wedge rolling without mandrel. J Cent South Univ 29(03):807–820

Zhang Z, Cui SS, Shi XM, Zhang JG, Chen L (2023) Influence of raw material, temperature and guide plate on the quality of wedge rolling products and the way to deal with the situation. Forging & Met Form 05:50–54

Pater Z, Tomczak J, Bulzak T, Hua L, Balint D, Lin J, Fiang J (2020) Establishment of a new hybrid fracture criterion for cross wedee rolling. Int J Mech Sci 167:105274

Pater Z, Tomczak J, Bulzak T (2020) Rapid estimation of ductile crack formation in cross-wedge rolling. J Mater Res Technol 9(6):14360–14371

Zeng J (2018) Study on deformation mechanism and application foundation on the cross wedge rolling without end concavity. J Mech Sci Res Inst 2023:12–26

Han L, Yu M (2022) The influence of process parameters on head of wedge rolling and their optimization. Yuxi Normal Univ J 38(06):52–60

Qu MI, Zheng SH, Wang Y (2022) The influence of diameter reduction on inner hole diameter of step hollow shaft in cross wedge rolling. J Ningbo Univ 35(05):27–33

Yan XZ, Liu JP, Ji HC, Wang BY, Zheng ZH, Li Z (2017) Effect of mandrel diameter on the wall thickness uniformity of the hollow valve of 5Cr21Mn9Ni4 by cross-wedge rolling. Chin J Eng 39(02):267–275

Huo YM, Huo CL, Ren X, He T, Wang BY, Cui YL, Jia CY, Liu KR, Du XY (2023) Numerical prediction of microstructure evolution of high-speed railway axle formed using hot cross wedge rolling. Mater Today Commun 35:105985

Feng P, Yang CP, Wang BY, Li JL, Liu R (2021) Microstructure and mechanical properties of TC4 titanium alloy hollow shaft formed by cross wedge rolling. Arch Civ Mech Eng 21(3):129

Xia YX, Shu XD, Zhu DB, Pater Z, Bartnicki J (2021) Effect of process parameters on microscopic uniformity of cross wedge rolling of GH4169 alloy shaft. J Manuf Process 66(10):145–152

Xu Q, Zhao AL, Chen ZG, Hu JL, Chen MZ, Hu HP (2022) Research on the influence of process parameters of titanium alloy cross wedge rolling on the evolution law of microstructure. Mod Ind Econ Inf 12(05):232–234

Chen XG, Shu XD, Lian QJ (2022) Effect of feed rate on forming quality of cross wedge rolling of gear shaft teeth. Metalurgija 61(3–4):713–716

Xu CL (2013) Three-dimensional finite element simulation of wedge cross rolling involute gear axle. Hot Work Technol 42(5):4

Xu CL, Wang GD (2013) Study of forming process optimization for involute gear shaft wedge cross rolling. Tuan Ya Chi Shu Forg Stamping Technol 38(1):5

Cai HL (2022) Study on the influence of billet temperature on the quality of gear splitting formed by cross wedge rolling of gear shaft. Mod Man Chnol Equip 58(10):94–97

Merkel P, Budde L, Grajczak J, Nowroth C, Prasanthan V, Kriwall M et al (2023) Feasibility study for the manufacturing of hybrid pinion shafts with the cross-wedge rolling process. Int J Mater Form 16(5):4

Wei G, Zhang W, Deng Y (2019) Identification and validation of constitutive parameters of 45 steel based on J-C model. Vib Shock 38(05):173–178

Wu LD (2012) Study on the quality of tooth profile of involute spur cylindrical gear shaft formed by cross wedge rolling. D. Zhejiang Univ-Sc(07)

Funding

This study was funded by the Natural Science Foundation of Zhejiang, China (Grant Number: LZ22E050002), the National Natural Science Foundation of China (Grant Number: U23A20629, 52375346), and the Major Project of Science and Technology Innovation 2025 in Ningbo City, China (Grant Number: 2022Z064, 2022Z009, 2022Z015).

Author information

Authors and Affiliations

Contributions

Conceptualization: L.L.C. and X.D.S.; modeling and simulation: L.L.C. and X.G.C.; data analysis: L.L.C. and Z.X. L.; data interpretation: L.L.C. and W.W.G.; experiment: L.L.C., H.J.X., Z.X.L. and G.X.C.; writing—original draft preparation: L.L.C.; writing—review and editing: X.D. S. and H.J. X. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

This work does not include human and animal; hence, ethical approval from any committee is not required.

Consent to participate

This work does not include human and animal; hence, consent to participate in the research is not required.

Consent for publication

The authors give the publisher the consent to publish the work.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lulu, C., Xuedao, S., Xiaogu, C. et al. Study on the regulation of deformation uniformity and microstructure law in the forming of gear shafts by cross wedge rolling. Int J Adv Manuf Technol 132, 2461–2476 (2024). https://doi.org/10.1007/s00170-024-13525-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13525-8