Abstract

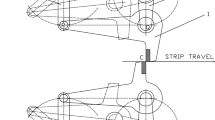

In problems requiring uniform cutting speeds uniform flow rates etc. slider-crank mechanisms provide economical solutions. Thus, the problem of designing slider-crank mechanisms for desirable slider positions and velocities is handled within a geometric framework in this paper. Here, the rotation of the crank has been related to the translation of the slider through a linear function. A unified methodology comprising the so-called Subdomain, Galerkin methods together with the classical collocation method is implemented to find the values of the parameters involved. The effectiveness of the methodology has been demonstrated on numerical examples. Since more than one solution results from the solution process, it is always possible to form multi-loop mechanisms. Moreover, designs with low velocity errors in the forward stroke exhibit similar feature in the backward stroke too.

Zusammenfassung

Schubkurbelmechanismen liefern ökonomische Lösungen für Probleme die gleichbleibende Schneidengeschwindigkeiten. Fliessgeschwindigkeiten usw. in bestimmten Stellungen benötigen. Deshalb wird das Problem der Konstruktion von Schubkurbelmechanismen zur Realisierung von gewünschten Stellungen und Geschwindigkeiten in dieser Arbeit im Rahmen der geometrischen Möglichkeiten behandelt. Hier wird die Drehung von der Kurbel auf die Schiebung des Gleitsteines durch eine lineare Funktion bezogen. Um die Werte von existierenden Parametern zu finden, wird eine vereinte Methodologie, die aus der sogenannten Subdomain und Galerkin Methode zusammen mit der klassischen Kollokation Methode bestehen, implementiert. Die Wirksamkeit der Methodologie wird an numerischen Beispielen demonstriert. Am Ende des Lösungsprozesses wird immer mehr als eine Lösung erzielt, so dass sich immer mehrere, mögliche Schubkurbelmechanismen ergeben. Konstruktionen mit geringen Abweichungen von den gewünschten Geschwindigkeiten bei der vorwärtsgerichteten Schiebung zeigen ähnliche Eigenschaften, wie die rückwärtsgerichtete Schiebung.

Similar content being viewed by others

Abbreviations

- A i ; B i ; B si :

-

Coefficients

- B ci ; C ci ; C i :

-

Coefficients

- C si ; P i ; Q i , i=1−5:

-

Coefficients

- A pL ; A ssL ; As0L:

-

Intermediate coefficients

- A ooL ; A soL , L=1,2:

-

Intermediate coefficients

- a1L ; a00L ; b3L :

-

Computable constants

- b2L ; b1L ; b oL :

-

Computable constants

- c3L ; c2L ; c1L :

-

Computable constants

- c0L , L=1,2:

-

Computable constants

- DEL:

-

Increment (rad)

- f(x):

-

A function of x variable

- G(s,ψ):

-

Displacement function

- R x :

-

Input scale (rad/m)

- R y :

-

Output scale (m/m)

- s :

-

Position of the slider (m)

- s 0 :

-

Initial position of the slider (m)

- w :

-

Angular speed of crank (rad/s)

- w i , i=1−5:

-

Weighting functions

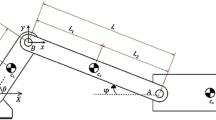

- \(\widehat{xOA_{0}}';\widehat{xOA_{n}}'\) :

-

Position of crank at the start and end of uniform motion in the backward stroke

- x 1 :

-

Crank length (m)

- x 2 :

-

Connecting rod length (m)

- x 3 :

-

Eccentricity (m)

- [x n ,x 0]:

-

Function interval (m)

- [x i−1,x i ], i=1−5:

-

Subinterval (m)

- x i :

-

Accuracy point (m)

- y i :

-

Function value at accuracy point (m)

- y0;y n :

-

Initial and final values of dependent variable (m)

- V :

-

Linear speed of slider (m/s)

- z1;z2;z3:

-

Design parameters

- Δs :

-

Uniform–velocity region (m)

- Δx :

-

Independent variable range (m)

- Δψ :

-

Amount of crank rotation (rad)

- δ :

-

Connecting rod angle (rad)

- ψ :

-

Crank angle (rad)

- ψ0;ψ n ;:

-

Initial and final crank angle (rad)

References

Nolle H (1974) Linkage coupler curve synthesis: a historical review. I. Developments up to 1875. Mech Mach Theory 9:147–158

Cakmak S (2010) There were marble factories 2000 years ago in West Anatolia. Turkish newspaper Cumhuriyet’s supplement No: 1192, 22 January, pp 6–7

Hain K (1967) Applied kinematics, 2nd edn. McGraw-Hill, New York

Hirschhorn J (1962) Kinematics and dynamics of plane mechanisms. McGraw-Hill, New York

Hartenberg RS, Denavit J (1964) Kinematic synthesis of linkages. McGraw-Hill, New York

Tao DC (1967) Fundamentals of applied kinematics. Addison-Wesley, Reading

Volmer J (1967) Getriebetechnik, Koppelgetriebe. Veb Verlag Technik, Berlin

Lee HS (2008) Creative design of an elliptical trainer with two degrees of freedom. Int J Mech Eng Educ 36(4):284–293

Yan H (2006) Innovation design of variable intermittent slider-crank mechanism. Int J Mech Eng Educ 34(4):349–363

Ottoviano E, Ceccarelli M, Giorgio J, Varone M (2006) Design and evaluation of a discretely actuated multi-module parallel manipulator. Proc ImechE, Part C: J Mech Eng Sci 220:513–526

Andrew IG (1985) A general method for determining the functional role of a muscle. J Biomech Eng 107:348–353

Freudenstein F, Primrose EJF, Ray S, Laks B (1976) Velocity fluctuation in four-bar linkages and slider-crank mechanism. Journal of Engineering for Industry 1255–1259

Hwang WM, Fan YS (2008) Coordination of two crank angles and two acceleration poles for a slider crank mechanism using parametric equations. Proc ImechE, Part C: J Mech Eng Sci 222:483–491

Zhang WJ, Li Q (2006) A closed-form solution to the crank position corresponding to the maximum velocity of the slider in a centric slider-crank mechanism. J Mech Des 128:654–656

Liu J, Hsin-Ting (1997) Synthesis and steady-state analysis of high-speed elastic cam-actuated linkages with fluctuated speeds by a finite element. J Mech Des 119:395–402

Fung RF, Shue LC (2002) Regulation of flexible slider-crank mechanism by Lyapunov’s direct method. Mechatronics 12:503–509

Saito H, Ishikawa J, Kamamichi N, Shiotsuki T, Furuta K (2009) Self-turning control for rotational speed of slider-crank mechanism. In: ICROS-SICE International Joint Conference, pp 29–33

Komaito Y, Furuta K (2008) Energy control of slider-crank mechanism. In: SICE Annual Conference, The University Electro-Communications, Japan, August 20–22, pp 2399–2403

Kao CC, Chuang CW, Fung RF (2006) The self-tuning PID control in a slider-crank mechanism system by applying particle swarm optimization approach. Mechatronics 16:513–522

Kimbrell JT (1991) Kinematics analysis and synthesis. McGraw-Hill, New York

Freudenstein F (1955) Approximate synthesis of 4-bar linkages. ASME Trans 77:853–861

Liaw DG (1975) Analytical synthesis of slider-crank function generation with fifth-order approximation. Bull JSME 18(122):891–896

Wu TM (2005) Non-linear solution of function generation of planar four- link mechanism by homotopy continuation method. Taiwan J Appl Sci 5(4):724–728

Reifschneider LG (2005) Teaching kinematic synthesis of linkages without complex mathematics. J Ind Technol 21(4)

Diavagna UM, Balli S, Shrinivas (2007) FSP synthesis of an off-set five bar-slider mechanism with variable topology. In: 13th national conference on mechanisms and machines, Bangalore, India, December 12–13, pp 345–350

Tso PL (1998) The kinematic synthesis of toggle clamps. J Manif Sci Eng 120:648–655

Crandall HS (1956) Engineering analysis. McGraw-Hill, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Akçalı, İ.D., Arıoğlu, M.A. Geometric design of slider-crank mechanisms for desirable slider positions and velocities. Forsch Ingenieurwes 75, 61–71 (2011). https://doi.org/10.1007/s10010-011-0134-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10010-011-0134-7