Abstract

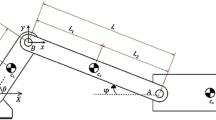

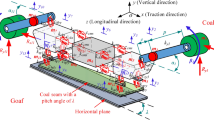

Flying crank shears are used for the cross-cutting of moving metal in rolling mills and downstream processing lines. Based on many factors including the product quality and knife wear, these machines are considered an excellent choice for cutting flat material of thickness exceeding 3 mm. During the cutting process using these shears, the knife velocity must match that of the material during the cut, making the knife trajectory complex, involving simultaneous translation and rotation. In this study, the model of a crank-type flying shear is developed following the kinematic analysis of its mechanism from the basic principles of multibody dynamics. This model is then used in the numerical simulation of a flying crank shear in cold shearing line, thereby validating for a given production speed, the machine dimensions, the motion control philosophy and prediction of the cut surface quality.

Similar content being viewed by others

Abbreviations

- \( a_{\text{cl}} \) :

-

Angular acceleration during cutting phase

- \( B \) :

-

Length of knife holder link

- \( {\text{Bu}} \) :

-

Flatness error of cut profile

- \( l_{\text{c}} \) :

-

Length of cut per piece, m

- \( n_{\text{c}} \) :

-

No. of cuts per minute

- t :

-

Time reckoned from the start of cycle, \( t \in [0 \;t_{\text{c}} ] \), s

- \( t_{\text{cl}} \) :

-

Time taken in linear cutting phase

- \( t_{\text{st}} \) :

-

Time taken from end of cutting phase to end of cycle

- \( t_{\delta } \) :

-

Dwell time between cuts

- \( T, \;T_{ \hbox{max} } \) :

-

Strip thickness and maximum allowed strip thickness

- \( t_{\text{c}} \) :

-

Cycle time for a single cut

- \( V_{\text{l}} \) :

-

Line speed, m/min

- \( V_{C} (t) \) :

-

Tangential velocity of the knife cutting point (C)

- \( V_{\text{CC}} (t) \) :

-

Component of \( V_{C} \) in the direction of cut (knife penetration)

- \( V_{\text{CM}} (t) \) :

-

Component of \( V_{C} \) in the direction of strip travel

- \( x_{1} (t),\;y_{1} (t) \) :

-

Knife holder instant center coordinates (Z)

- \( x_{2} (t),\;y_{2} (t) \) :

-

Coordinates of the pin joint of knife holder and rocker arm (R)

- \( x_{3} (t),\;y_{3} (t) \) :

-

Coordinates of the pin joint of knife holder and crank (Q)

- \( x_{4} (t),\;y_{4} (t) \) :

-

Knife cutting point coordinates (C)

- \( \alpha (t) \) :

-

Crank angular displacement

- \( \alpha_{l1} ,\;\alpha_{l2} \) :

-

Crank angular displacement with linear time–velocity relationship, before and after the end of cut

- \( \alpha_{\text{c}} ,\;\alpha_{\text{cm}} \) :

-

Crank angular displacement during cut for thicknesses \( T \) and \( T_{\hbox{max} } \)

- \( \beta (t) \) :

-

Rocker arm angular displacement

- \( \delta \) :

-

Angle between knife holder link and cutting face

- \( \sigma (t) \) :

-

Angle between the knife cutting face and positive X-axis

- \( \theta (t) \) :

-

Angle between \( V_{\text{C}} \) and the positive X-axis

- ω(t):

-

Crank angular velocity

- \( \omega_{1} (t) \) :

-

Rocker arm angular velocity

- \( \omega_{2} (t) \) :

-

Knife holder angular velocity about the instant center

- \( \omega_{\text{cs}} ,\;\omega_{\text{cf}} \) :

-

Crank angular velocity at the start and finish of actual cut

- \( \omega_{{{\text{cl}}1}} , \;\omega_{{{\text{cl}}2}} \) :

-

Crank angular velocities at the beginning and end of cutting phase

References

H. Malinowski, Finishing lines for hot Strip and plate, SMS Schloemann-Siemag Aktiengesellschaft (1985)

A.I. Tselikov, V.V. Smirnov, Rolling Mills, Chap III (Pergamon Press, Oxford, 1965)

P. Polukhin, N. Fedosov, A. Korolyov, Y. Matveyev, Rolling Mill Practice (Peace, Moscow, 1964), pp. 314–316

C. Tao, H. Yaping, Z. Jingpeng, Solid modeling and optimization design of crank rocking flying shear. Appl. Mech. Mater. 608, 7–13 (2014)

Y.M. Ding, in Design and Study on Crank Flying Shear, https://www.globethesis.com/?t=2181330422471075. Accessed 10 Oct 2018

Kinematics and Blade Clearance Analysis of Crank Rocker Flying Shear. Chen Jie. www.cnki.com.cn/Article_en/CJFDTOTAL-ZXJX201301012.htm. Accessed 10 Oct 2018

H. Baruh, Analytical Dynamics (McGraw-Hill, New York, 1999), pp. 200–202

N. Repanich, Introduction to Motor Sizing, pp. 1–3. www.mechatronicscenter.com. Accessed 10 Oct 2018

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghosh, K. A Study on Kinematic Analysis of Crank-Type Flying Shear Mechanism for Production-Oriented Design and Motion Control. J. Inst. Eng. India Ser. C 100, 851–858 (2019). https://doi.org/10.1007/s40032-018-0495-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40032-018-0495-x