Abstract

Research-based education is a long-standing tradition at the University of Tartu (UT). Basic knowledge of electrochemistry and the principles of developing electrochemical devices have been taught and implemented at UT since 1960. For instance, during then, self-made alkaline electrolysers were used to generate hydrogen. The hydrogen was further purified and used to saturate aqueous and non-aqueous electrolytes. The fundamental electrochemical research has formed a solid background on which the development of supercapacitors and Na+-ion or Li+-ion batteries is based today. Since 1991, the Ph.D., MSc and undergraduate students have investigated the properties of high surface–area carbon materials in non-aqueous electrolytes to develop energy conversion and storage devices with high energy and power density. Moreover, porous thin-film complex metal hydride–based hydrogen storage devices are also under study. The research of solid oxide fuel cells (SOFC) and polymer electrolyte membrane fuel cells (PEMFC) began at the UT in 2001 and 2010, respectively. Based on the collected knowledge, a sustainable green electricity and hydrogen generation-storage complex (GEHGSC) was constructed, consisting of solar cells and fuel cells for electricity generation, batteries for storage and electrolysers for hydrogen generation. The main aim of GEHGSC is to educate students, young scientists and local authorities specialized in sustainable energy technologies and applied electrochemistry. Electrolyzed hydrogen has been used for experimental testing of SOFC and PEMFC, produced at the Institute of Chemistry. The 300 bar hydrogen compressor has been installed, and thereafter, the PEMFC-powered self-driving car Iseauto, completed by contract for Auve Tech OÜ, has been fuelled with hydrogen produced by GEHGSC.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

European Union’s (EU) transition to a decarbonized sustainable energy community is underway [1,2,3,4,5]. All EU member states have ratified the Paris Agreement to keep global warming “well below 2 degrees of Celsius above preindustrial level” [1]. In 2018, Estonia joined the Linz Hydrogen Initiative [3]; in 2019, the European Green Deal [4], along with other EU’s clean industry initiatives [5,6,7]. Thus, the planned energy transition is fundamental and thus sometimes recognized as the 4th technology revolution, impacting all areas of human activities: transport systems, traditional and novel industries, chemical and biochemical industry, space and shipping technology and CO2-free central and local heating systems.

Global warming and air pollution in densely populated areas of the world are partially caused by fossil fuel–based central heating and transport systems producing large amounts of CO2 equivalent, including NOx, SOx, volatile organic compounds (VOC), nanoparticles (NP) and other pollutants [6]. The COVID-19 lockdown demonstrated the significant role of local fossil fuel–based traffic and old-fashioned heat and electricity generation enterprises in producing CO2, NOx, SOx, VOC and NP [8,9,10,11]. It should be stressed that in the regions where air contamination is very high or even critical, there are more illnesses such as asthma, allergy and COVID-19. Based on reports in the European Union, more than 300,000 premature deaths occurred in 2020 due to highly polluted air [12, 13]. At the same time, the combined effects of ambient and household air pollution are associated annually with 6.7 million premature deaths worldwide, according to World Health Organization, thus leading to substantial economic losses [14].

Estonia has a complicated industrial background from the Soviet Union. Namely, a large-scale oil shale industry was built after the Second World War in the North-East of Estonia not only to cover Estonia’s needs but also for the Soviet Union. Thus, in 1990, before the regaining of independence, 1007 g of CO2 equivalent was produced to generate 1 kWh of electricity [15]. It should be stressed that even today, Estonia generates vast quantities of CO2 along with other greenhouse gases (656 g of CO2 equivalent per 1 kWh of electricity) compared with the EU27 average (238 g/kWh, 2021 data)) [15]. This is mainly due to using oil shale to generate thermal heat for electricity. The oil shale consists of different organic and inorganic compounds containing carbonates, sulphur (organic and inorganic), nitrogen and oxygen, which form SOx, NOx and VOC and COx, as well as various NPs during the burning process [16, 17]. To reach the set target of reducing the emissions of greenhouse gases by 70% with respect to the level of 1990 by 2030 [18], Estonia must dramatically decrease greenhouse gas generation.

In addition, Estonian cars are, on average, nearly 4–5 years older (16.8 years old) than in more developed European countries [19]. Furthermore, a significant proportion of cars in Estonia are older diesel engine–based cars, generating vast quantities of NOx and unreacted VOC compounds and NPs. Based on the EASAC Report, 24% of greenhouse gases generated in the EU are caused by fuel combustion in the transport sector [6]. This number is most likely somewhat higher for Estonia, considering the abovementioned tendencies.

After long-lasting discussions, there has been noticeable progress during the last few years, and Estonia has joined various EU hydrogen and sustainable energy regulations [1,2,3,4,5,6,7, 20, 21]. The first complex (GEHGSC), combining photovoltaic electricity generation/storage, hydrogen electrolysis and pressurized storage, and the regeneration of electricity and heat, has been completed at the University of Tartu (Fig. 1) [22]. Ph.D. students and research fellows converted the self-driving car IseAuto [23] to a hydrogen-powered fuel cell car (Fig. 2), and more next-generation vehicles are under development. At the same time, the University of Tartu joined European Hydrogen and Fuel Cell Technology Platform (HFP) in 2019. Furthermore, Estonia has been included in the large-scale international Bothnia backbone hydrogen network proposed by Sweden and Finland [24] and has accepted the TEN-T corridors map calling for the application and refilling of hydrogen fuel cell-based transport vehicles by 2030 [25]. Additionally, Estonian companies, in cooperation with UT, founded Hydrogen Valley Estonia in 2022 [26].

Thus, considering the call for more sustainable technological solutions and the intense interest from Estonian companies, the curricula of electrochemical studies at the University of Tartu at both undergraduate and graduate levels have been continuously updated to meet the demand and solve relevant challenges whilst focusing on science-based teaching methodology.

Development of high-tech sustainable energy devices and teaching of students

Fundamental background for the development of modern devices

The development of electrochemical devices at UT has a long history as the university’s first rector, G. Parrot, did electricity generation experiments with voltaic pile from 1805 to 1807 [27]. Years later, the father of physical chemistry, W. Ostwald, studied chemistry at UT and obtained his Ph.D. in physical chemistry in 1878. He described the basic principles of thermodynamics of fuel cells from 1896 to 1899, when he was a professor at the University of Leipzig. W. Ostwald was awarded the Nobel Prize in chemistry in 1909 for his work on catalysis, chemical equilibria and reaction rates defining the theoretical background of electrochemical and catalytic processes in fuel cells and electrolysers [28, 29]. He was also a pioneer of sustainable hydrogen energy, formulating the concept of sustainable “green energy”.

In the 1950s and 1960s, the research on fundamental electrochemistry and hydrogen-powered alkaline fuel cells was re-established at the UT Department of Chemistry [30]. In 1961, the first complex alkaline fuel cell development at UT was carried out by Prof. V. Past, J. Raudsepp et al., including the participation of graduate and undergraduate students, but the group perished at the beginning of 1970 [31].

Since 1991, Estonian universities have followed the science-based teaching model. Thus, in addition to traditional lectures, seminars and lab classes, the students must conduct novel scientific research to solve relevant research problems already at the bachelor’s level. The extent of the conducted research during the curriculum is reflected by the awarded credit points, being 12, 30 and 180 ECTS for BSc, MSc and Ph.D. thesis, respectively [32]. In contrast with the state-of-the-art research, the lectures are based mainly on traditional subjects and topics in mathematics, physics, chemistry and materials science to establish a firm understanding of fundamental principles. In addition to traditional subjects, more specialized courses can be taken by students at different levels interested in electrochemistry (fundamental electrochemistry, applied electrochemistry and electrochemical kinetics), materials science or sustainable green energy technologies. These courses offer insight into the latest developments of given topics, including modern energy devices (electrochemical capacitors, batteries, fuel cells) and characterization techniques (operando synchrotron beam and neutron scattering methods). For the training of Ph.D. and outstanding MSc students, the doctoral school “Graduate School of Functional Materials and Technologies” was established in 2009 [33]. In principle, all Ph.D. students are welcome to participate in the scientific conferences of the doctoral school, where the students present oral presentations and posters based on their original research. In addition, every year, at least one summer school (but usually also a winter school) has been organized, where internationally well-known scientists teach Ph.D. and MSc students in different fields of sustainable green energy technology and materials science, as well as applied and fundamental electrochemistry.

Ph.D. and MSc students are also involved in the “Estonian Centre of Excellence in Science: Advanced Materials and High-technology Devices for Sustainable Energetics, Sensorics and Nanoelectronics” scientific work, supported by the European Regional Development Fund. This has provided them with an excellent platform to conduct research and participate in scientific conferences with reports and presentations. Although it is required that at least 3 papers, indexed by the Web of Science, must be published during Ph.D. studies, it is common that Ph.D. theses are based on 5–6 papers. Furthermore, some MSc and Ph.D. students (Ph.D. R. Palm, Ph.D. R. Härmas, MSc L. Kalder, MSc M. Koppel, etc.) have had the opportunity to actively participate in the development of novel characterization methods in the European Spallation Source II project, contributing to the design of the special operando electrochemical cells that is essential for conducting small-angle, wide-angle, quasi-elastic and inelastic neutron scattering measurements. Intensive cooperation with various world-leading neutron research centres (PSI, HZB, ISIS, J-Park, SNS, ILL, etc.) and scientists is essential to Ph.D. studies at UT. The cooperation with synchrotron radiation centres (MaxLab II and MaxLab IV, Bessy, Desy, PSI, ISIS, J-Park, etc.) has been used for training the Ph.D. students on synchrotron beam–based operando electrochemical methods.

Nowadays, many Estonian companies are interested in developing sustainable energy devices and complex hydrogen technologies that are based on the fundamental and small-scale applied science/devices studies, conducted by MSc and Ph.D. students alongside research fellows at UT. Therefore, the so-called industrial Ph.D. positions have been introduced for more industry-oriented research, where technological novelty is emphasized. In addition, lifelong learning has gained popularity in Estonia. To keep up with the trends and to increase the knowledge of modern energy technology and applied electrochemistry of a wider audience, the course and complimentary lab classes focusing on sustainable energy complexes and devices for green energy management have been prepared [34]. The lectures are given by enthusiastic young research fellows, as well as by 3rd and 4th year Ph.D. students as a part of their curriculum. They are very popular among engineers, system designers, local authorities, and even small-business representatives. Over 600 people have taken the course during three semesters, and 235 currently participate in the study process. Unfortunately, lab classes can be offered to selected participants due to the lack of resources. Based on the feedback of the students who passed the exam, we have started developing a new advanced course for training lifelong learning students at a more advanced level [35]. In addition to classes on sustainable energy complexes and devices for green energy management, there are other courses such as registration, evaluation authorization and restriction of chemicals (REACH) course and a special course for chemistry teachers.

To provide detailed demonstration of the science-based teaching at UT Institute of Chemistry (UTIC), some case studies will be followingly discussed. It should be noted that for thorough training of MSc and Ph.D. students, many topics will be conducted from fundamental to applied electrochemistry level. Due to limited space, only selected Ph.D. theses will be characterized.

Ph.D. studies in the field of fundamental and physical electrochemistry: the basis for applied electrochemistry projects

Since 1991, multiple Ph.D. theses have summarised systematic studies of electrical double layer (EDL) and adsorption at model electrode surfaces. The adsorption of organic compounds was the focus of Ph.D. thesis of A. Jänes [36], while the decisive role of the electronic characteristics of electrode metals has been demonstrated in [37,38,39,40,41,42,43,44], which formed a part of Ph.D. K. Lust’s thesis [45], studying the adsorption of anions on bismuth single-crystal electrodes. Complicated adsorption kinetics and the mechanism of organic compounds at single-crystal bismuth electrodes [46, 47], determining the supercapacitors’ characteristics, have been established during the studies of Ph.D. G. Nurk [48] and later by Ph.D. H. Kasuk [49]. Comparison of our data with the published data for Hg, Au(hkl), Cu(hkl), Ag(hkl), Ni(hkl), Zn(hklf) and other electrodes [50,51,52,53,54,55,56,57,58,59] demonstrates the decisive role of adsorbate (neutral aliphatic, aromatic and hetero-aromatic organic molecules) and electrolyte chemical composition and properties, along with the electrode’s crystallographic structure and characteristics (metallic or semi-metallic electronic structure, surface roughness) on the adsorption [60, 61]. Adsorption kinetics of ions at metal electrodes from aqueous and ionic liquid solutions has been demonstrated by Ph.D. L. Siinor [56, 62], defending her Ph.D. thesis in 2010 [63].

Ph.D. T. Romann has demonstrated a more detailed analysis of metal surface characteristics on the EDL parameters in his dissertation [64], where the semi-metallic nature of thin-film and porous bismuth layers has been established by impedance and Raman spectroscopy, atomic force microscopy and other methods [57, 65]. In dissertations by Ph.D. S. Kallip [66], Ph.D. V. Grozovski [67], Ph.D. E. Anderson [68] and Ph.D. P. Pikma [69], the atomic resolution level adsorption studies have been widened for other high hydrogen evolution overpotential metal electrodes, adsorbates and electrolytes such as ionic liquid [62, 70,71,72,73]. These works have enabled the current Ph.D. studies of MSc H. Ers, focusing on the ionic liquid interfacial behaviour as well as the adsorption of bipyridine from ionic liquids, illustrated in Fig. 3. These studies allow assessing the impact of the electrolyte on the organic’s adsorption as well as providing fundamental insights of the electrode-ionic liquid interface [74,75,76]. Strong adsorption of thiourea at Bi(hkl) has been discussed by Ph.D. V. Grozovski and Ph.D. S. Kallip, and specific adsorption that has been discussed for many years was verified [77]. Ph.D. C. Siimenson [78] demonstrated that halide adsorption from ionic liquids is similar to halide adsorption from aqueous and non-aqueous electrolyte mixtures [79, 80], completing Ph.D. studies in 2016. Systematic comparison of data for Bi(hkl), Sb(hkl) and Cd(hklf) with data for Au(hkl), Ag(hkl), Ni(hkl) and Pt(hkl) [81,82,83,84,85,86,87] demonstrated that chemical nature, reticular density of electrode surface and electronic characteristics have very well expressed influence on the adsorption kinetics, surface coverage and region of ideal polarizability of electrodes under study. For a more detailed fundamental understanding of EDL structure at the electrode surface [88,89,90,91,92,93], detailed computer simulations have been conducted during the Ph.D. studies of Ph.D. V. Ivaništšev [94] and Ph.D. A. Ruzanov [95], based on the developments of aforementioned experimental works.

Electrochemical kinetics at Bi and Cd single-crystal electrodes

Hydrogen evolution and electroreduction kinetics of complex anions (S2O8)2− and [Fe(CN)6]3− and complex cations [(Co(NH3)6]3+ and Eu3+ cations have been studied by Ph.D. K. Lust, Ph.D. T. Thomberg, Ph.D. R. Jäger, Ph.D. E. Monerjan (née Härk) and Ph.D. J. Nerut [96,97,98,99,100]. The very complicated (S2O8)2− reduction kinetic mechanism has been observed for Cd(hklf) as well as on Bi(hkl) in Ph.D. theses of Ph.D. T. Thomberg [101] and Ph.D. R. Jäger [102], respectively. Electroreduction of hexacyanoferrate(III) anion on Cd(0001) single-crystal electrode [100] has been studied by Ph.D. J. Nerut [103]. Electroreduction kinetics of [(Co(NH3)6]3+ and Eu3+ cations have been analysed by Ph.D. E. Monerjan during her studies [104]. It was established that the electroreduction parameters depend on the electrode surface’s metal electronic characteristics and crystallographic structure (including surface roughness). A more complicated reaction mechanism has been established for (S2O8)2−and for [Fe(CN)6]3− anions at sp-metal electrodes, which is probably caused by the strong adsorption of reaction intermediates. Thus, some differences and deviations from the classical conception and agreement with modern theories developed and discussed by Damaskin et al. [105], Samec et al. [106] and Nazmutdinov et al. [107] have been demonstrated. The influence of electrode metal and crystallographic structure was also studied by Ph.D. V. Grozovski, analysing oxygen electroreduction at shape-controlled Pt nanoparticles and composite catalysts, i.e. on Pt(100) nanocubes deposited onto micro-mesoporous carbon supports [108].

Complex studies of carbon materials and electrical double layer and hybrid capacitors

Electrical double-layer capacitors (EDLC) are energy storage devices that accumulate the energy in an electric field formed at the electrode–electrolyte interface. Capacitors are used as short-pulse power devices due to their high power densities, while batteries with high energy densities can provide electricity for extended periods of time. The main difference between supercapacitors and batteries is that the cell potential for batteries is nearly constant during discharging, while there is a nearly linear decrease of cell potential during discharging of EDLC.

In 1993, Ph.D. and MSc students started systematically studying high surface area micro-meso-macroporous (MMP) carbon materials and supercapacitors at UTIC. Some years later (in 1997), Tartu Technologies Ltd. began the development of supercapacitors with the participation of scientists of the UT Institute of Physical Chemistry, with the main aim of completing high surface area supercapacitors based on non-aqueous electrolyte solutions [109,110,111,112,113,114,115]. A comparison of data with the results by other well-renowned scientific groups [116,117,118,119,120,121,122] has been made, and the reasons for the influence of pore size distribution on the characteristic time constant values and the power density have been analysed. Many completed MSc and two Ph.D. (Ph.D. M. Arulepp [123] and Ph.D. M. Lätt [124]) works have focused on MMPs, based on the cooperation with Tartu Technologies. From 2005 to 2009, the company was reorganized. Nowadays, Skeleton Technologies OÜ continues the development of supercapacitors, being one of the world’s leading producers of supercapacitors. The company was awarded the European innovation prize in 2018 and European Inventor Award in 2022 [125, 126].

In parallel, studies of carbon materials have been conducted in UTIC [109,110,111,112,113,114,115, 127,128,129,130]. Using the very attractive MMP carbons prepared from binary carbides, the ionic-liquid-electrolyte–based capacitors have been studied in Ph.D. thesis by Ph.D. H. Kurig [131]. Na+-ion–based electrolytes have been studied by Ph.D. A. Laheäär [132]. Later, the MMP carbons were prepared from ternary carbides and applied in Ph.D. studies by Ph.D. I. Tallo [133].

The influence of ionic liquid chemical composition on the electrolyte-based capacitors’ power density, characteristic time constant and dependence on carbon micro-meso structure has been analysed by Ph.D. O. Oll [134, 135] in his dissertation [136]. The influence of ionic liquids containing Cl−, Br− and I− anions on the energy and power density characteristics, relaxation time and imaginary and real power density values [137] has been demonstrated by Ph.D.. J. Zhao [138]. Ph.D. student E. Tee modified the MMP carbons using CO2 and H2O as chemical activators to increase SiC-based carbon materials’ total porosity [139,140,141].

Follow-up investigations of MMP carbons prepared from D-glucose, white sugar and Estonian well-decomposed peat have been started [142,143,144,145]. MSc student T. Tooming and Ph.D. M. Härmas prepared porous carbon materials from d-glucose and white sugar that were chemically activated with ZnCl2 or ZnCl2 + KOH mixture [145,146,147,148]. Ph.D. M. Paalo (née Pohl) synthesised mesoporous carbons by sol–gel method and obtained extremely high power densities and very short characteristic relaxation times in EDLC using ionic liquids as electrolytes [149,150,151]. For the application of carbon electrodes within an extremely wide potential region, the diamond-like carbon thin-film electrodes, prepared by pulsed laser deposition methods, have been studied by Ph.D. J. Eskusson, who defended his dissertation in 2009 [152]. The main disadvantage of these materials was the low electrical conductivity of the prepared thin-film electrodes [153]. The relation between energy (E) and power density (P) of selected synthesised materials is demonstrated as Ragone plots in Fig. 4, highlighting the trade-off between energy capacity and power. This trade-off is caused by the different nature of energy storage — one arising from the electrostatic interactions at the interface (high P), while the other arises from the reversible chemical reactions (high energy density). The E of the EDLC can be estimated using the relation E = C(ΔE)2/2, where C is the capacitance and ΔE is the maximal potential of the cell. The P can be calculated from P = (ΔE)2/4RS, where RS is the equivalent series resistance, obtained from impedance complex plane plots (Nyquist plots) at frequencies approaching infinity.

Ragone plots for different synthesised carbon materials measured in EMImBF4 ionic liquid and 1 M Et3MeNBF4 in acetonitrile (AN) electrolyte, discussed in detail in Refs. [143, 145, 150, 154, 155]. The materials are microporous carbon derived from commercially available TiC (microporous TiC-CDC), d-glucose-derived carbon (GDAC), MMP d-glucose-derived carbon (MMP GDAC), steam-activated carbon derived from SiC (Steam SiC-CDC), carbon derived from granulated white sugar (GWS carbon), and peat-derived carbon

To optimize energy and power density characteristics, self-made nanowire polymer separators have been prepared by Ph.D. T. Thomberg and Ph.D. K. Liivand (née Tõnurist) for aqueous and dry non-aqueous electrolytes, discussed in [156,157,158,159], along with a granted patent [160]. It was demonstrated that the electrospinning conditions determine the membrane meso- and macroporosities influencing the characteristic relaxation time and very high–frequency series resistance values of EDLC. Thus, the separator properties mainly determine the EDLC power density values but moderately influence the energy density values.

Development of Na+-ion battery materials and single cells

Micro-mesoporous carbons have been prepared from d-glucose solution and used for the development of Na+-ion batteries discussed in the dissertation of Ph.D. R. Väli [161], demonstrating very high capacity values of negatively charged electrodes in the mixtures of NaPF6 and NaClO4 dissolved in methyl carbonate, propylene carbonate and diethyl carbonate [162, 163]. Later, the Estonian peat-derived carbons demonstrated very high capacities if applied as the negatively charged electrode of Na+-ion battery [164]. A detailed comparison with the results of other authors [165,166,167,168] demonstrated that the negatively charged carbon electrode prepared from Estonian well-decomposed peat has very high energy and power density. Nowadays, different carbon powders employed as negatively charged Na+-ion battery electrode materials (illustrated in Fig. 5), synthesized from different Estonian raw materials (well-decomposed peat, lignin, etc.), are under systematic study by Ph.D. student MSc A. Adamson and MSc student A. Olgo [164]. The specific capacity is shown relative to the mass of active compound to highlight the possible applications of given materials in electric vehicles. The analysis of the influence of carbon electrical conductivity, graphitization level, specific surface area and the ratio of micro-meso-macroporosity on the energy collection efficiency and cyclability of electrodes and devices, i.e. Na+-ion batteries, will continue.

Charge-discharge curves for lignin-derived hard carbon and Prussian blue analogue electrode materials for constant current method measured at 0.1 C at two electrode half-cells using 1 M NaClO4 solution in a 1:1 EC/DEC as an electrolyte, along with the SEM images of corresponding electrode materials. The anode/cathode capacity at a constant potential scan rate is estimated using the relation Q = ∫(I(t)/mactive)dt, where I, t and mactive are applied current, time at a given point and weight of active material in the electrode, respectively

Development of hydrogen storage materials and systems

Safe and energy-efficient hydrogen storage is one of the bottlenecks for wide-scale hydrogen application in small-scale and local energy complex systems. Therefore, the CH4 and H2 adsorption characteristics of micro-mesoporous carbon materials were under very intensive study at UTIC [169,170,171] by Ph.D. R. Palm during his Ph.D. studies [172]. The data collected agrees with the data discussed in the works [173,174,175]. To increase the amount of adsorbed H2 and adsorption/desorption rate, thin-film metal hydrides like NaAlH4/carbon-composite-based systems (demonstrated in Fig. 6) are under study [173]. NaAlH4 has a theoretical hydrogen storage capacity of 5.5% at 250 °C [176]. In the best-case scenario, hydrogen storage in NaAlH4 at room temperature can result in an H2 density similar to liquid hydrogen at − 253 °C. The main challenge of storing H2 in NaAlH4 has been reversibility. However, hydrogen storage is nearly reversible in thin-film metal hydrides deposited onto micro-meso-macroporous carbon supports. Therefore, the H2 storage in the metal hydrides can be a more sustainable way to store H2 in comparison with the liquefication of hydrogen, which requires a significant amount of energy [169,170,171]. The critical advantage of thin-film complex metal hydrides is that they are relatively safe hydrogen storage materials/devices that can be transported in the loaded form at normal temperature and pressure. The scaling-up stage of these devices by Ph.D. student MSc K. Tuul is under finalization during the following years.

Detailed analysis of the influence of the carbon porosity, pore size distribution, graphitization level, curvature of the graphitic layers, the linear dimension of graphitic regions, the thickness of graphitic areas, etc. have been analysed by small-angle, quasi-elastic and inelastic scattering methods in addition to gas adsorption analysis, including state-of-the-art calculation methods of gas adsorption parameters [177,178,179,180,181]. The influence of the raw material synthesis temperature and activation parameters on the carbon material pore shape has been established [177, 180], demonstrated in Fig. 7. These results have been summarised by Ph.D. R. Härmas [182]. Current Ph.D. students MSc M. Koppel and MSc L. Kalder are conducting studies by neutron scattering methods, investigating the role of pore wall surface corrugation on the hydrogen storage kinetics and adsorption parameters [181].

Development of porous carbons as catalyst supports and polymer membrane fuel cells characteristics

The polymer electrolyte membrane fuel cell studies were started by research fellows Ph.D. J. Nerut, Ph.D. R. Jäger and Ph.D. E. Monerjan in 2010–2012. The main aim was to systematically analyse the influence of the carbon micro-meso-macroporous structure, prepared from binary and ternary carbides [184,185,186,187,188], on the PEMFC single cells’ power densities and long-term polarisation stability. It was demonstrated that the partial graphitization of the surface regions of carbon particles is extremely important for the high catalytic activity of oxygen electroreduction rate and kinetics. Based on the collected information, the Ph.D. theses by Ph.D. K. Vaarmets and Ph.D. S. Sepp have been completed [189, 190]. In addition to carbides, d-glucose-derived carbon materials as Pt supports (MSc work by M. Taleb) have been studied at UT [191]. High current densities have been demonstrated in published papers [191, 192].

To decrease the demand for Pt-metals in PEMFCs, lower the price of the final product and help to reach the high number of fuel-cell-powered vehicles needed by 2050, the Pt-metal-free PEMFC studies were started in 2015, using Fe-Nx and Co-Nx catalytic centres deposited onto carbide-derived carbon (CDC) supports. MSc student P.-E. Kasatkin prepared PEMFCs based on Pt-metal-free Fe–N/C silicon carbide–derived carbon-supported catalysts [193, 194]. Micro-mesoporous carbon supports from Estonian well-decomposed peat [195] (Ph.D. studies by P. Teppor) and chromium-carbide-derived Pt–activated catalysts [196] (MSc H.Q.V. Nguyen) have been investigated. Future studies for preparing higher power density Pt-free PEMFC are ongoing. In the short term, the catalytic activity of Fe–N/C catalysts has been observed to decrease moderately; however, under long-lasting polarisation at high current densities, quick degradation has been established [193, 197]. The carbide-derived carbons, supporting catalysts with low Pt-metal content, are more stable [198,199,200]. However, during the following years, further increase in current and power density is inevitable to achieve the recommendations and standards by the US Department of Energy for the year 2030.

Based on the collected knowledge and experience, the 1.1, 1.2, 3.6 and 5.0 kW PEMFCs have been developed during 2019–2021; see Fig. 8. These PEMFCs have been installed onto the PEMFC-powered self-driving car Iseauto under the contract with Auve Tech OÜ [23]. The official demonstration of self-driving hydrogen-powered car took place on July 5, 2021. During the coming months, a systematic analysis of self-driving PEMFC-powered car sustainability and energy efficiency parameters will take place. For demonstrating the hydrogen energy solutions and the possibilities of fuel cell usage at homes, the fuel cells completed at UT have been used for powering the coffee and pancake machines.

Polarization curves (hollow) and power density curves (filled) measured for various PEMFC single cells demonstrating continuous improvements achieved throughout the self-driving hydrogen bus project. The power and current densities are given relative to the area of the PEMFC electrode to highlight the improvement of the developed materials

For the development of direct methanol fuel cells, the micro-mesoporous carbons activated by Pt nanoclusters deposited onto CeO2 and Pr6O11 have been synthesized by Ph.D. students MSc P. Valk and MSc H.Q.V.Nguyen alongside co-workers [201,202,203]. A very high methanol oxidation rate has been observed in comparison with other published results [204,205,206], demonstrating that the CDC can be used as supporting electrode materials for high-activity direct methanol fuel cells.

Development of electrode materials for solid oxide fuel and electrolysis cells

Estonian company Elcogen OÜ started scientific cooperation with the UT in 2001. The main aim of the cooperation is to develop the synthesis of materials for so-called medium temperature (500–650 °C) SOFC, using ceria-based electrolytes and activated perovskite-type cathodes, like La(1−x)SrxCoO3−δ, Pr(1−x)SrxCoO3−δ and Gd(1−x)SrxCoO3−δ (see Fig. 9a, b) [207,208,209,210,211,212]. Based on the information published in the literature [213,214,215,216,217,218,219,220], two types of SOFC have been developed. At UTIC, we are developing the planar SOFC completed and tested by Ph.D. and MSc students supervised by Ph.D. G. Nurk.

First SOFCs based on the Ni-metal nanocluster (Ni-cermet) activated anode, Ce(1−x)GdxO2−δ or Ce(1−x)SmxO2−δ electrolyte and La(1−x)SrxCoO3−δ, (or Pr(1−x)SrxCoO3−δ) cathode have been completed [207,208,209,210,211]. These cells have been tested using hydrogen generated by the electrolyser installed in sustainable green electricity and hydrogen generation-storage complex in Chemicum (see Fig. 1), which has largely been completed by MSc R. Kanarbik. In 2005, after intensive studies, patent applications (US and WO, Russian Federation and Estonian) were completed and finally granted in 2007 [221]. At the time being, Elcogen OÜ is one of the world’s leading SOFC stack producers, having received the European Union innovation prize in 2019. Ph.D. student P. Möller participated in studies and defended Ph.D. on the electrochemical characterization of selected cathode materials for medium temperature solid oxide fuel cells, synthesized by solid-state reaction technique [208,209,210,211,212, 222].

a Unit cell of perovskite structure; b the illustration of solid-oxide hybrid cell, working in fuel cell or electrolysis mode; c power density vs current density plots for Ni-Zr0.92Y0.08O2−δ | Zr0.92Y0.08O2−δ | Ce0.9Gd0.1O2−δ | Pr0.6Sr0.4CoO3−δ single cell at working temperatures, discussed in detail in [225]; d cell potential vs current density (scan rate 5 mV s–1) and power density vs current density curves of the fuel cells implementing La0.21Sr0.37Ca0.37Ti0.95Fe0.05O3−δ (LSCTF) and La0.25Sr0.25Ca0.4Ti0.95Ni0.05O3−δ (LSCTN) ceramic anodes at 850 °C in 97% H2 and 3% H2O atmosphere

Ph.D. R. Küngas during his MSc studies, systematically analysed the dependence of micro-mesostructure of powders, porosity and pore size distribution on the synthesis parameters as well as on the chemical composition of the cathode [209, 210] and demonstrated the dependence of the micro-mesoporosity and crystallographic parameters on the synthesis temperature and pore former concentration. It was summarised that the electroreduction kinetics of oxygen depends strongly on the chemical composition of the cathode. In general, a high concentration of oxide ion vacancies leads to high electrode electrocatalytic activity. Concurrently, the electrode stability decreases with the increase in oxide ion vacancies. Because of that, the concentration of vacancies (dependent on the A-site deficiency, nature of B-site cations etc.) should be carefully controlled to avoid the decomposition of the perovskite structure of the electrodes. At constant chemical composition and electrode potential, the specific surface area, micro- and mesoporosity determine the electrocatalytic activity of the cathodes [223]. Therefore, these parameters must be fine-tuned during the synthesis step.

In 2009, as a Ph.D. student, Ph.D. I. Kivi varied the A-site cation of A1−xSrxCoO3−δ (A = La3+, Pr3+4+, Gd3+) SOFC cathode and systematically studied the influence of porosity on the cathode activity in the case of La1−xSrxCoO3−δ and defended Ph.D. thesis [224]. Very high current densities for completed SOFC single cells have been measured by Ph.D. student MSc R. Kanarbik and demonstrated in Fig. 9c, where it is visible that the mobility of oxide ions in ceramic material along with the diffusional processes of gases in micro-meso-macroporous electrode structure is thermally activated [225].

Ph.D. K. Lillmaa (née Tamm), as a Ph.D. student in cooperation with the Pennsylvania State University SOFC development group led by Prof. R. Gorte, introduced the method for the impregnation of mixed-conductive cathode and anode materials into the porous electrolyte matrix and prepared active electrodes [226, 227] during his Ph.D. studies [228]. At the same time, Ph.D. I. Kivi introduced the operando electrochemical high-temperature X-ray diffraction method for the studies of perovskite cathodes’ crystallographic structure and demonstrated that the expansion of cathodes depended on electrode polarisation and oxygen partial pressure [229, 230]. In cooperation with the Ph.D. R. Struis group at the Paul Scherrer Institute, the operando X-ray absorption near edge structure method was introduced by Ph.D. G. Nurk during his post-doctoral fellowship, analysing the sulphur poisoning processes at Ni-cermet SOFC anode [231]. Complicated redox dynamics of Ce- and Ni-based sulphur compounds have been demonstrated, depending on temperature and sulphur compounds in the gas phase. Ultrasonic spray pyrolysis deposition method of dense and low-defect thin electrolyte layers [232] has been established by Ph.D. M. Vestli in his Ph.D. thesis defended in 2016 [233]. Analysis of the cross-sections of membrane-barrier layer-electrode systems by using the TOF–SIMS method demonstrated good functionality of Ce0.9Gd0.1O2−δ barrier layers prepared using spray pyrolysis. However, the best suppression of Sr mobility was obtained when using a barrier layer prepared by the pulsed laser deposition method [234].

For straightforward applications of solid oxide technology devices, the medium temperature ceramic materials used in so-called reversible SOFC/SOEL single cells have been started by Ph.D. K. Lillmaa and continued by Ph.D. M. Maide during his Ph.D. studies [235,236,237,238]. The main aim of the development of fully ceramic complex oxides, replacing Ni-cermet and Co-cermet anodes for SOFCs/SOELs, is related to avoiding the additives such as sulphur, halides, silanes and other micro additions that form passivating layers at the Ni-nanoclusters or Co-cermet–based SOFC anode surface. This allows the absence of the deep cleaning step of biogas or wood gas with expensive cleaning technologies, including the application of microporous carbon filters used for the final cleaning of biogas or wood gas [231, 235, 236].

Systematic studies of electrochemical and crystallographic changes during the initial stabilization period of La0.75Sr0.25Cr0.5Mn0.3Ni0.2O3−δ, due to differences in Ni concentration on La0.25Sr0.25Ca0.4Ti1−xNixO3−δ, and the development of operando measurement techniques for the reversible solid oxide cell electrodes have been started by Ph.D. O. Korjus (defended Ph.D. in 2021) [239,240,241,242]. Detailed studies [243, 244] of the influence of CO2 concentration and humidity on the stability of (La0.6Sr0.4)0.99Co(1−x)TixO3−δ cathode have been conducted by Ph.D. A. Heinsaar. Post-doctoral fellow Ph.D. S. Paydar synthesized the very promising La0.2Sr(0.7−x)CaxTi0.95Fe0.05O3−δ fuel cell anodes and demonstrated very high stability of materials and single cells under study [245], with measurement results of selected similar materials given in Fig. 9d.

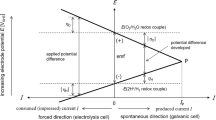

For a detailed fundamental analysis of processes at the cathode and anode electrodes under electrochemical polarization and gas-feeding conditions, the dual chamber near-ambient-pressure X-ray photoelectron spectroscopy (XPS) cell, connected with a synchrotron radiation beam-line, has been constructed by Ph.D. G. Nurk et al. [246]. It was demonstrated that applying the dual chamber cell configuration makes it possible to control precisely the oxygen partial pressure on the electrode analysed using NAP-XPS at elevated temperatures. Followingly, synchrotron-beam–based XPS measurements have been combined with impedance measurement methods, and a detailed discussion of electrochemical reaction parameters has been given by Ph.D. K. Kooser et al. [247]. In addition to fundamental studies discussed before, the industry-oriented Ph.D. student MSc F. Kukk is conducting research on the long-term stability of Ni-Zr0.92Y0.08O2−δ | Zr0.92Y0.08O2−δ | Ce0.9Gd0.1O2−δ | Pr0.6Sr0.4CoO3−δ single cell at SOFC and SOEC modes with the main aim to introduce the current cells into larger reversible SOFC/SOELs stacks [248]. This requires detailed analysis as the processes occurring at SOFC/SOEL regimes have different limiting steps. Furthermore, the gas gradients (H2, H2O) across the electrode vary, leading to different limiting stages with different activation energies and, thus, overvoltages in the selected regime. Precise overvoltage difference between SOFC and SOEL regimes is dependent on several components of the cell and therefore is very specific for each cell.

Considering the progress made in theoretical studies of solid oxide electrolyser materials and single cells, the high-temperature 300 W solid oxide electrolyser stacks have been completed and will be tested as a hydrogen generator using PV for electricity by the Estonian high-tech company H2Electro OÜ.

Conclusions

During 1991–1994 at the University of Tartu, the science-based BSc, MSc. and Ph.D. studies method was introduced. In addition to the regular physical chemistry, electrochemistry, materials science and green energetics lectures and lab classes, scientific-problem-based BSc, MSc and Ph.D. studies have been conducted. In 2020, the online course and lab classes for life-long learning were started. From 2014 to 2020, the UT participated in “Universities at Energy Transition” program, and currently, UT is participating in the work of “Hydrogen Europe Research” and “Hydrogen Europe” (industry) programs. Using this information, UTIC harmonized the main directions of modern green sustainable energetics studies and teaching directions.

For undergraduate and graduate students and post-doctoral fellows training, the PV electricity–based energy generation and hydrogen storage complex were completed between 2018 and 2020 at UT. This complex is necessary for training students, engineers and technicians, as well as for testing sustainable green energy devices prepared by undergraduate and graduate students alongside scientists at UTIC. The electrochemical and green energetics studies are supported by the Estonian Centre of Excellence in Science: Advanced materials and high-technology devices for energy recuperation complexes, sensorics and microelectronics and Graduate School of Functional materials and technologies. Mentioned programs have been indispensable for the training of bachelor, master, doctoral and post-doctoral students and for developing international research contacts. At the University of Tartu, 44 Ph.D. theses in the fields of fundamental and applied electrochemistry, materials science, sustainable green energy technologies and energetics have been defended since 2003, and many (more than 360) WoS papers have been published. Furthermore, there has been intense cooperation with local companies, as contracts with Elcogen OÜ, Auve Tech OÜ, H2Electro OÜ and Stargate Hydrogen Solutions OÜ, Eesti Energia AS, Elering AS, etc., have been fulfilled.

References

The Paris Agreement (2018) UNFCCC, Paris. https://unfccc.int/documents/184656. Accessed 11 Sept 2023

Report of the Conference of the Parties on its twenty-fifth session, held in Madrid from 2 to 15 December 2019 (2020) UNFCCC. Conference of the Parties, Madrid. https://unfccc.int/documents/210472. Accessed 11 Sept 2023

Informal meeting of energy ministers dedicated to hydrogen and energy storage solutions (2018) Austrian Presidency of the Council of the European Union 2018, Vienna. https://www.eu2018.at/latest-news/news/09-18-Informal-meeting-of-energy-ministers.html. Accessed 29 June 2023

The European Green Deal (2019) European Comission, Brussels. https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1588580774040&uri=CELEX%3A52019DC0640. Accessed 11 Sept 2023

The EU blue economy report 2020 (2020) European Commission, Directorate-General for Maritime Affairs and Fisheries, Joint Research Centre, Brussels. https://op.europa.eu/en/publication-detail/-/publication/83843365-c18d-11ea-b3a4-01aa75ed71a1/language-en/format-PDF/source-257506909. Accessed 11 Sept 2023

Decarbonisation of transport: options and challenges (2019) European Academies Science Advisory Council, Halle. https://easac.eu/publications/details/decarbonisation-of-transport-options-and-challenges/. Accessed 24 Jan 2023

A hydrogen strategy for a climate-neutral Europe (2020) European Commission, Brussels. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0301. Accessed 11 Sept 2023

Zhang R, Zhang Y, Lin H et al (2020) NOx emission reduction and recovery during COVID-19 in East China. Atmosphere 11. https://doi.org/10.3390/atmos11040433

Pansini R, Fornacca D (2021) Early spread of COVID-19 in the air-polluted regions of eight severely affected countries. Atmosphere 12. https://doi.org/10.3390/atmos12060795

Bourdrel T, Annesi-Maesano I, Alahmad B, et al (2021) The impact of outdoor air pollution on COVID-19: a review of evidence from in vitro, animal, and human studies. Eur Respir Rev 30. https://doi.org/10.1183/16000617.0242-2020

Le Quéré C, Jackson RB, Jones MW et al (2020) Temporary reduction in daily global CO2 emissions during the COVID-19 forced confinement. Nat Clim Change 10:647–653. https://doi.org/10.1038/s41558-020-0797-x

Health risk assessment of air pollution and the impact of the new WHO guidelines (2022) European Topic Centre on Human Health and the Environment, Kjeller. https://www.eionet.europa.eu/etcs/etc-he/products/etc-he-products/etc-he-reports/etc-he-report-2022-10-health-risk-assessment-of-air-pollution-and-the-impact-of-the-new-who-guidelines. Accessed 11 Sept 2023

Health impacts of air pollution in Europe (2022) European Environment Agency, Copenhagen. https://www.eea.europa.eu/publications/air-quality-in-europe-2022/health-impacts-of-air-pollution. Accessed 11 Sept 2023

World health statistics 2023: monitoring health for the SDGs, Sustainable Development Goals (2023) World Health Organization, Geneva. https://www.who.int/publications/i/item/9789240074323. Accessed 11 Sept 2023

Greenhouse gas emission intensity of electricity generation (2023) European Environment Agency, Copenhagen. https://www.eea.europa.eu/data-and-maps/daviz/co2-emission-intensity-13/#tab-chart_4. Accessed 27 June 2023

Aurela M, Mylläri F, Konist A, et al (2021) Chemical and physical characterization of oil shale combustion emissions in Estonia. Atmospheric Environ X 12:100139. https://doi.org/10.1016/j.aeaoa.2021.100139

Arro H, Prikk A, Pihu T (2003) Calculation of qualitative and quantitative composition of Estonian oil shale and its combustion products. Part 1. Calculation on the basis of heating value. Fuel 82:2179–2195. https://doi.org/10.1016/S0016-2361(03)00125-X

The basics of climate policy until 2050 (2017) Riigikogu, Tallinn. https://www.riigiteataja.ee/akt/307042017001. Accessed 11 Sept 2023

Vehicles in use, Europe 2023 (2023) European Automobile Manufacturers’ Association, Brussels. https://www.acea.auto/publication/report-vehicles-in-use-europe-2023/. Accessed 11 Sept 2023

Commission announces actions on Critical Raw Materials (2020) European Commission, Brussels. https://ec.europa.eu/commission/presscorner/detail/en/ip_20_1542. Accessed 24 Jan 2023

Hydrogen roadmap Europe: a sustainable pathway for the European energy transition (2019) Fuel Cells and Hydrogen 2 Joint Undertaking, Luxembourg. https://op.europa.eu/en/publication-detail/-/publication/0817d60d-332f-11e9-8d04-01aa75ed71a1/language-en. Accessed 11 Sept 2023

Development of first Estonian FC Car Iseauto and energy storage demo complex in Chemicum (2021) Estonian Hydrogen Association, Tallinn. http://h2est.ee/wp-content/uploads/2021/07/SC8_Development-of-first-Estonian-FC-Car-Iseauto-and-energy-storage-demo-complex-in-Chemicum-Rait-Kanarbik.pdf. Accessed 11 Sept 2023

Estonian first level 4 self-driving vehicle – ISEAUTO (2018) TalTech Autonomous Vehicles Lab, Tallinn. https://iseauto.taltech.ee/en/. Accessed 24 Jan 2023

European Hydrogen Backbone (2022) Guidehouse, Utrecht. https://ehb.eu/files/downloads/ehb-report-220428-17h00-interactive-1.pdf. Accessed 24 Jan 2023

H2NODES - Evolution of a European hydrogen refuelling station network by mobilising the local demand and value chains (2023) H2Nodes, Riga. https://www.h2nodes.eu/et/. Accessed 24 Jan 2023

Preliminary boundaries of the Hydrogen Valley scope (2022) Hydrogen Valley Estonia, Tallinn. https://vesinikuorg.ee/#Scope. Accessed 24 Jan 2023

Tohvri E (2019) Georges Frédéric Parrot : Tartu Keiserliku Ülikooli esimene rektor. University of Tartu Press, Tartu

Ostwald W (1896) Elektrochemie, Ihre Geschichte und Lehre. Verlag von Veit & Comp, Leipzig

The Nobel Prize in Chemistry 1909 (2023) Nobel Prize Outreach, Stockholm. https://www.nobelprize.org/prizes/chemistry/1909/ostwald/facts/. Accessed 24 Jan 2023

Palm U (1986) Development of the electrochemical investigations at Tartu State University. Acta Comment Univ Tartu 757:3–21

Past V (1986) Investigation of the kinetics of electrode processes at Tartu State University. Acta Comment Univ Tartu 757:22–33

Study Info (2021) University of Tartu Institute of Chemistry, Tartu. https://chem.ut.ee/en/node/113481. Accessed 25 Jan 2023

Doktorikool (2009) TÜ Ja TTÜ Doktorikool Funktsionaalsed Materjalid ja Tehnoloogiad, Tartu. https://fmtdk-2009-2014.ut.ee/?page_id=51. Accessed 28 Jun 2023

Algab vesinikutehnoloogia ja taastuvenergeetika aluste tasuta kursus (2022) University of Tartu Institute of Chemistry, Tartu. https://chem.ut.ee/et/sisu/algab-vesinikutehnoloogia-ja-taastuvenergeetika-aluste-tasuta-kursus. Accessed 28 June 2023

Populaarne vesinikukoolitus alustab taas! (2022) University of Tartu Institute of Chemistry, Tartu. https://chem.ut.ee/et/sisu/populaarne-vesinikukoolitus-alustab-taas. Accessed 25 Jan 2023

Jänes A (1998) Adsorption of organic compounds on antimony, bismuth and cadmium electrodes. Dissertation, Tartu, University of Tartu

Lust E, Jänes A, Lust K, Pullerits R (1997) Adsorption of organic compounds and hydrophilicity of bismuth, cadmium and antimony electrodes. J Electroanal Chem 431:183–201. https://doi.org/10.1016/S0022-0728(97)00150-2

Lust E, Jänes A, Miidla P, Lust K (1997) Adsorption of pyridine on the (111), (001) and (001) faces of bismuth. J Electroanal Chem 425:25–37. https://doi.org/10.1016/S0022-0728(96)04962-5

Lust E, Jänes A, Lust K, Ehrlich J (1999) Orientation of organic compounds at single-crystal bismuth electrodes. Electrochim Acta 44:4707–4720. https://doi.org/10.1016/S0013-4686(99)00221-2

Damaskin BB, Baturina OA, Safonov VA et al (2000) Adsorption parameters of n-hexanol on single-crystal faces of bismuth : a regression analysis of the differential capacitance data and comparing the capacitance and chronocoulometry measurements. Russ J Electrochem 36:673–678

Lust E, Jänes A, Sammelselg V et al (1998) Surface roughness of bismuth, antimony and cadmium electrodes. Electrochim Acta 44:373–383. https://doi.org/10.1016/S0013-4686(98)00084-X

Lust K, Väärtnõu M, Lust E (2000) Adsorption of halide anions on bismuth single crystal plane electrodes. Electrochim Acta 45:3543–3554. https://doi.org/10.1016/S0013-4686(00)00432-1

Lust K, Väärtnõu M, Lust E (2002) Adsorption of anions on bismuth single crystal plane electrodes from various solvents. J Electroanal Chem 532:303–318

Lust K, Lust E (2003) Influence of geometrical structure of the anions on the adsorption parameters at the Bi(0 0 1) electrode. J Electroanal Chem 552:129–139. https://doi.org/10.1016/S0022-0728(03)00014-7

Lust K (2003) Adsorption of anions on bismuth single crystal electrodes. Dissertation, Tartu, University of Tartu

Nurk G, Kasuk H, Lust K et al (2003) Adsorption kinetics of dodecyl sulfate anions on the bismuth (011̄) plane. J Electroanal Chem 553:1–19. https://doi.org/10.1016/S0022-0728(03)00200-6

Kasuk H, Nurk G, Lust K, Lust E (2003) Adsorption kinetics of uracil on bismuth single crystal planes. J Electroanal Chem 550–551:13–31. https://doi.org/10.1016/S0022-0728(03)00140-2

Nurk G (2003) Adsorption kinetics of some organic compounds on bismuth single crystal electrodes. Dissertation, Tartu, University of Tartu

Kasuk H (2007) Thermodynamic parameters and adsorption kinetics of organic compounds forming the compact adsorption layer at Bi single crystal electrodes. Dissertation, Tartu, University of Tartu

Bard AJ, Stratmann M, Gileadi E, Urbakh M (2002) Encyclopedia of electrochemistry: thermodynamics and electrified interfaces. Wiley VCH, Weinheim

Lorenz W, Möckel F (1956) Adsorptionsisotherme und Adsorptionskinetik kappillaraktiver organischer Molekeln an der Quecksilberelektrode. Z Electrochem 60:507–515

Frumkin AN, Melik-Gaykazyan VI (1951) Determination of the kinetics of organic substances by measuring the capacitance and conductivity at the electrode-solution boundary. Dokl Akad Nauk USSR 77:855–858

Armstrong RD, Race WP, Thirsk HR (1968) The kinetics of adsorption of neutral organic compounds at a mercury electrode. J Electroanal Chem Interfacial Electrochem 16:517–529. https://doi.org/10.1016/S0022-0728(68)80142-1

Vollhardt D, Retter U, Szulzewsky K et al (1981) Investigations on adsorption kinetics of sodium decyl sulphate at the mercury/electrolyte interface: part II. Effect of bulk concentration. J Electroanal Chem Interfacial Electrochem 125:157–166. https://doi.org/10.1016/S0022-0728(81)80332-4

Frumkin AN, Damaskin BB (1964) Adsorption of organic compounds at electrodes. In: Bockris JO, Conway BE (eds) Modern Aspects of Electrochemistry. Butterworth, London, pp 149–223

Siinor L, Lust K, Lust E (2007) Impedance study of adsorption of iodide ions at Bi(001) electrode from the aqueous solutions with constant ionic strength. J Electroanal Chem 601:39–46. https://doi.org/10.1016/j.jelechem.2006.10.031

Romann T, Lust E (2010) Electrochemical properties of porous bismuth electrodes. Electrochim Acta 55:5746–5752. https://doi.org/10.1016/j.electacta.2010.05.012

Grozovski V, Kallip S, Lust E (2013) In situ STM studies of Sb(111) electrodes in aqueous electrolyte solutions. Surf Sci 613:108–113. https://doi.org/10.1016/j.susc.2013.03.021

Grozovski V, Ivaništšev V, Kasuk H et al (2014) Balance of the interfacial interactions of 4,4′-bipyridine at Bi(111) surface. Electrochim Acta 120:86–95. https://doi.org/10.1016/j.electacta.2013.12.047

Kasuk H, Nurk G, Lust K, Lust E (2005) Adsorption of uracil on bismuth single crystal planes. J Electroanal Chem 580:128–134. https://doi.org/10.1016/j.jelechem.2005.03.017

Kasuk H, Nurk G, Lust E (2008) Adsorption of sodium dodecyl sulfate on the bismuth (1 1 1), (0 0 1) and planes. J Electroanal Chem 613:80–96. https://doi.org/10.1016/j.jelechem.2007.10.012

Anderson E, Grozovski V, Siinor L et al (2014) In situ STM studies of Bi(111)|1-ethyl-3-methylimidazolium tetrafluoroborate + 1-ethyl-3-methylimidazolium iodide interface. Electrochem Commun 46:18–21. https://doi.org/10.1016/j.elecom.2014.05.032

Siinor L (2010) Adsorption kinetics of ions at bi single crystal planes from aqueous electrolyte solutions and room-temperature ionic liquids. Dissertation, Tartu, University of Tartu

Romann T (2010) Preparation and surface modification of bismuth thin film, porous, and microelectrodes. Dissertation, Tartu, University of Tartu

Romann T, Anderson E, Kallip S et al (2010) Electroless deposition of bismuth on Si(111) wafer from hydrogen fluoride solutions. Thin Solid Films 518:3690–3693

Kallip S (2006) Surface structure of some bismuth and antimony single crystal electrodes. Dissertation, Tartu, University of Tartu

Grozovski V (2014) Adsorption of organic molecules at single crystal electrodes studied by in situ STM method. Dissertation, Tartu, University of Tartu

Anderson E (2015) In situ scanning tunnelling microscopy studies of the interfacial structure between Bi(111) electrode and a room temperature ionic liquid. Dissertation, Tartu, University of Tartu

Pikma P (2015) Interfacial structure and adsorption of organic compounds at Cd(0001) and Sb(111) electrodes from ionic liquid and aqueous electrolytes: an in situ STM study. Dissertation, Tartu, University of Tartu

Pikma P, Kasuk H, Oll O et al (2015) Adsorption of 4,4′−bipyridine on the Cd(0001) single crystal electrode surface. Electrochim Acta 180:965–976. https://doi.org/10.1016/j.electacta.2015.08.003

Pikma P, Siinor L, Oll O, Lust E (2015) Formation of 2,2′-bipyridine adlayers at Sb(111)|ionic liquid + 2,2′-bipyridine solution interface. Electrochem Commun 61:61–65. https://doi.org/10.1016/j.elecom.2015.08.012

Pikma P, Grozovski V, Kasuk H, Lust E (2014) In situ STM studies of electrochemically polished Cd(0001) electrode in aqueous electrolyte solutions. Surf Sci 628:86–91. https://doi.org/10.1016/j.susc.2014.05.009

Anderson E, Grozovski V, Siinor L et al (2015) Comparative in situ STM, cyclic voltammetry and impedance spectroscopy study of Bi(111) | 1-ethyl-3-methylimidazolium tetrafluoroborate interface. J Electroanal Chem 758:201–208. https://doi.org/10.1016/j.jelechem.2015.08.036

Ers H, Siinor L, Siimenson C et al (2022) Order beyond a monolayer: the story of two self-assembled 4,4′-bipyridine layers on the Sb(111) | ionic liquid interface. Electrochimica Acta 421:140468. https://doi.org/10.1016/j.electacta.2022.140468

Ers H, Siinor L, Pikma P (2023) The adsorption of 4,4ʹ-bipyridine at a Cd(0001)|ionic liquid interface – the descent into disorder. Electrochem Commun 148:107451. https://doi.org/10.1016/j.elecom.2023.107451

Ers H, Voroshylova IV, Pikma P, Ivaništšev VB (2022) Double layer in ionic liquids: temperature effect and bilayer model. J Mol Liq 363:119747. https://doi.org/10.1016/j.molliq.2022.119747

Grozovski V, Kasuk H, Kallip S, Lust E (2014) Adsorption of thiourea on Bi(111) electrode surface. J Electroanal Chem 712:103–112. https://doi.org/10.1016/j.jelechem.2013.11.006

Siimenson C (2016) Electrochemical characterization of halide ions adsorption from ionic liquid mixtures at Bi(111) and pyrolytic graphite electrode surface. Dissertation, Tartu, University of Tartu

Siimenson C, Siinor L, Lust K, Lust E (2015) Electrochemical characterization of iodide ions adsorption kinetics at Bi(111) electrode from three-component ionic liquids mixtures. ECS Electrochem Lett 4:H62–H65. https://doi.org/10.1149/2.0011512eel

Siimenson C, Lembinen M, Oll O et al (2016) Electrochemical investigation of 1-Ethyl-3-methylimidazolium bromide and tetrafluoroborate mixture at Bi (111) electrode interface. J Electrochem Soc 163:H723–H730. https://doi.org/10.1149/2.0111609jes

Langkau T, Baltruschat H (1998) The rate of anion and hydrogen adsorption on Pt(111) and Rh(111). Electrochim Acta 44:909–918. https://doi.org/10.1016/S0013-4686(98)00194-7

Jović VD, Parsons R, Jovic BM (1992) Anion absorption on the (111) face of silver. Int J Devoted Asp Electrode Kinet Interfacial Struct Prop Electrolytes Colloid Biol Electrochem 339:327–337. https://doi.org/10.1016/0022-0728(92)80461-C

Pajkossy T, Wandlowski T, Kolb DM (1996) Impedance aspects of anion adsorption on gold single crystal electrodes. J Electroanal Chem 414:209–220. https://doi.org/10.1016/0022-0728(96)04700-6

Müller P, Ando S, Yamada T, Itaya K (1999) Formation of an ordered structure of iodine adsorbed on Ni(111) and the anodic dissolution processes: in-situ STM study. J Electroanal Chem 467:282–290. https://doi.org/10.1016/S0022-0728(98)00433-1

Kolb DM (1996) Reconstruction phenomena at metal-electrolyte interfaces. Prog Surf Sci 51:109–173. https://doi.org/10.1016/0079-6816(96)00002-0

Łukomska A, Sobkowski J (2006) Adsorption of thiourea on monocrystalline silver electrodes in neutral solution. Electrochim Acta 51:2247–2254. https://doi.org/10.1016/j.electacta.2005.04.076

Maurice V, Klein LH, Strehblow H-H, Marcus P (2003) In situ STM study of the initial stages of anodic oxidation of Cu(111) in the presence of sulfates. J Electrochem Soc 150:B316. https://doi.org/10.1149/1.1576225

Ruzanov A, Karu K, Ivaništšev V et al (2016) Interplay between the hydrophilicity of metal electrodes and their interfacial capacitance. Electrochim Acta 210:615–621. https://doi.org/10.1016/j.electacta.2016.05.110

Ruzanov A, Lembinen M, Ers H et al (2018) Density functional theory study of ionic liquid adsorption on circumcoronene shaped graphene. J Phys Chem C 122:2624–2631. https://doi.org/10.1021/acs.jpcc.7b12156

Ivaništšev V, Nazmutdinov RR, Lust E (2010) Density functional theory study of the water adsorption at Bi(111) electrode surface. Surf Sci 604:1919–1927. https://doi.org/10.1016/j.susc.2010.07.028

Ivaništšev V, Nazmutdinov RR, Lust E (2013) A comparative DFT study of the adsorption of H2O molecules at Bi, Hg, and Ga surfaces. Surf Sci 609:91–99. https://doi.org/10.1016/j.susc.2012.11.009

Voroshylova IV, Ers H, Koverga V et al (2021) Ionic liquid–metal interface: the origins of capacitance peaks. Electrochim Acta 379:138148. https://doi.org/10.1016/j.electacta.2021.138148

Voroshylova IV, Lembinen M, Ers H et al (2019) On the role of the surface charge plane position at Au(hkl)–BMImPF6 interfaces. Electrochim Acta 318:76–82. https://doi.org/10.1016/j.electacta.2019.05.058

Ivaništšev V (2012) Double layer structure and adsorption kinetics of ions at metal electrodes in room temperature ionic liquids. Dissertation, Tartu, University of Tartu

Ruzanov A (2018) Computational investigation of the electrical double layer at metal-aqueous solution and metal-ionic liquid interfaces. Dissertation, Tartu, University of Tartu

Thomberg T (2000) Electroreduction of peroxodisulfate anion at a Cd(0001) single-crystal plane electrode. J Electroanal Chem 485:89–93. https://doi.org/10.1016/S0022-0728(00)00089-9

Härk E, Lust E (2006) Electroreduction of hexaamminecobalt (III) cation on Bi (hkl) electrodes from weakly acidified LiClO4 solutions. J Electrochem Soc 153:E104

Härk E, Jäger R, Lust K et al (2012) The kinetics of electroreduction of europium(III) cations at bismuth single-crystal electrode. J Solid State Electrochem 16:921–926. https://doi.org/10.1007/s10008-011-1443-3

Jäger R, Härk E, Möller P et al (2004) The kinetics of electroreduction of hexaamminecobalt (III) cation on Bi planes in aqueous HClO4 solutions. J Electroanal Chem 566:217–226. https://doi.org/10.1016/j.jelechem.2003.11.030

Nerut J, Möller P, Lust E (2004) Electroreduction of hexacyanoferrate(III) anions on electrochemically polished Cd(0 0 0 1) plane. Electrochim Acta 49:1597–1604. https://doi.org/10.1016/j.electacta.2003.11.021

Thomberg T (2005) The kinetics of electroreduction of peroxodisulfate anion on cadmium (0001) single crystal electrode. Dissertation, Tartu, University of Tartu

Jäger R (2007) Electroreduction of peroxodisulfate anion on bismuth electrodes. Dissertation, Tartu, University of Tartu

Nerut J (2007) Electroreduction of hexacyanoferrate(III) anion on Cd(0001) single crystal electrode. Dissertation, Tartu, University of Tartu

Härk E (2008) Electroreduction of complex cations on electrochemically polished Bi(hkl) single crystal electrodes. Dissertation, Tartu, University of Tartu

Damaskin BB, Stenina EV, Baturina OA, Sviridova LN (1998) Selecting a model of the diffuse layer when describing electroreduction of anions in the framework of the slow-discharge theory. Sov Electrochem 34:972–977

Samec Z, Bittner AM, Doblhofer K (1997) Origin of electrocatalysis in the reduction of peroxodisulfate on gold electrodes. J Electroanal Chem 432:205–214. https://doi.org/10.1016/S0022-0728(97)00204-0

Nazmutdinov RR, Tsirlina GA, Kharkats YI et al (1998) Activation energy of electron transfer between a metal electrode and reagents of nonspherical form and complicated charge distribution. Cr(EDTA) Complexes. J Phys Chem B 102:677–686. https://doi.org/10.1021/jp9721309

Grozovski V, Kasuk H, Nerut J et al (2015) Oxygen reduction at shape-controlled platinum nanoparticles and composite catalysts based on (100)Pt nanocubes on microporous–mesoporous carbon supports. ChemElectroChem 2:847–851. https://doi.org/10.1002/celc.201500021

Lust E, Nurk G, Jänes A et al (2003) Influence of nanoporous carbon electrode thickness on the electrochemical characteristics of a nanoporous carbon|tetraethylammonium tetrafluoroborate in acetonitrile solution interfac. J Solid State Electrochem 7:91–105. https://doi.org/10.1007/s10008-002-0316-1

Lust E, Jänes A, Pärn T, Nigu P (2003) Influence of nanoporous carbon electrode thickness on the electrochemical characteristics of a nanoporous carbon|tetraethylammonium tetrafluoroborate in acetonitrile solution interface. J Solid State Electrochem 8:224–237. https://doi.org/10.1007/s10008-003-0396-6

Jänes A, Permann L, Arulepp M, Lust E (2004) Electrochemical characteristics of nanoporous carbide-derived carbon materials in non-aqueous electrolyte solutions. Electrochem Commun 6:313–318. https://doi.org/10.1016/j.elecom.2004.01.009

Eikerling M, Kornyshev AA, Lust E (2005) Optimized structure of nanoporous carbon-based double-layer capacitors. J Electrochem Soc 152:E24–E33. https://doi.org/10.1149/1.1825379

Arulepp M, Leis J, Lätt M et al (2006) The advanced carbide-derived carbon based supercapacitor. J Power Sources 162:1460–1466. https://doi.org/10.1016/j.jpowsour.2006.08.014

Leis J, Arulepp M, Perkson A (2004) Method to modify pore characteristics of porous carbon and porous carbon materials produced by the method. Patent No. US20060140846A1

Jänes A, Permann L, Arulepp M, Lust E (2004) Voltammetric and electrochemical impedance spectroscopy studies of the nanoporous carbon|1 M (C2H5)3CH3NBF4 electrolyte solution interface. J Electroanal Chem 569:257–269. https://doi.org/10.1016/j.jelechem.2004.03.008

Frackowiak E, Abbas Q, Béguin F (2013) Carbon/carbon supercapacitors J Energy Chem 22:226–240. https://doi.org/10.1016/S2095-4956(13)60028-5

Chmiola J (2006) Anomalous increase in carbon capacitance at pore sizes less than 1 nanometer. Science 313:1760–1763. https://doi.org/10.1126/science.1132195

Gogotsi Y, Nikitin A, Ye H et al (2003) Nanoporous carbide-derived carbon with tunable pore size. Nat Mater 2:591–594. https://doi.org/10.1038/nmat957

Salitra G, Soffer A, Eliad L et al (2000) Carbon electrodes for double-layer capacitors I. Relations between ion and pore dimensions. J Electrochem Soc 147:2486–2493

Shilina Y, Levi MD, Dargel V et al (2013) Ion size to pore width ratio as a factor that determines the electrochemical stability window of activated carbon electrodes. J Electrochem Soc 160:A629. https://doi.org/10.1149/2.058304jes

Abbas Q, Béguin F (2018) Sustainable carbon/carbon supercapacitors operating down to −40 °C in aqueous electrolyte made with cholinium salt. Chemsuschem 11:975–984. https://doi.org/10.1002/cssc.201701957

Laheäär A, Delpeux-Ouldriane S, Lust E, Béguin F (2014) Ammonia treatment of activated carbon powders for supercapacitor electrode application. J Electrochem Soc 161:A568–A575

Arulepp M, Jänes A, Lust E (2003) Electrochemical characteristics of porous carbon materialsand electrical double layer capacitors. Tartu University Press, Tartu

Lätt M (2009) Carbide derived microporous carbon and electrical double layer capacitors. Dissertation, Tartu, Tartu University

Jaan Leis, Mati Arulepp and Anti Perkson - Superior carbon-based materials for ultracapacitors (2022) European Patent Office, Munich. https://www.epo.org/en/news-events/european-inventor-award/meet-the-finalists/jaan-leis-mati-arulepp-and-anti-perkson. Accessed 26 Jan 2023

EIT InnoEnergy: Skeleton Technologies wins 2018 SET Awards (2018) European Institute of Innovation & Technology, Budapest. https://eit.europa.eu/news-events/news/eit-innoenergy-skeleton-technologies-wins-2018-set-awards. Accessed 26 Jan 2023

Väli R, Laheäär A, Jänes A, Lust E (2013) Characterization of quaternary solvent mixture and Na-salt based electrolytes in a wide temperature range. ECS Meet Abstr MA2013-02:633. https://doi.org/10.1149/MA2013-02/9/633

Laheäär A, Jänes A, Lust E (2014) Cesium carborane as an unconventional non-aqueous electrolyte salt for electrochemical capacitors. Electrochim Acta 125:482–487. https://doi.org/10.1016/j.electacta.2014.01.145

Kurig H, Jänes A, Lust E (2010) Electrochemical characteristics of carbide-derived carbon|1-ethyl-3-methylimidazolium tetrafluoroborate supercapacitor cells. J Electrochem Soc 157:A272–A279. https://doi.org/10.1149/1.3274208

Kurig H, Romann T, Jänes A, Lust E (2010) Electrochemical characteristics of titanium carbide derived carbon|1-ethyl-3-methylimidazolium tetrafluoroborate electrical double layer capacitorS. ECS Trans 25:15. https://doi.org/10.1149/1.3328507

Kurig H (2011) Electrical double-layer capacitors based on ionic liquids as electrolytes. Dissertation, Tartu, University of Tartu

Laheäär A (2013) Electrochemical characterization of alkali metal salt based non-aqueous electrolytes for supercapacitors. Dissertation, Tartu, University of Tartu

Tallo I, Thomberg T, Kurig H et al (2014) Novel micromesoporous carbon materials synthesized from tantalum hafnium carbide and tungsten titanium carbide. Carbon 67:607–616. https://doi.org/10.1016/j.carbon.2013.10.034

Oll O, Väärtnõu M, Gorbatovski G et al (2019) Adsorption of anions on bismuth and cadmium single crystal plane electrodes from various solvents and ionic liquid mixtures. Electrochim Acta 319:895–908. https://doi.org/10.1016/j.electacta.2019.06.179

Oll O, Romann T, Siimenson C, Lust E (2017) Influence of chemical composition of electrode material on the differential capacitance characteristics of the ionic liquid|electrode interface. Electrochem Commun 82:39–42. https://doi.org/10.1016/j.elecom.2017.07.015

Oll O (2018) Electrical double layer structure and energy storage characteristics of ionic liquid based capacitors. Dissertation, Tartu, University of Tartu

Zhao J, Gorbatovski G, Oll O et al (2019) Effect of alkali and halide ion doping on the energy storage characteristics of ionic liquid based supercapacitors. Electrochim Acta 319:82–87. https://doi.org/10.1016/j.electacta.2019.06.176

Zhao J (2022) Electrochemical Characteristics of Bi( hkl ) and micro-mesoporous carbon electrodes in ionic liquid based electrolytes. Dissertation, Tartu, University of Tartu

Tee E, Tallo I, Thomberg T et al (2018) Steam and carbon dioxide Co-activated silicon carbide-derived carbons for high power density electrical double layer capacitors. J Electrochem Soc 165:A2357. https://doi.org/10.1149/2.1261810jes

Tee E (2019) Analysis and development of selective synthesis methods of hierarchical micro- and mesoporous carbons. Dissertation, Tartu, University of Tartu

Tee E, Tallo I, Kurig H et al (2015) Huge enhancement of energy storage capacity and power density of supercapacitors based on the carbon dioxide activated microporous SiC-CDC. Electrochim Acta 161:364–370. https://doi.org/10.1016/j.electacta.2015.02.106

Härmas M, Palm R, Thomberg T et al (2020) Hydrothermal and peat-derived carbons as electrode materials for high-efficient electrical double-layer capacitors. J Appl Electrochem 50:15–32. https://doi.org/10.1007/s10800-019-01364-5

Tooming T, Thomberg T, Kurig H et al (2015) High power density supercapacitors based on the carbon dioxide activated d-glucose derived carbon electrodes and 1-ethyl-3-methylimidazolium tetrafluoroborate ionic liquid. J Power Sources 280:667–677. https://doi.org/10.1016/j.jpowsour.2015.01.157

Shpigel N, Levi MD, Sigalov S et al (2016) In situ hydrodynamic spectroscopy for structure characterization of porous energy storage electrodes. Nat Mater 15:570–575. https://doi.org/10.1038/nmat4577

Härmas M, Thomberg T, Romann T et al (2017) Carbon for energy storage derived from granulated white sugar by hydrothermal carbonization and subsequent zinc chloride activation. J Electrochem Soc 164:A1866–A1872. https://doi.org/10.1149/2.0681709jes

Härmas M, Thomberg T, Kurig H et al (2016) Microporous–mesoporous carbons for energy storage synthesized by activation of carbonaceous material by zinc chloride, potassium hydroxide or mixture of them. J Power Sources 326:624–634. https://doi.org/10.1016/j.jpowsour.2016.04.038

Härmas M (2020) Impact of activated carbon microstructure and porosity on electrochemical performance of electrical double-layer capacitors. Dissertation, Tartu, University of Tartu

Härmas M, Thomberg T, Jänes A (2020) Effect of zinc chloride activation on D-glucose derived carbons based capacitors performance in ionic liquid. J Electrochem Soc 167:080533. https://doi.org/10.1149/1945-7111/ab8ecf

Paalo M (2022) Synthesis and characterization of novel carbon electrodes for high power density electrochemical capacitors. Dissertation, Tartu, University of Tartu

Härmas R, Palm R, Härmas M et al (2018) Influence of porosity parameters and electrolyte chemical composition on the power densities of non-aqueous and ionic liquid based supercapacitors. Electrochim Acta 283:931–948. https://www.sciencedirect.com/science/article/pii/S0013468618314038?via%3Dihub

Paalo M, Tallo I, Thomberg T et al (2019) Enhanced power performance of highly mesoporous sol-gel TiC derived carbons in ionic liquid and non-aqueous electrolyte based capacitors. J Electrochem Soc 166:A2887. https://doi.org/10.1149/2.0721913jes

Eskusson J (2009) Synthesis and characterization of the diamond-like carbon thin films prepared by pulsed laser deposition method. Dissertation, Tartu, University of Tartu

Eskusson J, Jaaniso R, Lust E (2008) Synthesis of DLC films by PLD from liquid target and dependence of film properties on the synthesis conditions. Appl Phys A 93:745–749. https://doi.org/10.1007/s00339-008-4706-9

Tee E, Tallo I, Lust E et al (2019) Electrical double layer capacitors based on steam and CO2-steam co-activated carbon electrodes and ionic liquid electrolyte. J Electrochem Soc 166:A1558

Tooming T, Thomberg T, Siinor L et al (2014) A type high capacitance supercapacitor based on mixed room temperature ionic liquids containing specifically adsorbed iodide anions. J Electrochem Soc 161:A222–A227. https://doi.org/10.1149/2.014403jes

Tõnurist K, Thomberg T, Jänes A, Lust E (2013) Specific performance of supercapacitors at lower temperatures based on different separator materials. J Electrochem Soc 160:A449–A457. https://doi.org/10.1149/2.044303jes

Tõnurist K (2013) Influence of electrospun separator materials properties on electrochemical performance of electrical double-layer capacitors. Dissertation, Tartu, University of Tartu

Tõnurist K, Thomberg T, Jänes A et al (2012) Specific performance of electrical double layer capacitors based on different separator materials in room temperature ionic liquid. Electrochem Commun 22:77–80. https://doi.org/10.1016/j.elecom.2012.05.029

Tõnurist K, Jänes A, Thomberg T et al (2009) Influence of mesoporous separator properties on the parameters of electrical double-layer capacitor single cells. J Electrochem Soc 156:A334–A342

Lust E, Liivand K, Vaas I et al (2018) Separators, electrodes, half-cells, and cells of electrical energy storage devices. Patent No US 9951443. 31.12.2015

Väli R (2019) Glucose-derived hard carbon electrode materials for sodium-ion batteries. Dissertation, Tartu, University of Tartu

Väli R, Jänes A, Lust E (2017) Alkali-metal insertion processes on nanospheric hard carbon electrodes: an electrochemical impedance spectroscopy study. J Electrochem Soc 164:E3429–E3437. https://doi.org/10.1149/2.0431711jes

Väli R, Jänes A, Thomberg T, Lust E (2017) Synthesis and characterization of d-glucose derived nanospheric hard carbon negative electrodes for lithium- and sodium-ion batteries. Electrochim Acta 253:536–544. https://doi.org/10.1016/j.electacta.2017.09.094

Adamson A, Väli R, Paalo M et al (2020) Peat-derived hard carbon electrodes with superior capacity for sodium-ion batteries. RSC Adv 10:20145–20154. https://doi.org/10.1039/D0RA03212C

Jiang C, Fang Y, Zhang W et al (2018) A multi-ion strategy towards rechargeable sodium-ion full batteries with high working voltage and rate capability. Angew Chem Int Ed 57:16370–16374. https://doi.org/10.1002/anie.201810575

Park Y, Shin D-S, Woo SH et al (2012) Sodium terephthalate as an organic anode material for sodium ion batteries. Adv Mater 24:3562–3567. https://doi.org/10.1002/adma.201201205

Xie F, Zhang L, Ye C et al (2019) The application of hollow structured anodes for sodium-ion batteries: from simple to complex systems. Adv Mater 31:1800492. https://doi.org/10.1002/adma.201800492

Zhang L, Li X, Yang M, Chen W (2021) High-safety separators for lithium-ion batteries and sodium-ion batteries: advances and perspective. Energy Stor Mater 41:522–545. https://doi.org/10.1016/j.ensm.2021.06.033

Kurig H, Russina M, Tallo I et al (2016) The suitability of infinite slit-shaped pore model to describe the pores in highly porous carbon materials. Carbon 100:617–624. https://doi.org/10.1016/j.carbon.2016.01.061

Palm R, Kurig H, Aruväli J, Lust E (2018) NaAlH4/microporous carbon composite materials for reversible hydrogen storage. Micropor Mesopor Mat 264:8–12. https://doi.org/10.1016/j.micromeso.2017.12.027

Palm R, Tallo I, Romann T, Kurig H (2015) Methane adsorption on specially designed TiC and Mo2C derived carbons with different pore size and surface morphology. Micropor Mesopor Mat 218:167–173. https://doi.org/10.1016/j.micromeso.2015.07.016

Palm R (2018) Carbon materials for energy storage applications. Dissertation, Tartu, University of Tartu