Abstract

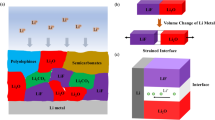

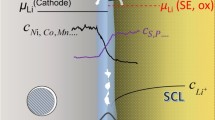

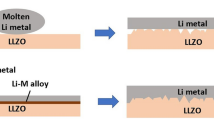

The interfacial contact between the electrolyte and electrode is a crucial factor influencing the interface impedance in all-solid-state lithium batteries. This paper investigates the effects of temperature and strain rate of lithium metal on the interfacial contact and stress state of the Li-Li7La3Zr2O12 interface using the finite element method. To predict the plastic flow behavior of lithium metal, a modified Zerilli–Armstrong constitutive model is proposed over a wide temperature range (198 to 398 K) and strain rate range (4 × 10−5 s−1 to 2 × 10−2 s−1). Based on the experimental data, the parameters in the constitutive model of lithium are determined based on gray wolf optimizer. After optimizing the parameters, the average absolute relative error is 6.22% and the correlation coefficient is 0.9882. Based on the finite element simulation, the effects of temperature and strain rate on the interface contact and stress state under different Li7La3Zr2O12 surface roughness are further analyzed. Results show that temperature and strain rate have significant effects on the interface contact and stress state. Specifically, the interfacial contact region increases with the decrease in the strain rate and with the increase in temperature.

Similar content being viewed by others

References

Placke T, Kloepsch R, Dühnen S et al (2017) Lithium ion, lithium metal, and alternative rechargeable battery technologies: the odyssey for high energy density. J Solid State Electrochem 21:1939–1964

Xia S, Wu X, Zhang Z et al (2019) Practical challenges and future perspectives of all-solid-state lithium-metal batteries. Chem 5(4):753–785

Wu Z, Xie Z, Yoshida A et al (2019) Utmost limits of various solid electrolytes in all-solid-state lithium batteries: a critical review. Renewable Sustainable Energy Rev 109:367–385

Kerman K, Luntz A, Viswanathan V et al (2017) Review-practical challenges hindering the development of solid state Li ion batteries. J Electrochem Soc 164(7):A1731

Zhao N, Khokhar W, Bi Z et al (2019) Solid garnet batteries Joule 3(5):1190–1199

Gao Z, Sun H, Fu L et al (2018) Promises, challenges, and recent progress of inorganic solid-state electrolytes for all-solid-state lithium batteries. Adv Mater 30(17):1705702

Murugan R, Thangadurai V, Weppner W (2007) Fast lithium ion conduction in garnet-type Li7La3Zr2O12. Angew Chem Int Ed 46(41):7778–7781

Zhu Y, Connell JG, Tepavcevic S et al (2019) Dopant-dependent stability of garnet solid electrolyte interfaces with lithium metal. Adv Energy Mater 9(12):1803440

Ni JE, Case ED, Sakamoto JS et al (2012) Room temperature elastic moduli and Vickers hardness of hot-pressed LLZO cubic garnet. J Mater Sci 47:7978–7985

Wen J, Zou Q, Wei Y (2021) Physics-driven machine learning model on temperature and time-dependent deformation in lithium metal and its finite element implementation. J Mech Phys Solids 153:104481

Monroe C, Newman J (2005) The impact of elastic deformation on deposition kinetics at lithium/polymer interfaces. J Electrochem Soc 152(2):A396

Pervez SA, Cambaz MA, Thangadurai V et al (2019) Interface in solid-state lithium battery: challenges, progress, and outlook. ACS Appl Mater Interfaces 11(25):22029–22050

Porz L, Swamy T, Sheldon BW et al (2017) Mechanism of lithium metal penetration through inorganic solid electrolytes. Adv Energy Mater 7(20):1701003

Wang C, Gong Y, Liu B et al (2017) Conformal, nanoscale ZnO surface modification of garnet-based solid-state electrolyte for lithium metal anodes. Nano Lett 17(1):565–571

Wang C, Xie H, Zhang L et al (2018) Universal soldering of lithium and sodium alloys on various substrates for batteries. Adv Energy Mater 8(6):1701963

Alexander GV, Patra S, Raj SV et al (2018) Electrodes-electrolyte interfacial engineering for realizing room temperature lithium metal battery based on garnet structured solid fast Li+ conductors. J Power Sources 396:764–773

Han X, Gong Y, Fu KK et al (2017) Negating interfacial impedance in garnet-based solid-state Li metal batteries. Nat Mater 16(5):572–579

Shao Y, Wang H, Gong Z et al (2018) Drawing a soft interface: an effective interfacial modification strategy for garnet-type solid-state Li batteries. ACS Energy Lett 3(6):1212–1218

Shi K, Wan Z, Yang L et al (2020) In situ construction of an ultra-stable conductive composite interface for high-voltage all-solid-state lithium metal batteries. Angew Chem Int Ed 132(29):11882–11886

Duan J, Wu W, Nolan AM et al (2019) Lithium-graphite paste: an interface compatible anode for solid-state batteries. Adv Mater 31(10):1807243

Barai P, Higa K, Srinivasan V (2017) Lithium dendrite growth mechanisms in polymer electrolytes and prevention strategies. Phys Chem Chem Phys 19(31):20493–20505

Doux JM, Nguyen H, Tan DH et al (2020) Stack pressure considerations for room-temperature all-solid-state lithium metal batteries. Adv Energy Mater 10(1):1903253

Wang MJ, Choudhury R, Sakamoto J (2019) Characterizing the Li-solid-electrolyte interface dynamics as a function of stack pressure and current density. Joule 3(9):2165–2178

Krauskopf T, Hartmann H, Zeier W G et al (2019) Toward a fundamental understanding of the lithium metal anode in solid-state batteries—an electrochemo-mechanical study on the garnet-type solid electrolyte Li6.25Al0.25La3Zr2O12. ACS Appl Mater Interfaces 11(15):14463–14477

Verma A, Kawakami H, Wada H et al (2021) Microstructure and pressure-driven electrodeposition stability in solid-state batteries. Cell Rep Phys Sci 2(1):100301

Schnell J, Günther T, Knoche T et al (2018) All-solid-state lithium-ion and lithium metal batteries – paving the way to large-scale production. J Power Sources 382:160–175

Ito S, Fujiki S, Yamada T et al (2014) A rocking chair type all-solid-state lithium ion battery adopting Li2O–ZrO2 coated LiNi0.8Co0.15Al0.05O2 and a sulfide based electrolyte. J Power Sources 248:943–950

Fincher CD, Ojeda D, Zhang Y et al (2020) Mechanical properties of metallic lithium: from nano to bulk scales. Acta Mater 186:215–222

Masias A, Felten N, Garcia-Mendez R et al (2019) Elastic, plastic, and creep mechanical properties of lithium metal. J Mater Sci 54(3):2585–2600

Narayan S, Anand L (2018) A large deformation elastic-viscoplastic model for lithium. Extreme Mech Lett 24:21–29

LePage WS, Chen Y, Kazyak E et al (2019) Lithium mechanics: roles of strain rate and temperature and implications for lithium metal batteries. J Electrochem Soc 166(2):A89-97

Yamamoto M, Takahashi M, Terauchi Y et al (2017) Fabrication of composite positive electrode sheet with high active material content and effect of fabrication pressure for all-solid-state battery. J Ceram Soc 125(5):391–395

Sharafi A, Meyer HM, Nanda J et al (2016) Characterizing the Li-Li7La3Zr2O12 interface stability and kinetics as a function of temperature and current density. J Power Sources 302:135–139

Johnson GR, Cook WH (1985) Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng Fract Mech 21(1):31–48

He S, Yang H, Wang Z (2023) Comparative study on several constitutive models of GCr15 steel at high strain rates. J Mater Eng Perform. https://doi.org/10.1007/s11665-023-08092-0

Mirjalili S, Mirjalili SM, Lewis A (2014) Grey wolf optimizer Adv Eng Software 69:46–61

Song X, Tang L, Zhao S et al (2015) Grey wolf optimizer for parameter estimation in surface waves. Soil Dyn Earthquake Eng 75:147–157

Gupta S, Deep K (2019) A novel random walk grey wolf optimizer. Swarm Evol Comput 44:101–112

Zhou J, Qiu Y, Zhu S et al (2021) Optimization of support vector machine through the use of metaheuristic algorithms in forecasting TBM advance rate. Eng Appl Artif Intell 97:104015

Zerilli FJ, Armstrong RW (1987) Dislocation-mechanics-based constitutive relations for material dynamics calculations. J Appl Phys 61(5):1816–1825

Rockett AM (1983) Arc length, area, and the arcsine function. Math Mag 56(2):104–110

Funding

This work is supported by National Key R&D Program of China (Grant No. 2022YFB3401901) and Sichuan Science and Technology Program (Grant Nos. 2023NSFSC0394 and 2023NSFSC1988).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

He, S., Yang, H. & Wang, Z. A strain rate-dependent interfacial contact model by considering the strain rate and temperature of lithium for LLZO-based solid-state lithium batteries. J Solid State Electrochem 27, 3465–3476 (2023). https://doi.org/10.1007/s10008-023-05634-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-023-05634-3