Abstract

Eight derivatives of chromeno-oxadithiin and chromeno disulfide were greenly synthesized during the reactions of different derivatives of 3-Chloro-3-chlorosulfenylchromanones (2a–d) with potassium iodide. The chemical structure of the newly prepared compounds was confirmed by using different spectroscopic methods (IR, 1H &13C NMR, and MS). The redox properties of the prepared compounds were investigated via cyclic voltammetry where most of the compounds exhibited one quasi-reversible redox couple beside one irreversible reduction peak. The charge transfer process was found to be under diffusion control. Some of these compounds were studied as inhibitors for mild steel corrosion in 0.6 M NaCl by using electrochemical techniques. Both the electrochemical methods and the computational simulations proved that adding 1 × 10–3 M of Trispiro[cyclohexane-1,2′-chroman-3′,2″-2H-chromeno[3,4-e][1,3,4]oxadithiin-5″,1″′-cyclohexan]-4′-one (3b) to 0.6 M NaCl inhibited mild steel corrosion by an efficiency of 98.8%. The morphology of mild steel surface after 7 days of immersion in this solution studied by scanning electron microscope (SEM) and showed a homogenous surface. The theoretical studies showed that 1,2-Bis (3-chlorospirochroman-2,1′-cyclohexyl-4-one) disulfane (4b) is the most stable one with an electronic energy of − 3101 au. The effects of the methyl and cyclohexane groups, as well as the effects of heterolysis on the corrosion efficiency, were studied.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Corrosion of metals is a serious problem that causes an economic damage and safety loss. It results in degradation of metals during different industrial processes such as pickling by acids and descaling. The demand of metallic resources increases due to the development of engineering and technology fields; therefore, the attention of the corrosion researchers is directed to control and prevent the corrosion of metals and alloys to avoid these enormous losses of metals and decrease the high cost of corrosion [1]. Using corrosion inhibitors is from the most top methods of preventing corrosion due to its low costs, ease of usage, and its fitting for the industrial process [2, 3]. Several numbers of organic compounds were considered as corrosion inhibitors for metals in aggressive solutions. The presence of polar groups (–OH, -SH, -NH), hetero atom sites, delocalized electrons, aromatic ring, and side chains on the organic compounds investigated as important factors in facilitating the adsorption of these compounds on the metal surface and offered good inhibition efficiency [4, 5]. In addition, the presence of polar groups allows the use of these organic compounds as inhibitors in aqueous solutions. However, most of these organic compounds are non-degradable and toxic that deliver an opposing effect on the environment and the living beings. Therefore, eco-friendly environmental corrosion inhibitors are denoted as new trendy in decreasing the corrosion of metals [6,7,8,9,10]. Chromanones were represented as naturally occurring substances that contain polar groups, heteroatoms, and delocalized electrons [11,12,13]. They are pharmacophores and honored in medicinal chemistry as they have used as anticancer drugs [14,15,16]. In spite of the high effectiveness cytotoxicity, low side effects of chromanones, and the solubility of most of them in water not in organic solvents [17], there are little works in using such compounds as environmentally friendly inhibitors for steel corrosion [18,19,20]. Therefore, herein, a comparison between the efficiency of using four different chromanone compounds (differ on the side chain and functional groups) to inhibit the corrosion of mild steel in 0.6 M NaCl solution have done by using different electrochemical techniques and the theoretical studies. Recently, there is a great progress in using theoretical quantum-chemical studies in studying the corrosion inhibition mechanism where this progress is coming from the availability of knowing the inhibition activity of the molecules by associating certain parameters, such as the dipole moment, the highest occupied molecular orbital energy (EHOMO), the lowest unoccupied molecular orbital (ELUMO), and Mulliken atomic charges [21]. The theoretical studies were used in many previous works to investigate the correlation between the ability of organic molecules to inhibit the mild steel surface and the structure of the inhibitor molecules. Guo et al. [22] used it to correlate the effect of the adsorption of triazole derivatives on the steel surface, where it was recommended that the adsorption took place due to the interaction of the donor–acceptor of the π-electrons for the heterocycle and the d-orbitals of the iron atoms. Quraishi et al. showed also that the interaction of chromeno-carbonitriles compounds with the steel metallic surface was taken place through the donor–acceptor mechanism and the Monte Carlo studies showed that the adsorption of these molecules is spontaneously [19]. It was suggested also that both the neutral and the protonated forms of Chromeno naphthyridines molecules adsorbed on steel surface in parallel way [20]. Therefore, the DFT calculations and the molecular dynamic simulation have been used in this study to validate the experimental results.

Some derivatives of chromene-α-oxo-thioketones were isolated as dimers with 1,3,4-oxadithiin structure during the reaction of tertiary phosphanes or potassium iodide with chloro-α-chlorothiocarbonyl compounds produced [23,24,25,26]. Herein, we have repeated the reaction of some 3-chloro-3-chlorosulfenyl chroman-4-ones (2a–d) compounds with potassium iodide to prepare 1,2-Bis(3-chloro-2,2-dimethyl chroman-4-one)disulfane (4a), 1,2-Bis (3-chlorospirochroman-2,1′-cyclohexyl-4-one)disulfane (4b, 4c), 1,2-Bis (3-chloro-4′-methylspirochroman-2,1′-cyclohexyl-4-one)disulfane (4d), 2,2,5′,5′-Tetramethylspiro[chroman-3,2′-2H-chromeno[3,4-e][1,3,4]oxadithiin]-4-one (3a), Trispiro[cyclohexane-1,2′-chroman-3′,2″-2H-chromeno[3,4-e][1,3,4]oxadithiin-5″,1″′-cyclohexan]-4′-one (3b, 3c), and 4,4″′-Dimethyltrispiro[cyclohexane-1,2′-chroman-3′,2″-2H-chromeno[3,4-e][1,3,4]oxadithiin-5″,1″′-cyclohexan]-4′-one (3d). Studying of the electron transfer behavior of these compounds is very important as they are used as anticancer drugs [27, 28]; therefore, cyclic voltammetry technique is used for these purposes due to its several advantages such as its simplicity and low cost.

Experimental

Chemistry

A solution of (0.1 mol compound 2 + 100 ml CHCl3) was added to a solution of (0.1 mol of KI + 200 ml CH3CN) by stirring for 1 h. The reaction mixture was added to a solution of sodium thiosulphate, separating funnel was used to separate the organic layer and then evaporation of the solvent was occurred under vacuum to give a mixture of 3 and 4, which were separated by column chromatography with an eluent petroleum ether (40–60 °C)/ethyl acetate (20/1) and silica gel (Merck silica gel 60, particle size 0.040–0.063 mm).

A digital melting point apparatus was used to obtain the melting point values of the prepared compounds where they are uncorrected. Brucker-Vector 22 (Bruker Rhein-Stetten, Germany) was used to obtain the Infrared spectra for neat samples (for liquids) or KBr wafers (for solids). Shimadzu GCMS-QP 1000EX (EI, 70 eV) (Shimadzu, Japan) was used to obtain the mass spectra. JEOL EX-500 MHz spectrometers and (CDCl3) with TMS as internal standard were used to obtain 1H NMR and 13C NMR spectra, respectively. Chemical shifts were quoted in δ and were related to that of the solvents. Splitting patterns were designated as follows: s singlet; d doublet; t triplet; m multiplet. Mario Elementar apparatus was used for the elemental analyses. All the reactions were monitored by TLC. The compounds 2a,b [29], 2c [30], 2d [17], 3d [17], and 4d [17] were prepared as reported in the literature. The Supplemental Materials contains sample 1H and 13C NMR and mass analysis for the prepared compounds.

Electrochemical measurements

Cyclic voltammetry measurements

Origlays potentiostat/galvanostat was used to determine the electrochemical behavior of the prepared compounds by using three electrodes glass cell. 0.005 M solution of the compound + 0.05 M tetrabutylammonium perchlorate (TBAP) dissolved in dimethyl sulphoxide (DMSO) was used as the electrolyte under N2 atmosphere where nitrogen gas was purged for 10 min in the solution, and the cell solution(s) were maintained under this atmosphere during the recording of the voltammograms. The three electrodes consist of the working electrode (a platinum rod), Ag/AgCl reference electrode (E° = 0.203 V versus standard hydrogen electrode (SHE)), and the counter electrode (a pure Pt wire). The electrochemical behavior of all the prepared compounds (2d, 3d, 4d, 3b, 4b, 3a, 4a, and 3c) was characterized by Cyclic voltammetry technique in the potential range of − 1.5 to 1.5 V by using different scan rates of 0.01–0.5 Vs−1. Wetted polishing cloth with fine alumina was used to polish the working electrode surface, and then thoroughly washed with double distilled water.

Corrosion studies

Potentiodynamic polarizations of mild steel were carried out after immersion for 5 min in 0.6 M NaCl without and with different concentrations of four compounds (2,2,5′,5′-Tetramethylspiro[chroman-3,2′-2H-chromeno[3,4-e][1,3,4]oxadithiin]-4-one (3a), 1,2-Bis(3-chloro-2,2-dimethyl chroman-4-one)disulfane (4a), Trispiro[cyclohexane-1,2′-chroman-3′,2″-2H-chromeno[3,4-e][1,3,4]oxadithiin-5″,1″′-cyclohexan]-4′-one (3b), and 1,2-Bis (3-chlorospirochroman-2,1′-cyclohexyl-4-one)disulfane (4b)) with scan rate of 0.001 V s−1 in the potential range (− 0.8 to 0 V). The effect of immersion time was also conducted in the same manner after 7 days of immersion. The inhibition efficiency (IE%) was calculated from the corrosion current density by using this formula:

where icorr and i′corr are the corrosion current density in the absence and presence of inhibitors.

Surface examination

After 7 days of mild steel immersion in 0.6 M NaCl without and with inhibitors, the surface morphology of the specimens was performed by using scanning electron microscope JEOL-JSM-5600 equipped with an energy dispersive X-ray spectrometer OXFORD Link-ISIS-300.

DFT and MD calculations

Geometry optimization and frequency calculations of the ground state geometries of four compounds (3b, 3a, 4b, and 4a) were performed using B3LYP/6-31G (d) level of theory as implemented in the Gaussian software [31]. The optimized geometries are true minima. It is known that the corrosion inhibition efficiency of molecular inhibitors is strongly influenced by the structural geometry and electronic and molecular properties. For that, a certain number of electronic and molecular properties such as the ionization potential (IP), electronic affinity (EA), gap energy between the HOMO and LUMO (ΔE), electronegativity (χ), chemical hardness (η), softness (S = 1/η), electrophilicity (ω), and dipole moment (μ) were calculated and correlated to the measured inhibition efficiencies (Eqs. 2–8). The electronic and molecular properties were calculated from IP and EA, which in turn were calculated considering Koopman’s theorem IP = − EHOMO and EA = − ELUMO.

The fraction of the transferred electrons (∆N) between the inhibitor and the surface of the metal was calculated using the Pearson theory [34] as in Eq. (9):

where χ represents the electronegativity, Fe is the iron atom, η is the hardness, and inh is the inhibitor. A theoretical value, χFe = 7.00 eV mol−1 and value of ηFe = 0 eV mol−1 for iron according to Pearson’s electronegativity scale, assumes that for a metallic bulk I = A, because they are softer than neutral metallic atoms. The atomic sites of 3b, 3a, 4b, and 4a that may interact with the surface of metal/solution were located by the analysis of electrostatic potential maps (ESP) and frontier molecular orbitals (FMOs). The ESPs and frontier molecular orbitals were visualized using Gaussian View 6.

The molecular dynamic calculations are performed using the COMPASSII force field in the Forcite model as implemented in the Material studio package (BIOVIA Accelrys, San Diego, CA, USA, 2014). The adsorption energy of 3b, 3a, 4b, and 4a on the iron surface is calculated using the following formula:

where Inh is for inhibitor.

Results and discussions

Chemistry

The reactions of compounds 2a–d with potassium iodide resulted in separating compounds 3a–d in addition to compounds 4a–d (Scheme 1), whereas the compounds 4a–c were separated as new compounds. The structure of compounds 4a–c was verified by IR, 1H&13C NMR, and MS. The IR of compound 4a, as an example, shows νC = O at 1698 cm−1, its 1H NMR shows signals at δ 1.49 (s, 3H), 1.59 (s, 3H), 1.80 (s, 6H) ppm along with the other expected signals, its 13C NMR shows signals at δ 85.63 (C-2), 86.27 (C-3), 180.59 (C = O) along with the remind expected signals, and its MS displays the M+ peak at m/z 482 (80.32%) (cf. Supplementary).

Cyclic voltammetry measurements

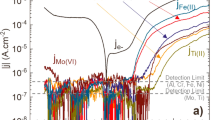

The redox properties of the prepared compounds (2d, 3d, 4d, 3b, 4b, 3a, 4a, and 3c) were studied by using cyclic voltammetry technique for 5 × 10 −3 M of each compound dissolved in DMSO containing 0.05 M TBAP as supporting electrolyte with scan rate 0.1 V/s (Fig. 1) to evaluate their electron-transfer potential. The cyclic voltamogramms (CV) of all the compounds show one oxidation peak at potential near 1.0 V and a corresponding reduction peak at (− 0.5 to − 0.7 V), this quasi-reversible redox couple may be attributed to the redox reaction of the carbonyl group. Another irreversible reduction peak at approximately − 0.9 V was observed for all the compounds except for compound 2d which may be attributed to the reduction of -S–S- to thiol.

The peak potentials and currents (Epa, Epc, Ipa, and Ipc) for both the anodic and the cathodic branch are evaluated from Fig. 1; the peak potential separation (∆E = Epa − Epc) and the ratio of the anodic to cathodic currents (Ipa/Ipc) are calculated and listed in Table 1. The parameters in Table 1 confirmed the quasi-reversible property of the redox couple where ∆E values are higher than 0.059 V and the ratio of the anodic to cathodic current is shifted from one indicating slow kinetics of the electron transfer [1, 27, 32].

The effect of the scan rate on the electro-oxidation for 5 × 10−3 M of each compound was studied in the range 0.01– 0.5 V s−1 as shown in Fig. 2a–h. It was noted that, the increase in the scan rate shifted the potential of the oxidation peak to more positive values and the potential of the reduction peak to more negative values that confirms the quasi-reversible state of the peak. In addition, both the anodic and the cathodic currents of the peaks were raised to higher values. The relation between the current of the anodic peak (Ipa) for compounds 2d and 3d with the scan rate (υ) related linearly as shown in Fig. 3a. It was noted that, the peak current increases with increasing the scan rate which indicates that the charge transfer is under diffusion process, and the relation between the anodic current peak and the scan rate (υ) is described by the following equations:

The dependence of the anodic current peak Ip for 2d and 3d on the square root of the scan rate υ1/2 was represented also by linear relation as in Fig. 3b and described by following equations:

As shown from Fig. 3b, the straight lines did not pass through the origin. The presence of certain values for the coefficient of the linear relation indicated the occurrence of a chemical reaction on the electrode surface [33, 34].

The slope of the linear plot of log Ip with log \(\upsilon\) for the anodic peaks of 2d and 3d Fig. 3c was found to be near 0.5 that confirms the diffusion control of the charge transfer process [34], and the following equations can describe this relation

Potentiodynamic polarization measurements

Potentiodynamic polarization curves of mild steel after immersion in 0.6 M NaCl solution without and with different concentrations of the inhibitors (3b, 4b, 3a, and 4a) are presented in Fig. 4a-d. It was noted from the curves that; the presence of inhibitors shifted the cathodic branch to more noble values and the corrosion potential (Ecorr) to more negative values which indicated that the inhibitors affect mainly the cathodic reaction. The corrosion parameters deduced from Tafel lines such Tafel slopes (bc, ba), corrosion current density (icorr), corrosion potential Ecorr, and the calculated inhibition efficiency IE% (by using Eq. (1)) are presented in Table 2. The values of icorr for mild steel in NaCl solution with different concentrations of compounds 3b, 4b, 3a, and 4a are lower than icorr for mild steel in NaCl solution. As the concentration of 3b increases, the icorr value decreases and the inhibition efficiency IE% increases; however, increasing the concentration of 4b results in increasing icorr and the inhibition efficiency IE% decreases. IE% for mild steel decreases with increasing the concentration of 3a and 4a until concentration of 5 × 10–5 M; then, it increases, while the values of icorr are still lower than icorr for the uninhibited NaCl solution. These decrease in icorr may be explained by the adsorption of the inhibitor molecules on the surface of the metal that hinders the active sites. The IE% values of using different concentrations of the two similar geometry inhibitors (3b and 3a) are higher than 4b and 4a, and the maximum value of IE% is 98.8% for concentration of 1 × 10–3 M 3b which can be attributed to the adsorption of inhibitor molecules through both hetero atoms –S, -O and the carbonyl group on the mild steel surface that causing blocking of active sites as that always takes place in sulfur and oxygen containing inhibitors [10, 35, 36]. The adsorption of the inhibitor on the electrode surface increases with increasing the inhibitor concentration that results in suppressing both the anodic and cathodic processes which also indicated by shifting the Ecorr value to more negative and by changing the values of bc, ba especially in the cathodic branch. The observed shift in Ecorr, bc, and ba indicated that the inhibition occurred by the energy effect such as blocking the active sites and electrocatalytic effect which is more predominate than the geometric blocking effect [37,38,39].

The optimum concentration at which the maximum inhibition observed is 1 × 10–3 M for compounds 3b and 4a; however, it is 5 × 10–6 M and 1 × 10–5 M for 4b and 3a, respectively. The difference in Ecorr values of mild steel in NaCl without and with different concentrations of inhibitor is higher than 85 mV; therefore, the inhibitor acts as cathodic inhibitor; in some cases, at high inhibitor concentration values, the difference is lower than 85 mV indicating mixed inhibition effect [9, 40].

Figure 5a shows the difference in the polarization curves of mild steel in 0.6 M NaCl + 1 × 10–3 M of compounds 3a, 3b, 4a, and 4b. It was noted that compound 3b is the most effective inhibitor followed by 3a, 4a, and 4b. This behavior is attributed to the molecular structure of the inhibitor which exchanges electrons with the metal surface and forms new bonds [19, 41]. The structure of the inhibitor molecule in space and its direction is substantial where they give the ability to form stronger bond, the parallel orientation is preferred for more adsorbed molecules on the metal surface [42]. In addition, the difference in the substituent on the moieties of the inhibitor molecules plays a role on the inhibition efficiency where 3b is substituted by cyclohexane while 3a is substituted by two methyl groups as discussed in details in the theoretical section.

a Potentiodynamic polarization curves for mild steel immersed in 0.6 M NaCl without and with 1 × 10–3 M of compounds 3b, 4b, 3a, and 4a. b Open circuit measurements for mild steel immersed in 0.6 M NaCl without and with 1 × 10–3 M of compound 3b for 7 days. c Comparison of the potentiodynamic polarization curves for mild steel immersed in 0.6 M NaCl after 5 min, 7 days and with adding 1 × 10–3 M of compound 3b for 7 days

To study the effect of time on the corrosion behavior of mild steel, the open circuit potential (Eocp) was recorded with time for the surface of mild steel electrode in 0.6 M NaCl solution with and without 1 × 10–3 M of 3b as shown in Fig. 5b. The potential of mild steel in 0.6 M NaCl increases to more negative potentials during 1440 min of immersion due to the dissolution of the metals from the alloy, then the steady state was reached by the formation of the oxide films. However, in the presence of the inhibitors, the potential of mild steel immersed in 0.6 M NaCl + 1 × 10–3 M 3b reached the steady state after 120 min of immersion indicating that the adsorption of inhibitor (3b) molecules on mild steel surface decreases the corrosion and helps in forming effective protective film on the surface within the first 2 h of immersion [9, 10, 19, 43]. The Eocp values for the two samples shifted to more negative values and when comparing the values of Eocp after 7 days of immersion, it is clear that the inhibitor could be classified as cathodic inhibitors and the adsorption of 3b molecules on the active sites of mild steel surface results in suppressing the cathodic reaction and hence preventing the dissolution of metals.

In addition, the potentiodynamic polarization of mild steel after 7 days of immersion in 0.6 M NaCl with and without 1 × 10–3 M of 3b was presented in Fig. 5c. It was noted that both the cathodic and the anodic branch of the Tafel plots shifted to more noble values, indicating passivation of mild steel due to the formation of oxide film on the surface after long immersion. The addition of 1 × 10–3 M of 3b to the chloride solution results in increasing the passivation of the surface which is indicated by the decrease in corrosion current. This behavior was confirmed by the morphology of the two surfaces as shown in Fig. 6a, b. The film formed on the surface of mild steel immersed in NaCl for 7 days appears to be very thin that leads to the appearance of some scratches on the surface with some pores filled with crystals from the chloride solution; however, the surface of mild steel immersed in NaCl with 1 × 10–3 M 3b for 7 days was seemed to be homogenous with the presence of a new feature with needle structure that filled the pores due to the adsorption of 3b molecules. The homogeneity of the surface is due to the formation of the protective film by adsorbing the inhibitor molecules [44].

Adsorption isotherm

To investigate the structural information of the linkage between the metal surface and the amount of inhibitor added and their effect on retarding the corrosion rate, the adsorption isotherm was studied. Figure 7 shows the Langmuir adsorption isotherm which is the best adsorption model that fits the experimental data of the four compounds used as inhibitors (3b, 4b, 3a, & 4a). The Langmuir adsorption isotherm can be represented by the following equation [45]:

where Kads is the equilibrium constant of adsorption, Cinh is the concentration of the inhibitor (mM), and θ is the degree of surface coverage which can be calculated from the following equation:

It was noted from Fig. 7 that the relation between Cinh/θ and Cinh was represented by straight line with regression coefficient (R2) near to unity as shown from Table 3. By using the intercept of this line, Kads can be deduced and the change in the standard free energy of adsorption \({\Delta G}_{\mathrm{ads}}^{\mathrm{o}}\) can be calculated by using the following equation [46, 47]:

where T is the absolute temperature, R is the gas constant (8.314 J mol−1 K−1), and the value of \({C}_{\mathrm{water}}\) is the concentration of water in solution (55.5 mol L−1).

As shown from the results in Table 3, compounds 3b and 3a have higher \({K}_{\mathrm{ads}}\) values indicating strong adsorption of the inhibitor molecules on the metal surface. The values of \({\Delta G}_{\mathrm{ads}}^{\mathrm{o}}\) is equal to or less negative than − 20 kJ mol−1 indicating that the molecules of the inhibitors attached to the metal surface by an electrostatic interaction (physical adsorption).

DFT results

The corrosion inhibition efficiencies of compounds 3b, 3a, 4b, and 4a are displayed in Table 4. The compounds differ slightly. Indeed, they contain two main moieties 2H-chromene and chroma-4-one. Compounds 3b and 3a differ by the substituted groups in chromene and chroma-4-one. In 3a, both moieties are substituted by two methyl groups, while in 3b, they are substituted by cyclohexane. Compounds 4b and 4a resulted from 3b and 3a by the heterolysis of the CO bond of the central moiety in the latter, i.e., 3b and 3a. The effects of the methyl and cyclohexane groups, as well as the effects of the heterolysis on the corrosion efficiency, are investigated by correlating the electronic and molecular properties of 3b, 3a, 4b, and 4a to their corrosion inhibition efficiencies (Table 4).

Except, for the dipole moment, all considered electronic and molecular properties were found to be significantly correlated with the corrosion inhibition efficiency with correlation coefficients in the range of 97–99.5%. Except for the transfer of electron property (ΔN), all other investigated properties are inversely proportional to the inhibition efficiency. In addition, to the correlation coefficients, the standard deviations were determined for each variable (Table 4). The transfer of electron (ΔN) to the metal surface is proportional to the inhibition efficiencies of 3b, 3a, 4b, and 4a, the greater ΔN, the higher is the inhibition efficiency. Compounds 4b and 4a show lower inhibition efficiencies compared to that of 3b and 3a, which may return to the heterolysis of the CO covalent bond of the central moiety. The heterolysis reduces the planarity, and thus, the number of the transfer electrons to the metal surface is reduced; therefore, the inhibition efficiency decreased. The substituted methyl and cyclohexane moieties have slight effects on both the inhibition efficiencies and the electronic and molecular properties in subgroups, i.e., 3b and 3a from one side and 4b and 4a from the other side. The stability of the synthesized compounds was investigated by calculating the electronic energies of 3b, 3a, 4b, and 4a. The compound 4b is found to be the most stable one with an electronic energy of − 3101 au. The relative electronic energy of 3b, 3a, and 4a with respect to the stable one is shown in Table 4.

To determine the organic moieties and the atomic sites of compounds 3b, 3a, 4b, and 4a that may be adsorbed on the metal surface, their corresponding optimized geometries, ESPs, and frontier orbitals HOMO and LUMO were obtained (Fig. 8). It is clear that the planarity has an important effect on the inhibition efficiency as mentioned above, and as can be realized from the 3D structural geometries of the subgroups 3b and 3a from one side and 4b and 4a from the other side (Fig. 8). Compounds 3b and 3a are more planar and thus have higher corrosion inhibition efficiencies. In 3b and 3a, the HOMO is mainly localized on the chromene moieties, which may indicate that this moiety may act as a donor of electrons to the metal surface. In 4b and 4a, the HOMO is localized on the chroman-4-one and the central part, which may indicate that these two moieties may act as donors of electrons to the metal surface. ESPs analysis reveals that the oxo group of chroman-4-one moiety in the compounds 3b, 3a, 4b, and 4a may act as the favorable site to be adsorbed on the metal surface (Fig. 8).

MD results

Figure 9 shows the adsorption of 3b, 3a, 4b, and 4a onto the metal surface. The calculated adsorption energies of 3b, 3a, 4b, and 4a are − 446.98, − 406.88, − 500.14, and − 464.09 kcal mol−1. The adsorption energy values with its negative sign indicated high adsorption of the inhibitor molecules on the metal surface which leads to good corrosion inhibition. For compound 3a, its adsorption is mainly involved 2H-chromene moiety, and both the oxygen and sulfur atoms linked to 2H-chromene moiety. In compound 3b, in addition to the 2H-chromene moiety, and the oxygen and sulfur atoms linked to 2H-chromene moiety; the oxygen atom of chroman-4-one is involved in its adsorption on the iron surface, which may be explained its high adsorption energy compared to that of compound 3a. For compound 4a, both chroman-4-one moieties along with the disulfide group that linked the two chroman-4-ones are involved in its adsorption on the iron metal surface, which may be explained its high adsorption energy compared to those of 3a and 3b. The high adsorption energy of 4b may return to the adsorption of keto groups on the iron metal surface (Fig. 9).

Conclusion

In the present study some chromeno-oxadithiin and chromeno disulfide derivatives were synthesized and characterized spectrochemically and electrochemically. All the prepared compounds exhibited similar quasi-reversible redox behavior as was determined by cyclic voltammetry and the charge transfer was through diffusion control. Some of these compounds have shown high performance in inhibiting the corrosion of mild steel in 0.6 M NaCl, and the results are summarized:

-

All investigated inhibitors suppressed both the cathodic and anodic reactions and they are classified as mixed type inhibitors; however, 3b compound represents the best inhibitor with inhibition efficiency of 98.8% at 1 × 10–3 M due to the difference in the substituent on the moieties of the inhibitor molecules, and the ability of forming stronger bond with the metal surface through the parallel orientation of the inhibitor molecules.

-

Long immersion of mild steel in 0.6 M NaCl with 1 × 10–3 M 3b increases the adsorption of the inhibitor molecules on the surface leading to passivation of mild steel surface and increasing the homogeneity of the film formed on the surface as seen from SEM.

-

The adsorption of the inhibitor molecules on the metal surface obeys the Langmuir adsorption isotherm. The values of \({\Delta G}_{\mathrm{ads}}^{\mathrm{o}}\) is equal to or less negative than − 20 kJ mol−1 indicating that the molecules of the inhibitors attached to the metal surface by an electrostatic interaction (physical adsorption).

-

The theoretical calculations refer the lower in inhibition efficiency values of using 3b and 3a to the heterolysis of the CO covalent bond of the central moiety which reduces the planarity, and thus the number of the transfer electrons to the metal surface.

-

ESPs analysis reveals that the oxo group of chroman-4-one moiety in 3b, 3a, 4b, and 4a may act as the favorable site of adsorption on the metal surface.

-

The compound 4b is found to be the most stable one with an electronic energy of -3101 au

-

The adsorption energy values from MD results indicated strong adsorption of the molecules on the metal surface

Data availability

The authors declare that the data supporting the findings of this study are available within the paper and its supplementary files. Any raw data files be needed in another format will be available from the corresponding author upon reasonable request.

References

Morsi RM, Mandour HS, Fathi AM, Awad HM et al (2019) Electrical properties, cyclic voltammetry, and anticancer activities of N-(4-(2-hydrazinyl-2-oxoethoxy) phenyl) acetamide complexes. J Phys Org Chem 32:e3945

Yadav DK, Quraishi MA (2012) Application of some condensed uracils as corrosion inhibitors for mild steel: gravimetric, electrochemical, surface morphological, UV–visible, and theoretical investigations. Ind Eng Chem Res 51:14966–14979

Yan T, Zhang S, Feng L, Qiang Y, Lu L, Fu D, Wen Y, Chen J, Li W, Tan B et al (2020) Investigation of imidazole derivatives as corrosion inhibitors of copper in sulfuric acid: combination of experimental and theoretical researches. J Taiwan Inst Chem Eng 106:118–129

Goyal M, Kumar S, Bahadur I, Verma C, Ebenso EE et al (2018) Organic corrosion inhibitors for industrial cleaning of ferrous and non-ferrous metals in acidic solutions: a review. J Mol Liq 256:565–573

Solomon MM, Umoren SA, Quraishi MA, Salman M et al (2019) Myristic acid based imidazoline derivative as effective corrosion inhibitor for steel in 15% HCl medium. J Colloid Interface Sci 551:47–60

Akrout H, Bousselmi L, Triki E, Maximovitch S, Dalard F et al (2004) Effect of non-toxic corrosion inhibitors on steel in chloride solution. J Mater Sci 39:7341–7350

Kardas G, Solmaz R (2006) Electrochemical investigation of barbiturates as green corrosion inhibitors for mild steel protection. Corros Rev 24:151–172

Fathi AM, Mandour HS, Abd Elkarim AM et al (2016) The Inhibiting effect of non toxic 4-amino antipyrine and 4, 6-dimethyl-1H-pyrazolo [3, 4-b] pyridin-3-amine on mild steel corrosion in sulphuric acid. Int J Electrochem Sci 11:5580–5595

Mandour HS, Abdel-Karim AM, Fathi AM et al (2021) Inhibition efficiency of copper corrosion in a neutral chloride solution by barbituric and thiobarbituric acids, Portugaliae. Electrochim Acta 39:85–103

Fathi AM, Anouar EH, Soliman HA, Shamroukh AH, Kotb ER, Hegab MI et al (2022) Evaluation of the inhibition effect of novel cyclohepta [b] pyridine derivatives for copper corrosion and theoretical calculations. J Phys Org Chem 35:e4297

Feng L, Maddox MM, Alam MZ, Tsutsumi LS, Narula G, Bruhn DF, Wu X, Sandhaus S, Lee RB, Simmons CJ et al (2014) Synthesis, structure–activity relationship studies, and antibacterial evaluation of 4-chromanones and chalcones, as well as olympicin A and derivatives. J Med Chem 57:8398–8420

Demirayak S, Yurttas L, Gundogdu-Karaburun N, Karaburun AC, Kayagil I et al (2017) New chroman-4-one/thiochroman-4-one derivatives as potential anticancer agents. Saudi Pharmaceutical Journal 25:1063–1072

Kaur R, Taheam N, Sharma A, Kharb R et al (2013) Important advances on antiviral profile of chromone derivatives. Res J Pharm Biol Chem Sci 4:79–96

Keri RS, Budagumpi S, Pai RK, Balakrishna RG et al (2014) Chromones as a privileged scaffold in drug discovery: a review. Eur J Med Chem 78:340–374

Alizadeh BH, Saeedi M, Dehghan G, Foroumadi A, Shafiee A et al (2015) Synthesis of some novel pyrano [2, 3-f] chromenone derivatives. J Iran Chem Soc 12:605–612

Emami S, Ghanbarimasir Z (2015) Recent advances of chroman-4-one derivatives: synthetic approaches and bioactivities. Eur J Med Chem 93:539–563

El Malah T, Shamroukh AH, Kotb ER, Soliman HA, Mahmoud K, Hegab MI et al (2021) Chemical and anticancer activity studies for some 3-chloro-3-chlorosulfenyl-4′-methylspiro [chroman-2, 1′-cyclohexane]-4-ones. Phosphorus Sulfur Silicon Relat Elem 196:970–977

Ansari KR, Quraishi MA, Singh A et al (2017) Chromenopyridin derivatives as environmentally benign corrosion inhibitors for N80 steel in 15% HCl. Journal of the Association of Arab Universities for Basic and Applied Sciences 22:45–54

Quadri TW, Olasunkanmi LO, Akpan ED, Alfantazi A, Obot I, Verma C, Al-Mohaimeed AM, Ebenso EE, Quraishi M et al (2021) Chromeno-carbonitriles as corrosion inhibitors for mild steel in acidic solution: electrochemical, surface and computational studies. RSC Adv 11:2462–2475

Salman M, Ansari K, Srivastava V, Chauhan DS, Haque J, Quraishi M et al (2021) Chromeno naphthyridines based heterocyclic compounds as novel acidizing corrosion inhibitors: Experimental, surface and computational study. J Mol Liq 322:114825

Rodríguez JA, Cruz-Borbolla J, Arizpe-Carreón PA, Gutiérrez E et al (2020) Mathematical models generated for the prediction of corrosion inhibition using different theoretical chemistry simulations. Materials 13:5656

Guo L, Zhu S, Zhang S, He Q, Li W et al (2014) Theoretical studies of three triazole derivatives as corrosion inhibitors for mild steel in acidic medium. Corros Sci 87:366–375

El-Essawy FA, Yassin SM, El-Sakka IA, Khattab AF, Søtofte I, Madsen JØ, Senning A et al (1998) Cycloadditions with 2, 2-dialkyl-3-thioxochroman-4-one S-sulfides including an unprecedented [3+ 5] cycloaddition. J Org Chem 63:9840–9845

El-Essawy FA, Yassin SM, El-Sakka IA, Khattab AF, Søtofte I, Madsen JØ, Senning AEE et al (1998) Nucleophilic substitution and redox reactions with alpha-chloro beta-oxo sulfenyl chlorides. Sulfur Lett 22:19–32

Hegab MI, Abdel-Megeid FM, Gad FA, Shiba SA, Møller J, Senning AEE et al (1998) Derivatization of alpha-chloro beta-oxo sulfenyl chlorides. Sulfur Lett 22:9–18

Hegab MI, Moustafa A (2006) Thermolysis of some spirobenzopyran-3’, 2-[1, 3, 4] oxadithiino-[5, 6-c] benzopyran-4’-ones in the presence of some homodienes and crystallographic studies of some adducts. Zeitschrift für Naturforschung B 61:1413–1420

Fathi AM, Mandour HS, HassaneAnouar E et al (2021) Characteristics of multidentate Schiff base ligand and its complexes using cyclic voltammetry, fluorescence, antimicrobial behavior and DFT-calculations. J Mol Struct 1224:129263

Bobbitt JM, Willis JP (1980) Electrochemistry of natural products. 7. Oxidative decarboxylation of some tetrahydro-.beta.-carbolinecarboxylic acids. J Org Chem 45:1978–1984

Gabbutt CD, Hepworth JD, Heron BM et al (1994) A new reaction of α-chloro-α-chlorosulfenyl ketones: facile syntheses of 3, 3-dichloro-and 3-chloro-chroman-4-ones and thiochroman-4-ones. Tetrahedron 50:5245–5254

Hegab MI, Amr AE-GA, Abdel-Megeid FM et al (2002) [4+ 2]-Cycloaddition reactions involving α-oxo thioketone intermediates. Zeitschrift für Naturforschung B 57:922–927

Frisch M, Trucks G, Schlegel H, Scuseria G, Robb M, Cheeseman J, Scalmani G, Barone V, Petersson G, Nakatsuji H et al (2016) Gaussian 16, in. Gaussian, Inc., Wallingford, CT

Yamada H, Yoshii K, Asahi M, Chiku M, Kitazumi Y et al (2022) Cyclic Voltammetry Part 1: Fundamentals. Electrochemistry 90:102005–102005

Masek A, Chrzescijanska E, Zaborski M et al (2013) Characteristics of curcumin using cyclic voltammetry, UV–vis, fluorescence and thermogravimetric analysis. Electrochim Acta 107:441–447

Bard AJ, Faulkner LR, White HS et al (2022) Electrochemical methods: fundamentals and applications. John Wiley & Sons

Badawy WA, Ismail KM, Fathi AM et al (2006) Corrosion control of Cu–Ni alloys in neutral chloride solutions by amino acids. Electrochim Acta 51:4182–4189

Kazansky L, Selyaninov I, Kuznetsov YI et al (2012) Adsorption of 2-mercaptobenzothiazole on copper surface from phosphate solutions. Appl Surf Sci 258:6807–6813

Wang Z (2012) The inhibition effect of bis-benzimidazole compound for mild steel in 0.5 M HCl solution. Int J Electrochem Sci 7:11149–11160

Al-Amiery AA, Kadhum AAH, Alobaidy AHM, Mohamad AB, Hoon PS et al (2014) Novel corrosion inhibitor for mild steel in HCl. Materials 7:662–672

Martinez S, Metikos-Hukovic M (2003) A nonlinear kinetic model introduced for the corrosion inhibitive properties of some organic inhibitors. J Appl Electrochem 33:1137–1142

Hegazy M, Abdallah M, Ahmed H et al (2010) Novel cationic gemini surfactants as corrosion inhibitors for carbon steel pipelines. Corros Sci 52:2897–2904

Udhayakala P, Samuel A, Rajendiran T, Gunasekaran S et al (2013) Theoretical assessment of corrosion inhibition performance of some pyridazine derivatives on mild steel. J Chem Pharmac Res 5:142–153

Subramanian R, Lakshminarayanan V (2002) Effect of adsorption of some azoles on copper passivation in alkaline medium. Corros Sci 44:535–554

Verma CB, Quraishi M, Singh A et al (2015) 2-Aminobenzene-1, 3-dicarbonitriles as green corrosion inhibitor for mild steel in 1 M HCl: electrochemical, thermodynamic, surface and quantum chemical investigation. J Taiwan Inst Chem Eng 49:229–239

Mishra A, Verma C, Srivastava V, Lgaz H, Quraishi M, Ebenso EE, Chung I-M et al (2018) Chemical, electrochemical and computational studies of newly synthesized novel and environmental friendly heterocyclic compounds as corrosion inhibitors for mild steel in acidic medium. J Bio- Tribo-Corros 4:1–20

Döner A, Solmaz R, Özcan M, Kardaş G et al (2011) Experimental and theoretical studies of thiazoles as corrosion inhibitors for mild steel in sulphuric acid solution. Corros Sci 53:2902–2913

Damaskin BB, Petrii OA, Batrakov VV, Uvarov E, Parsons R et al (1971) Adsorption of organic compounds on electrodes.

Lipkowski J, Ross PN (1992) Adsorption of molecules at metal electrodes. VCH, New York

Acknowledgements

The authors of this work wish to thank the authorities of (National Research Center) for financial support (research grant no. 12010101) to carry out this study.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

We declare that this manuscript is original, has not been published before, and is not currently being considered for publication elsewhere.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fathi, A.M., Anouar, E.H., Ahmed, A.O. et al. Electrochemical, molecular dynamics, density functional theory, and corrosion inhibition studies of some chromeno-oxadithiin and chromeno disulfide derivatives for mild steel in 3.5% NaCl. J Solid State Electrochem 27, 3539–3555 (2023). https://doi.org/10.1007/s10008-023-05614-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-023-05614-7