Abstract

On the normal platinum electrode and mesoporous Pt electrode, the electrochemical behaviour of catechol was studied using convolutive cyclic voltammetry and numerical simulation. The nanostructured mesoporous platinum structure was electrochemically deposited from the hexadic liquid crystalline template of C16EO8 surfactant. The electrocatalytic feature and reversibility of the mesoporous platinum electrode within the oxidation of catechol in 1.0 M HClO4 have been found to be extraordinary. At ordinary and mesoporous platinum electrodes, the separation between the peaks (∆Ep) became reduced from 430 to 75 mV vs. SCE. Catechol cyclic voltammograms show one anodic peak inside the forward scan, but the corresponding cathodic one disappears in the reverse direction, and a new peak is observed at a lower potential value at the ordinary Pt electrode. In the case of the mesoporous Pt electrode, the voltammogram gives one anodic peak inside the first scan of potential and one cathodic peak inside the reverse direction. On the basis of the electrochemical behaviour, we conclude an ECEC mechanism for the electrochemical oxidation of catechol in 1.0 M HClO4 at each electrode. A numerical simulation was used to verify the proposed electrode response.

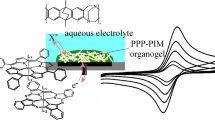

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Catechol, a nature-based molecule, has been given attention for use as a drug. The database of comprehensive medicinal chemistry (CMC) added 78 specific drugs [1]. Catechol compounds with antioxidant features are widely recognised for their potential to defend against reactive oxidative species [2,3,4]. Some pharmacological effects of catecholic tablets are adrenergic (isoproterenol, epinephrine, dopamine), antioxidant (gossypol, baicalein), (antiasthmatic isoproterenol levisoprenaline, antibiotic cefetecol, fomidacillin), enzyme inhibitor (benserazide, carbidopa) [1], and anticancer [5]. Catechol can be easily oxidised electrochemically to o-benzoquinones at low oxidation potentials [6]. In keeping with several studies, o-benzoquinone undergoes a coupling reaction with anionic and dianionic catechol species to form a C-C or C-O bond [7]. Nanostructured mesoporous metallic films, which include platinum [8,9,10], cobalt [11], nickel [12], and palladium, can be produced by way of an electrochemical deposition system from the hexadic lyotropic liquid crystalline template combinations. The deposited mesoporous metallic layers are outstanding with the aid of their excessive actual surface region because of the existence of a supremely orderly nanostructured hexadic array of cylindrical pores. The pore diameter and separation distance are in the range of 2–10 nm, depending on the deposition conditions and the template employed. Nanostructured mesoporous Pt film has attracted much attention because of its application in electrocatalysis [13, 14]. It was established that the nanostructured mesoporous platinum thin films can act as catalysts for thiourea electro-oxidation in the presence of microwave active action [15,16,17,18]. The mesoporous platinum (Pt) structure formed on a rod-shaped Pt microelectrode was reported for developments in glucose sensors without any enzymes. The measured current responses at 40 mM glucose solution of the fabricated plane Pt, Pt black, and mesoporous Pt electrodes are approximately 12.4 nA/mm2, 2.1 μA/mm2, and 2.8 μA/mm2, respectively. These data indicate that the mesoporous Pt electrode is much more sensitive than the other Pt electrodes and has a strong potential for enzymeless electrochemical sensor applications [19].

Also, mesoporous Pt catalysts fabricated by electrodeposition provide a simple method for the generation of high-performance cathodes for direct methanol PEM fuel cells, rechargeable batteries, supercapacitors, fuel cells, and electrolyzers [20, 21].

Today, it has been established that inorganic nanocomposite has a green process and has many applications in various fields such as photocatalysis, antibacterial activities, catalysts to treat water containing organic pollution and microorganisms, efficient nano-photocatalysts in the photodegradation of acid red 151 and acid blue 92, bacterial growth inhibition and bactericidal mortality, antiferromagnetic behaviour, potential hydrogen storage materials, superionic systems, applicable magnetic performance, intrinsic structure nature, narrow size distribution, good optical properties, and excellent photocatalytic efficiency [22,23,24,25,26,27,28,29,30]. By anodizing an Al-Pt alloy (98.5 at% Al and 1.5 at% Pt) made by magnetron sputtering, a Pt-nanoparticle-loaded mesoporous alumina coating is created. In a 0.4 M sulphuric acid solution at ambient temperature, it was discovered that the Al-Pt alloy could be successfully anodized at voltages between 2.8 and 4.5 V (SCE). Pt nanoparticles of 5–50 nm in size were consistently distributed throughout the porous anodic alumina layer as a result of the anodizing operations. The suggested technique can be applied widely and expanded to additional alloy systems made up of a valve metal and various alloying elements having a Gibbs free energy of oxide formation less negative than that of the valve metal [31]. Due to the fact that porous platinum combines platinum’s high specific catalytic activity with a large surface area, its synthesis and production of porous platinum electrodes have received a lot of interest recently. Because of this, porous platinum is frequently employed in chemical engineering for a wide variety of organic reactions, including hydrogenations, petroleum refinement, and the production of automobile exhausts [32]. The mesoporous Pt@Pt-skin Pt3Ni CSFWs structure was purposefully intended to combine the benefits of a 1D ultrathin atomic-jagged Pt nanowire (3 nm in diameter) core and a 3D open lattice-strained Pt-skin Pt3Ni framework shell, resulting in high activity, stability, and Pt utilisation efficiency. The existence of mesopores in the 3D open lattice-strained Pt-skin Pt3Ni framework shell, in particular, allowed for highly exposed surface regions, maximising the utilisation of Pt atoms and speeding up reactant transport [33].

The purpose of this article is to provide an electrochemical examination of catechol at normal Pt and mesoporous Pt electrodes built in a nanostructured form in an acidic medium using the convolution transform and numerical simulation for comparing the catalytic features of the two electrodes used in this text with those reported in the literature at various electrodes. At a scan rate of 50 mV s−1, it was discovered that the mesoporous Pt electrode significantly improved the movement of electron transfer kinetics and the separation among the peaks potentials (∆Ep) for catechol at nanostructured Pt electrodes.

In the future, we hope to investigate the efficiency of catalytic processes using nanostructured electrocatalysts produced by nickel-platinum electrodeposition (Ni-Pt). Based on our findings, we anticipate that the alloying of Pt with Ni in the fabricated electrodeposited nickel-platinum (Ni-Pt) catalysts will maximise the efficiency of the catalysts. In addition, we can investigate the effect of the fabricated nickel-platinum nanomaterial on corrosion resistance to determine its long-term viability.

Experimental

Chemical reagents

Analytical-grade substances have been used without additional purification. Cetyl ether surfactant C16EO8 (99%), C16H33(OCH2CH2)10OH, hydrogen hexachloro platinate (IV) hydrate (HCPA) (99.9%), and polyethylene (10) had been received from Fluka. Additionally, from Aldrich, HClO4, catechol, and H2SO4 have been purchased. Deionised and filtered water with a resistivity higher than 18 M ohm-cm was taken from an Elga water purification gadget. Argon (BOC, UK) was used to remove air from solutions earlier in each experiment.

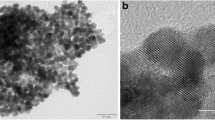

Fabrication of a nano-architecture Pt layer

The hexadic liquid crystalline plating template combination was modified into an organised manner consistent with a literature manner [11, 12] with the useful resource of dissolving hexachloroplatinic acid (HCPA) (20 wt%) in distilled water (40 wt%). The obtained solution was then thoroughly mixed with melted C16EO8 surfactant (40 wt%) at 45 °C. The mesoporous platinum films have been electrochemically deposited from the template combination at a constant potential of 100 mV vs. SCE. After electrodeposition, the template aggregate is removed from the mesoporous Pt films with the aid of soaking overnight in agitated water at 40 °C. The electrodeposited mesoporous metallic films are produced with a totally high surface area (roughness) because of the existence of a fairly ordered nanostructured hexagonal array of cylindrical pores, as proven in Scheme 1.

Instrumentation

Condesim had been performed in a traditional 3-electrode cell using a micro-Autolab Type III system (Eco Chemie, NL). A saturated calomel electrode (SCE) is used as the reference electrode. The ordinary Pt working electrode was a 1 mm diameter with an electrode surface area 7.85 × 10−3 cm2. The electrode surface area of the mesoporous Pt electrode was determined from the height of the peak current of the cyclic voltammogram via the Randles–Sevcik equation [34, 35] and found to be 1.05 × 10−2cm2. The numerical simulation of the data was run using techniques of finite difference through the EG & G condesim software program. The data was numerically simulated using finite difference techniques using the EG and G condesim software package. In the condesim software package, algorithms for the simulation software were coded and applied.

Results and discussion

Cyclic voltammetry behaviour of catechol

Figure 1 depicts the CV curves recorded at (a) a normal Pt electrode and (b) a mesoporous Pt electrode at a 50 mV s−1 scan rate of 5 mM catechol in 1.0 M HClO4. At the normal Pt electrode, the catechol oxidative peak appeared to be at 738 mV, while the reductive peak in the reverse direction appeared to be at 300 mV vs. SCE. Figure 1b shows cyclic voltammetry studies of catechol oxidation on the mesoporous Pt electrode in 1.0 M HClO4 solution at a scan rate of 50 mV s−1, demonstrating unequivocally that catechol oxidation occurs at a low overpotential due to the quick electron transfer kinetics performed at the mesoporous electrode.

The improved electrocatalytic properties of catechol oxidation at a mesoporous Pt electrode were discovered by a significant decrease in ∆Ep and a significant increase in anodic and cathodic height currents, which precisely resemble the enhancements discovered at chemically modified electrodes [36, 37], indicating fast electron transfer kinetics. Figure 1c depicts a multi-scan of the catechol cyclic voltammogram at a scan rate of 50 mV s−1 at the mesoporous electrode. It was discovered that after the first scan, there was a slight decrease in the peak’s current; then the height of the peak became stable for over 50 cycles. This behaviour confirms the stability of catechol on the mesoporous electrode surface and its superior catalytic interest over the standard Pt electrode.

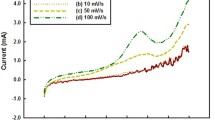

The effect of scan rate

As shown in Fig. 2 (Table 1), as the scan rate increases, so does the capability separation between the anodic and cathodic peak positions; the anodic location shifts towards more positive potentials, while the cathodic location shifts towards less positive potentials. In general, the current ratios (ipc/ipa) of mesoporous Pt electrode and normal Pt electrode are significantly lower than unity. The ratio determined on the mesoporous Pt electrode is greater than that determined on the ordinary one. This behaviour could be explained by the presence of a chemical step after the oxidative process at the ordinary Pt electrode that is faster than the one at the mesoporous one. Furthermore, at a scan rate of 50 mVs−1, the peak separation between the anodic and cathodic peak potentials is 428 and 73. 3 mV, respectively, at ordinary and mesoporous platinum electrodes, which is greater than 59 mV/n and is one of the indications that the system is not a reversible process.

The effect of the potential scan rate on the electrochemical process was investigated in order to better understand electrode behaviour and the reversibility of electrode reactions. Figure 3 shows a representation of anodic peak current extracted from a cyclic voltammogram of 5 mM catechol in 1.0 M HClO4 at a nanostructured mesoporous Pt electrode with the square root of the scan rate (v) and scan rate (v). It was noted that as the scan rate increased, the height of the oxidation peak current produced a nice linear connection with the scan rate squared (Fig. 3a). While the curve does not follow linearity in the case of the experimental scan rate. The observed behaviour supports the hypothesis that the mass transport of catechol species on the mesoporous Pt electrode in 1.0 M HClO4 is diffusion-based, controlling the electrode response [37]. Table 3 displays the values of the diffusion coefficient on the normal and mesoporous Pt electrodes as assessed by the slope of ip vs. v1/2. As shown in Fig. 4, it was found that the peak distance separation (∆Ep) increases with increasing scan rate. The difference between the peak potentials is significantly greater than 59 mV, and the distance between the two signals is in the range of 0.07 to 0.181 V. As a result, the rate of heterogeneous electron transfer for the catechol redox reaction under consideration is a quasi-reversible system.

As stated, increasing v causes an increase in current and a shift in the peak potential position to greater positive values in the scan’s forward direction (Table 2) [35]. Ep and ip are strongly correlated, but quantitative analysis of this relationship is rare. ip and Ep have a close association; however, this link has rarely been quantified. One approach to analysing the potential shift is to plot ipa against Epa [38] as shown in Fig. 5. Plotting ipa against Epa [37, 38] is one way to examine the possible shift. The result is depicted in Fig. 5. On each straight line, the extrapolation to zero current potential ought to be roughly equal to the half wave potential (E1/2) [38]. The results are shown in Fig. 5. The intercept values for the oxidative peaks at ordinary and mesoporous Pt electrodes are 0.752 V and 0.580 V, respectively. In contrast, the intercept values for reductive peaks at ordinary and mesoporous Pt electrodes were 0.315 V and 0.480 V, respectively. The oxidative and reductive transfer coefficients were calculated using the following equation [39] (Eq. 1) and are shown in Table 3.

Furthermore, diffusion coefficient values were calculated using the relationship between peak current ‘ip’ and the square root of scan rate ‘v1/2’ [39] and are shown in Table 3. In addition, the values of the heterogeneous rate constant ‘ks’ were calculated from the half peak potential ‘Ep-Ep/2’ versus the dimensionless parameter ‘ψ’ as established in the literature [40] and listed in Table 3.

Convolutive voltammetry

Following a voltammetric, chronoamperometric, or chronocoulometric experiment, a mathematical transformation (convolution) is performed. The technique generates quantities that are directly connected to the concentration of electroactive species at the electrode surface (rather than the flux of a compound, as in the original procedures), and it is generally resistant to iR drop. Fick’s second law was realised to be in the case of a simple electron transfer mechanism for electroactive species A [39]: This could be solved at the electrode to provide

This equation may be solved at the electrode to provide

S represents the surface electrode area, and I1 signifies the semi-integration of current, which is defined as [39]:

Under pure diffusion-controlled situations [i.e. when C(0,t) = 0], I1(t) gives its limiting value, Ilim,under the condition of pure diffusion-controlled [i.e. C(0,t) = 0], I1(t) gives its limiting value, Ilim:

As a result, semi integration converts the cyclic curve (i–E) shape to an S-shape plot of the I(t)–E curve, which produces a steady-state curve and, in some cases, is more adjustable for data analysis [39].

The following algorithm [39] was used to evaluate the I1(t):

I(jΔt) represents the current at equal intervals of Δt, and Γ(x) is the gamma function of x. The I1 convolution curve of the investigated catechol at an ordinary Pt electrode is depicted in Fig. 6a, which shows a clear separation between the forward and backward sweep when driven in the reverse direction [40, 42]. This behaviour can be explained by the presence of a slow electron transfer rate. Furthermore, the inability of the backward scan of I1 convolution to return to zero confirms and supports the inclusion of a chemical step in the redox pathway of catechol in 0.1 M HClO4 at the ordinary Pt electrode surface.

The convolution voltammogram curve of the experimented catechol at the mesoporous Pt electrode is illustrated in Fig. 7a, which shows a smaller potential separation distance between the forward and backward scan than that observed at the ordinary Pt electrode, clearly indicating that the rate of electron transfer at the mesoporous Pt electrode is faster [41]. Deconvolution voltammetry is defined as [42,43,44]:

The symbols a and ζ are defined as follows:

The deconvolution voltammetry curve at an ordinary Pt electrode with v = 50 mVs−1 is displayed in Fig. 6b. The half-width of the deconvoluted peak should be [42]:

The half-width of the deconvoluted peak at half its own height (wp) was measured experimentally and found to be 98.2 mV, revealing that electron transfer of catechol at an ordinary Pt electrode surface seems to be moderate. The symmetry factor (α) values were calculated using Eq. (10) and are shown in Table 3. Furthermore, the distance between the oxidative peak (O) and the reductive peak (R) is large, denoting that the reduction peak of catechol at the Pt electrode is not coupled with the oxidation process. The ratio (dI1/dt)f/(dI1/dt)b is greater than 1.0, confirming the chemical reaction’s rapidity in the experiment’s time scale. The slight displacement of the maximum and minimum peaks of deconvolution using a mesoporous electrode is strong proof of electron transfer’s quasi-reversibility in oxidative processes. Table 3 contains the experimentally determined electrochemical parameters.

The height of the deconvolution voltammetric peak was used for the calculation of the diffusion coefficient (D) via Eq. (11) [43] and put in Table 3.

The symbol ep is the height of the forward deconvolution peak (in amperes), and the remaining parameters have their known meanings. The determined values of the diffusion coefficient using Eq. (11) are cited in Table 3. Also from Eq. (12), the number of electrons involved in the mechanistic pathway was calculated.

The calculated number of electrons, n, involved in the electrode reaction via Eq. (12) was found to be 2.01 for anodic and cathodic reactions. As shown, the above equation provides a successful and simple method for determining the number of electrons consumed in the electrode reaction without knowing the electrode surface area. From the above results, it was noted that the I1 vs. E and (dI1/dt) vs. E curves were easier to elucidate and confirm the nature of the electrode reaction.

The data obtained in this work are compared with those established in the literature and summarised in Table 4, which indicates the good catalytic activity of mesoporous Pt electrodes.

Numerical simulation

The numerical simulation method is an important and successful tool for knowing the type of mechanistic pathway of electrode reactions and obtaining the kinetic parameters theoretically [44]. The transfer coefficient, the half-wave potential, the diffusion coefficient, and the heterogeneous rate constants for anodic and cathodic electrode mechanisms were estimated experimentally and confirmed via numerical simulation [41, 42, 44]. The best fit between experimental and theoretical curves consists of finding the electrochemical parameters that exhibit the fewest differences between the numerically simulated curves and the experimental plots. As shown in Fig. 8, there is good matching between the theoretical and the captured experimental voltammograms, confirming the validity of the ECEC mechanistic pathway of the electrode reaction and the accuracy of the electrochemical parameters calculated experimentally.

Conclusion

In this article, we discussed the advantages of using nanostructured Pt electrodes for catechol electrooxidation over conventional Pt electrodes in 1.0 M HClO4. The potential peak separation from cyclic voltammograms in 1.0 M HClO4 at 0.05 mV s−1 revealed that mesoporous Pt electrodes had higher electrocatalytic activity than ordinary Pt electrodes. The structure of the nanostructured Pt electrode also influences the rate of the electrochemical reaction steps within the mesoporous film. The electrocatalytic enhancement, stability, and selectivity for catechol oxidation demonstrate the utility of nanostructured mesoporous films in a variety of critical applications. The proposed electrode reaction pathway and experimentally measured electrochemical parameters were also validated using numerical simulation.

Data availability

All data generated or analysed during this study are included in this published article.

References

Yang DP, Ji HF, Tang GY, Ren W, Zhang HY (2007) How many drugs are catecholics. Molecules 12:878–884. https://doi.org/10.3390/12040878

Tejero I, Gonzalez-García N, Gonzalez-Lafont A, Lluch J (2007) Tunneling in green tea: Understanding the antioxidant activity of catechol-containing compounds. J Am Chem Soc 129:5846–5854. https://doi.org/10.1021/ja063766t

Justino GC, Catarina FC, Lurdes M, Rui MBDS, José AMS, Ana MS, Célia S, Bárbara G (2006) Antioxidant activity of a catechol derived from abietic acid. J Agric Food Chem 54:342–348. https://doi.org/10.1021/jf052062k

Bernini R, Roberta B, Fernanda C, Maurizio B, Daniela T, Valentina B, Augusto G (2012) Synthesis and structure/antioxidant activity relationship of novel catecholic antioxidant structural analogues to hydroxytyrosol and its lipophilic esters. J Agric Food Chem 60:7408–7416. https://doi.org/10.1021/jf301131a

Afsar A, Deepak B, Nagendra KK, Neha K, Eun HC, Rajeev G (2014) Syntheses, characterization, and anti-cancer activities of pyridine-amide based compounds containing appended phenol or catechol groups. J Chem Sci 126:1091–1105. https://doi.org/10.1007/s12039-014-0671-3

Nematollahi D, Rafiee M, Fotouhi L (2009) Mechanistic study of homogeneous reactions coupled with electrochemical oxidation of catechols. J Iran Chem Soc 6:448–476. https://doi.org/10.1007/BF03246523

Rayn MD, Yueh A, Chen WY (1980) The electrochemical oxidation of substituted catechols. J Electrochem Soc 127:1489. https://doi.org/10.1149/1.2129936

Nematollahi D, Rafiee M, Samadi-Meybodi A (2004) Mechanistic study of electrochemical oxidation of 4-tert-butylcatechol: A facile electrochemical method for the synthesis of new trimer of 4-tert-butylcatechol. Electrochim Acta 49:2495–2502. https://doi.org/10.1016/j.ele-ctacta.2004.02.005

Golabi SM, Nematollahi D (1997) Electrochemical study of catechol and some 3-substituted catechols in the presence of 4-hydroxy coumarin: Application to the electro-organic synthesis of new coumestan derivatives. J Electroanal Chem 420:127. https://doi.org/10.1016/S0022-0728(96)04804-8

Attard GS, Bartlett P, Coleman N, Elliott JM, Owen J, Wang JH (1997) Mesoporous platinum films from lyotropic liquid crystalline phases. Science 278:838–840. https://doi.org/10.1126/science.278.5339.838

Elliott JM, Attard G, Bartlett P, Coleman N, Merckel DAS, Owen J (1999) Nanostructured platinum (HI-ePt) films: Effects of electrodeposition conditions on film properties. Chem Mater 11:3602–3609. https://doi.org/10.1021/cm991077t

Elliott JM, Birkin PR, Bartlett PN, Attard GS (1999) Platinum microelectrodes with unique high surface areas. Langmuir 15:7411–7415. https://doi.org/10.1021/la9908945

Birkin PR, Elliot JM, Watson YE (2000) Electrochemical reduction of oxygen on mesoporous platinum microelectrodes. Chem Commun 1693–1694. https://doi.org/10.1039/B004468G

Evans SAG, Joanne ME, Andrews LM, Bartlett PN, Doyle PJ, Denuault G (2002) Detection of hydrogen peroxide at mesoporous platinum microelectrodes. Anal Chem 74:1322–1326. https://doi.org/10.1021/ac011052p

Park S, Chung TD, Kim HC (2003) Nonenzymatic glucose detection using mesoporous platinum. Anal Chem 75:3046–3049. https://doi.org/10.1021/ac0263465

Kucernak A, Jiang J (2003) Mesoporous platinum as a catalyst for oxygen electroreduction and methanol electrooxidation. Chem Eng J 93:81–90. https://doi.org/10.1016/S1385-8947(02)00111-0

Ghanem MA, Marken F (2005) Mesoporous platinum hosts for electrode∣ liquid∣ liquid–triple phase boundary redox systems. Electrochem Commun 7:1333–1339. https://doi.org/10.1016/j.elecom.2005.09.013

Ghanem MA, Coles BA, Compton RG, Marken F (2006) Microwave activation of processes in mesopores: The thiourea electrooxidation at mesoporous platinum. Electroanalysis 18:793–800. https://doi.org/10.1002/elan.200603490

Seo HK, Park DJ, Park JY (2008) Fabrication and characterization of platinum black and mesoporous platinum electrodes for in-vivo and continuously monitoring electrochemical sensor applications. Thin Solid Films 516:5227. https://doi.org/10.1016/j.tsf.2007.07.098

Esteban AF, Mariano MB, Federico AV, Federico JW, Matías J, Horacio RC (2012) Mesoporous Pt electrocatalyst for methanol tolerant cathodes of DMFC. Electrochim Acta 71:173. https://doi.org/10.1016/j.electacta.2012.03.121

Lianhai Z, Wei Z, Longbing Q, Liangliang L, Wei L, Aibing Y, Dongyuan Z (2020) Mesoporous materials for electrochemical energy storage and conversion. Adv Energy Mater 10:2002152. https://doi.org/10.1002/aenm.202002152

Makarim AM, Seyede RY, Layth SJ, Masoud SN (2022) Green synthesis of DyBa2Fe3O7.988/DyFeO3 nanocomposites using almond extract with dual eco-friendly applications: photocatalytic and antibacterial activities. Int J Hydrog Energy 47:4319–1433. https://doi.org/10.1016/j.ijhydene.2022.02.175

Seyede RY, Mojgan G, Omid A, Zeynab M, Pourya M, Morteza HO, Masoud SN (2021) Dy2BaCuO5/Ba4DyCu3O9.09 S-scheme heterojunction nanocomposite with enhanced photocatalytic and antibacterial activities. J Am Chem Soc 104:2909. https://doi.org/10.1111/jace.17696

Seyede RY, Hassan AA, Omid A, Masoud SN (2021) Synthesis, characterization and application of Co/Co3O4 nanocomposites as an effective photocatalyst for discoloration of organic dye contaminants in wastewater and antibacterial properties. J Mol Liq 337:116405. https://doi.org/10.1016/j.molliq.2021.116405

Seyede RY, Azam S, Hassan AA, Masoud SN (2021) Green sonochemical synthesis of BaDy2NiO5/Dy2O3 and BaDy2NiO5/NiO nanocomposites in the presence of core almond as a capping agent and their application as photocatalysts for the removal of organic dyes in water. RSC Adv 11:11500. https://doi.org/10.1039/D0RA10288A

Seyede RY, Omid A, Masoud SN (2019) Control sonochemical parameter to prepare pure Zn0.35Fe2.65O4 nanostructures and study their photocatalytic activity. Ultrason Sonochem 58:104619. https://doi.org/10.1016/j.ultsonch.2019.104619

Seyede RY, Maryam MA, Maryam SM, Masoud SN, Hossein M (2019) Hydrothermal synthesis of DyMn2O5/Ba3Mn2O8 nanocomposite as a potential hydrogen storage material. Int J Hydrog Energy 44:24005. https://doi.org/10.1016/j.ij-hydene.2019.07.113

Seyede RY, Azam S, Masoud SN (2017) A new nanocomposite superionic system (CdHgI4/HgI2): synthesis, characterization and experimental investigation. Adv Powder Technol 28:1258. https://doi.org/10.1016/j.apt.2017.02.013

Seyede RY, Davood G, Masoud SN, Mohammad H (2016) Photo-degradation of organic dyes: Simple chemical synthesis of Ni(OH)2 nanoparticles, Ni/Ni(OH)2 and Ni/NiO magnetic nanocomposites. J Mater Sci: Mater Electron 27:1244. https://doi.org/10.1007/s10854-015-3882-6

Poury M, Mina J, Makarim AM, Waleed KA, Layth SJ, Seyede RY, Masoud SN (2023) Rapid microwave fabrication of new nanocomposites based on Tb-Co-O nanostructures and their application as photocatalysts under UV/visible light for removal of organic pollutants in water. Arab J Chem 16:104579. https://doi.org/10.1016/j.arabjc.2023.104579

Yanlong M, Hua L, Yi L (2020) Fabrication of Pt-nanoparticle-loaded mesoporous alumina coating through anodizing of an Al-Pt alloy. ECS J Solid State Sci Technol 9:123003. https://doi.org/10.1149/2162-8777/abc80d

Arne K, von Felix S, Roland Z, Sven K (2011) Strategies for the fabrication of porous platinum electrodes. Adv Mater 23:4976. https://doi.org/10.1002/adma.201102182

Hui J, Zhewei X, Zhi-Yi H, Zhiwen Y, Zhao W, Zhao D, Ping W, Shihao F, Shunhong D, Jinfeng L, Sicheng L, Zhaodong Q, Liang Z, Liqiang M, Bao-Lian S, Dongyuan Z, Yong L (2023) Mesoporous Pt@Pt-skin Pt3Ni core-shell framework nanowire electrocatalyst for efficient oxygen reduction. Nat Commun 14:1518. https://doi.org/10.1038/s41467-023-37268-4

Pengcheng Z, Yuyuan Z (2019) Cyclic voltammetry measurements of electroactive surface area of porous nickel: Peak current and peak charge methods and diffusion layer effect. Mater Chem Phys 233:60–67. https://doi.org/10.1016/j.matchemphys.2019.05.03

Ghanem MA (2007) Electrocatalytic activity and simultaneous determination of catechol and hydroquinone at mesoporous platinum electrode. Electrochem Commun 9:2501–2506. https://doi.org/10.1016/j.elecom.2007.07.023

Qi H, Zhang C (2005) Simultaneous determination of hydroquinone and catechol at a glassy carbon electrode modified with multiwall carbon nanotubes. Electroanalysis 17:832–838. https://doi.org/10.1002/elan.200403150

DuVall SH, McCreery RL (1999) Control of catechol and hydroquinone electron-transfer kinetics on native and modified glassy carbon electrodes. Anal Chem 71:4594–4602. https://doi.org/10.1021/ac990399d

Zhang C, Aoki KJ, Chen J, Nishiumi T (2013) Blocking of two-electron reduction of non-charged species in the absence of supporting electrolyte at nanoelectrodes. J Electroanal Chem 708:101–107. https://doi.org/10.1016/j.jelechem.2013.09.023

Nicholson RS, Shain I (1965) Experimental verification of an ECE mechanism for the reduction of p-nitrosophenol, using stationary electrode polarography. Anal Chem 37:190–195. https://doi.org/10.1021/ac60221a003

Bard AJ, Faulkner LR (2001) Electrochemical methods: Fundamentals and applications. John Wiley & Sons

Leddy J, Bard AJ (1985) Polymer films on electrodes: Part XVIII. Determination of heterogeneous electron transfer kinetics at poly (vinylferrocene) and nafion/Ru (bpy)2+3 polymer-modified. J Electrolanal Chem 189:203–219. https://doi.org/10.1016/0368-1874(85)80068-X

Garrido JA, Rodriguez RM, Bastido RM, Brillas E (1992) Study by cyclic voltammetry of a reversible surface charge transfer reaction when the reactant diffuses to the electrode. J Electroanal Chem 32:19–32. https://doi.org/10.1016/0022-0728(92)80033-Z

Oldham KB, Osteryoung RA (1966) On the determination of kinetic parameters from potential-step and voltage-step measurements. J Electroanal Chem 11:397–405. https://doi.org/10.1016/0022-0728(66)80008-6

Al-Owais AA, El-Hallag IS, El-Mossalamy EH (2022) Voltammetric investigation of electrooxidation of Methyl (E)-2-cyno (N-ethyl carbazol-2-yl) acrylate at a gold electrode. Int J Electrochem Sci 17:220821. https://doi.org/10.20964/2022.08.08

Guo Y, He D, Xie A, Qu W, Tang Y, Zhou L, Zhu R (2019) The electrochemical oxidation of hydroquinone and catechol through a novel poly-geminal dicationic ionic liquid (PGDIL)–TiO2 composite film electrode. Polymers 11:1907. https://doi.org/10.3390/polym11111907

Chumillas S, Palomäki T, Zhang M, Laurila T, Climent V, Feliu JM (2018) Analysis of catechol, 4-methylcatechol and dopamine electrochemical reactions on different substrate materials and pH conditions. Electrochim Acta 292:309–321. https://doi.org/10.1016/j.electacta.2018.08.113

Da-Silva ARL, Dos-Santosa AJ, Martinez-Huitle CA (2018) Electrochemical measurements and theoretical studies for understanding the behavior of catechol, resorcinol and hydroquinone on the boron doped diamond surface. RSC Adv 8:3483–3492. https://doi.org/10.1039/C7R-A12257H

Abrha T, Pal R, Saini RC (2017) A study on voltametric electro-kinetic mechanism of catechol at ℓ-glutamic acid-carbon paste sensor. J Surface Sci Technol 33:1–11. https://doi.org/10.18311/jsst/2017/6187

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

Ibrahim El-Hallag: He suggested the idea of the present work, wrote the manuscript, elucidated the electrochemical behaviour, determined the electrochemical parameters, and submitted the manuscript to JSEL. Ahmed A. Al-Owais: He did the experimental part as well as the numerical simulation. Elsayed El-Mossalamy: He revised the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

El-Hallag, I.S., Al-Owais, A.A. & El-Mossalamy, E.H. Electrochemical studies of catechol at ordinary and mesoporous platinum electrodes via convolutive voltammetry and numerical simulation methods. J Solid State Electrochem 27, 3325–3337 (2023). https://doi.org/10.1007/s10008-023-05584-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-023-05584-w