Abstract

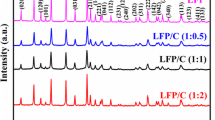

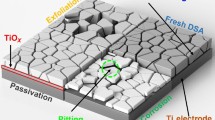

The paper presents several experimental results regarding the electrodeposition of Cu-Sn alloy coatings prepared in ChCl-EG deep eutectic solvents (DESs). The electrochemical behavior of Cu2+ and Sn2+ on glassy carbon electrode (GC) was studied by cyclic voltammetry (CV). The nucleation mechanism of Cu2+ and Sn2+ at different potentials was analyzed by the potentiostatic current density transient (chronoamperometry (CA)). Surface and phase composition of Cu-Sn alloy coating were characterized by scanning electron microscopy (SEM/DEX) and X-ray diffraction (XRD). The corrosion resistance of Cu-Sn coating was studied by potentiodynamic polarization (Tafel) and electrochemical impedance spectroscopy (EIS). From the results, it can be seen that the Cu-Sn alloy can be co-deposited at the potential from − 0.5 to − 0.8 V. The surface of the coating showed a different microstructure when the deposition potential changed. With the negative shift of deposition potential (− 0.5 to − 0.8 V), the particle size of the coating decreased. Comparison in the corrosion behavior of the coatings showed that the change of Sn content had an effect on the corrosion resistance of Cu-Sn alloy. The thickness of the coating (from 7 to 11 μm) was obtained by electrodeposition at − 0.8 V (1 h).

Similar content being viewed by others

References

Jordan M (2010) Electrodeposition of tin lead alloys, in: Schlesinger M, Paunovic M (eds.) Modern electroplating, 5th Edition, John Wiley & Sons, Hoboken, New Jersey

Piccinini N, Ruggiero GN, Baldi G, Robotto A (2000) Risk of hydrocyanic acid release in the electroplating industry. J Hazard Mater 71:395–407

Pewnim N, Roy S (2013) Electrodeposition of tin-rich Cu-Sn alloys from a methanesulfonic acid electrolyte. Electrochim Acta 90:498–506

Survila A, Bražinskienė D, Kanapeckaitė S, Mockus Z, Jasulaitienė V (2010) Codeposition of copper and tin from acidic sulfate solutions containing polyethylene glycols. Effect of length of the hydrocarbon chain. J Solid State Electrochem 14:507–514

Meng G, Sun F, Wang S, Shao Y, Zhang T, Wang F (2010) Effect of electrodeposition parameters on the hydrogen permeation during Cu–Sn alloy electrodeposition. Electrochim Acta 55:2238–2245

Correia AN, Façanha MX, Lima-Neto PD (2007) Cu–Sn coatings obtained from pyrophosphate-based electrolytes. Surf Coat Tech 201:7216–7221

Johannsen K, Page D, Roy SA (2000) Systematic investigation of current efficiency during brass deposition from a pyrophosphate electrolyte using RDE, RCE, and QCM. Electrochim Acta 45:3691–3702

Walsh FC, Low CTJ (2016) A review of developments in the electrodeposition of tin-copper alloys. Surf Coat Tech 304:246–262

Martyak NM, Seefeldt R (2004) Additive-effects during plating in acid tin methanesulfonate electrolytes. Electrochim Acta 49:4303–4311

Zanella C, Xing S, Deflorian F (2013) Effect of electrodeposition parameters on chemical and morphological characteristics of Cu–Sn coatings from a methanesulfonic acid electrolyte. Surf Coat Tech 236:394–399

Jung M, Lee G, Choi J (2017) Electrochemical plating of Cu-Sn alloy in non-cyanide solution to substitute for Ni undercoating layer. Electrochim Acta 241:229–236

Hansal WEG (2012) Pulse plating of tin and its alloys, in: Hansal WEG, Roy S (Eds.) Pulse Plating, Leuze Verlag, Bad Saulgau

Liu F, Deng Y, Han X, Hu W, Zhong C (2016) Electrodeposition of metals and alloys from ionic liquids. J Alloy Compo 654:163–170

Tachikawa N, Serizawa N, Katayama Y, Miura T (2008) Electrochemistry of Sn(II)/Sn in a hydrophobic room-temperature ionic liquid. Electrochim Acta 53:6530–6534

Anicai L, Petica A, Costovici S, Prioteasa P, Visan T (2013) Electrodeposition of Sn and NiSn alloys coatings using choline chloride based ionic liquids—evaluation of corrosion behavior. Electrochim Acta 114:868–877

Sun J, Ming T, Qian H, Li Q (2019) Electrochemical behaviors and electrodeposition of single-phase Cu-Sn alloy coating in [BMIM]Cl. Electrochim Acta 297:87–93

Liu D, Groult H, Gaillon L, Rizzi C, Soulmi N, Julien CM, Briot E, Krulic D (2015) Tunable electrodeposition of Sn and Sn-based alloys using ionic liquids. J Solid State Electrochem 19:2517–2532

Ott D, Ilgen F, Kralisch D, König B, Kreisel G (2008) Evaluating the greenness of alternative reaction media. Green Chem 10:1170–1181

Mejía-Caballero I, Aldana-González J, Manh TL, Romero Romo M, Arce-Estrada EM, Campos-Silva I, Ramírez-Silva MT, Palomar-Pardavé M (2018) Mechanism and kinetics of chromium electrochemical nucleation and growth from a choline chloride/ethylene glycol deep eutectic solvent. J Electrochem Soc 16:D393

Qian H, Sun J, Li Q, Sun H, Fu X (2020) Electrochemical mechanism of trivalent chromium reduction in ChCl-EG deep eutectic solvents containing trivalent chromium. J Electrochem Soc 167:102511

Gu CD, Mai YJ, Zhou JP, You YH, Tu JP (2012) Non-aqueous electrodeposition of porous tin-based film as an anode for lithium-ion battery. J Power Sources 214:200–207

Ghosh S, Roy S (2015) Codeposition of Cu-Sn from ethaline deep eutectic solvent. Electrochim Acta 183:27–36

Yuea D, Jia Y, Yao Y, Sun J, Jing Y (2012) Structure and electrochemical behavior of ionic liquid analogue based on choline chloride and urea. Electrochim Acta 65:30–36

Barrado E, Rodriguez JA, Hernández P, Castrillejo Y (2016) Electrochemical behaviour of copper species in the 1-buthyl-3-methylimidazolium ch loride (BMIMCl) ionic liquid on a Pt electrode. J Electroanal Chem 768:89–101

Haerens K, Matthijs E, Binnemans K, Van der Bruggen B (2009) Electrochemical decomposition of choline chloride based ionic liquid analogues. Green Chem 11:1357–1365

langhus DL (2002) Fundamentals of electrical chemistry (monk, Paul MS). J Chem Educ 79:112–113

Heerman L, Tarallo A (2000) Electrochemical nucleation with diffusion-limited growth. Properties and analysis of transients. Electrochem Commun 2:85–89

Berzins T, Delahay P, Oscillographic P (1953) Waves for the reversible deposition of metals on solid electrodes. J Am Chem Soc 75:555–559

Scharifker B, Hills G (1983) Theoretical and experimental studies of multiple nucleation. Electrochim Acta 28:879–889

Scharifker BR, Mostany J (1984) Three-dimensional nucleation with diffusion controlled growth: part I. Number density of active sites and nucleation rates per site. J Electroanal Chem 177:13–23

Scharifker BR, Mostany J (2014) Nucleation and growth of new phases on electrode surfaces, developments in electrochemistry: science inspired by Martin Fleischmann. John Wiley & Sons, Ltd

Serruya A, Mostany J, Scharifker BR (1999) The kinetics of mercury nucleation from Hg22+ and Hg2+ solutions on vitreous carbon electrodes. J Electroanal Chem 464:39–47

Mostany J, Scharifker BR, Saavedra K, Borrás C (2008) Electrochemical nucleation and the classical theory: overpotential and temperature dependence of the nucleation rate. Russ J Electrochem 44:652–658

Kasach A, Kharitonov D, Makarova I, Wrzesińska A, Zharskii IM, Kurilo II (2020) Effect of thiourea on electrocrystallization of Cu–Sn alloys from sulphate electrolytes. Surf Coat Tech 399:126137

Palomar-Pardavé M, Mostany J, Muñoz-Rizo R, Botello LE, Aldana-González J, Arce-Estrada EM, Montes de Oca-Yemha M, Ramírez-Silva MT, Romo MR (2019) Electrochemical study and physicochemical characterization of iron nanoparticles electrodeposited onto HOPG from Fe(III) ions dissolved in the choline chloride-urea deep eutectic solvent. J Electroanal Chem 851:113453

Bengoa LN, Pary P, Conconi MS, Egli WA (2017) Electrodeposition of Cu-Sn alloys from a methanesulfonic acid electrolyte containing benzyl alcohol. Electrochim Acta 256:211–219

Wu L, Graves JE, Cobley AJ (2018) Mechanism for the development of Sn-Cu alloy coatings produced by pulsed current electrodeposition. Mater Lett 217:120–123

Shima K, Tirdad N, Akram A (2011) Effects of bovine serum albumin on the corrosion behaviour of AISI 316L, Co–28Cr–6Mo, and Ti–6Al–4V alloys in phosphate buffered saline solutions. Corros Sci 53:3262–3272

Meng G, Zhang L, Shao Y, Zhang T, Wang F, Dong C, Li X (2009) Effect of refining grain size on the corrosion behavior of Cr(III) conversion layers on zinc coatings. Scr Mater 61:1004–1007

Acknowledgements

We like to express our gratitude to the anonymous reviewers of this paper for their criticisms and suggestions that contributed to improve our work.

Funding

This work was supported by the project of Liaoning Province Shenyang National Laboratory for Materials Science Joint Research (Project 2019JH3/30100021) and Shenyang Ligong University Innovation Team Fund Support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qian, H., Fu, X., Chi, Y. et al. Study on electrodeposition and corrosion resistance of Cu-Sn alloy prepared in ChCl-EG deep eutectic solvent. J Solid State Electrochem 26, 469–479 (2022). https://doi.org/10.1007/s10008-021-05086-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-021-05086-7