Abstract

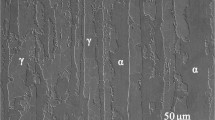

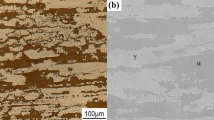

Pitting corrosion resistance of 2205 duplex stainless steel aged at 850 °C was investigated in the hot concentrated seawater (i.e., the simulated low-temperature multi-effect distillation environment) by optical microscopy (OM), scanning electronic microscopy (SEM), and electrochemical measurement techniques. The precipitation of the σ phase leads to sensitization in the specimens during the aging treatment. The degree of sensitization (DOS) presents a maximum value with the change of σ phase content. The pitting corrosion resistance of the specimens degrades markedly in the presence of very weak sensitization. The pitting potential decreases almost linearly with the logarithm of DOS. The pit propagation mainly takes place along the Cr-depleted region around the σ phase. The repassivation ability of the specimens changes insignificantly with the aging time.

Similar content being viewed by others

References

Khawaji AD, Kutubkhanah IK, Wie JM (2008) Advances in seawater desalination technologies. Desalination 221(1-3):47–69

Elimelech M, Phillip WA (2011) The future of seawater desalination: energy, technology, and the environment. Science 333(6043):712–717

Xin SS, Li MC (2014) Electrochemical corrosion characteristics of type 316L stainless steel in hot concentrated seawater. Corros Sci 81:96–101

Hassan AM, Malik AU (1989) Corrosion resistant materials for seawater RO plants. Desalination 74:157–170

Mahmoud H, Sánchez M, Alonso MC (2015) Ageing of the spontaneous passive state of 2304 duplex stainless steel in high-alkaline conditions with the presence of chloride. J Solid State Electrochem 19(10):2961–2972

Xiong J, Tan MY, Forsyth M (2013) The corrosion behaviors of stainless steel weldments in sodium chloride solution observed using a novel electrochemical measurement approach. Desalination 327:39–45

Zhang Z, Zhao H, Zhang H, Hu J, Jin J (2017) Microstructure evolution and pitting corrosion behavior of UNS S32750 super duplex stainless steel welds after short-time heat treatment. Corros Sci 121:22–31

Zhang Z, Wang Z, Jiang Y, Tan H, Han D, Guo Y, Li J (2012) Effect of post-weld heat treatment on microstructure evolution and pitting corrosion behavior of UNS S31803 duplex stainless steel welds. Corros Sci 62:42–50

Arutunow A, Darowicki K (2008) Impact of sensitization on dissolution process of AISI 304 stainless steel during intergranular corrosion evaluated using DEIS technique. J Solid State Electrochem 13:1687–1694

Lee KM, Cho HS, Choi DC (1999) Effect of isothermal treatment of SAF 2205 duplex stainless steel on migration of δ/γ interface boundary and growth of austenite. J Alloy Compd 285(1-2):156–161

Chen T, Yang J (2001) Effects of solution treatment and continuous cooling on σ-phase precipitation in a 2205 duplex stainless steel. Mater Sci Eng A 311(1-2):28–41

Ramirez A, Lippold J, Brandi S (2003) The relationship between chromium nitride and secondary austenite precipitation in duplex stainless steels. Metall Mater Trans A 34(8):1575–1597

Michalska J, Sozańska M (2006) Qualitative and quantitative analysis of σ and χ phases in 2205 duplex stainless steel. Mater Charact 56(4-5):355–362

Pohl M, Storz O, Glogowski T (2007) Effect of intermetallic precipitations on the properties of duplex stainless steel. Mater Charact 58(1):65–71

Sieurin H, Sandström R (2007) Sigma phase precipitation in duplex stainless steel 2205. Mater Sci Eng A 444(1-2):271–276

Ghosh S, Mondal S (2008) High temperature ageing behaviour of a duplex stainless steel. Mater Charact 59(12):1776–1783

Souza CM, Abreu HFG, Tavares SSM, Rebello JMA (2008) The σ phase formation in annealed UNS S31803 duplex stainless steel: texture aspects. Mater Charact 59(9):1301–1306

Martins M, Casteletti LC (2009) Sigma phase morphologies in cast and aged super duplex stainless steel. Mater Charact 60(8):792–795

Cho H-S, Lee K (2013) Effect of cold working and isothermal aging on the precipitation of sigma phase in 2205 duplex stainless steel. Mater Charact 75:29–34

Zhang B, Jiang Z, Li H, Zhang S, Feng H, Li H (2017) Precipitation behavior and phase transformation of hyper duplex stainless steel UNS S32707 at nose temperature. Mater Charact 129:31–39

Adhe KM, Kain V, Madangopal K, Gadiyar HS (1996) Influence of sigma-phase formation on the localized corrosion behavior of a duplex stainless steel. J Mater Eng Perform 5(4):500–506

Wilms ME, Gadgil VJ, Krougman JM, Kolster BH (1991) The effect of σ-phase precipitation at 800° C on the mechanical properties of a high alloyed duplex stainless steel. Mater High Temp 9(3):160–166

Nilsson JO, Wilson A (1993) Influence of isothermal phase transformations on toughness and pitting corrosion of super duplex stainless steel SAF 2507. Mater Sci Tech 9(7):545–554

El Koussy M, El Mahallawi I, Khalifa W, Al Dawood M, Bueckins M (2004) Effects of thermal aging on microstructure and mechanical properties of duplex stainless steel weldments. Mater Sci Tech 20(3):375–381

Wilms ME, Gadgil VJ, Krougman JM, Ijsseling FP (1994) The effect of σ-phase precipitation at 800° C on the corrosion resistance in sea-water of a high alloyed duplex stainless steel. Corros Sci 36(5):871–881

Ravindranath K, Malhotra SN (1995) The influence of aging on the intergranular corrosion of 22 chromium-5 nickel duplex stainless steel. Corros Sci 37(1):121–132

Magnabosco R, Alonso-Falleiros N (2005) Pit morphology and its relation to microstructure of 850 C aged duplex stainless steel. Corrosion 61(2):130–136

Kashiwar A, Vennela NP, Kamath SL, Khatirkar RK (2012) Effect of solution annealing temperature on precipitation in 2205 duplex stainless steel. Mater Charact 74:55–63

Badji R, Bouabdallah M, Bacroix B, Kahloun C, Bettahar K, Kherrouba N (2008) Effect of solution treatment temperature on the precipitation kinetic of σ-phase in 2205 duplex stainless steel welds. Mater Sci Eng A 496(1-2):447–454

Ravindranath K, Malhotra SN (1994) Influence of aging on intergranular corrosion of a 25% chromium-5% nickel duplex stainless steel. Corrosion 50(4):318–328

Gong J, Jiang YM, Deng B, Xu JL, Hu JP, Li J (2010) Evaluation of intergranular corrosion susceptibility of UNS S31803 duplex stainless steel with an optimized double loop electrochemical potentiokinetic reactivation method. Electrochim Acta 55(18):5077–5083

Hong J, Han D, Tan H, Li J, Jiang Y (2013) Evaluation of aged duplex stainless steel UNS S32750 susceptibility to intergranular corrosion by optimized double loop electrochemical potentiokinetic reactivation method. Corros Sci 68:249–255

Deng B, Wang Z, Jiang Y, Wang H, Gao J, Li J (2009) Evaluation of localized corrosion in duplex stainless steel aged at 850°C with critical pitting temperature measurement. Electrochim Acta 54(10):2790–2794

Ebrahimi N, Momeni M, Moayed MH, Davoodi A (2011) Correlation between critical pitting temperature and degree of sensitisation on alloy 2205 duplex stainless steel. Corros Sci 53(2):637–644

Deng B, Wang Z, Jiang Y, Sun T, Xu J, Li J (2009) Effect of thermal cycles on the corrosion and mechanical properties of UNS S31803 duplex stainless steel. Corros Sci 51(12):2969–2975

Peng W, Wu Z, Xu Y, Ran Q, Xu W, Li J, Xiao X (2017) Internal oxidation behaviour of Fe-Mn-Al-C duplex light-weight steels with good combination of strength and ductility. Corros Sci 120:148–157

Zhang Z, Zhao H, Zhang H, Yu Z, Hu J, He L, Li J (2015) Effect of isothermal aging on the pitting corrosion resistance of UNS S82441 duplex stainless steel based on electrochemical detection. Corros Sci 93:120–125

Ortiz N, Curiel FF, López VH, Ruiz A (2013) Evaluation of the intergranular corrosion susceptibility of UNS S31803 duplex stainless steel with thermoelectric power measurements. Corros Sci 69:236–244

Maehara Y, Ohmori Y, Murayama J, Fujino N, Kunitake T (1983) Effects of alloying elements on σ phase precipitation in δ–γ duplex phase stainless steels. Metal Sci 17(11):541–548

Calliari I, Zanesco M, Ramous E (2006) Influence of isothermal aging on secondary phases precipitation and toughness of a duplex stainless steel SAF 2205. J Mater Sci 41(22):7643–7649

Duprez L, De Cooman B, Akdut N (2000) Microstructure evolution during isothermal annealing of a standard duplex stainless steel type 1.4462. Steel Res 71(10):417–422

Duprez L, De Cooman BC, Akdut N (2001) Redistribution of the substitutional elements during σ and χ phase formation in a duplex stainless steel. Steel Res 72(8):311–316

Palumbo G, King PJ, Aust KT (1987) Pitting corrosion behavior of alloy 800 in chloride-sulfate media. Corrosion 43(1):37–45

Bellezze T, Roventi G, Fratesi R (2004) Electrochemical characterization of three corrosion-resistant alloys after processing for heating-element sheathing. Electrochim Acta 49(17-18):3005–3014

Thompson NGS, B.C. (1992) Relationship between conventional pitting and protection potentials and a new, unique pitting potential. Corrosion 48(8):649–658

Ebrahimi N, Moayed MH, Davoodi A (2011) Critical pitting temperature dependence of 2205 duplex stainless steel on dichromate ion concentration in chloride medium. Corros Sci 53(4):1278–1287

Sathirachinda N, Pettersson R, Wessman S, Pan J (2010) Study of nobility of chromium nitrides in isothermally aged duplex stainless steels by using SKPFM and SEM/EDS. Corros Sci 52(1):179–186

Ahn Y, Kang J (2000) Effect of aging treatments on microstructure and impact properties of tungsten substituted 2205 duplex stainless steel. Mater Sci Tech 16(4):382–388

Chen T, Weng K, Yang J (2002) The effect of high-temperature exposure on the microstructural stability and toughness property in a 2205 duplex stainless steel. Mater Sci Eng A 338(1-2):259–270

Calliari I, Brunelli K, Dabalà M, Ramous E (2009) Measuring secondary phases in duplex stainless steels. JOM 61(1):80–83

Dos Santos DC, Magnabosco R (2016) Kinetic study to predict sigma phase formation in duplex stainless steels. Metall Mater Trans A 47(4):1554–1565

Morais LC, Magnabosco R (2017) Experimental investigations and DICTRA® simulation of sigma phase formation in a duplex stainless steel. Calphad 58:214–218

Luo H, Dong CF, Li XG, Xiao K (2012) The electrochemical behaviour of 2205 duplex stainless steel in alkaline solutions with different pH in the presence of chloride. Electrochim Acta 64:211–220

Lopez N, Cid M, Puiggali M (1999) Influence of o-phase on mechanical properties and corrosion resistance of duplex stainless steels. Corros Sci 41(8):1615–1631

Eghbali F, Moayed MH, Davoodi A, Ebrahimi N (2011) Critical pitting temperature (CPT) assessment of 2205 duplex stainless steel in 0.1M NaCl at various molybdate concentrations. Corros Sci 53(1):513–522

Aldykiewicz AJ, Isaacs HS (1998) Dissolution characteristics of duplex stainless steels in acidic environments. Corros Sci 40(10):1627–1646

Funding

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51571139 and U1960103).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zeng, H., Yang, Y., Xu, R. et al. Pitting corrosion resistance of sensitized type 2205 duplex stainless steel in hot concentrated seawater. J Solid State Electrochem 23, 2793–2801 (2019). https://doi.org/10.1007/s10008-019-04372-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-019-04372-9