Abstract

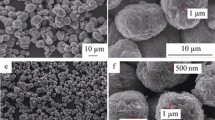

In this paper, the LiNi0.5Mn1.5O4 cathode materials of lithium-ion batteries are synthesized by a co-precipitation spray-drying and calcining process. The use of a spray-drying process to form particles, followed by a calcination treatment at the optimized temperature of 750 °C to produce spherical LiNi0.5Mn1.5O4 particles with a cubic crystal structure, a specific surface area of 60.1 m2 g−1, a tap density of 1.15 g mL−1, and a specific capacity of 132.9 mAh g−1 at 0.1 C. The carbon nanofragment (CNF) additives, introduced into the spheres during the co-precipitation spray-drying period, greatly enhance the rate performance and cycling stability of LiNi0.5Mn1.5O4. The sample with 1.0 wt.% CNF calcined at 750 °C exhibits a maximum capacity of 131.7 mAh g−1 at 0.5 C and a capacity retention of 98.9% after 100 cycles. In addition, compared to the LiNi0.5Mn1.5O4 material without CNF, the LiNi0.5Mn1.5O4 with CNF demonstrates a high-rate capacity retention that increases from 69.1% to 95.2% after 100 cycles at 10 C, indicating an excellent rate capability. The usage of CNF and the synthetic method provide a promising choice for the synthesis of a stabilized LiNi0.5Mn1.5O4 cathode material.

Micro/nanostructured LiNi0.5Mn0.5O4 cathode materials with enhanced electrochemical performances for high voltage lithium-ion batteries are synthesized by a co-precipitation spray-drying and calcining routine and using carbon nanofragments (CNFs) as additive.

Similar content being viewed by others

References

Wang J, Yao XY, Zhou XF, Liu ZP (2011) Synthesis and electrochemical properties of layered lithium transition metal oxides. J Mater Chem 21(8):2544–2549. https://doi.org/10.1039/C0JM03388J

Gu YJ, Li Y, Fu Y, Zang QF, Liu HQ, Ding JX, Wang YM, Wang HF, Ni JF (2015) LiNi0.5Mn1.5O4 synthesized through ammonia-mediated carbonate precipitation. Electrochim Acta 176(125):1029–1035. https://doi.org/10.1016/j.electacta.2015.07.114

Balogun MS, Qiu WT, Luo Y, Meng H, Mai WJ, Onasanya A, Olaniyi TK, Tong YX (2016) A review of the development of full cell lithium-ion batteries: the impact of nanostructured anode materials. Nano Res 9(10):2823–2851. https://doi.org/10.1007/s12274-016-1171-1

Hu M, Pang XL, Zhou Z (2013) Recent progress in high-voltage lithium ion batteries. J Power Sources 237(3):229–242. https://doi.org/10.1016/j.jpowsour.2013.03.024

Kraytsberg A, Ein-Eli Y (2012) Higher, stronger, better. A review of 5 volt cathode materials for advanced lithium-ion batteries. Adv Energy Mater 2(8):922–939. https://doi.org/10.1002/aenm.201200068

Manthiram A, Chemelewski K, Lee ES (2014) A perspective on the high-voltage LiMn1.5Ni0.5O4 spinel cathode for lithium-ion batteries. Energy Environ Sci 7(4):1339–1350. https://doi.org/10.1039/c3ee42981d

Shi J, Wan Z, Fu YQ (2017) Density functional theory analysis of surface structures of spinel LiNi0.5Mn1.5O4 cathode materials. J Mater Sci 52(1):605–612. https://doi.org/10.1007/s10853-016-0357-y

Pieczonka NPW, Liu Z, Lu P, Olson KL, Moote J, Powell BR, Kim JH (2013) Understanding transition-metal dissolution behavior in LiNi0.5Mn1.5O4 high-voltage spinel for lithium ion batteries. J Phys Chem C 117(31):15947–15957. https://doi.org/10.1021/jp405158m

Kim JH, Pieczonka NPW, Li Z, Wu Y, Harris S, Powell BR (2013) Understanding the capacity fading mechanism in LiNi0.5Mn1.5O4/graphite li-ion batteries. Electrochim Acta 90:556–562. https://doi.org/10.1016/j.electacta.2012.12.069

Mahootcheianasl N, Kim JH, Pieczonka NPW, Liu Z, Kim Y (2013) Multilayer electrolyte cell: a new tool for identifying electrochemical performances of high voltage cathode materials. Electrochem Commun 32:1–4. https://doi.org/10.1016/j.elecom.2013.03.031

Liu J, Manthiram A (2009) Understanding the improvement in the electrochemical properties of surface modified 5 V LiMn1.42Ni0.42Co0.16O4 spinel cathodes in lithium-ion cells. Chem Mater 21(8):1695–1707. https://doi.org/10.1021/cm9000043

Sun YK, Myung ST, Park BC, Prakash J, Belharouak I, Amine K (2009) High-energy cathode material for long-life and safe lithium batteries. Nat Mater 8(4):320–324. https://doi.org/10.1038/nmat2418

Sun YK, Chen ZH, Noh HJ, Lee DJ, Jung HG, Ren Y, Wang S, Yoon CS, Myung ST, Amine K (2012) Nanostructured high-energy cathode materials for advanced lithium batteries. Nat Mater 11(11):942–947. https://doi.org/10.1038/nmat3435

Wang DH, Choi DW, Li J, Yang ZG, Nie ZM, Kou R, Hu DH, Wang CM, Saraf LV, Zhang JG (2009) Self-assembled TiO2-graphene hybrid nanostructures for enhanced li-ion insertion. ACS Nano 3(4):907–914. https://doi.org/10.1021/nn900150y

Tang X, Jan SS, Qian YY, Xia H, Ni JF, Savilov SV, Aldoshin SM (2014) Graphene wrapped ordered LiNi0.5Mn1.5O4 nanorods as promising cathode material for lithium-ion batteries. Sci Rep 11958(5):1–10

Zhang CY, Zeng LX, Zhu XH, Yu CM, Zuo XX, Xiao X, Nan JM (2013) Electrocatalytic oxidation and simultaneous determination of catechol and hydroquinone at a novel carbon nano-fragment modified glassy carbon electrode. Anal Methods 5(9):2203–2208. https://doi.org/10.1039/c3ay26603f

Zuo XX, Jiao QF, Zhu XH, Zhang CY, Xiao X, Nan JM (2014) Preparation, characterization and electrochemical properties of a graphene-like carbon nano-fragment material. Electrochim Acta 130:156–163. https://doi.org/10.1016/j.electacta.2014.02.147

Lafont U, Locati C, Borghols WJH, Łasińska A, Dygas J, Chadwick AV, Kelder EM (2009) Nanosized high voltage cathode material LiMg0.05Ni0.45Mn1.5O4: structural, electrochemical and in situ investigation J. Power Sources 189(1):179–184. https://doi.org/10.1016/j.jpowsour.2008.09.121

Ooms FGB, Kelder EM, Schoonman J, Wagemaker M, Mulder FM (2002) High-voltage LiMgδNi0.5−δMn1.5O4 spinels for li-ion batteries. Solid State Ionics 152–153:143–153

Zhong Q, Bonakdarpour A, Zhang M, Gao Y, Dahn JR (1997) Synthesis and electrochemistry of LiNixMn2−xO4. J Electrochem Soc 144(1):205–213. https://doi.org/10.1149/1.1837386

Kim JH, Myung ST, Yoon CS, Kang SG, Sun YK (2004) Comparative study of LiNi0.5Mn1.5O4-δ and LiNi0.5Mn1.5O4 cathodes having two crystallographic structures: Fd-3m and P4332. Chem Mater 16(5):906–914. https://doi.org/10.1021/cm035050s

Yi TF, Hu XG (2007) Preparation and characterization of sub-micro LiNi0.5-xMn1.5+xO4 for 5V cathode materials synthesized by an ultrasonic-assisted co-precipitation method. J Power Sources 167(1):185–191. https://doi.org/10.1016/j.jpowsour.2007.02.003

Sun C, Rajasekhara S, Goodenough JB, Zhu F (2011) Monodisperse porous LiFePO4 microspheres for a high power li-ion battery cathode. J Am Chem Soc 133(7):2132–2135. https://doi.org/10.1021/ja1110464

Liu H, Wen G, Bi S (2016) High rate cycling performance of nanosized Li4Ti5O12/graphene composites for lithium ion batteries. Electrochim Acta 192:38–44. https://doi.org/10.1016/j.electacta.2016.01.180

Liu J, Manthiramn A (2009) Improved electrochemical performance of the 5 V spinel cathode LiMn1.5Ni0.42Zn0.08O4 by surface modification. J Electrochem Soc 156(1):A66–A72. https://doi.org/10.1149/1.3028318

Kunduraci M, Al-Sharab JF, Amatucci GG (2006) High-power nanostructured li Mn2-xNixO4 high-voltage lithium-ion battery electrode materials: electrochemical impact of electronic conductivity and morphology. Chem Mater 18(15):3585–3592. https://doi.org/10.1021/cm060729s

Fang HS, Li LP, Li GS (2007) A low-temperature reaction route to high rate and high capacity LiNi0.5Mn1.5O4. J Power Sources 167(1):223–227. https://doi.org/10.1016/j.jpowsour.2007.02.015

Xie HM, Wang RS, Ying JR, Zhang LY, Jalbout AF, Yu HY, Yang GL, Pan XM, Su ZM (2006) Optimized LiFePO4-polyacene cathode material for lithium-ion batteries. Adv Mater 18(19):2609–2613. https://doi.org/10.1002/adma.200600578

Oh SW, Myung ST, Bang HJ, Yoon CS, Amine K, Sun YK (2009) Nanoporous structured LiFePO4 with spherical microscale particles having high volumetric capacity for lithium batteries. Electrochem Solid Lett 12(9):A181–A185. https://doi.org/10.1149/1.3143901

Huang B, Zheng XD, Jia DM, Lu M (2010) Design and synthesis of high-rate micron-sized, spherical LiFePO4/C composites containing clusters of nano/microspheres. Electrochim Acta 55(3):1227–1231. https://doi.org/10.1016/j.electacta.2009.10.018

Acknowledgments

This work was financially supported by the science and technology projects of Guangdong Province (2013B090500025, 2015A040404043, 2016A050502054), the science and technology projects of Guangzhou (201604016131).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Highlights

1. Micro/nanostructured LiNi0.5Mn1.5O4 is synthesized by a co-precipitation spray-drying and calcining process.

2. Carbon nano-fragment (CNF) is introduced into the LiNi0.5Mn1.5O4 particles to improve the conductivity and protect the surface of sub-particles.

3. CNF-modified LiNi0.5Mn1.5O4 shows the enhanced electrochemical performance.

Rights and permissions

About this article

Cite this article

Ma, Y., Wang, L., Zuo, X. et al. Co-precipitation spray-drying synthesis and electrochemical performance of stabilized LiNi0.5Mn1.5O4 cathode materials. J Solid State Electrochem 22, 1963–1969 (2018). https://doi.org/10.1007/s10008-018-3884-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-018-3884-4