Abstract

The Randles–Sevčik relationship has been applied to evaluate atomic hydrogen diffusivity in massive LaNi5 intermetallic compound. The electrode was cathodically hydrogenated in 6 M KOH solution (22 °C), and then voltammetry measurements were carried out at various, very slow potential scan rates (υ = 0.01–0.1 mV · s−1). At potentials more noble than the equilibrium potential of the H2O/H2 system, the anodic peaks were registered as a consequence of oxidation of hydrogen absorbed in cathodic range. The peak potentials linearly increase with the logarithm of the scan rate with a slope of 0.059 V. The slope testifies to a symmetric charge transfer process with symmetry factor α = ½. The peak currents linearly increase with the square root of the potential scan rate, and the straight line runs through the origin of the coordinate system. The slope of the I (peak)a = f(υ 1/2) straight line is a measure of the atomic hydrogen diffusion coefficient. Assuming the hydrogen concentration in the LaNi5 material after cathodic exposure to be C 0,H = 0.071 mol · cm−3 (63 % of theoretical value), the hydrogen diffusion coefficient equals D H = 2.0 · 10−9 cm2s−1. Extrapolation of rectilinear segments of potentiodynamic polarization curves with Tafel slopes of 0.12 V and linear polarization dependencies from voltammetry tests allowed the exchange current densities of the H2O/H2 system on the tested material to be determined. The exchange current densities on initially hydrogenated LaNi5 alloy are close to 1 mA · cm−2, irrespective of the electrode potential scan rate.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

LaNi5 intermetallic compound and numerous monophase and multiphase alloys on its basis belong to the group of metallic materials capable of absorbing large amounts of atomic hydrogen and are called hydrogen storage materials or metal hydride materials. One of the most spectacular applications of the LaNi5-based alloys is in rechargeable metal hydride batteries (NiMH type)—as negative electrodes of these batteries. The negative composite electrodes are usually made of LaNi5-based fine-grained powders, mixed with binder, conducting powders and mechanically pressed [1–7]. The hydrogen absorption of such porous electrodes manufactured of fine-grained powder particles easily accessible for alkaline electrolyte consists of cathodic charging (charge transfer takes place at the surface of individual particles) and diffusion of hydrogen atoms from the particle surface into the depth of the particle. The hydrogen transport across the electrode is a very complex process. Apart from the diffusion of H atoms in the crystal lattice, one should mention “easy paths” of diffusion on grain boundaries, between neighboring particles, inside material cracks or crevices and its slowdown by corrosion products (oxide/hydroxide phases, etc.). The resulting hydrogen transport in powdered, composite material (hydrogen diffusivity) can be characterized by the effective diffusion coefficient (\( {\overline{D}}_{\mathrm{H}} \)), which takes on values of the order of 10−11–10−7 cm2s−1 [5, 8, 9]. The effective hydrogen diffusivity increases with the increase of easy paths of diffusion and decreases with particle oxidation, so it changes with electrode cycling [10–12]. For the first cycles, \( {\overline{D}}_{\mathrm{H}} \) usually increases because of an increase in material porosity. For the latest cycles, when the significance of corrosion processes increases, the formed deposits of corrosion products distinctly limit the hydrogen diffusivity [11, 13, 14].

Hydrogen diffusion coefficients in metallic materials can be determined with high accuracy using hydrogen permeation across metal membranes (Devanathan–Stachurski method [15, 16] and that modified by Zakroczymski [17, 18]). Unfortunately, hydrogen storage alloys (e.g., LaNi5) undergo mechanical degradation and decrepitation as a result of charging, so the membrane techniques appear to have been useless for these materials. The most frequently quoted methods of determining \( {\overline{D}}_{\mathrm{H}} \) for LaNi5-based powder composite electrodes are chronoammetric [8, 19–21] and cyclic voltammetry methods [9, 20–22]. Both mentioned methods suffer from experimental confinements, among which the mean powder particle radius and so-called geometric surface of the composite electrode are charged with greatest uncertainty. In voltammetric method, the height of hydrogen oxidation peak (I (peak)a [A]) at a given potential scan rate (υ [V · s−1]) is a measure of hydrogen diffusivity in the electrode material. For a semi-infinite diffusion and an irreversible charge transfer, the Randles–Sevčik type dependence takes on the following form [9, 21, 22]:

where D H [cm2s−1] is the atomic hydrogen diffusion coefficient, C 0,H [mol · cm−3] is the concentration of H-atoms in the electrode material, S is the geometric surface area of the active electrode, n is the number of electrons per one oxidized H atom (n = 1), α is the transfer coefficient, and R, T, and F are the gas constant, temperature, and Faraday constant, respectively.

Khaldi et al. [9] assumed for porous powder pressed electrodes (active powder mixed with 5 % black carbon and 5 % PTFE) that S was a geometric surface area of the electrode. As it is known [12, 22], the real active surface of porous composite electrode increases with time and with cycle number. Long-lasting cycling, however, causes corrosion effects and generation of material oxide phases (e.g., NiO) on material particles [10–12], which decreases the effective electrode surface. It has been shown in [22] that for LaNi5 particles of mean radius 0.0018 cm, the real initial effective surface of the composite pellet (containing 0.040 g of active material) was approximately 17 times greater than the geometric area of the final electrode. This efficient material surface area distinctly increases with cycling owing to further material pulverization (particularly for some first cycles [10–12, 23]). As a consequence, the hydrogen diffusion coefficient in Eq. (1) for porous composite material should be treated as a formal value (effective diffusion coefficient, \( {\overline{D}}_{\mathrm{H}} \)), which changes with cycling [10, 11]. Large differences in \( {\overline{D}}_{\mathrm{H}} \) values determined by the same authors [9] using the two mentioned methods (even 2 orders of magnitude) may result mainly from uncertainty as for active material surface area in composite electrode.

For massive LaNi5-based electrodes, the initial geometric surface area is known with good accuracy; however, the hydrogen concentration in the electrode material volume (C 0,H) is difficult to determine, and it is usually calculated from the integration of anodic part of voltammetric curve (charge resulting from cathodic hydrogen absorption). Such approach to C 0,H is arbitrary because amount of hydrogen absorbed by the electrode in cathodic range strongly depends on charging conditions (electrode dimensions, preliminary charge/discharge, start potential, potential scan rate, etc.) and obviously, the C 0,H concentration is not uniform within the electrode. On the other hand, to ensure constant and maximal concentration of H atoms in the material, the long-lasting charging and low electrode thickness are required. Moreover, the electrochemical capacity of the LaNi5-based electrodes depends on many electrochemical factors like charge rate, cycle number, external pressure and temperature [4, 6, 10–12].

In the present study, we apply the Randles–Sevčik dependence to determine hydrogen diffusion coefficient D H for massive crystalline LaNi5 material. To ensure constant concentration of atomic hydrogen in the tested material, the long-lasting cathodic charging before each polarization measurement has been carried out.

Experimental

The pieces of LaNi5 compound (Alfa–Aesar, Johnson Matthey, 99.9 % purity) have been used to cut massive (ø = 3 mm, h = 0.5 − 1 mm) disk electrodes. The sides of the disks have been isolated with epoxy resin. After polishing (No 2000 waterproof paper) and rinsing with distilled water and alcohol, the disk electrodes (operating area 0.071 cm2) have been used as working electrodes in 50 mL Teflon cell equipped with Au auxillary and HgO/Hg reference electrodes. The reference electrode has been placed in a small container with Luggins capillary, situated 0.5 mm from the working electrode surface. The argon (99.95 % purity)-saturated 6.0 M KOH solution (chemical grade purity, pH = 15.12) with a temperature of 22 ± 0.2 °C has been applied as test solution.

Prior to each polarization measurement, the electrodes were cathodically charged (I ch = 1 mA, 4 h) in order to ensure absorption of approximately 10−4 mol of hydrogen per 1 cm2 of electrode surface, i.e., amounts of at least two times greater than amounts of hydrogen oxidized during electrode discharge (3 to 6 · 10−5 mol · cm−2 for fast and slow scanning, respectively).

Electrode galvanostatic charging, potentiodynamic polarization curves (scan rate 1 mV · s−1, E start = −1.6 V, E end = −0.75 V vs HgO/Hg), and slow voltammetry measurements (υ = 0.01–0.1 mV · s−1; –1.15 to −0.6 V) have been carried out using CH Instruments Electrochemical Station (Austin, Texas).

All potentials have been measured and expressed versus HgO/Hg electrode (its equilibrium potential in 6 M KOH is 0.0315 V). More details concerning cell construction and electrochemical tests can be found in our previous papers [24–26]

Results and discussion

In Fig. 1, a typical potentiodynamic polarization curve of the tested massive LaNi5 electrode is presented in logi - E coordinate system. Although Tafel behavior is observed for half decade of logi only, the plot of cathodic and anodic curves in the range of \( {E}_{{\mathrm{H}}_2\mathrm{O}/{\mathrm{H}}_2}^{\mathrm{eq}}\pm 100 \) mV is symmetric and allows for determining both exchange current density and equilibrium potential of the H2O/H2 system on graphical way (see extrapolation of corresponding tangents at b = 0.12 V in Fig. 1). The equilibrium potential is \( {E}_{{\mathrm{H}}_2\mathrm{O}/{\mathrm{H}}_2}^{\mathrm{eq}}=-0.94\mathrm{V} \), which is a little more negative than theoretical value for H2O/H2 system (at pH = 15.12 and p ext = 1 bar, the \( {E}_{{\mathrm{H}}_2\mathrm{O}/{\mathrm{H}}_2}^{\mathrm{eq},\mathrm{theor}}=-0.925\mathrm{V} \) vs HgO/Hg). The slight shift (approximately 15 mV) of the measured value of \( {E}_{{\mathrm{H}}_2\mathrm{O}/{\mathrm{H}}_2}^{\mathrm{eq}} \) toward negative values is typical for LaNi5-based electrodes and probably results from the fact of partial passivation of the electrode material in alkaline electrolyte [24]. Exchange current density of the H2O/H2 system is 1 mA · cm−2 which is approximately two times greater than \( {i}_{{\mathrm{H}}_2\mathrm{O}/{\mathrm{H}}_2}^0 \) values most frequently quoted in literature for massive LaNi5-based alloys [5, 27].Footnote 1 In Fig. 1, potential of anodic peak is additionally shown. This peak represents the hydrogen oxidation process (½ H2 + OH- –e → H2O) and results from slow diffusion of atomic hydrogen absorbed by the material during cathodic charging [9, 22].

Potentiodynamic polarization curve (1 mV · s−1) of cathodically charged (1 mA, 4 h) LaNi5 massive electrode (S = 0.071 cm2) in Ar-saturated, 6 M KOH solution (22 °C). The dotted lines visually present graphical determining of exchange current density and equilibrium potential of H2O/H2 system as well as anodic peak current density and the peak potential

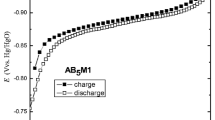

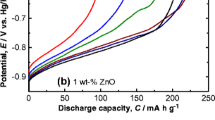

In Fig. 2, voltammetric curves measured at four potential scan rates are presented. After long-lasting galvanostatic charging (1 mA, 4 h), the electrodes were polarized in anodic direction, starting with −1.6 V up to −0.6 V (HgO/Hg). The anodic peak current densities i ((peak)a = I (peak)a /S allow the calculation of the hydrogen diffusion coefficient according to Eq. (1).

Long-lasting initial charging of the electrode allows to provide given C 0,H in the tested LaNi5 alloy. As it was found in some of our previous papers [10, 11], at standard external pressure (1 bar and at 22 °C), the maximum capacity of LaNi5 compound possible to obtain by cathodic hydrogenation is approximately 63 % of its theoretical value and corresponds to chemical formula of the hydrogenated material to be LaNi5H3.8. Assuming \( {M}_{{\mathrm{LaNi}}_5} \) = 432.4 g · mol−1, M H = 1.008 g · mol−1 and alloy density 8.3 g · cm−3, one can find that the maximum atomic hydrogen concentration in cathodically charged LaNi5Hx (x = 3.8) electrode is C 0,H = 0.072 mol · cm−3. It may be roughly evaluated from van Mal formula [2] that the depth of electrode hydrogenation was \( y=\sqrt{2{D}_{\mathrm{H}}\cdot t}\approx 80\div 120 \)μm (depending on potential scan rate).Footnote 2

The inset in Fig. 2 presents linear polarization behavior observed for the tested system in the vicinity (±20 mV) of equilibrium potential. The slopes of linear segments are measure of exchange current density of the H2O/H2 system:

The constant 0.026 [V] in the denominator of Eq. 2 assumes that the cathodic and anodic Tafel slopes are equal to 0.12 V [30, 31], R p is the polarization resistance, and η is the overpotential of the H2O/H2 electrode. In Table 1, kinetic parameters calculated from the linear polarization data are presented for applied potential scan rates.

As seen in Table 1, exchange current densities of the H2O/H2 system do not practically depend on potential scan rate and are in good agreement with \( {i}_{{\mathrm{H}}_2\mathrm{O}/{\mathrm{H}}_2}^0 \) found by extrapolation method (Fig. 1).

To determine transfer coefficient (α), the E (peak)a = f(logυ) dependence must be drawn because this dependence should be linear with a slope of [9, 21]

As it results from Fig. 3, the slope of straight line E (peak)a = f(logυ) is just exactly 0.059 V. Assuming number of electrons for considered charge transfer reaction to be n = 1 [30, 31], one can obtain α = ½. This value of transfer coefficient confirms correctness of the assumption b = 0.12 V for H2O + e → ½ H2 + OH- partial electrode reaction (compare Fig. 1). It should be mentioned that the authors of paper [9] for similar hydride system (LaNi5 partly substituted with Mn, Al and Co or Fe) found for α distinctly smaller values: 0.155 and 0.226, respectively.

Anodic peak potentials (read from Fig. 2) versus logarithm of potential scan rate

In Fig. 4, current densities corresponding to anodic peaks are presented as a function of square root of potential scan rate to determine hydrogen diffusion coefficient in the massive LaNi5 alloy. As it results from Fig. 4, the height of anodic peak current density linearly increases with \( {\upsilon}^{\frac{1}{2}} \), and a corresponding straight line crosses the origin of coordinate system, which fully satisfies Eq. 1. The slope of the straight line is B = 0.713 A · cm−2 s1/2 V−1/2. Transformation of Eq. 1 gives

Height of anodic peak read from Fig. 2 as a function of square root of potential scan rate

Substituting R = 8.314 [V · A · s−1 · mol−1 · K−1], T = 295 K, F = 96500 [A · s], α = 0.5, and C 0,H = 0.072 [mol · cm−3], we finally get D H = 2.2 · 10−9 cm2s–1.

A critical look at Eq. 3 shows that the greatest influence to the correctness and accuracy of determining hydrogen diffusion coefficient has proper assumption as for C 0,H. It should be noted that Khaldi et al. [9], Moussa et al. [21], and Kukula and Bala [22] evaluated the hydrogen concentration in powder composite electrodes by integration of surface under anodic voltammetric curve. The cited authors assumed uniform H concentration across the electrode pellet just before beginning of H oxidation (i.e., at potentials \( E<{E}_{{\mathrm{H}}_2\mathrm{O}/{\mathrm{H}}_2}^{\mathrm{eq}} \)) and hydrogen concentration equal to zero at the end potential (E end = −0.6 V). Such attitude is justified for powder-bonded electrodes, since for mean particle radii 10–20 μm, the constant H concentration is settled after approximately 10 minutes of charging.

For massive electrode material, assumption of H concentration uniformity in the whole electrode volume does not seem to be applicable even in case that the electrodes are comparatively thin (e.g. <1 mm) because even long-lasting sample hydrogenation allows for its saturation with hydrogen in depths of the order of 100 μm only. However, such a depth of C 0,H = const is sufficient if we took into account that even at the slowest scan rate (υ = 0.01 mV · s−1) the thickness of the H diffusion layer is max. 80 μm. It results from Fig. 2 that at E end = −0.6 V, anodic currents are of the order of 0.1 mA · cm−2 (for 0.01 mV · s−1) to 1 mA · cm−2 (0.1 mV · s−1), which indicates that cathodically absorbed hydrogen still diffuses and oxidizes on the working electrode.

Conclusions

-

1.

In strong alkaline solution, the H2O/H2 exchange current densities determined by voltammetric method on cathodically charged massive LaNi5 electrode are of the order of 1 mA · cm−2 and practically do not depend on potential scan rate.

-

2.

Transfer coefficient for H2O/H2 system determined at the massive LaNi5 electrode on the basis of voltammetric peak potentials (for different potential scan rates [0.01–0.1 mV · s−1]) is exactly equal to 0.5.

-

3.

Atomic hydrogen diffusion coefficient in massive LaNi5 alloy is equal to 2.2 · 10−9 cm2s−1 (22 °C).

Notes

Exchange current density of H2O/H2 system increases with electrode cycling which is typical for composite, powder metal hydride electrodes [12, 28]. For massive electrodes, the \( {i}_{{\mathrm{H}}_2\mathrm{O}/{\mathrm{H}}_2}^0 \) also increases with cycling but much less distinctly [29]. As it is known, cycling causes surface development of the active material and increase of its porosity [10, 11, 22]. It seems that comparatively large value of \( {i}_{{\mathrm{H}}_2\mathrm{O}/{\mathrm{H}}_2}^0 \) found from polarization curves presented in Fig. 1 is a consequence of long-lasting electrode charging with hydrogen prior to polarization experiment.

For hydrogen diffusion coefficient, it was assumed to be D H = 2 · 10−9 cm2s−1 (value found in this research—see succeeding parts of the paper). The total hydrogenation time t was assumed to be 4 h (initial charge time) plus cathodic polarization time read from voltammetric curves. For example, at υ = 0.01 mV · s−1, the time between E start = −1.15 V and \( {E}_{{\mathrm{H}}_2\mathrm{O}/{\mathrm{H}}_2}^{\mathrm{eq}}=-0.94\mathrm{V} \) is 210 mV/0.01 mV · s−1 = 21000 s (i.e., 5.8 h). Then, the total hydrogenation time was t = 4.0 + 5.8 = 9.8 h (i.e., 3.5 · 104 s). The hydrogenation depth determined from van Mal formula is \( y=\sqrt{2\cdot 2\cdot {10}^{-9}\cdot 3.5\cdot {10}^4}=0.012 \)cm i.e., 120 μm.

References

Ivey DG, Chittim RI, Chittim KJ, Northwood DO (1981) J Mater Energ Syst 3:3–19

Willems JJG (1984) Philips J Res 39:1–94

Sandrock G (1999) J Alloys Compd 877:293–295

Linden D, Reddy TB (2002) Handbook of batteries, 3rd edn. McGraw-Hill, New York

Kleperis J, Wojcik G, Czerwinski A, Skowronski J, Kopczyk M, Beltowska-Brzezinska M (2001) J Solid State Electrochem 5:229–249

Iwakura C, Matsuoka M (1991) Prog Batter Batter Mater 10:81–114

Notten PHL, van Beek JRG (2000) Chem Ind 54:102–115

Iwakura C, Fukuda K, Senoh H, Inoue H, Matsuoka M, Yamamoto Y (1998) Electrochim Acta 43:2041–2046

Khaldi C, Mathouthi H, Lamloumi J, Percheron-Guegan A (2004) Int J Hydrog Energy 29:307–311

Dymek M, Bala H (2013) Ochrona Przed Korozją 56:3–6

Dymek M, Bala H (2013) Ochrona Przed Korozją 56:115–119

Bala H, Kukula I, Giza K, Marciniak B, Rozycka-Sokolowska E, Drulis H (2012) Int. J. Hydrogen Energy 37:16817–16822

Adzic GD, Johnson JR, Mukerjee S, McBreen J, Reilly JJ (1997) J Alloys Compd 253–254:579–582

Reilly JJ, Adzic GD, Johnson JR, Vogt T, Mukerjee S, McBreen J (1999) J Alloys Compd 293–295:569–582

Devanathan MAV, Stachurski Z (1962) Proc Roy Soc A270:90–102

Danielson MJ (2002) Corros Sci 44:829–840

Zakroczymski T (1999) J Electroanal Chem 475:82–88

Zakroczymski T (2006) Electrochim Acta 51:2261–2266

Zheng G, Popov BN, White RE (1995) J Electrochem Soc 142:2695–2698

Nishina T, Ura H, Uchida I (1997) J Electrochem Soc 144:1273–1277

Moussa MB, Abdellaoui M, Mathlouthi H, Lamloumi J, Percheon-Guegan A (2008) J Alloys Compd 458:410–414

Kukuła I, Bala H (2010) Ochrona Przed Korozją 53:596–599

Yayama H, Ichinomiya O, Hirakawa K (1983) Japan J Appl Phys 22:L621–L623

Bala H, Giza K, Kukula I (2010) J Appl Electrochem 40:791–797

Bala H, Kukuła I, Drulis H, Hackemer A (2012) Physico-Chem Mech Mater 2:387–392

Kukuła I, Bala H (2010) XI international scientific conference “new technologies and achievements in metallurgy and materials engineering”, series: Monographs, No 2, 594–597. Czestochowa, Poland

Hu WK, Shen PW, Zhang YS, Wang GS, Song DY, Zhou ZX (1995) Int J Hydrogen Energy 20:245–246

Bala H, Dymek M, Adamczyk L, Giza K, Drulis H, J Solid State Electrochem (in press)

Kukula I (2011) Efektywność pochłaniania wodoru i zachowanie korozyjne materiału elektrodowego LaNi4(Zn, Bi). Czestochowa University of Technology, Czestochowa

Erdey-Gruz T (1972) Kinetics of electrode processes. Wiley-Interscience, Budapest

Kiss L (1988) Kinetics of electrochemical metal dissolution. Akad, Kiado

Acknowledgments

The research was cosupported by Wrocław Research Centre EIT + under the project eNanoMat (POIG.01.01.02-02-002/08) financed by the European Regional Development Fund (Innovative Economy Operational Programme, 1.1.2) and by MNiSW (Statutory Research BS/PB-207-301/2007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Dymek, M., Bala, H. Hydrogen diffusivity in the massive LaNi5 electrode using voltammetry technique. J Solid State Electrochem 18, 3033–3037 (2014). https://doi.org/10.1007/s10008-013-2339-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-013-2339-1