Abstract

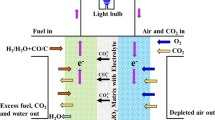

Molten carbonate fuel cell is one of the most promising high efficiency and sustainable power generation technologies, as demonstrated by the availability of several commercial units nowadays. Despite the significant progress made over the past few decades, the issues like component stability in carbonate melts and lower power density as compared to other high-temperature fuel cell systems need to be overcome to meet cost and lifetime targets. An improvement in the catalysts and system design for in situ reforming of fuel is critical to make molten carbonate fuel cells (MCFCs) compatible with real world fuels with minimal preprocessing requirements. Thus a significant opportunity exists for materials R&D in the MCFC area. In the present review, the key issues with MCFC component materials: cathode, anode, matrix, current collectors and bipolar plates, are discussed. The alternative materials and strategies adapted by the MCFC R&D community to mitigate these issues are discussed with emphasis on research trends and developments over the past decade.

Similar content being viewed by others

References

Smithsonian Institution, USA, Available at http://americanhistory.si.edu/fuelcells/mc/mcfcmain.htm. Accessed May 2010

Moreno A, McPhill S, Bove R (2008) ENEA International status of molten carbonate fuel cell (MCFC) Technology Report, Available at http://www.energyagency.at/fileadmin/aea/pdf/energietechnologien/molten-carbonate.pdf. Accessed May 2012

Fuel Cell Energy Inc, USA, Available at www.fce.com, Accessed May 2010

Tomczyk P (2006) MCFC versus other fuel cells—characteristics, technologies and prospects. J Power Sources 160:858–862

EG&G Services, Parsons Inc (2000) Fuel cell handbook, 5th edn. U.S. Department of Energy, Morgantown, USA

Selman JR, Blomen MJ, Mugerwa MN (1993) Fuel cell systems. Plenum, New York

Remick R, Wheeler D (2010) Molten carbonate and phosphoric acid stationary fuel cells: overview and gap analysis, National Renewable Energy Laboratory Technical Report. NREL/TP-560-49072

Tanimoto K (1998) Long-term operation of small sized single MCFCs. J Power Sources 72:77–82

Dicks A (2004) Molten carbonate fuel cells. Curr Opin Solid State Mater Sci 8:379–383

Farooque M (2005) Carbonate fuel cell technology and materials. MRS Bull 30:602–606

Minh N (1988) Technological status of nickel oxide cathodes in molten carbonate fuel cells–a review. J Power Sources 24:1–19

Freni S (1998) The dissolution process of NiO cathodes for molten carbonate fuel cells: state of the art. Int J Energy Res 22:17–31

Ota K, Mitsushima S, Kato S, Asano S, Yoshitake H, Kamiya N (1992) Solubilities of nickel oxide in molten carbonate. J Electrochem Soc 139:667–671

Selman JR, Yazici MS, Izaki Y (1993) NiO cathode dissolution in the MCFC: a review. Am Chem Soc Div Fuel Chem 38(4):1429–1434

Vogel W, Bregoli L, Kunz H, Smith S (1984) Stability of NiO cathodes in molten carbonate fuel cells. Proc Symp MCFC Tech Honolulu 84–13:443–451

Mitsushima S, Matsuzawa K, Kamiya N, Ota K (2002) Improvement of MCFC cathode stability by additives. Electrochim Acta 47:3823–3830

Belhomme C (2003) New insight in the cyclic voltammetric behaviour of nickel in molten carbonate. J Electroanal Chem 545:7–17

Yoshioka C, Urushibata H (1997) Simulation of cathode dissolution and shorting for molten carbonate fuel cells. J Electrochem Soc 144(3):815–822

Yoshikawa M, Mugikura Y, Watanabe T, Kahara T, Mizukamib T (2001) NiO cathode dissolution and Ni precipitation in Li/Na molten carbonate fuel cells. J Electrochem Soc 148(11):A1230–A1238

Morita H, Kawase M, Mugikura Y, Asano K (2010) Degradation mechanism of molten carbonate fuel cell based upon long term performance. J Power Sources 195:6988–6996

Giorgi L, Carewskaa M, Patriarcaa M, Scaccia S, Simonetti E, Bartolomeob AD (1994) Development and characterization of novel cathode for MCFC. J Power Sources 49:227–243

Kaun TD, Fannon TM, Baumert BA (1984) Solubility of proposed cathode materials for molten carbonate fuel cells. 166th Electrochem Soc Meet 84–2:76–77

Plomp L, Veldhuis JBJ, Sitters EF, van der Molen SB (1992) Improvement of molten-carbonate lifetime. J Power Sources 39:369–373

Plomp L, Sitters EF, Vessies C, Eckes FC (1991) Polarization characteristics of novel MCFC cathodes. J Electrochem Soc 138(2):629–630

Wijayasinghe A (2004) Development and characterisation of cathode materials for the molten carbonate fuel cell. Doctoral Dissertation Royal Institute of Technology, Stockholm, Available at kth.diva-portal.org/smash/get/diva2:9666/FULLTEXT01. Accessed May 2012

Kucera GH, Brown AP, Roche MF, Indacochea EJ, Krumplet M, Myles KM (1993) Cathode materials for MCFCs. American Chem Soc Meet OSTI USA

Bloom I, Lanagan MT, Krumpelt M, Smith JL (1999) The Development of LiFeO2–LiCoO2–NiO cathodes for molten carbonate fuel cells. J Electrochem Soc 146(4):1336–1340

Smith JL, Kucera GH, Brown AP (1990) Development of cathode materials and structures for the molten carbonate fuel cell. Proc. 2nd Symp Molten Carbonate Fuel Cell Tech (eds), JR Selman, DA Shores, HC Maru, and I Uchida, Electrochem Soc 90(16):226–246

Makkus RC, Hemmes K, de Wit JHW (1994) A comparative study of NiO(Li), LiFeO2, and LiCoO2 porous cathodes for molten carbonate fuel cells. J Electrochem Soc 141(12):3429–3438

Antolini E (2004) LiCoO2: Fromation, structure, lithium and oxygen nonstoichchiometry. Solid State Ion 170:159–171

Lundblad A, Schwartz S, Bergman B (2000) Effect of sintering procedures in development of LiCoO cathodes. J Power Sources 90:224–230

Bergman B (2001) Contact corrosion resistance between the cathode and current collector plate in the molten carbonate fuel cell. J Electrochem Soc 148(1):A38–A43

Bloom I, Kaun TD, Lanagan MT, Krumpelt M (1998) MCFC component development at ANL. Available at http://www.osti.gov/bridge/servlets/purl/10727-n8Z6af/webviewable/10727.pdf. Accessed 23 Nov 2011

Wijaysinghe A, Lagergren C, Bergmen B (2011) LiFeO–LiCoO–NiO cathodes for molten carbonate fuel cells. Fuel Cells 2:181–188

Wijaysinghe A, Bergmen B, Lagergren C (2006) LiFeO2–LiCoO2–NiO materials for molten carbonate fuel cell cathodes. Part I: Powder synthesis and material characterization. Solid State Ion 177(1–2):165–173

Wijaysinghe A, Bergmen B, Lagergren C (2006) LiFeO2–LiCoO2–NiO materials for molten carbonate fuel cell cathodes. Part II: Fabrication and characterization of porous gas diffusion cathodes. Solid State Ion 177(1–2):175–184

Zecheva E, Stoyanova R (1993) Stabilization of the layered crystal structure of LiNiO2 by Co substitution. Solid State Ion 66:143–149

Escudero MJ, Novova XR, Rodrigo T, Daza L (2002) Study of a Li–Ni oxide mixture as a novel cathode for molten carbonate fuel cells by electrochemical impedance spectroscopy. J Appl Electrochem 32:929–936

Delmas C, Saadoune I (1992) Electrochemical and physical properties of the Li x Ni1−y Co y O2 phases. Solid State Ion 370:53–56

Ganesan P, Colon H, Haran B, White R, Popov BN (2002) Study of cobalt-doped lithium–nickel oxides as cathodes for MCFC. J Power Sources 111:109–120

Kim SG, Yoon SP (2004) A study on the chemical stability and electrode performance of modified NiO cathodes for molten carbonate fuel cells. Electrochim Acta 49:3081–3089

Kim MH, Hong MZ, Kim YS, Park E, Lee H, Ha W (2006) Cobalt and cerium coated Ni powder as a new candidate cathode material for MCFC. Electrochim Acta 51:6145–6151

Kim YS, Yi CW, Choi HS, Kim K (2011) Modification of Ni-based cathode material for molten carbonate fuel cells using Co3O4. J Power Sources 196:1886–1893

Huang B, Li F, Yu Q, Chen G, Zhao B, Hu K (2004) Study of NiO cathode modified by ZnO additive for MCFC. J Power Sources 128:135–144

Escudero MJ, Nova XR, Rodrigo T, Daza L (2002) Influence of lanthanum oxide as quality promoter on cathodes for MCFC. J Power Sources 106:196–205

Liu ZP, Guo PY, Zheng CL (2007) Effect of Dy on the corrosion of NiO/Ni in molten (0.62Li, 0.38 K)2CO3. J Power Sources 166:348–353

Huang B, Ye X, Wang S, Yu Q, Nei H, Hu Q, Shi J, Hu K, Wen T (2006) Electrochemical performance of Y2O3/NiO cathode in the molten Li0.62/K0.38 carbonates eutectics. Mater Res Bull 41:1935–1948

Simonetti E, Presti RL (2006) Characterization of Ni porous electrode covered by a thin film of LiMg0.05Co0.95O2. J Power Sources 160:816–820

Mansour C, Pauporté T, Ringuedé A, Albin V, Cassir M (2006) Protective coating for MCFC cathode: low temperature potentiostatic deposition of CoOOH on nickel in aqueous media containing glycine. J Power Sources 156(1):23–27

Escuderoa MJ, Rodrigob T, Mendozac L, Cassirc M, Dazaa L (2005) Porous nickel MCFC cathode coated by potentiostatically deposited cobalt oxide: I. A structural and morphological study. J Power Sources 140(1):81–87

Fukui T, Ohara S, Okawa H, Hotta T, Naito M (2000) Properties of NiO cathode coated with lithiated Co and Ni solid solution oxide for MCFCs. J Power Sources 86:340–346

Kuk ST, Song YS, Kim K (1999) Properties of a new type of cathode for molten carbonate fuel cells. J Power Sources 83:50–56

Brenscheidt Th, Nitschke F, Sollner O, Wendt H (2001) Molten carbonate fuel cell research II. Comparing the solubility and the in-cell mobility of the nickel oxide cathode material in lithium/potassium and lithium/sodium carbonate melts. Electrochim Acta 46(6):83–797

Paoletti C, Carewska M, Presti R, Mc Phail S, Simonetti E, Zaza F (2009) Performance analysis of new cathode materials for molten carbonate fuel cells. J Power Sources 193:292–297

Kuk ST, Song YS, Suh SI, Kim JY, Kim K (2001) The formation of LiCoO2 on a NiO cathode for a molten carbonate fuel cell using electroplating. J Mat Chem 11:630–635

Mendoza L, Albin V, Cassir M, Galtayries A (2003) Electrochemical deposition of Co3O4 thin layers in order to protect the nickel-based molten carbonate fuel cell cathode. J Electroanal Chem 548:95–107

Mendoza L, Ringuede´ A, Cassir M, Galtayries A II. Structural, morphological, chemical and electrochemical analysis of nickel covered by electrochemically deposited Co3O4 in molten Li2CO3–Na2CO3 at 650 °C. J Electroanal Chem 576 1:147–160

Mansour C, Pauporté T, Ringuedé AV, Cassir M (2006) Protective coating for MCFC cathode: low temperature potentiostatic deposition of CoOOH on nickel in aqueous media containing glycine. J Power Sources 156(1):23–27

Ganesan P, Colon H, Haran B, Popov BN (2003) Performance of La0.8Sr0.2CoO3 coated NiO as cathodes for molten carbonate fuel cells. J Power Sources 115:12–18

Soler J, González T, Escudero MJ, Rodrigo T, Daza L (2002) Endurance test on a single cell of a novel cathode material for MCFC. J Power Sources 106:189–195

Song S, Jang S-C, Han J, Yoon SP, Nam SWOhI, Lim T (2011) Enhancement of cell performance using a gadolinium strontium cobaltite coated cathode in molten carbonate fuel cells. J Power Sources 196:9900–9905

Tanimoto K, Miyazaki Y, Yanagida M, Tanase S, Kojima T, Ohtori N, Okuyama H, Kodama T (1992) Cell performance of molten-carbonate fuel cell with alkali and alkaline–earth carbonate mixtures. J Power Sources 39:285–297

Tanimoto K, Kojima T, Yanagida M, Nomura K, Miyazaki Y (2004) Optimization of the electrolyte composition in a (Li0.52Na0.48)2−2x AE x CO3 (AE = Ca and Ba) molten carbonate fuel cell. J Power Sources 131:256–260

Matsuzawa K, Tatezawa G, Matsuda Y, Mitsushima S, Kamiya N, Ota K (2005) Effects of rare-earth additives in Li/Na eutectic carbonate. Electrochem Soc 152(6):A1116–A1120

Matsuzawa K, Mizusaki T, Mitsushima S, Kamiya N, Ota K (2005) The effect of La oxide additive on the solubility of NiO in molten carbonates. J Power Sources 140:258–263

Scaccia S, Frangini S, Dellepiane S (2008) Enhanced O2 solubility by RE2O3. J Mol Liq 138:107–112

Escudero MJ, Rodrigo T, Daza L (2005) Molten carbonate fuel cell cathodes: improvement of the electrocatalytic activity. Catal Today 107–108:377–387

Odemondo V, Dellepiane S, Bampi R, Capobianco P (2009) Molten carbonate fuel cell performance under different cathode conditions. J App Electrochem 39:2123–2128

Bergaglio E, Capobianco P, Dellepiane S, Durante G, Scagliotti M, Valli C (2006) MCFC cathode dissolution: an alternative approach to face the problem. J Power Sources 160:796–799

Larminie J, Dicks A (2008) Fuel cell systems explained. Wiley, New York

Selman JR (2006) Molten-salt fuel cells—technical and economic challenges. J Power Sources 160(6):852–857

Yuh C, Johnsen R, Farooque M, Maru H (1995) Status of carbonate fuel cell materials. J Power Sources 56:1–10

Iacovagelo CD (1986) Stability of molten carbonate fuel cell nickel anodes. Electrochem Soc 133:2410–2415

Kim YS, Lim JH, Chun HS (2006) Creep mechanism of porous MCFC Ni anodes strengthened by Ni3Al. AIChE J 52(1):359–365

Jung D, Lee I, Lim H, Lee D (2003) On the high creep resistant morphology and its formation mechanism in Ni–10 wt.% Cr anodes for molten carbonate fuel cells. Mater Chem 13:1717–1722

Kim G, Moon Y, Lee D (2002) Preparation of Ni–5 wt% Al alloy. J Power Sources 104:181–189

Hwang ER, Park JW, Kim YD, Kim SJ, Kang SG (1997) Effect of alloying elements on the copper-base anode for molten carbonate fuel cells. J Power Sources 69:55–60

Vielstich W, Lamm A, Gasteiger HA (eds) (2007) Handbook of fuel cells—fundamentals technology and application. Wiley, Hokeben

Wee J, Song D, Jun C, Lim T, Hong S, Lim H, Lee K (2005) Evaluation of Ni–Ni3Al(5 wt.%)–Al(3 wt.%) as an anode electrode for molten carbonate fuel cell Part I: Creep and sintering resistance. J Alloys Compd 390:155–160

Wee J, Lee K (2006) Overview of the effects of rare-earth elements used as additive materials in molten carbonate fuel cell systems. J Mater Sci 41:3585–3592

Andreas Bodén (2007) Ph.D. thesis. The anode and the electrolyte in the MCFC. KTH Chemical Science and Engineering, Stockholm, Available at kth.diva-portal.org/smash/get/diva2:12059/FULLTEXT01. Accessed May 2012

Hong S, Oh I, Lim T, Nam S, Ha H, Yun SP, Han J, Kang BS (2004) Anode for molten carbonate fuel cell coated with porous ceramic films. US Patent 6834913

Wee J (2006) Creep and sintering resistance of a Ce added anode. Mater Chem Phys 98:273–278

Wee J (2007) Effect of cerium addition to Ni–Cr anode electrode for molten carbonate fuel cells: surface fractal dimensions. Mater Chem Phys 101(2–3):322–328

Yoshikawa M, Bodén A, Sparr M, Lindbergh G (2006) Experimental determination of effective surface area and conductivities in the porous anode of molten carbonate fuel cell. J Power Sources 158:94–102

Youn JY, Yoon SP, Han J, Nam SW, Lim T, Hong S, Lee KY (2006) Fabrication and characteristics of anode as an electrolyte reservoir for MCFC. J Power Sources 157:121–127

Cavallaro S, Freni S, Cannistraci R, Aquino M, Giordanoj N (1992) Alkali effect on the MCFC internal reforming catalysts life. Int J Hydrog Energy 17(3):181–186

Dicks AL (1998) Advances in catalysts for internal reforming in high temperature fuel cells. J Power Sources 71:111–122

Clarke SH, Dicks AL, Pointon K, Smith TA, Swann A (1997) Catalytic aspects of the steam reforming of hydrocarbons. Catal Today 38(4):1–423

Katikaneni S, Yuh C, Abens S, Farooque M (2002) The direct carbonate fuel cell technology: advances in multi-fuel processing and internal reforming. Catal Today 77:99–106

Berger RJ, Doesburg EBM, Ommen JG (1996) The direct carbonate fuel cell technology: advances in multi-fuel processing and internal reforming. J Electrochem Soc 14:3186–3191

Moon HD, Lim TH, Lee HI (1999) Chemical poisoning of Ni/MgO catalyst by alkali carbonate vapor in the steam reforming reaction of DIR-MCFC. Bull Kor Chem Soc 20:1413–1417

Gaskell DR (2003) Introduction to the thermodynamics of materials. Taylor & Francis, New York

Matsumura M, Hirai C (1998) Deterioration mechanism of direct internal reforming catalysts. J Chem Eng Jpn 31:734–740

Choi J, Kwon H, Lim T, Hong S, Lee H (2004) Development of nickel catalyst supported on MgO–TiO2. Catal Today 93–95:553–560

Takeguchi T, Kani Y, Yanoa T, Kikuchia R, Eguchia K, Tsujimotob K, Uchidac Y, Uenoc A, Omoshikic K, Aizawac M (2002) Study on steam reforming of CH4 and hydrocarbons. J Power Sources 112:588–595

Nakagawa N (2001) Catalytic activity of Ni–YSZ–CeO2 anode for the steam reforming of methane. J Power Sources 92(1–2):88–94

Choi J, Yun J, Kwon H, Lim T, Hoang S, Lee H (2005) Effect of lithium carbonate on nickel catalysts for direct internal reforming MCFC. J Power Sources 145:652–658

Park DS, Li Z, Devianto H, Lee H (2010) Characteristics of alkali-resistant Ni/MgAl2O4catalyst for direct internal reforming molten carbonate fuel cell. Int J Hydrog Energy 35(11):5673–5680

Shin YJ, Moon HD, Lim T, Lee H (2000) Effects of Gd2O3 doping and steam/carbon ratio on the activity of the catalyst for internal steam reforming in molten carbonate fuel cell. Stud Surf Sci Catal 130:431–436

Zhang J, Zhang X, Tu M, Liu W, Liu H, Qiu J, Zhou L, Shao Z, Ho HL, Yeung KL (2012) Preparation of core (Ni base)–shell (Silicalite-1) catalysts and their application for alkali resistance in direct internal reforming molten carbonate fuel cell. J Power Sources 198:14–22

Fang B, Liu X, Wang X, Duan S (1998) Surface modification of a MCFC anode by electrodeposition of niobium. J Electroanal Chem 441:1–3

Devianto H, Yoon SP, Nam SW, Han J, Lim T (2006) The effect of a ceria coating on the H2S tolerance of anode. J Power Sources 159:1147–1152

Yoon SP, Han J, Nam S, Lim TH, Oh I, Devianto H, Lee H, Ham HC, Kim YC (2008) MCFC anode for internal reforming of ethanol, manufacturing process thereof. US patent 0241611

Zhu WZ, Deev SC (2003) A review on the status of anode materials for solid oxide fuel cells. Mater Sci Eng 362(1–2):228–239

Tagawa T, Yanase A, Goto S, Yamaguchi M, Kondo M (2004) Ceramic anode catalyst for dry methane type molten carbonate fuel cell. J Power Sources 126:1–7

Antolini E (2011) The stability of molten carbonate fuel cell electrodes: a review of recent improvements. Appl Energy 88:4274–4293

Parizotto NV, Rocha KO, Damyanova S, Passos FB, Zanchet D, Marques CMP, Bueno JMC (2007) Alumina-supported Ni catalysts modified with silver for the steam reforming of methane: effect of Ag on the control. Appl Catal 330:12–22

Li Z, Devianto H, Kwon H, Yoon SP, Lim T, Lee H (2010) The catalytic performance of Ni/MgSiO3 catalyst for methane steam reforming in operation of direct internal reforming MCFC. J Ind Eng Chem 16:485–489

Baker B (1989) Fuel Cell apparatus for internal reforming. US Patent 4877693

Lacovangelo CV, Pasco WD (1988) Hot-roll-milled electrolyte structures for molten carbonate fuel cells. J Electrochem Soc 135:221–224

Bohme O, Leidich FU, Salge HJ, Wendt H (1994) Development of materials and production technologies for molten carbonate fuel cells. Int J Hydrog Energy 19(4):349–355

Zhou L, Lin H, Yi B (2007) Sintering behavior of porous α-lithium aluminate matrices in molten carbonate fuel cells at high temperature. J Power Sources 164:24–32

Morita H, Komodab M, Mugikuraa Y, Izakia Y, Watanabea T, Masudac Y, Matsuyamac T (2002) Performance analysis of molten carbonate fuel cell using a Li/Na electrolyte. J Power Sources 112(2):509–518

Yoshiba F, Morita H, Yoshikawa M, Mugikura Y, Nakanishi A, Mizukami T, Takahashi K, Masuda Y (2003) Development of practical molten carbonate fuel cell stack applying Li/Na carbonate electrolyte, Japan Science and Technology Agency, Available at: http://sciencelinks.jp/j-east/article/200401/000020040103A0864964.php. Accessed 23 Nov 2011

Murai M, Takizawa K, Soejima K, Sotouchi H (1996) Crystal growth of lithium aluminate in molten Li/K carbonates. J Electrochem Soc 143:2776–2783

Takizawa K, Hagiwara A (2002) The transformation of LiAlO2 crystal structure in molten Li/K carbonate. J Power Sources 109(1):127–135

Tomimatsu N, Ohzu H, Akasaka Y, Nakagawa K (1997) Phase stability of LiAlO2 in molten carbonate. J Electrochem Soc 144(12):4182–4186

Terada S, Nagashima I, Higaki K, Ito Y (1998) Stability of LiAlO2 as electrolyte matrix for molten carbonate fuel cells. J Power Sources 75:223–229

Terada S, Higaki K, Nagashima I, Ito Y (1999) Addition of potassium tungstate to the electrolyte of a molten carbonate fuel cell. J Power Sources 83:178–185

Bartra VS, Maudgal S, Bali S, Tewari PK (2002) Addition of potassium tungstate to the electrolyte of a molten carbonate fuel cell. J Power Sources 112:322–325

Bergaglio E, Sabattini A, Capobianco P (2005) Research and development on porous components for MCFC applications. J Power Sources 149:63–65

Ferrari E, Ghisolfi E, Amelio C, Baccaro S (2011) MCFC matrix: a comparison between the traditional tape casting process and the upgraded plastic extrusion technology set up by FN. Int J Hydrog Energy 36:8094–8097

Hyun SH, Cho SC, Cho JY, Ko DH (2001) Reinforcement of molten carbonate fuel cell matrixes by adding rod-shaped. J Mater Sci 36:441–450

Kim S, Hyun S, Lim TH, Hong SA (2004) Effective fabrication method of rod-shaped LiAlO2 particles for molten carbonate fuel cell matrices. J Power Sources 137:24–29

Li I, Kim W, Moon Y, Lim H, Lee D (2001) Influence of aluminium salt addition on in situ sintering of electrolyte matrices for molten carbonate fuel cells. J Power Sources 101:90–95

Kim J, Patil K, Han J, Yoon SP, Nam S, Lim T, Hong S, Kim H, Lim H (2009) Using aluminum and Li2CO3 particles to reinforce the α-LiAlO2 matrix for molten carbonate fuel cells. Int J Hydrog Energy 34:9227–9232

Choi HJ, Lee JJ, Hyun SH, Lim HC (2010) Phase and microstructural stability of electrolyte matrix materials for molten carbonate fuel cells. Fuel Cells 10(4):613–618

Patil KY, Yoon SP, Han J, Lim T, Nam SW, Oh I, Hong S (2011) Phase stabilities in molten Li/K carbonate of efficient matrix materials for molten carbonate fuel cells: thermodynamic calculations and experimental investigations. J Mater Sci 46:2557–2567

Zhu B, Liu X, Zhou P, Yang X, Zhu Z, Zhu W (2001) Innovative solid carbonate–ceria composite electrolyte fuel cells. Electrochem Commun 3:566–571

McPhail SJ (2010) Status and challenges of molten carbonate fuel cells. Adv Sci Tech 72:283–290

Frangini S, Moreno A, Zaza F (2010) Solutions for material corrosion problems in MCFC. Adv Sci Tech 72:291–298

Zhu B, Lindbergh G, Simonsson D (1998) Comparison of electrochemical and surface characterisation methods for investigation of corrosion of bipolar plate materials in molten carbonate fuel cell: Part I. Electrochemical study. Corros Sci 41:1497–1513

Spigel M, Biedenkopf P, Grabke HJ (1997) Corrosion of iron base alloy and high alloy steels in the Li2CO3–K2CO3 eutectic mixture. Corros Sci 39(7):1193–1210

Frangini S (2006) Testing procedure to obtain reliable potentiodynamic polarization curves on type 310 S stainless steel in alkali carbonate melts. Mater Corros 57(4):330–337

Donado RA, Marianowskiru LG, Maru HC (1984) Corrosion of the wet-seal area in molten carbonate fuel cells. J Electrochem Soc 131(11):2535–2540

Yuh C, Colpetzer J, Dickson K, Farooque M, Xu G (2006) Carbonate fuel cell materials. J Mater Eng Perform 15(4):457–462

Yuh C, Hilmi A, Farooque M, Leo T, Xu G (2009) Direct fuel cell materials experience. ECS Trans 17(1):637–654

Huijsmans JPP, Kraaij GJ, Makkus RC, Rietveld G, Sitters EF, Reijers HThJ (2000) An analysis of endurance issues for MCFC. J Power Sources 86:117–121

Durante G, Vegnia S, Capobianco P, Golgovici F (2005) High temperature corrosion of metallic materials in molten carbonate fuel cells environment. J Power Sources 152(1):204–209

Frangini S, Loreti S (2007) The role of alkaline-earth additives on the molten carbonate corrosion of 316 L stainless steel. Corros Sci 49:3969–3987

Colón-Mercado H, Ganesan P, Popov B (2007) Performance studies of bare and Co-plated titanium alloy as cathode current collector in molten carbonate fuel cell (MCFC). Surf Coat Technol 201:6452–6459

Vossen JPT, Plomp L, Wit JHW, Rietveid G (1995) Corrosion behavior of stainless steel and nickel-base alloys in molten carbonate. J Electrochem Soc 142(10):3327–3335

Biedenkopf P, Bischoff MM, Wochner T (2000) Corrosion phenomena of alloys and electrode materials in molten carbonate fuel cells. Mater Corros 51:287–302

Parezanović I, Strauch E, Spiegel M (2004) Development of spinel forming alloys with improved electronic conductivity for MCFC applications. J Power Sources 135:52–61

Randström S, Lagergren C, Capobianco P (2006) Corrosion of anode current collectors in molten carbonate fuel cells. J Power Sources 160:782–788

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kulkarni, A., Giddey, S. Materials issues and recent developments in molten carbonate fuel cells. J Solid State Electrochem 16, 3123–3146 (2012). https://doi.org/10.1007/s10008-012-1771-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-012-1771-y