Abstract

The treatment of Ag, Pd, Au and Pt electrodes with OH• radicals can be used to get information on the nature of the electrocatalytic sites. Atomic force microscopy (AFM) measurements, various electrochemical techniques, and chemical solution analysis show a more or less effective surface dissolution of these metals upon OH• treatment. The effect of the surface alterations on the electrocatalytic activity with respect to the quinone/hydroquinone system revealed distinct differences between Ag and Au (previous studies) on one side, and Pt and Pd on the other side. Whereas, in case of Pt and Pd, the electrocatalytic properties are obviously related to the regular surface atoms, in case of Ag and Au the active centers are highly reactive surface atoms which can be removed by OH• radicals.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Electrocatalysis is of prime importance, both from a practical as well as from a theoretical point of view. As in chemical catalysis, the extent of experimental results gathered over the years is vast and the theoretical understanding started with empirical free energy relationships and now reached a level where quantum chemical calculations and atomically resolved surface structure analysis starts to reveal the mechanisms of electrocatalysis on a molecular level [1–5]. However, despite the undeniable progress that has been achieved, it should be remembered that we are not yet able to model and understand the role of all the different structure elements which build up a real metal surface. These structure elements comprise (1) small domains of well ordered single crystal planes, (2) all kinds of defects (various point defects and extended defects, steps, etc.), as well as (3) surface clusters and surface atoms chemically bond to foreign chemical elements (e.g., surface oxides). Finally, the dynamics of surfaces [6] should not be forgotten, as they may play a crucial role in catalysis. Whereas it is possible to study model reactions at some kinds of these surface elements by microscopy, spectroscopy and theoretical calculations, it is yet illusive to achieve this for “single atom defect structures”, e.g., for single metal atoms at sites where they are either partially oxidized or in some unknown state. Burke [7–10] has published several papers in which he has shown that very rough and—one must admit that—yet undefined metal surfaces, possess an exceedingly high electrocatalytic activity. Again, it seems to be illusive to identify the active centers on such surfaces. For these reasons, it is interesting to treat the metal surface with chemical reagents which attack and dissolve these most reactive, and thus—probably—also most electrocatalytically active sites, in order to obtain information on their role in electrocatalysis. The idea behind this is, if we cannot make these sites visible, we may try to destroy them in order to see the impact of this action on electrocatalysis. Their destruction can be concluded from the chemical analysis of the etching solutions after treating the metals, and—at least to some extent—from atomic force microscopy (AFM) images and conventional electrochemical determinations of the real electrode surface area.

The present paper is a preliminary attempt to follow the outlined strategy. In this work, we are extending our research on the interaction of OH• radicals with materials [11–13] to silver, palladium and platinum, and discuss the results together with the previous results for gold. In the case of gold, we have shown recently that OH• radicals dissolve the surface asperities which resulted from a previous mechanical polishing, and we could show that the removal of these asperities leads to a decreased electrocatalytic activity. In the case of glassy carbon, the results were different: the OH• radicals led to increased roughening of the surface accompanied, however, with a decrease of the number of active sites for metal deposition. In this article, we describe the consequences of treating silver and palladium with OH• radicals. The most inspiring aspect of this research is that it gives hints to the nature of the electrocatalytic centres.

Experimental

Cyclic voltammetry was performed with an Autolab, model 12 potentiostat (Eco-Chemie, Utrecht, the Netherlands). All voltammetric experiments were carried out in the three-electrode system. Silver and palladium disc electrodes were used as the working electrodes, an Ag/AgCl electrode served as the reference electrode and a platinum wire was used as the auxiliary electrode. The working electrodes were prepared by sealing polycrystalline wires (0.5 mm diameter) in glass capillaries. To achieve a tight sealing this was performed under vacuum and the wires were appropriately cut and polished to provide suitable disc electrodes. The metal wires were delivered by Goodfellow (England) and the purity was 99.95% and 99.99% for Pd and Ag, respectively. Before experiments, the surfaces of the tested metals were polished with 1.0 and 0.3 μm Al2O3 powder on a wet pad. To remove residual alumina completely from the electrode surface after each polishing, the electrode was rinsed with a direct stream of ultrapure water (Milli-Q, Millipore, conductivity of ~0.056 μS/cm) and dried with argon. In all experiments, the electrochemical cell was kept in a Faraday cage to minimize the electrical noise. Before treatment with Fenton solution the electrodes were subjected to potential cycles in sulfuric acid (Pd and Au) and perchloric acid (Ag) to get reproducible curves.

The Fenton solution was always freshly prepared from EDTA (Merck), 0.01 M acetate buffer (pH 4.7), hydrogen peroxide solution and either ammonium iron(II) sulfate hexahydrate (Merck) or iron(II) sulfate heptahydrate (Sigma-Aldrich) in the case of palladium. Before each measurement, the surface of the working electrode was also freshly prepared (polished) and introduced to the Fenton solution for a defined time interval: electrodes were treated with Fenton solutions always for 5 min (since the OH• formation decays rapidly) and these 5-min treatments were repeated as often as necessary to have a certain overall treatment time, e.g., eight times for a 40-min overall treatment time. The reaction of the Fenton solution with each electrode was terminated by removing the electrode from the Fenton solution and by washing it with water.

AFM images were recorded in contact mode with a “NanoScope I” (Digital Instruments) using the software “NanoScope E 4.23r3”. To avoid the catalytic reaction of H2O2 at the silver or palladium surface and at the cantilever during AFM imaging, the OH• radicals were generated electrochemically (simultaneous reduction of Fe(III) to Fe(II), and of oxygen to H2O2). The studied electrode surfaces were fixed in a home designed cell with a three-electrode assembly under pure oxygen atmosphere. The reference electrode was an Ag/AgCl (3 M KCl) electrode, the working and counter electrodes were platinum. The electrolyte contained 0.1 mol l−1 Na2SO4, 0.1 mmol l−1 FeSO4 and 0.1 M H2SO4. H2O2 and Fe(II) were galvanostatically generated (to form OH• radicals) with 60 mA current for 10 s. After this an AFM image was recorded and H2O2 and Fe(II) were generated again to form OH• radicals. This procedure was repeated until no further changing of the metal surface was detectable. By doing so, the H2O2 concentration was small enough to avoid the generation of oxygen bubbles on the metal surface and the platinum coated cantilever.

Inductively coupled plasma atomic emission spectroscopy (ICP-AES) was performed with the ICP-Optical Emission Spectrometer Optima 2,100 DV (Perkin Elmer, USA). High-purity argon (Ar 5.0, Praxair, Germany) was used for plasma generation, applying a radio frequency power of 1,300 W.

Results

Free radicals can cause substantial changes in the morphology and activity of the electrode surfaces. As a result, the real surface area of electrodes can diminish or increase, and the voltammetric response of the electrodes to various analytes can change. As has been already shown, in the case of gold electrodes treated with OH• radicals, the electron transfer rate and possibly the reaction path can change [11, 12].

Effects of the interaction of silver with OH• radicals

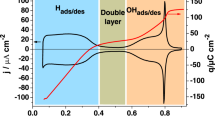

The treatment of silver with the Fenton solution leads to similar changes as in the case of gold. The OH• radicals preferentially dissolve the silver atoms, which are part of small asperities that are present on the surface, even after a careful mechanical polishing. Of course, these asperities may be a result of that polishing. Figure 1 depicts AFM images of the silver surface after mechanical polishing and after the attack by OH• radicals that follows the polishing step. The polishing effect of the OH• radicals is very clearly visible. The ICP-AES analytical measurements showed that the dissolution rate was high at the beginning of the action (about 45 ng cm−2 s−1) and practically dropped to zero at the end of the treatment. The decrease of real surface area of the silver electrode was studied using two independent electrochemical methods: (a) cyclic voltammetry in the potential range 0.2 to −0.5 V (vs. Ag/AgCl) in 0.1 M HClO4 solution, and (b) underpotential deposition (upd) of Pb. In these experiments, the electrode was always mechanically polished before the attack by OH• radicals, that is, the mechanical polishing was essentially roughening the surface compared to the smoothing effect of OH• radicals. The cyclic voltammetric curves of the Ag electrode, recorded after various times of reaction between Ag and OH• radicals, are presented in Fig. 2a. In the potential range from 0.1 to −0.3 V, the currents are of capacitive nature. In the range of negative potentials the electroreduction of protons takes place. Since the capacitive current can be described by I c = AC d v (where A is the surface area, C d is the differential capacity, and v is the scan rate), the changes in capacitive current for the same potential and the same scan rate will determine the real surface area. Hupp et al. [14] have shown how a change in roughness factor can lead to corresponding substantial change in the differential capacity at polycrystalline silver electrodes. The changes in the measured capacitive currents must therefore reflect the changes in electrode surface area. We have measured the difference between the cathodic and anodic currents at −0.1 V after 60-min treatments. This difference must also be proportional to the real surface area. The real surface area diminished with time of treatment of the electrode with OH• radicals by 55%. Very similar results were obtained when the charge of the capacitive current was calculated (integration of voltammograms) in the potential ranges between 0 and 0.1, −0.1 and −0.2 V and for three different scan rates (50, 100 and 200 mV/s); the decrease in real surface area ((Q t=60 s/Q t=0) × 100%)) calculated for all these cases was in the range of 52–60%. In fact, it is known that the capacitance of Ag electrode decreases simply by being in contact with an electrolyte solution [15]; however, under our experimental conditions, that decrease was only 30% after a 60-min contact with the solution without radicals. This means that the treatment of the silver electrode with OH• radicals produced a considerable additional effect. Furthermore, the reduction current of protons observed at more negative potentials is also strongly decreased (Fig. 2a), which we interpret as an effect of decreased surface area.

a Cyclic voltammograms of polycrystalline Ag electrode in 0.1 M HClO4 for different time of reaction with OH• radicals. Inset: dependence of the ratio of the real Ag electrode surface area A t to the real electrode surface area A t=0 before treatment with OH• radicals versus time of reaction with OH• radicals. Experimental conditions: concentrations of Fe2+, EDTA, H2O2 are 0.5, 0.5 and 1 mM; scan rate 100 mV/s; silver disc electrode (ø = 0.5 mm). b Cyclic voltamograms for upd formation of Pb/Ag before and after immersing to Fenton solution. Inset: dependence the reduction and oxidation charge of upd of Pb at silver electrode versus time of exposure to OH• radicals. Experimental conditions: 12 mM Pb(NO3)2 in 0.1 M HClO4 and 0.1 M KNO3; scan rate: 10 mV/s; for other conditions, see Fig. 3a

Similar results were obtained from the charge of the Pb monolayer electrodeposited on the Ag electrode. Only one upd Pb peak on polycrystalline Ag electrode was observed (see Fig. 2b). The shapes of the voltammograms are shown in Fig. 2b. The anodic and cathodic peak charges of Pb decreased to circa 47% of the initial value after the attack of OH• radicals for 70 min, which means that the final real surface area dropped to 47% of the initial area. The control experiments have shown that the changes of electrode surface area take place only in the presence of OH• radicals. The treatment of the electrode surface by hydrogen peroxide or by Fe2+/3+ did not yield any changes.

We have also checked the influence of smoothing the silver surface by OH• radicals on the electrode process of the quinone–hydroquinone (Q/HQ) redox couple. Typical cyclic voltammograms of Q/HQ are presented in Fig. 3. The Q/HQ process was depressed with increasing time of interaction between silver and OH• radicals. Interestingly, the peak separation in cyclic voltammetry did not increase, but remained almost constant, and the peak currents dropped to almost zero. This can only be explained by the assumption that the Q/HQ system is only active at a certain number of active sites, and the OH• radicals completely destroy these sites. Taken that a reduction of the real electrode surface area by 44% happened after the attack of OH• radicals, one could speculate that these 44% surface area were the area at which the Q/HQ system is active. However, the latter could be also just a share of the removed real surface area. In conclusion, this means that immersing the electrode in the Fenton solution led, due to removal of asperities, to a deactivation of the electrode surface with respect to the Q/HQ system in the applied potential range.

Cyclic voltammograms of hydroquinone (5 mM) at silver electrode in 0.1 M HClO4 containing 10 mM NaClO4 before and after immersing the electrode in 0.5 mM Fenton solution with addition of 1 mM H2O2; for other conditions, see Fig. 2a

Effects of the interaction of palladium with OH• radicals

Palladium behaves similarly to silver and gold. As shown in Fig. 4, with increasing time of exposing the electrode to OH• radicals, the surface becomes smoother. The obtained ICP-AES analytical results that are presented in Fig. 5 indicate that the rate of dissolution of palladium was also high at the beginning, and dropped to very low values after 20 min of exposure to OH• radicals. In the AFM experiments with in situ generation of OH• radicals, the dissolution was observable over a longer period of time, but one cannot compare the ex situ and in situ experiments with respect to the time scale, as the concentrations of OH• radicals differ in these experiments.

The changes in the surface area of palladium were studied electrochemically by recording cyclic voltammograms between 0.15 and 1.35 V (vs. Ag/AgCl) in 0.1 M H2SO4. The charge of the reduction peak of palladium oxide strongly decreased after a series of treatments with OH• radicals (see Fig. 6a). The control experiments showed that the palladium oxide system was also strongly affected by hydrogen peroxide while in both cases the oxide peaks were unaffected by the Fe2+ and Fe3+ ions. This is understandable because metallic Pd can easily produce OH• or similar aggressive radicals when decomposing hydrogen peroxide.

a Cyclic voltammograms of Pd recorded in 0.1 M H2SO4 after exposure to OH• radicals. Inset: charge of the reduction peak of Pd versus time of reaction with OH• radicals. Experimental conditions: concentrations of Fe2+, EDTA, H2O2 are 1, 1 and 10 mM; scan rate 100 mV/s; palladium disc electrode (ø = 0.5 mm). b Cyclic voltammograms of the hydroquinone after exposure the electrode to Fenton solution recorded in 0.1 M HClO4 containing 100 mM NaClO4 and 5 mM hydroquinone. Experimental conditions: concentrations of Fe2+, EDTA, H2O2 are 1, 1 and 10 mM, respectively; scan rate 100 mV/s; palladium electrode diameter ø = 0.5 mm

Most interestingly, with increasing time of interactions between palladium and OH• radicals, the surface became smoother but the activity of the electrode did not change. Figure 6b shows typical cycling voltammograms of Q/HQ obtained with a mechanically polished Pd electrode before and after a series of treatments with OH• radicals. This system did not show any significant changes in the peak potentials nor peak currents as a result of attack by OH• radicals. Evidently, the reaction rate is similar at the asperities and the smooth surface.

Effects of the interactions of platinum with OH• radicals

The study of the interactions of a Fenton solution (OH• radicals) with platinum is much more difficult than with Ag, Au and Pd because of the very intensive, catalytic decomposition of H2O2. However, the following result can be safely given: the surface of Pt is not significantly altered. This is evident from AFM measurements and also from the electrocatalysis tests (results not shown because it would be trivial to show identical data).

Discussion and conclusions

The results of this study (Ag, Pd, Pt) and of the previous study of Au allow the following conclusions: (1) The highly electrocatalytically active metals Pt and Pd are not, or only marginally affected by treating the surface with OH• radicals. (2) On the other side, the electrocatalytic activity of the less active metals Ag and Au are seriously affected. This cannot be a result of the formation of a surface oxide layer, as that layer has been reduced back to the metal before the electrocatalytic reactions (quinone/hydroquinone system) commence at the appropriate potentials. Hence, it must be a result of a different kind of surface alterations. From AFM, differential capacity measurements, upd measurements and chemical analysis (ICP-AES) of the Fenton solutions after treating the metals, it is clear that in the case of Au, Ag, and Pd, a dissolution of surface asperities takes place. The effect of Fenton solution did not depend on the time elapsed between mechanical polishing and Fenton treatment, which indicates that no detectable surface relaxation happened during that time. It must be concluded that in the case of Au and Ag, the surface asperities are also the locus of the catalytically active sites. Of course, we do not claim that the entire asperities are the active sites, but the active sites are obviously associated with them and located somewhere on them. In the case of Pt and Pd, the active sites are obviously part of the regular surface structure. This led us to an idea that the active sites of Ag and Au are highly active atoms located at places where the regular structure of the metal surface has been considerably changed by the mechanical polishing, which, especially in the case of the rather soft Ag and Au, must result in mechanical displacements of atoms which, once they are not anymore bonded to the regular surface lattice, will be more easily oxidized (or rehybridized in the sense of d → s). These atoms may behave very similarly to the atoms of gold clusters as reported by van Bokhoven et al. [16]. Thus, Ag and Au, due to their electronic structure, will attain a d10−x electron configuration, a state which can be hypothesized to be stabilized at such locations. The d10−x with x = 1 electron configuration is exactly that which is made responsible for the electrocatalytic activity of regular surface atoms of Pt, and probably also of catalytically active Pd atoms [17]. The results prompt us to conclude that the electrocatalytic activity (for quinone/hydroquinone) of Pt and Pd is basically a property of the regular surface atoms, whereas that of Ag and Au is basically a property of special active sites which can be easily knocked out by reaction with OH• radicals. Future studies must be directed on the effect of OH• radicals on the electrocatalysis at single face electrodes of these metals, and must be expanded towards other electrochemical systems to be catalyzed. The ultimate goal would be a spectroscopic identification of the active centers; however, we have some doubt that this will ever be possible as the analytical surface concentration may be very low. Finally, the dissolution of asperities (and active sites) must be discussed in terms of thermodynamics and kinetics. OH• radical is a very strong oxidant (\( E_{{{\text{O}}{{\text{H}}^{ \bullet }}/{{\text{H}}_{{2}}}{\text{O}}}}^{{\rlap{--}{\bigcirc }}}{ } = { 2}{\text{.38 V}} \); [18]) capable to oxidize the surface of Ag, Au, Pd, and Pt. This always happens, independently of the surface state of the metals. In the case of a surface in equilibrium, an oxide layer is formed, whereas in case of non-equilibrium (highly active) structures, the active surface atoms are dissolved. Probably, it just needs the correct positions of the neighboring metal atoms to convert them to the oxide layer. If the neighborhood is distorted, the metal ions leave the surface. Thus the dissolution of surface atoms is not caused by the roughness (asperities) of the surface per se. Only if the asperities are built up of disordered (reactive) metal atoms, they are dissolved by the OH• radicals. We have clearly seen this for gold electrodes with rough surfaces obtained by electrochemical and vacuum deposition: In these cases the asperities are practically not dissolved by OH• radicals because they consist of equilibrium structures.

References

Keith JA, Jacob T (2010) Angew Chem Int Ed 49:9521–9525

Koper MTM (2008) Faraday Discuss 140:11–24

Ertl G (2008) Angew Chem Int Ed 47:3524–3535

Kibler LA (2006) ChemPhysChem 7:985–991

Bockris JOM (2005) J Serb Chem Soc 70:475–487

Dakkouri AS, Kolb D (1999) Reconstruction of gold surfaces. In: Wieckowski A (ed) Interfacial electrochemistry. Theory, experiment, and application. Marcel Dekker, New York

Burke LD (2004) Gold Bull 37:125–135

Burke LD, Moran JM, Nugent PF (2003) J Solid State Electrochem 7:529–538

Burke DL, Hurley LM (2002) J Solid State Electrochem 6:101–110

Garbariono S, Burke LD (2010) Int J Electrochem Sci 5:828–851

Nowicka AM, Hasse U, Hermes M, Scholz F (2010) Angew Chem Int Ed 49:1061–1063

Nowicka AM, Hasse U, Sievers G, Donten M, Stojek Z, Fletcher S, Scholz F (2010) Angew Chem Int Ed 49:3006–3009

Rapecki T, Nowicka AM, Donten M, Scholz F, Stojek Z (2010) Electrochem Commun 12:1531–1534

Hupp JT, Larkin D, Weaver MJ (1983) Surf Sci 125:429–451

Safonov VA, Krivenko AG, Choba MA (2008) Electrochim Acta 53:4859–4866

van Bokhoven JA, Louis C, Miller JT, Tromp M, Safonova OV, Glatzel P (2006) Angew Chem Int Ed 45:4651–4654

Rodriguez JA, Goodman DW (1995) Acc Chem Res 28:477–478

Hoare JP (1985) Oxygen. In: Bard AJ, Parsons R, Jordan J (eds) Standard potentials in aqueous solution. Marcel Dekker, New York, pp 63–64

Acknowledgements

Support for this work by the Polish Ministry of Science and Higher Education Grant IP2010 028570 is gratefully acknowledged.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Additional information

F.S. dedicates this paper to Prof. Dr. Fritz Pragst on the occasion of his 70th birthday. Fritz Pragst was a great teacher (although I was not in his group) and a cooperative partner during my early years in electrochemistry.

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Nowicka, A.M., Hasse, U., Donten, M. et al. The treatment of Ag, Pd, Au and Pt electrodes with OH• radicals reveals information on the nature of the electrocatalytic centers. J Solid State Electrochem 15, 2141–2147 (2011). https://doi.org/10.1007/s10008-011-1488-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-011-1488-3