Abstract

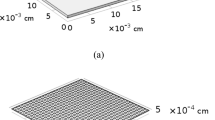

Surface exchange reactions and diffusion of oxygen in ceramic composites consisting of a dilute and random distribution of inclusions in a polycrystalline matrix (host phase) are modeled phenomenologically by employing the finite element method. The microstructure of the mixed conducting composite is described by means of a square grain model, including grain boundaries of the matrix and interphase boundaries between the inclusions and grains of the host phase. An instantaneous change of the oxygen partial pressure in the surrounding atmosphere may give rise to an oxygen exchange process, i.e., oxidation or reduction of the ceramic composite. Relaxation curves for the total amount of exchanged oxygen are calculated, emphasizing the role played by fast diffusion along the interfaces. The relaxation curves are interpreted in terms of effective medium diffusion, introducing appropriate equations for the effective diffusion coefficient and the effective surface exchange coefficient. When extremely fast diffusion along the grain and interphase boundaries is assumed, the re-equilibration process shows two different time constants. Analytical approximations for the relaxation process and relations for the separate relaxation times are provided for this limiting case as well as for blocking interphase boundaries. Furthermore, conductivity relaxation curves are calculated by coupling diffusion and dc conduction. In the case of effective medium diffusion, the conductivity relaxation curves do not deviate from those for the total amount of exchanged oxygen. On the contrary, the conductivity relaxation curves differ remarkably from the time dependence of the total amount of exchanged oxygen, when the different phases of the composite re-equilibrate with separate time constants.

Similar content being viewed by others

References

Maier J (1995) Prog Solid State Chem 23:171–263

Steele BCH, Hori KM, Uchino S (2000) Solid State Ionics 135:445–450

Ji Y, Kilner JA, Carolan MF (2005) Solid State Ionics 176:937–943

Zhang K, Yang YL, Ponnusamy D, Jacobson AJ, Salama K (1999) J Mater Sci 34:1367–1372

Diethelm S, van Herle J, Sfeir J, Buffat P (2004) Br Ceram Trans 103:147–152

Sase M, Hermes F, Yashiro K, Sato K, Mizusaki J, Kawada T, Sakai N, Yokokawa H (2008) J Electrochem Soc 155:B793–B797

Sase M, Yashiro K, Sato K, Mizusaki J, Kawada T, Sakai N, Yamaji K, Horita T, Yokokawa H (2008) Solid State Ionics 178:1843–1852

Sata M, Eberman K, Eberl K, Maier J (2000) Nature 408:946–949

Peters A, Korte C, Hesse D, Zakharov, Janek J (2007) Solid State Ionics 178:67–76

Gryaznov D, Fleig J, Maier J (2006) Solid State Ionics 177:1583–1586

Gryaznov D, Fleig J, Maier J (2008) Solid State Sci 10:754–760

Bunde A, Dieterich W (2000) J Electroceramics 5:81–92

Knauth P (2000) J Electroceramics 5:111–125

McLachlan DS, Blaszkiewicz M, Newnham RE (1990) J Am Ceram Soc 73:2187–2203

Kalnin JR, Kotomin EA, Maier J (2002) J Phys Chem Solids 63:449–456

Belova IV, Murch GE (2004) Phil Mag 84:17–28

Belova IV, Murch GE (2005) J Phys Chem Solids 66:722–728

Jamnik J, Kalnin JR, Kotomin EA, Maier J (2006) Phys Chem Chem Phys 8:1310–1314

Preis W (2009) J Phys Chem Solids 70:616–621

Preis W (2009) Monatsh Chem 140:1059–1068

Yoo HI, Lee CE (2009) Solid State Ionics 180:326–337

Carslaw HS, Jaeger JC (1959) Conduction of heat in solids. Clarendon, Oxford

Crank J (1975) The mathematics of diffusion. Oxford University Press, Oxford

Preis W, Sitte W (2005) J Phys Chem Solids 66:1820–1827

Preis W, Sitte W (2008) Solid State Ionics 179:765–770

Katsuki M, Wang S, Dokiya M, Hashimoto T (2003) Solid State Ionics 156:453–461

Preis W, Bucher E, Sitte W (2002) J Power Sources 106:116–121

Preis W, Bucher E, Sitte W (2004) Solid State Ionics 175:393–397

Preis W, Holzinger M, Sitte W (2001) Monatsh Chem 132:499–508

Boukamp BA, den Otter MW, Bouwmeester HJM (2004) J Solid State Electrochem 8:592–598

Preis W, Sitte W (2005) J Appl Phys 97:093504

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

The effective diffusion coefficient of the polycrystalline matrix (grains of phase 1 and grain boundaries) can be written as

by employing the two-dimensional Maxwell–Garnett relation, where g′ is the volume fraction of grain boundaries in the matrix and s′ is defined by Eq. 5b. If fast grain boundary diffusion is assumed and the thickness of the grain boundaries is much smaller than the grain size, i.e., \( D{\prime} > > {D_1} \) and \( g{\prime} < < 1 \), Eq. A1 can be approximated by

Introducing the area fraction of grain boundaries, \( \varepsilon = \delta /d = g{\prime}/2 \), one arrives at Eq. 17, which has been derived for the effective diffusivity with respect to fast grain boundary diffusion previously [20, 24, 25, 31].

When the heterointerfaces are arbitrarily combined with the inclusions (phase 2), the effective diffusion coefficient, \( {D{\prime}_2} \) is given by

in analogy to relation (A1). In this case g″ is given by \( g{\prime}{\prime} = 4\delta /d = 2\varepsilon \), such that Eq. 18 is obtained assuming D″>> D2 and g″ <<1. For the sake of simplicity grain, boundaries are neglected in the inclusions. However, the extension of the relations for effective medium diffusion to polycrystalline inclusions is straightforward.

Rights and permissions

About this article

Cite this article

Preis, W. Modeling of surface exchange reactions and diffusion in composites including transport processes at grain and interphase boundaries. J Solid State Electrochem 15, 2013–2022 (2011). https://doi.org/10.1007/s10008-010-1223-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10008-010-1223-5