Abstract

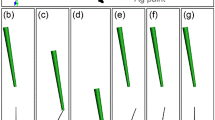

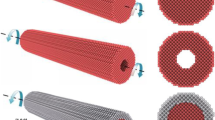

The nanomechanical properties, deformation, and shape recovery mechanism of NiTi nanowires (NWs) under torsion are studied using molecular dynamics simulations. The effects of loading rate, aspect ratio of NWs, and NW shape are evaluated in terms of atomic trajectories, potential energy, torque required for deformation, stress, shear modulus, centro-symmetry parameter, and radial distribution function. Simulation results show that dislocation nucleation starts from the surface and then extends to the interior along the {110} close-packed plane. For a high loading rate, the occurrence of torsional buckling of a NW is faster, and the buckling gradually develops near the location of the applied external loading. The critical torsional angle and critical buckling angle increase with aspect ratio of the NWs. Square NWs have better mechanical strength than that of circular NWs due to the effect of shape. Shape recovery naturally occurs before buckling.

Similar content being viewed by others

References

Buehler WJ, Gilfrich JV, Wiley RC (1963) Effect of low–temperature phase changes on the mechanical properties of alloys near composition TiNi. J Appl Phys 34:1475–1477

Duerig TW (1990) Engineering aspects of shape memory alloys. Butterworth-Heinemann, London

Otsuka K, Wayman CM (1999) Shape memory materials. Cambridge University Press, Cambridge

Brailovski V, Prokoshkin S, Terriault P, Trochu F (2003) Shape memory alloys: Fundamentals, modeling and applications. Montreal: ETS Publ

Biesiekierski A, Wang J, Gepreel MAH, Wena C (2012) A new look at biomedical Ti-based shape memory alloys. Acta Biomater 8:1661–1669

Pequegnat A, Daly M, Wang J, Zhou Y, Khan MI (2012) Dynamic actuation of a novel laser-processed NiTi linear actuator. Smart Mater Struct 21:094004 doi:10.1088/0964-1726/21/9/094004

Prokoshkin SD, Khmelevskaya IY, Dobatkin SV, Trubitsyna IB, Tatyanin EV, Stolyarov VV, Prokofiev EA (2005) Alloy composition, deformation temperature, pressure and post-deformation annealing effects in severely deformed Ti-Ni based shape memory alloys. Acta Mater 53:2703–2714

Lei X, Rui W, Yong L (2011) The optimization of annealing and cold-drawing in the manufacture of the Ni-Ti shape memory alloy ultra-thin wire. Int J Adv Manuf Technol 55:905–910

Chen YF, Sung PH, Wu CD, Fang TH (2012) Studies of nanomechanical properties and fatigue strength of annealed Ni-Ti shape memory alloy. Mater Lett 71:84–87

Wu CD, Fang TH, Sung PH, Hsu QC (2012) Recovery, and mechanical property of nanoimprinted Ni-Al alloys investigation using molecular dynamics simulation. Comput Mater Sci 53:321–328

Sung PH, Wu CD, Fang TH (2012) Investigation of nanomechanical properties of Al/Ni and Ni/Al nanomultilayers under nanobending using molecular dynamics simulation. Comput Mater Sci 56:43–48

Wu CD, Fang TH, Chan CY (2011) A molecular dynamics simulation of the mechanical characteristics of a C60-filled carbon nanotube under nanoindentation using various carbon nanotube tips. Carbon 49:2053–2061

Wu CD, Fang TH, Wu TT (2012) Effects of humidity and temperature on laser-assisted dip-pen nanolithography array studied using molecular dynamics simulations. J Colloid Interface Sci 372:170–175

Wu CD, Fang TH, Wu TT (2012) Study of process parameters and formative mechanism of patterns on a dip-pen nanolithography array using molecular dynamics simulations. Polymer 53:857–863

Zeng ZY, Hu CE, Cai LC, Chen XR, Jing FQ (2011) Molecular dynamics study of the melting curve of NiTi alloy under pressure. J Appl Phys 109:043503

Sato T, Saitoh KI, Shinke N (2006) Molecular dynamics study on microscopic mechanism for phase transformation of Ni-Ti alloy. Model Simul Mater Sci Eng 14:39–46

Liang W, Srolovitz DJ, Zhou M (2007) A micromechanical continuum model for the tensile behavior of shape memory metal nanowires. J Mech Phys Solids 55:1729–1761

Lai WS, Liu BX (2000) Lattice stability of some Ni-Ti alloy phases versus their chemical composition and disordering. J Phys Condens Matter 12:L53–L60

Hwang CC, Chang JG, Huang GJ, Huang SH (2001) Investigation of cluster size and cluster incident energy effect on film surface roughness for ionized cluster beam deposition. J Appl Phys 92:5904–5912

Haile JM (1992) Molecular dynamics simulation: Elementary methods. Wiley, New York

Packeiser D, Gwinner D (1980) The formation mechanisms of dislocation networks in twisted silicon. Philos Mag 42:661–670

McClintock FA, Prinz F (1983) A model for the evolution of a twist dislocation network. Acta Metall 31:827–832

Gao H, Huang Y, Nix WD, Hutchinson JW (1999) Mechanism-based strain gradient plasticity. I.-Theory. J Mech Phys Solids 47:1239–1263

Kelchner CL, Plimpton SJ, Hamilton JC (1998) Dislocation nucleation and defect structure during surface indentation. Phys Rev B 58:11085–11088

Jiang S, Zhang H, Zheng Y, Chen Z (2009) Atomistic study of the mechanical response of copper nanowires under torsion. J Phys D Appl Phys 42:135408

Gao Y, Wang F, Zhu T, Zhao J (2010) Investigation on the mechanical behaviors of copper nanowires under torsion. Comput Mater Sci 49:826–830

Sung PH, Wu CD, Fang TH (2012) Effects of temperature, loading rate, and nanowire length on torsional deformation and mechanical properties of aluminum nanowires investigated using molecular dynamics simulation. J Phys D Appl Phys 45:215303

Khoei AR, Ban E, Banihashemi P, Abdolhosseini Qomi MJ (2011) Effects of temperature and torsion speed on torsional properties of single-walled carbon nanotubes. Mater Sci Eng C 31:452–457

Leckie FA, Dal Bello DJ (2009) Strength and stiffness of engineering systems. Springer, Heidelberg

Acknowledgments

This work was supported by the National Science Council of Taiwan under grants NSC 100-2628-E-151-003-MY3 and NSC 100-2221-E-151-018-MY3.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, CD., Sung, PH. & Fang, TH. Study of deformation and shape recovery of NiTi nanowires under torsion. J Mol Model 19, 1883–1890 (2013). https://doi.org/10.1007/s00894-013-1752-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00894-013-1752-9