Abstract

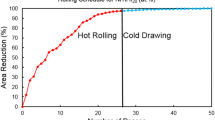

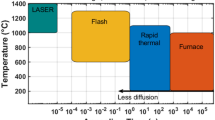

In this paper, the mechanical properties of the Ni–50.5 at.%–Ti alloy super-elastic wires manufactured by a conditioned multi-passed process of annealing and cold-drawing have been studied. The annealing temperature of 450~800°C, time of 20 min~3 h and the cold-drawing amount of 6.9%~39% were chosen. Their effects on the thermo, mechanical, and surface morphology of the Ni–Ti wires have been studied. The differential scanning calorimetry and tensile-recovery tests were adopted to obtain the phase transformation temperatures and mechanical hysteresis of the Ni–Ti SMA wires with different treatment conditions. The results show that the phase transition temperature of Ni–Ti wire can be changed by varying the annealing temperature and time; cold-drawing deformation and subsequent annealing have a great influence on the super-elasticity. The process with 39% cold-drawing amount, 600°C and 20 min annealing is shown to be effective in the manufacturing.

Similar content being viewed by others

References

Kin-tak L (2002) Vibration characteristics of SMA composite beams with different boundary conditions. Mater Des 23(8):741–749

Pan W, Qin Y, Law F, Ma YL, Brockett A, Juster N (2008) Feasibility study and tool design of using shape memory alloy as tool-structural elements for forming-error compensation in microforming. Int J Adv Manuf Technol 38:393–401

Khalili SMR, Shokuhfar A, Ghasemi FA (2007) Effect of smart stiffening procedure on low-velocity impact response of smart structures. J Mater Process Tech 190:142–152

Simpson JC, Boiler C (2008) Design and performance of a shape memory alloy-reinforced composite aerodynamic profile. Smart Mater Struct 7(2):025028

Sari U, Aksoy I (2008) Micro-structural analysis of self-accommodating martensites in Cu-11.92 wt%Al-3.78 wt%Ni shape memory alloy. J Mater Process Tech 195:72–76

Salonitis K, Pandremenos J, Paralikas J, Chryssolouris G (2010) Multifunctional materials: engineering applications and processing challenges. Int J Adv Manuf Technol 49:803–826

Liu Y, Van HJ, Stalmans R, Delaey L (1997) Some aspects of the properties of NiTi shape memory alloy. J Alloy Compd 247(1–2):115–121

Wu SK, Lin HC, Yen YC (1996) A study on the wire drawing of TiNi shape memory alloys. Mater Sci Eng A 215(1–2):113–119

Wu SK, Lin HC, Yen YC, Chen JC (2000) Wire drawing conducted in the R-phase of Ti–Ni shape memory alloys. Mater Lett 46(2–3):175–180

Chang SH, Wu SK (2004) Textures in cold-rolled and annealed Ti50–Ni50 shape memory alloy. Scr Mater 50(7):937–941

Demers V, Brailovski V, Prokoshkin SD, Inaekyan KE (2009) Optimization of the cold rolling processing for continuous manufacturing of nanostructured Ti–Ni shape memory alloys. J Mater Process Tech 209(6):3096–3105

Chen MC, Wu SK (2009) Surface analyses and biocompatibility study of 500°C oxidized Ni50–Ti50 and Ni40–Ti50–Cu10 shape memory alloys. Surf Coat Tech 12:1715–1721

Chiang LJ, Li CH, Hsu YF, Wang WH (2008) Effects of thermal cycling on multiple-stage transformation in Ti49.3Ni50.7 shape memory alloy. J Alloy Compd 462(12):47–51

He Z, Wang F (2008) Effect of heat treatment on transformation behavior of superelastic alloy Ti49.8Ni1.0Co. Acta Metall Sin 44(1):23–28

Sadiq H, Wong MB, Al-Mahaidi R, Zhao XL (2010) The effects of heat treatment on the recovery stresses of shape memory alloys. Smart Mater Struct 19(3):035021

Nae FA, Ikeda T, Matsuzaki Y (2004) The active tuning of a shape memory alloy pseudoelastic property. Smart Mater Struct 13(3):503–511

Ng SB, Huang WM, Shu DW (2008) Plastic energy and tearing energy of a NiTi shape memory alloy wire. Mater Des 29(5):1066–1069

Chen MC, Wu SK (2009) Surface analyses and biocompatibility study of 500°C oxidized Ni50–Ti50 and Ni40–Ti50–Cu10 shape memory alloys. Surf Coat Tech 203(12):1715–1721

Goryczka T, Paczkowski P, Lelatko J, Wierzchon T, Morawiec H (2007) Characterization of nitrided/oxidized layers covering Ni–Ti shape memory alloy. Appl Crystallogr XX 130:151–154

Kim KS, Jee KK, Kim WC, Jang WY, Han SH (2008) Effect of heat treatment temperature on oxidation behavior in Ni–Ti alloy. Mater Sci Eng A 481:658–661

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lei, X., Rui, W. & Yong, L. The optimization of annealing and cold-drawing in the manufacture of the Ni–Ti shape memory alloy ultra-thin wire. Int J Adv Manuf Technol 55, 905–910 (2011). https://doi.org/10.1007/s00170-010-3116-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-010-3116-2