Abstract

Ocean thermal energy conversion is one of the promising renewable energy resources yet relatively unexplored due to its high capital cost for being utilized in commercial scale. In the aim to reduce the capital cost, this paper introduces a concept design of the floating structure from a converted oil tanker ship. To propose the design process, the general principles of designing a converted tanker FPSO is adapted and then modified to deal with ocean thermal energy conversion (OTEC) characteristic. In the design process, the arrangement of the OTEC layout is carried out by constraint satisfaction method and the prospective floating structure size is varied using Monte Carlo simulation. The variables in the design process consist of the velocities of cold water and warm water transport, the size of the plantship, and the location of the OTEC equipment to the seawater tank. Constraints are introduced as allowable border to determine the acceptability for particular case including the provided space and buoyancy, and the net power output estimation. The results show that the ‘typical’ size of a Suezmax oil tanker ship is the optimum one for the plantship with the velocity of the water transport of 2–3 m/s. The general arrangement is also conceptualized in this paper.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Ocean thermal energy conversion (OTEC) is a technology which utilizes the temperature difference between warm surface water and cold deep water. To be deployed in a viable and effective way, the temperature gradient between surface and subsurface should be more than 20 °C [1]. With the surface temperature of about 25 °C and deep cold water of 5 °C, reduced by the efficiency of OTEC equipment, the efficiency of the Rankine cycle of this system was only about 3–5% [2]. Ammonia was selected as the working fluid due to its low boiling point which allows it to transform into gas and liquid phases with a small temperature difference [3, 4].

Nowadays, with the state-of-the-art OTEC system technology, the Rankine cycle efficiency of the OTEC system is predicted to be still around 6–7% [5]. Additionally, the system requires around 30% of the gross energy product to maintain the process especially used for pumping system. The necessity of very high capital investment is also a reason why this technology gets stuck on the pilot project [6].

Literature survey on OTEC cost estimation resulted in very limited resources which were mainly evaluated by Vega and Lockheed Martin [6,7,8,9,10,11,12,13]. It was first assessed by Vega in 1990 resulting in a statement that the required cost per kW decreases as much as how bigger the capacity of the power plant is as presented in Ref. [7]. It indicates that developing a OTEC power plant in commercial scale is more cost-effective compared with the small scale. Completing the capital cost estimation for 100 MW-net capacity, in 2003, Vega included the effect of the offshore distance to the estimation yielding the result of how the capital cost would increase with an inclusion of the offshore distance [8].

Updating the previous estimation, Vega recalculated the required capital cost in 2010 also considering the recent development of OTEC system technology and its implication on the OTEC system costs [9] and then attempting to reduce the capital cost using the project fund management scenario [6]. Enhancing the cost estimation procedures proposed by Vega, in 2012, Lockheed Martin evaluated the cost estimation for the whole life cycle of commercial OTEC power plant associated with long-term operation, for 100 MW, 200 MW and 400 MW capacity [10]. The results of the cost estimation done by Vega and Lockheed Martin are also highlighted in several papers [11, 12]. Gathering information from those studies related to the present paper, some points can be highlighted as follows: (1) for a OTEC power plant with capacity more than 50 MW, a floating structure is economically feasible; (2) the required capital cost for building a 100 MW OTEC power plant is approximately about 8000 USD/kW which is much higher compared with other renewable energies; (3) the cost of heat exchanger and floating vessel takes the biggest portion of the total cost which is about 21% for heat exchanger and 22% for the floating vessel.

There are limited design concepts for OTEC floating structure available. Some of the proposed designs are just a sketch without appropriate detailed explanations of how the arrangement is set [6, 8, 13]. At the beginning of the early stage study, several projects were carried out to analyze the must-have characteristic of OTEC power plant both for land-based and offshore plants [14,15,16,17]. A more detailed early stage design of a floating OTEC power plant was proposed by George and Richard [18]. There are two types of floating structure which are moored barge and grazing barge. Both of them can be used for a 40 MW-net OTEC power plant. Offering a more detailed consideration yet remaining conventional, Vega conceptualized a barge-type floating vessel made from concrete with 250 m length, 60 m breadth, 28.5 m height and draft of 20 m [13].

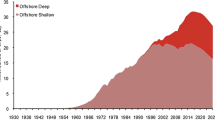

By the end of twentieth century, due to the rapid development of other energy resources such as nuclear power plant and coal power plant, the interest in the OTEC development declined [12]. During this period, the improvement of the OTEC floating structure did not show any significant progress except the introduction of semi-submersible and spar-type OTEC floating structure by Avery and Wu [19]. In the early 2010s, the rising concern of green energy issues made other sources of renewable energy get more attention. After recovery of the OTEC interest, some new ‘modernized’ OTEC floating structures have been proposed. Vega suggested a new-built ship-shaped floating structure for 50 MW-net OTEC power plant [3], Yee designed a very large floating structure for OTEC application [20] and Lockheed Martin suggested a grid-connected floating structure type [10]. These new floating structure concepts are to ensure the safety of the floating structure. Because the designs are made of steel, the new floating vessel’s cost is higher compared with the conventional one.

Srinivasan also attempted to reduce the capital cost through new design concepts. He designed a floating structure with J-spar type, tensioned-leg platform type and semi-submersible type. Even though the new designs were claimed to be successfully decrease the required size of the floating vessel, the decrease of the floating vessel cost was only about 10% compared with the barge type [21]. This number is appreciable, but it is still necessary to create a more cost-effective design.

In the terms of safety, the capital cost is not the only concern. The proposed floating vessel must be able to sustain the applied load from both external and internal. The configuration must meet the requirements of the OTEC system as well as the convenience of the workforce.

To overcome the addressed issues, this paper aims to design and conceptualize a plantship for a OTEC floating structure with the target of 100 MW-net electricity. Considering the success of building FPSO from an oil tanker conversion, its design philosophy is adopted to propose the floating structure for OTEC application. It has been already practically well known that converting an oil tanker ship has some benefits compared with the new-built structure. The two main motivations which persuade to utilize a converted oil tanker ship are cost saving benefit and shorter delivery time [22, 23]. Additionally, to reduce the capital cost and parasitic loss energy, this paper also evaluates the most optimum size of the plantship and the arrangement of the OTEC system. To ensure the safety of the plantship, the general arrangement is designed following the guidance notes of OTEC floating structure regulation issued by a classification society [24].

The authors and other researchers made an introductory assessment about the most suitable type of oil tanker to be converted as the plantship [25]. Due to lack of the on-site data, the results were roughly focused on the required space and buoyancy without considering the installation of major OTEC system equipment. However, to bring the technology into commercial scale, it must be profitable, appealing for the investment and ensuring that all the system works. Thus, the performance of the whole electricity power generation system must be evaluated using the actual data on the site. To deal with that issue, the on-site experiment was also conducted to measure the environment of the work and then the data are used as the basic input for the design requirements.

2 OTEC system

Figure 1 shows the component and process of OTEC cycle. Basically, OTEC system has four main components which are heat exchanger, working fluid, turbine generator and pumps. The warm seawater passes through the evaporator providing heat to the working fluid, in this case ammonia, then the working fluid will form into gas phases. The vaporized ammonia is pumped to drive the turbine and produces the electricity using generator. After that, low-pressure working fluid will be condensed into liquid form using the cold water pumped from deep water. To maintain the cycle, the liquid ammonia will be pumped back to the evaporator. This cycle is repeated continuously [3].

3 Design method

The efficiency of the power plant does not only depend on the efficiency of the major components, but also its arrangement and installation [2]. Figure 2 shows the design flowchart. There are two main processes. Initially, Monte Carlo simulation is used to vary the possible size of the oil tanker ship and then for each size of the proposed plantship, the constraint satisfaction method is employed to optimize the OTEC system. These two flow design processes are correlated in the calculation of net power output.

Constraint satisfaction method is a method used to narrow down a very large possible solution considering the imposed constraints [26]. The purpose of this particular step is not defining the best size of the plantship but rather than categorizing whether the specific size of the plantship is acceptable, rejected or even overdesigned based on the constraints. Thus, the recommended size of the oil tanker is in range between bottom and upper limit which are determined by the constraints. This study also examines the effects of the position of the OTEC equipment on the required work of pumping system.

There are three types of parameters imposed in the design process named as fixed variables, independent variables and constraints. Fixed variables are the parameters which are kept constant during the iteration. These parameters entail the environment data of the site and the target of net power output. Independent variables are the parameters which varied during the analysis including the size of the plantship, the velocity of seawater transport and the location of the OTEC equipment to the seawater tank. Constraints are variables set as a limitation during the process to ensure the acceptability of the cases. In Fig. 2, the constraints are shown in the dotted rectangular shape.

The constraints imposed in this step are constraint due to abrasion phenomena on the seawater pipe, constraint due to seawater flow inside seawater tanks, loss of energy due to pumping system and freeboard allowance. After procuring the size of the plantship, the constraint satisfaction method is also used to determine the placement of the OTEC system equipment and the compartmentation of the plantship. The constraints include the stability and trim condition.

In Fig. 2, the number inside the parenthesis denotes the procedure order which is also identical to the numbering in the following explanations. In the design process, initially the on-site experiment was conducted to measure the surface temperature and gradient temperature decrease at substantial depth. The measurement was done until the temperature difference between the surface water and deep water reached more than 20 °C (1). From these data, the required gross power for yielding 100 MW-net electricity and the required length of the risers can be assessed (2).

After acquiring the input design conditions, the constraint satisfaction method was applied. The first step is determining the required seawater debit (3). By keeping the seawater debit constant, the required diameter of the risers is calculated for various seawater transport velocities. The limitation of the seawater transport velocity is determined by the constraint due to abrasion phenomena on the pipe (4). Knowing the length and diameter of the risers, its required thickness is estimated considering the properties of the chosen material. Then, the dry weight and wet weight of the risers are estimated to be included in total weight calculation (5).

To deposit the seawater before being delivered to the heat exchanger or spilled out back into the ocean, the seawater tanks are required to be installed. As the seawater transport brings huge momentum which may trigger excessive pressure acting on the seawater tanks, it is important to analyze the fluid phenomena inside the tanks and use the results as constraints to design the seawater tanks. This simulation is done using Ansys inc. interface software. The result of the analysis is the dynamic pressure acting on the seawater walls. Summing up the dynamic pressure obtained from the simulations and static pressure adopted from classNK, the total pressure can be evaluated. The obtained total pressure then will be compared with ClassNK regulation for tank installation codes. Employing the comparison result, the required size for seawater tanks can be decided for various velocities of seawater transport (6).

Targeting net electricity product of 100 MW with 30% energy loss as the constraint, the major OTEC components including heat exchanger, turbine generator and pumps are determined (7). The capacity and dimensions of the components are adopted from a well-established manufacturer. This particular step informs the numbers, required space and required weight of major OTEC components (8). The next steps are estimating the volumetric space and weight of the working fluid (9) and supporting systems (10). By adding the required capacities of risers, seawater tanks and major OTEC components with 20% spare for additional equipment, the total required volumetric space and buoyancy can be computed.

Separately, Monte Carlo simulation is used to vary the prospective size of the plantship. There are four types of plantship including Aframax, Suezmax, VLCC, and ULCC. The first step is defining the statistical parameters of the plantship dimensions which cover the length, the breadth, the draft, and block coefficient of the plantship (11). For each type, 250 sets of plantship dimensions are generated (12). For every single dimension set, the provided space and buoyancy capacity are estimated (13).

Comparing the provided capacities with the required capacities obtained previously from constraint satisfaction method procedure (15), the acceptance for particular plantship dimension will be determined based on the constraint due to freeboard allowance (16). If the provided capacities are not enough to cover the required one, the case will be rejected. If the plantship has enough space and buoyancy, the process will continue to the arrangement of OTEC major components.

Adapting the common design practice of cargo hold for oil tanker ship [27, 28], the space for OTEC system components is set to be 80% of the total plantship length locating from forepeak bulkhead to after the peak bulkhead. On the deck at the designated draft, the major OTEC components are arranged considering its required space and the piping diagram. The arrangement is done based on the condition where the heat exchanger is located next to seawater tanks and above the seawater tanks. The space for heat exchanger is estimated by reducing the provided space for OTEC components with the required space for seawater tanks.

From the arrangement, the length of the pipeline, the joint configurations, elbowing, bending of the pipeline and other piping layout parameters can be approximated to get the coefficients for calculating the pressure difference. The total pressure difference will be used to get the required pump works (14). The net power output can be obtained by reducing the gross power with the required pumps works. This process is repeated for all plantship dimensions and for two OTEC system arrangement layouts (17).

Taking into account the constraint due to abrasion phenomena on the pipe, seawater flow inside seawater tanks, loss of energy due to pumping system, and freeboard allowance, the case can be concluded whether it is rejected, recommended or even overdesigned (18). After defining the size of the plantship, a set of scantling is picked up from the range to design the general arrangement (19). The details for each step are broken down in the following sections.

4 Independent variables

4.1 Size of the plantship

In the previous study done by the authors, several types of oil tanker ship have been examined to get the best size for the conversion. The size of the plantship was set to be constant based on several types [25]. However, in the real condition, it is merely hard to find the exact size of the plantship. Thus, the size of the plantship in this study is varied using Monte Carlo simulation. The stochastic data including the mean value of the size is adopted as reported from [29, 30] and the variance of the data is assumed to follow normal distribution. The mean value of the statistical data of the plantship is shown in Table 1. Referring the statistical parameters, 1000 sets of data of ship are generated, analyzed and then classified to find the acceptability for the conversion.

4.2 Velocity of seawater transport

The velocity of seawater transport is the base value to determine the size of the risers and seawater tanks. With constant required seawater debit, the higher velocity will make the size of the riser smaller. But high water transport velocity will cause additional dynamic pressure acting on the riser and the seawater tanks. Initially, the velocity of seawater transport through the riser is varied from 2 to 6 m/s with increment of 0.5 m/s. During the iteration process on the constraints’ analysis, the velocity of seawater transport above 4 m/s caused a tremendous amount of pressure on the top part of seawater tank. Here onwards, the considered velocity is limited from 2 to 4 m/s.

4.3 Location of OTEC system to the seawater tanks

The placement of the heat exchanger and turbine generator will affect the piping system which covers around 30% of total energy loss. In this analysis, the OTEC system is placed either above the seawater tank or next to the seawater tank. If the heat exchanger is located next to the seawater tank, the seawater flow direction is parallel to the heat exchanger. This makes the energy loss due to pumping system less, but the required width of the plantship will be larger. On the other hand, if the heat exchanger is located above the seawater tank, the pumping system will require more energy to pump up the seawater to the heat exchanger, but the compartmentation, construction and maintenance will be easier to do. The sketch of the piping diagram is shown in Fig. 3 for OTEC system equipment above seawater tanks and Fig. 4 for OTEC system equipment next to seawater tanks.

5 Fixed variables

5.1 Location of the site

Having a tropical ocean, small temperature variation throughout the year and relatively calm seawater make Indonesia one of the countries having a huge potential for OTEC development [1]. The potential of OTEC development has been studied by several researchers all around the country. Jaswar Koto et al. stated several locations in Indonesia where harvesting OTEC in commercial scale is possible as shown in Fig. 5 [31,32,33]. Region A is Siberut island located in West Sumatra, region B is North Sulawesi, region C is Morotai island, region D is West Papua, region E is Buru island and region F is Seram island. Koto et al. did a study on 100 kW of ocean thermal energy conversion in Karangkelong, North Sulawesi, Indonesia [34]. Considering the number of population and regional development, Siberut island (S01°34.660, E099°14.443) was chosen as the research site.

Prospective sites for OTEC development in Indonesia [32]

An on-site experiment was conducted to measure the temperature profile to a substantial depth. It was conducted from 15th to 20th August 2017. The result is shown in Fig. 6 [35]. This result is used to determine the surface and deep water temperature and the required length of cold water pipe. As shown in Fig. 6, the temperature difference between surface and deep water is more than 20 °C at the depth of 700 m. The warm surface water temperature of Indonesia’s ocean is affected by the monsoon cycle. The southwest monsoon influences the dry season from June to October and the northwest monsoon causes the rainy season from November to March. The difference of the surface water temperature between the peak of rainy season and the peak of dry season in Mentawai island is about 2 °C [36]. To bear with the uncertainties, the cold seawater will be brought up from a water depth of 800 m with consideration that the temperature difference between surface water and water depth of 800 m is above 20 °C for both dry and rainy seasons.

5.2 Required flow rate

Nihous proposed a standard temperature ladder during the OTEC process [37]. From the scheme drawn in Fig. 7, the gross electrical power \({P_{\text{g}}}\) can be written as:

Nihous’ temperature ladder model during OTEC process [37]

where \(\rho\) is the density of seawater in kg/m3, \(c\) is the specific heat of seawater, as 4 kJ/kg K, \({Q_{{\text{cw}}}}\) is cold water flow rate in m3, \({T_{\text{w}}}\) is the temperature of warm surface water in K, \(\Delta T\) is the temperature difference between warm water and cold water in K, \({\varepsilon _{{\text{tg}}}}\) is the turbine generator efficiency and \(\gamma\) is the ratio between warm water and cold water flow rate.

The next step is breaking down the equation of gross power output into net power output equation. The loss of energy is mainly due to power consumption to transport the seawater through an OTEC system. This parasitic power consists of two main parts. The first part is the energy to sustain the given deep seawater flow rate as 18% \({P_{\text{g}}}\) at design and the second is the loss of energy which varies if \(\gamma\) is adjusted, e.g., \(\{ 0.12{(\gamma /2)^{2.75}}\}\) times \({P_{\text{g}}}\) at design [8]. From the simplified theory above, the net power output can be calculated as:

By setting up the value of \(\gamma\) equal to 2 and assuming that the absolute seawater temperature is fairly constant (\(T \cong {T_{{\text{design}}}}\)), the parasitic power can be represented as a decrease of \(\{ 0.3\Delta {T^2}_{{{\text{design}}}}\} ~\) imposed on \(\Delta T\) in Eq. 2 [37]. As stated in [37], typical OTEC plant configurations consume about 30% of \({P_{\text{g}}}\). Inputting the value of warm and cold surface temperature from on-site experiment data, it corresponds to a total deep water flow rate of 2.3 m3/s per MW (net) at design condition \(\gamma\) equal to 2. In this research, the addressed net power output is 100 MW. Thus, the required flow rate will be 235 m3/s for cold seawater and 470 m3/s for warm seawater. The required flow rate is kept constant during the design process.

5.3 Required OTEC system equipment

5.3.1 Risers’ design

The risers are utilized to transport seawater from the ocean to the seawater tank and vice versa. There are four risers suspended on the bottom of the plantship which are inlet cold water pipe, outlet cold water pipe, inlet warm water pipe and outlet warm water pipe. The thickness was estimated using the approximation formula for riser of oil and gas exploration [38]. The features of the cold water pipe were adopted here as reported in [13] which are also used in [25]. The cold water pipe (CWP) is made of a fiberglass-reinforced plastic sandwich construction with a laminate density of 4125 kg/m3; the density of syntactic foam of 1015 kg/m3; modulus of elasticity of 13,776 MPa; and flexural rigidity of 2.89 × 1011 N m2. The result of the estimation is shown in Table 2.

5.3.2 Heat exchanger, turbine generator and pumps

In the present study, the system and its components of the heat exchangers are simply adopted. Uehara and Ikegami found that plate-type heat exchanger is the best fitted for OTEC [2]. Thus, this study adopted the compact plane-fin heat exchanger developed by Argon National Laboratory, USA. The core dimensions of this compact plane-fin heat exchangers are 6.1 m (L) × 1.2 m (B) × 4.6 m (H) [3, 39]. To produce 4 MW-gross power, four heat exchanger cores are required to assemble the submodules. With assumption that the energy loss is about 30% of the total gross power, 36 evaporator and condenser submodules must be integrated to get 100 MW-net.

The technology of turbine generator was developed in the market and is available from a well-established manufacturer [3]. The maximum capacity is about 15 MW-gross with dimensions 12 m (L) × 8 m (B) × 5 m (H). Totally, nine turbine generators are required.

The pumps used to transport the seawater and working fluid are also inputs from a manufacturer [40]. The capacity per unit pump is 18,000 m3/h. The core dimensions of the pump are 9 m (L) × 3.5 m (B) × 6 m (H) including motor and 3.5 m lifting height. The volumetric space of heat exchanger, turbine generator, and pumps is listed in Table 3. It depends on the location of heat exchanger and turbine generator to the seawater tank.

6 Constraints

The constraints induced in this design procedure can be categorized into two functions. The constraints due to abrasion phenomena on the pipe, seawater flow inside seawater tanks, loss of energy due to pumping system and freeboard allowance are used to determine the size of the plantship. The constraints due to stability and trim condition are utilized to design and conceptualize the general arrangement of the plantship.

To minimize the required length of the submarine cable, the plantship is floated on the ocean where its local depth is more than the required but close to the shore as near as possible. Thus, the distance between seabed and the intake of cold water pipe is relatively close. The deep seawater transported along the seawater pipe will contain sand particles. The friction between the pipe and the seawater will wear the surface of the pipe. The excessive velocity of seawater transport may cause material degradation which can gradually trigger the failure relating to the piping’s integrity. The abrasion phenomena are imposed on the design procedure to limit the allowed velocity of the seawater transport. The erosive wear equation is adopted from [41]. The estimation yields a result that by setting up the lifetime of the cold water pipe of 25 years, the critical velocity of seawater transport is 3.7 m/s. This result is also stated in the previous study [25].

The seawater will be stored in the seawater tank before distributed to the heat exchanger. As calculated in Sect. 5.2, the required debit of the seawater is so large. This amount of seawater flow rate coming up from the outlet seawater pipe with certain velocity will convey massive momentum. At this point, analyzing the flow inside seawater tank is very crucial. The result of this particular analysis will be used as the constraint to decide the size of the seawater tanks. The analysis will be done using a commercial software named Ansys interface. The detail will be explained in Sect. 6.1.

The next constraint is due to loss of energy for the pumping system. This constraint is to decide the arrangement of the OTEC system including the heat exchanger, turbine generator and the pumps. The arrangement plan will be used to estimate the required space and buoyancy of the OTEC system. The details of the pumping power estimation and the net power output calculation will be described in Sect. 6.2.

By comparing the required buoyancy and space with the provided capacities, the acceptance of a particular set dimension of a plantship can be determined. This constraint is named as the constraint due to freeboard allowance. The space for OTEC system equipment including the seawater tanks will be located between forepeak bulkhead and after peak bulkhead. The required space depends on the size of seawater tanks which are decided by the constraint due to seawater flow inside seawater tanks and by the arrangement of the OTEC system equipment which is yielded from the constraint due to pumping power. In the case of the required buoyancy estimation, it will be broken down specifically in Sect. 6.3.

After obtaining the possible size of the plantship, the next step is setting the general arrangement. To ensure the safety, constraints due to stability and trim condition are imposed to the design procedure. This analysis is also to assess the necessity of ballasting system. The method for analyzing the statistic stability is adopted from [27] and then modified to take into account the effects of riser installation. To ensure that the floating structure has adequate stability, IS code is adopted as the parameters’ guidance [24]. For trim estimation, the calculation process is done referring [28]. The common understanding is that plantship trim less than 1% of LPP is recommended.

6.1 Size of seawater tank

If the wall of seawater tank does not have adequate distance from the riser, the wall will be subject to pressure caused by seawater momentum delivered during the transportation. As the plantship is converted from an existing structure, the applied load must not exceed the design load at the initial design condition. The total applied pressure consists of static pressure loading and dynamic pressure loading. The static pressure loading formulation is adopted from ClassNK regulation [42] and the dynamic pressure loading is obtained from Ansys interface simulation using Ansys CFX and Ansys Structural [43,44,45]. The total applied pressure is then compared with the allowable pressure acting on the wall of the seawater tanks adopted from ClassNK regulation.

The second constraint is the area of seawater tank, \({A_{{\text{swt}}}}\), compared with the cross-section area of the risers, \({A_{\text{r}}}\). Insufficient area of seawater tank in a ceratin level of seawater transport velocity will increase the pressure difference in the pumping system calculation as shown in Eqs. 5 and 12. The simulation is carried out by varying the value of \({A_{{\text{swt}}}}/{A_{\text{r}}}\) from 10 to 50 with an increment of 5.

The case configuration for the Ansys interface simulation and required pumping power estimation due to change of area of seawater tank is listed in Table 4. The details of the analyzed dimension of seawater tank are drawn in Fig. 8. Results intended from this particular analysis are the minimum distance between riser and side wall of seawater tank, \(d\), minimum height of the tank, \({H_{\text{t}}}\), and minimum area of the tank, \({L_{\text{t}}} \times {B_{\text{t}}}.\)

The Ansys interface simulation refers to the coupled analysis between computational structural mechanics (CSM) and computational fluid dynamics (CFD). The input data initially is set using CFD in the inlet and outlet boundary conditions. The CFD simulation then brings the loads from the fluid dynamics to the structural analysis. In the modelling process, the structure is divided into three parts which are inlet pipe, outlet pipe and tank walls. The inlet pipe imitates the seawater pipe and the outlet pipe is used to model the pipe connecting seawater tanks and heat exchanger. However, to model the whole length of cold water pipe is simply impossible due to software license limitation. Thus, the inlet pipe only covers the 1 m upper part of the cold water pipe. The effect of the shortened inlet pipe model is taken into account in the boundary definition process.

Because the main purpose of the simulation is to measure the pressure acting on the wall of seawater tanks, the wall of the tanks is modeled as rigid wall which means the shape of the seawater tanks remain the same during the simulation. The convergence analysis is also carried out to define the optimum mesh size. The details of the model scantling are listed in Table 4. The boundary condition of the system is numbered as shown in Fig. 9 and detailed in Table 5. The environment setting is set so that the velocity of seawater transport at the inlet is same as the designed case.

Figure 10 shows the sample result for analyzing the minimum distance between riser and sidewall of the tank. In the sample model, the distance between riser and sidewall of the tank is 20 m and the velocity of the seawater transport is 2 m/s. As the model has symmetrical scantlings, the pressure distribution for all side walls is identic. Figure 10 only shows one part of the sidewall tank. The critical region is rendered in red and pointed inside the cycle. In the ClassNK regulation for designing fluid tanks, the rule states that the maximum allowed pressure acting on the whole surface of the wall should not be more than the value defined by the regulation. Thus, the maximum value of the pressure distribution is taken as the dynamic pressure. This procedure is repeated for all other cases. The collective results will be discussed in the following section.

6.2 Net power output product

Equation 2 is built by assuming that the pumping system will use about 30% of gross energy product. As the pumping system is affected by the layout, it must be analyzed considering the general arrangement plan of the plantship. The elements of the pumping system such us piping diagram, flange position, piping elbow and other elements must be set so the required pumping powers do not exceed the assumption. Basically the pumping system embodies warm seawater pumping system, cold water pumping system, and working fluid pumping system. The equation to calculate the loss of energy due to pumping system has been explained in detail in [2]. The schematic OTEC plant proposed in [2] does not have seawater tanks’ installation. Thus, the equation to calculate the total pressure difference adapted from [2] has been modified in this present study to involve the pressure drop on the seawater tanks.

6.2.1 Working fluid pumping power

The working fluid pumping power \({E_{{\text{wf}}}}\) is given as [2]:

\({m_{{\text{wf}}}}\) is working fluid mass transported along the pipe. This mass change depends on its form during the cycle. \(g\) is the gravity acceleration. \({\eta _{{\text{wfp}}}}\) is the efficiency of the working fluid pump. \(\Delta {P_{{\text{wf}}}}\)is the total pressure difference of the working fluid piping modified from [2] as:

\({(\Delta {P_{{\text{wf}}}})_{\text{S}}}\) is the saturation pressure difference between condenser and evaporator as [2]:

where \({\rho _{{\text{wf}}}}\) is the density of the working fluid.

\({(\Delta {P_{{\text{wf}}}})_{\text{p}}}\) is the pressure difference of the working fluid along the pipes [46]. This pressure difference relies on the piping diagram which is a sum of the pressure difference on the straight pipes \({(\Delta {P_{{\text{wf}}}})_{{\text{SP}}}}\) and the bending loss \({(\Delta {P_{{\text{wf}}}})_{\text{B}}}\). It simply can be defined as [46]:

where

\({L_{{\text{wf}}}}\) is the length of working fluid pipe, \({D_{{\text{wf}}}}\) is the diameter of the working fluid pipe, \({V_{{\text{wf}}}}\) is the velocity of the working fluid and \({C_{{\text{wf}}}}\) is the roughness coefficient of the pipe:

\(\gamma\) is loss coefficient and the indexes are I for inlet, V for valve, S for separating, J for joint, O for outlet, E for elbow, D for diffuser, and R for reducer. These loss coefficients are referred from the reference [46]. These coefficients are not a single value. They are calculated based on the several parameters which vary depending on the local partitions. For example, calculating the loss coefficient due to joint connection, \({\gamma _{\text{J}}}\), it is required to consider the type of the connection, the direction of initial flow, and the elongation angle of the joint connection. Thus, the value of \({\gamma _{\text{J}}}\) for joint connection between pipes from seawater tank to the heat exchanger, from heat exchanger to the turbine, and other pipe connections will be different. Additionally, although the philosophy of the calculation is same, but the calculation depends on the piping configuration, and the concrete values of these loss coefficients cannot be literally referred to the other cases.

\({(\Delta {P_{{\text{wf}}}})_{\text{C}}}\) is the pressure difference of the working fluid inside the condenser. This pressure difference can be read as [2]:

\({\alpha _{\text{C}}}\) is the coefficient which depends on the Reynolds number of the working fluid inside the condenser, \(R{e_{{\text{wf}}}}\) as \(6.19 \times {10^6}R{e_{{\text{wf}}}}^{{ - 1.21}}\), \({l_{\text{C}}}\) is the length of the condenser plate and \({({D_{{\text{eq}}}})_{\text{C}}}\) is the equivalent diameter of the condenser.

6.2.2 Seawater pumping power

Seawater pumping power \({E_{{\text{sw}}}}\) consists of warm water pumping power \({E_{{\text{ww}}}}\) and cold water pumping power \({E_{{\text{cw}}}}\). The philosophy and principle to calculate the required work for both are the same. Here the general equation to calculate the required pumping power for seawater is broken down. To transform the equation, the index \({\text{sw}}\) is just simply changed to \({\text{ww}}\) for warm water pumping and \({\text{cw}}\) for cold water pumping. The seawater pumping power \({E_{{\text{sw}}}}\) is calculated as [2]:

\({m_{{\text{sw}}}}\) is seawater mass transported along the pipe. \({\eta _{{\text{swp}}}}\) is the efficiency of the seawater pump. \(\Delta {P_{{\text{sw}}}}\) is the total pressure difference of the seawater piping modified from [2] as:

\({(\Delta {P_{{\text{sw}}}})_{\text{p}}}\)is the pressure difference of the seawater pipes, \({(\Delta {P_{{\text{sw}}}})_{\text{E}}}\) is the pressure difference of the working fluid inside the heat exchanger [2]. The procedure to calculate these pressure differences is the same as the equation for calculating the pressure difference for the working fluid as stated in Eqs. 6–9.

\({(\Delta {P_{{\text{sw}}}})_{{\text{SWT}}}}\) is the depth of seawater on the tanks transported per 1 second.

In the case of cold water pumping system, the pressure difference calculated in Eq. 11 is added by the pressure difference due to density change between warm water and cold water as seen in [2]:

\({\rho _{{\text{ww}}}}\)is the density of warm water sea and \({\rho _{{\text{cw}}}}\) is the density of cold water sea.

6.3 Required buoyancy

The required buoyancy is the total weight of the structure and all equipment with the added margin of 5% to bear the uncertainties. The total weight of the plantship can be broken down into two main parts which are the weight of the OTEC system equipment and the weight of the supporting system. The supporting system refers to all part of the plantship which does not directly correlate with the OTEC process. This weight embodies weight of the steel, accommodation, crew, station keeping system and navigation equipment, sanitation, fresh water and storage, etc. The approach to calculate this weight is widely known, as it is not that different from other types of floating structure [47, 48]. Thus, this part emphasizes more on the estimation process for the weight of the OTEC system.

6.3.1 Weight of the riser

From the main dimensions of the risers listed in Table 3 and its material properties, the total weight of all risers suspended on the risers is obtained as shown in Table 6.

6.3.2 Weight of the heat exchanger, turbine generator and pumps

The weight of the heat exchanger, turbine generator and pump is adopted from the manufacturer’s catalogue as shown in Table 7. The supporting equipment such as piping line, pump, flange is calculated referring to the sketch as drawn in Figs. 3 and 4 for particular cases of the plantship size.

6.3.3 Weight of the fluids on board

The fluids on board cover the weight of the working fluid and seawaters either circulated through the OTEC equipment or deposited in the tanks. The calculation of the weight of the circulated working fluid is done considering the temperature ladder shown in Fig. 7 and the energy balance of the system as shown in Fig. 11. The weight of the working fluid in storage is set as 30% of the weight of circulated working fluid. In case of seawater, its weight depends on the size of the seawater tank. To avoid free surface effect on the seawater tank, the seawater tanks must be in the fully loaded condition.

7 Results

7.1 Calculation results for net power output estimation

The equation to govern the net power output can be derived as follows:

\({P_{\text{n}}}\) is the gross power output calculated using Eq. 1. \({P_{\text{a}}}\) is the additional required power for lightening, control system and other supporting systems which were assumed to be 5% of \({P_{\text{g}}}\). \({E_{{\text{wf}}}},\,{E_{{\text{ww}}}}\), and \({E_{{\text{cw}}}}\) are the required pumping power as defined in Sect. 6.1.

Since net power estimation is done for all plantship dimensions which has sufficient space and buoyancy, the results of the net power estimation are also as many as the number of the analyzed plantship. Obtaining the required pumping power for particular plantship size, the data will be analyzed using statistical formulation to get its mean value. The mean value obtained here is also investigated for both the conditions where the heat exchanger is located above the seawater tank and next to the seawater tank. In the case of Aframax type, first all of its stochastic dimensions are rejected due to insufficient space and buoyancy. To overcome this matter, a deeper draft is adjusted until it has sufficient space and buoyancy. By this method, the net power estimation for Aframax also can be performed. However, at the end of the design process, the Aframax type is excluded in the process due to deficient freeboard allowance.

Figure 12 is a histogram graph showing the net power output estimation for Suezmax plantship with seawater transport velocity in the OTEC system of 2 m/s and that the location of the heat exchanger is next to the seawater tank. The mean value of this case is about 100.2 MW. Obtaining the histogram graphs for all cases and calculating its mean value, a graph correlating the effect of the seawater transport during the OTEC cycle and location of the heat exchanger to the net power output can be obtained as shown in Fig. 13. As shown in Fig. 13, the involvement effect of seawater transport velocity in the OTEC system is not relatively significant compared with the effects of the plantship size and the location of heat exchanger. Figure 13 also indicates that the net power output decreases with increase of seawater transport velocity in the OTEC system. From the figure, it also can be concluded that locating the heat exchanger next to seawater tanks will save around 5–6 MW or around 5% of the net power target. Setting up the targeted net power of 100 MW and locating the heat exchanger parallel with the seawater tanks, Aframax and Suezmax types of oil tanker ships are still sufficient as the plantship and even the seawater transport velocity during the OTEC cycle is set up to 5 m/s. But locating the heat exchanger above the seawater tanks will make Aframax and Suezmax types suitable as long as the velocity of seawater transport in the OTEC system does not exceed 4.5 m/s. For ULCC, the net power output of 100 MW can be achieved if the heat exchanger is located next to seawater tanks with seawater transport during the OTEC cycle below 3.5 m/s. In the case of VLCC, it is clearly pointed that it is not suitable for the plantship.

7.2 Required size of seawater tanks

The analysis is carried out by varying the height of seawater tank with seawater transport increasing from 1 to 5.5 m/s. The result correlating the velocity of seawater transport and the total pressure acting on the top of the tank for various heights of seawater tanks is shown in Fig. 14. At the first stage of the analysis, seawater transport velocity of 1 m/s needs excessive size of the risers. This makes the scantling of the riser stated in Sect. 5.3.1 unable to sustain the applied loads. By comparing the total pressure and the initial load design, the minimum height of the seawater tanks at a certain level of seawater velocity can be estimated. To naturally push up the deep seawater to the surface, the draft of the plantship must be the same level as the top of seawater tanks. Thus, besides designing the size of seawater tanks, the result from this particular analysis is also used to set the minimum required draft of the plantship. From Fig. 14, it can be clearly known that seawater velocity more than 4 m/s will cause excessive pressure acting on the top part of the tank, if the height of seawater tanks is less than 14 m. Hereafter, the seawater transport velocity is focused only from 2 m/s to 4 m/s. The second analysis is to investigate the minimum distance between riser and sidewall of the tanks which then became the basic consideration to decide the breadth and the length of the seawater tank. Indirectly, the result will also discern the minimum breadth and length of the plantship. Figure 15 shows the correlation between the distance between the riser and sidewall with the dynamic pressure acting on the sidewall of the tank. The total pressure acting on the sidewall is a sum of dynamic pressure in Fig. 15 and static pressure which depends on the height of seawater tank. The initial design load for sidewall tank is also affected by the height of seawater tanks but not less than 25 kN/m2 [42]. The static pressure and the initial design load are calculated referring to ClassNK regulation [42].

7.3 Final results

Varying the size of the plantship using Monte Carlo simulation, sharpening the OTEC system choices using constraint satisfaction method, the final results are obtained as shown in Table 8. From the results, the sufficient velocity of seawater transport is between 2 and 3 m/s. If the velocity of seawater transport is less than 1 m/s, the diameter of cold water pipe will be too large for the top joint connection to sustain the applied load. Considering the constraint due to seawater flow inside seawater tanks, seawater transport velocity of more than 3 m/s requires an excessive size of the seawater tanks to keep the acting pressure below the design load.

In the case of plantship decision, if the excessive provided capacity is more than 5% of the required parameter, the plantship will be considered as overdesigned. But if the provided capacity is less than the required one, the plantship size will be rejected. It will be recommended if the provided capacity is more than the required one and less than 105% of the required.

The process is divided into two conditions, the first is when the heat exchanger is located above the seawater tank and the second is the heat exchanger is placed next to the seawater tank. In case one, Aframax type is rejected because the length, the breadth and buoyancy of the plantship are less than the required ones. On the other hand, ULCC and VLCC are also rejected due to oversize capacity. Suezmax type is the only plantship that suits the criteria with the scantling listed in Table 8. For case two, Aframax type is also insufficient because of not enough capacity and VLCC is also unacceptable, because the provided scantling was far beyond the required ones. Suezmax type is acceptable for case two, but compared with the first case, the required breadth of the plantship is larger. This is because in case two, the heat exchanger is arranged parallel to the seawater tanks which makes the required breadth of the plantship larger. For the same reason, ULCC type which is considered oversized in case one can be accepted in case two. The details of the scantlings of the possible plantship for case two are also listed in Table 8.

As shown in Table 8, in the case where the heat exchanger is above the seawater tanks, the required draft for the OTEC plantship is around 16–20 m. If compared with the original draft listed in Table 1, there is a remarkable gap between them. It implies that for the same volumetric space, the required buoyancy for OTEC plantship is lower than the oil tanker ship. As the draft per breadth ratio decreases, the stability problem might be triggered. This is one factor to be considered in a general arrangement design. In case two, the heat exchangers are divided into two layers. So, the height of seawater tanks at least must be twice than the required height of one submodule. This brings a consequence that the draft must be at least 26 m, which embodies 21 m for seawater tanks and 5 m of riser handling equipment. To submerse the plantship of 26 m, the solid ballast will be installed on board. Additionally, the freeboard allowance should be considered more in this case especially for damaged ship analysis.

8 General arrangement

The novelty of the general arrangement for OTEC floating structure is the installation of the seawater tanks and suspended pipes for both aspirating and discharging seawater. The inlet pipes are used to deliver the seawater to the floating structure and the inlet seawater tanks are necessary to store the seawater before being distributed to the OTEC system equipment. After utilization, the seawater will be discharged at a substantial depth, so the discharged seawater which has lower temperature will not affect the temperature of the warm surface seawater. To spill out the seawater at the certain depth, it is required to install outlet pipes. Following this condition, the outlet seawater tanks are also necessary to collect the seawater from the heat exchanger before being discharged through outlet pipes.

The preliminary design of general arrangement in this section is conceptualized ensuring that it could be designed, installed, and built as a commercial platform for OTEC power plant. The general arrangement is drawn for two design conditions, case one is the arrangement when the heat exchanger is located above the seawater tank and case two is when the heat exchanger is next to seawater tank. The philosophy of the design is same for both plantships. The difference is just the size of the seawater tank. In the second design, the distance between the risers and sidewall of the tanks is limited by the space for heat exchanger. In this condition, local strengthening system must be installed to resist the deflection happening on the wall plate due to dynamic pressure.

First, the center of buoyancy is estimated and the arrangement is objected, so the distance between center of buoyancy and center of gravity does not cause extreme longitudinal trim. The electricity production units are divided into two compartments with pair specifications. They are in front of the cold water tank and behind the cold water tank. Beneath the seawater tank, there is space for riser handling equipment with inner bottom height of 5 m.

The general arrangement for both cases are drawn with the size of the plantship as the mid-value of the obtained results that is shown in Table 8. The sample design has a length of waterline of 285 m, breadth of 50 m, with adjustment draft of 17 m for case one and 26 m for case two. Consideration based on the temperature gradient at the site and required flow rate of OTEC system implies that a cold water pipe of 800 m long with diameter of 12 m is required for it to be suspended at around mid-ship. A pair of warm water pipes are also necessary to pump up the warm water surface from 20 m of seawater depth. To avoid the ecological damage on the surface ocean due to temperature mix, a pair of cold water discharge pipes and a pair of warm water discharge pipes are also attached on the keel of the plantship with a length of 40 m. The seawater transport velocity for CWP inlet is set to be 2 m/s, but for CWP outlet, WWP inlet, and WWP outlet it is set to be 3 m/s. The location of the risers is determined considering the longitudinal stability and dynamic motion of the plantship by placing the risers in proportional distance and placing the cold water pipe at approximately near by the center of gravity. These risers are supported by a ball and socket structure incorporated in the hull which allow to rotate up to 20° about the vertical axis. In the most recent state-of-the-art riser manufacturing technology, there is still a big gap between the estimated size and the practice. Thus, a specific study on the OTEC riser is necessary to be carried out. One of the solutions is examining the possibility of installing multiple risers to deliver the seawater. It can be examined to decrease the diameter of the risers.

Figures 16, 17, 18 and 19 show general arrangement for case one. Figure 16 is the side view of the plantship. Figures 17, 18, and 19 are the top view at waterline 5 m, 17 m and 26 m, respectively. The distance between the second and the third deck is set being about 9 m high to cope with the size of the heat exchanger. On the second deck, 36 submodules of condenser and evaporator are placed symmetrically to maintain the stability. The turbine- generator and all pumping systems are placed on the third deck. The relative location is intended to minimize the parasitic loss energy as much as possible. However, because the seawater tanks, heat exchanger and the turbine generator are not parallel to each other, it still needs a large amount of energy to pump up the seawater from seawater tanks to heat exchanger and working fluid from heat exchanger to turbine generator.

Placing the heat exchanger parallel with seawater tanks is the best solution to overcome the issue mentioned above. The design process indicates that it is impossible to also set the turbine generator parallel with the heat exchanger due to limited space. As the mass density of the working fluid is not relatively large compared with the seawater, the parasitic loss energy due to this condition is extensively acceptable. The arrangements are shown in Figs. 20, 21 and 22. Figure 20 is the side view of the plantship. Figures 21 and 22 are the top view at waterline 5 m and 16 m, respectively. For the waterline 26 m, the top view is the same as case one.

For both designs, the hotel, living quarters, office room and other business rooms are located on the superstructure. The fore peak and after peak will be used for plantship control system. In case for the electricity delivery to the shore, marine cable will be used.

9 Conclusion

The plantship is considered to be from an oil tanker ship conversion and is designed to be utilized in Mentawai island, west part of Indonesia. The process of designing 100 MW-net OTEC power plant yields results implying that Suezmax oil tanker type is sufficient to be the plantship. The optimum water transport velocity also has been examined on the basis of recent progress of OTEC system and components. It can be concluded that seawater transport of 2–3 m/s is the optimum velocity.

The placement decision for the heat exchanger is solely hard to be determined. The result shows that placing the heat exchanger above seawater tank will sacrifice about 5–6% of net power output. For the second case, setting up the heat exchanger parallel to the seawater tanks requires a larger size of the plantship and the necessity of deeper draft. Due to this condition, solid ballast might be needed to be installed on board. These will increase the capital cost.

The proposed win–win solution might be decreasing the space for seawater tanks, so the heat exchanger and seawater tanks can be placed parallel in one layer. By this way, the required size and draft of the plantship will be decreased. However, decreasing the size of the tanks may trigger excessive pressure acting on the sidewall of the tanks. To deal with this condition, installing local stiffening system on the tanks could be one solution. The visibility of this solution needs further investigation and will be done in the future.

Additionally, in this paper, converting an oil tanker ship to be used for OTEC floating structure aims to decrease the capital cost. The cost estimation analysis and study comparison between the proposed solution and others will be carried out in the near future.

References

Syamsuddin ML, Attamimi A et al (2015) OTEC potential in the Indonesian seas. Energy Procedia 65:215–222

Uehara H, Ikegami Y (1990) Optimization of a closed-cycle OTEC system. J Sol Energy Eng 112:247–256

Vega LA, Michaelis D (2010) First generation 50 MW OTEC plantship for the production of electricity and desalinated. In: Proceeding of offshore technology conference (OTC 20957). Offshore technology conference, Texas, pp 1–17

Finney KA (2008) Ocean thermal energy conversion. Guelph Eng J 1:17–23

Engels W, Zahibian F (2014) Principle and preliminary calculation of ocean thermal energy conversion. In: Proceeding of American society for engineering education (ASEE 2014). American Society for Engineering Education, Bridgeport, pp 1–5

Vega LA (2012) Ocean thermal energy conversion. In: Meyers RA (ed) Encyclopedia of sustainability science and technology, vol 6. Springer, New York, pp 7296–7328

Vega LA (1992) Economics of ocean thermal energy conversion (OTEC). In: Seymour RJ (ed) Ocean energy recovery: the state of the art. American Society of Civil Engineers, New York, pp 152–181

Vega LA (2003) Ocean thermal energy conversion primer. Mar Technol Soc J 6:25–35

Vega LA (2010) Economics of ocean thermal energy conversion (OTEC): an update. In: Proceeding of offshore technology conference (OTC 21016). Offshore technology conference, Texas, pp 1–18

Lockheed Martin Mission Systems and Sensors (2012) Ocean thermal energy conversion life cycle cost assessment (final technical report DE-EE0002663). Lockheed Martin, Maryland

International Renewable Energy Agency (2014) Ocean thermal energy conversion: technology brief. IRENA, Abu Dhabi

Aldale AM (2017) Ocean thermal energy conversion (OTEC). Am J Eng Res 6:164–167

Nihous GC, Vega LA (1993) Design of a 100 MW OTEC-hydrogen plantship. Mar Struct 6:207–221

Gibbs & cox, Inc. (1978) Ocean thermal energy conversion (OTEC): platform configuration and integration. Gibbs & cox, Inc., Washington

Glosten LR (1979) A baseline design of an OTEC pilot plantship. Johns Hopkins University, Maryland

Office of Ocean Minerals and Energy (1981) Ocean thermal energy conversion (OTEC): final environmental impact statement. National Oceanic and Atmospheric Administration, Washington

Marine Board of the Commission on Engineering and Technical System (1983) Ocean engineering for ocean thermal energy conversion. National Academic Press, Washington

George JF, Richards D (1980) Baseline designs of moored and grazing OTEC pilot plants. Johns Hopkins University, Maryland

Avery WH, Wu C (1994) Renewable energy from the ocean: a guide to OTEC. Oxford University Press, New York

Yee AA (2015) OTEC platform. In: Wang CM, Wang BT (eds) Large floating structures: technological advances. Springer, Singapore, pp 261–280

Srinivasan NA (2009) New improved ocean thermal energy conversion system with suitable floating vessel design. In: Proceeding of international conference on offshore mechanics and arctic engineering (OMAE2009). American Society of Mechanical Engineers, Hawaii, pp 1119–1129

D’Souza RB, Delepine YM, Cordy AR (1994) An approach to the design and selection of a cost effective floating production storage and offloading system. In: Proceeding of offshore technology conference (OTC 7443). Offshore technology conference, Texas, pp 1–14

Paik JK, Thayamballi AK (2007) Overview of ship-shaped offshore installations. In: Paik JK, Thayamballi AK (eds) Ship-shaped offshore installations. Cambridge University Press, Cambridge, pp 1–28

Bureau Veritas (2018) Classification and certification of ocean thermal energy converter (OTEC). Bureau Veritas, France

Adiputra R, Utsunomiya T (2018) Design optimization of floating structure for a 100-MW ocean energy conversion (OTEC) power plant. In: Proceeding of the 37th international conference on ocean, offshore, and arctic engineering-ASME (OMAE 2018). American Society of Mechanical Engineers, Spain, p V010T09A016

Brailsford SC, Potts CN, Smith BM (1999) Constraint satisfaction problems: algorithms and applications. Eur J Oper Res 119:557–581

Minning GC (1956) The theory and technique of ship design. The MIT Press, New York

Parson MG (2004) Parametric design. Society of Naval Architects and Marine Engineers (SNAME), New York

Papanikolaou A (2014) Ship design methodologies of preliminary design. Springer, Amsterdam

TERMPOL Surveys and Studies (2014) TERMPOL review process report on trans mountain pipeline expansion project. Transport Canada, Canada

Koto J (2017) Potential of 100 kW ocean thermal energy convention in Indonesia. In: Proceeding of the Japan society of naval architects and ocean engineers (JASNAOE meeting spring). Tokyo, Japan, pp 763–767

Koto J (2016) Potential of ocean thermal energy conversion in Indonesia. Int J Environ Res Clean Energy 4:1–7

Fahmie M, Koto J, Nofrizal et al (2018) Ocean thermal energy conversion in Layang-Layang and Kuala Baram, Malaysia. Int J Environ Res Clean Energy 11:12–21

Koto J, Negara RB (2017) Potential of 100 kW of ocean thermal energy conversion in Karangkelong, Sulawesi Utara, Indonesia. Int J Environ Res Clean Energy 5:1–10

Koto J, Tasri A, Kamil I et al (2017) Sea temperature profiles for ocean thermal energy conversion (OTEC) in Siberut-Mentawai, Sumatera Barat, Indonesia. J Subsea Offshore 11:10–16

Susanto RD, Mooree TS, Marra J (2006) Ocean color variability in the Indonesian seas during SeaWiFS era. Geochem Geophys Geosyst 7:1–16

Nihous GC (2007) A preliminary assessment of ocean thermal energy conversion resources. J Energ Resour ASME 129:10–17

Yong B (2001) Pipelines and riser, vol 3. Elsevier Science Ltd., London

Panchal CB, Pandolfini PP et al (2009) Technical report no. ANL/ESD/09-6 ocean thermal plantships for production of ammonia as the hydrogen carrier. Energy systems division Argonne National Laboratory, Chicago

Torishima Pump Inc. (2018) CDM pump catalogue. Torishima Pump Inc., Takatsuki

Cheremisinoff NP (1995) Fiberglass reinforced plastic: manufacturing techniques and applications. Noyes Publications, New York

ClassNK (2017) Rules for the survey and construction of steel ships 2017. ClassNK, Tokyo

Bauchau O, Craig J (2009) Structural analysis. Springer, New York

ANSYS Inc. (2017) ANSYS software version 17, ANSYS HELP. ANSYS Inc., New York

ANSYS Inc. (2017) ANSYS software version 17, ANSYS CFX HELP. ANSYS Inc., New York

Idelchik I (1960) Handbook of hydraulic resistance. National Technical Information Service, New York

Watson DGM (2002) Practical ship design. Elsevier Science Ltd., London

Schneekluth H (1998) Ship design for efficiency and economy. Elsevier Science Ltd., London

Acknowledgements

Funding was provided by Indonesia Endowment Fund for Education (LPDP) (Grant no. PRJ-873 /LPDP.3/2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Adiputra, R., Utsunomiya, T., Koto, J. et al. Preliminary design of a 100 MW-net ocean thermal energy conversion (OTEC) power plant study case: Mentawai island, Indonesia. J Mar Sci Technol 25, 48–68 (2020). https://doi.org/10.1007/s00773-019-00630-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00773-019-00630-7