Abstract

The purpose of this paper is to propose the wake field design system which outputs a bare hull form generating a desired input wake distribution, and to demonstrate capability and effectiveness of this system through a practical hull form design project considering the interference effect of ESD and propeller. Our proposed wake field design system outputs a hull form which achieves desired input wake distribution utilizing hull form and wake field database. In the system, the database is analyzed by a method for the first time proposed in the present study, that is, a scheme using the Euclidean distance and hull form blending (morphing). To validate our system, the one-leave-out cross validation is performed, which is widely used for the validation of the database analysis. There, it is confirmed that the proposed method has practical accuracy. A practical demonstration is also performed in this paper, where a 749 gross tonnage cargo ship is selected as object ship. The initial (original) hull form in this research was developed in a project of the Japan society of naval architects and ocean engineers as a considerably promising bare hull form. This hull form is defined as the original design in this study, then we try to further modify the design to reduce delivered horse power in a condition of hull with duct type ESD. Importantly, we design a new hull form to improve wake field suitable for the duct along with the consideration of reduction of cavitation. To confirm the effectiveness of our proposed system, the towing tank test is conducted to measure the wake distribution, using 2 model ships (original and new design) with 6.8 m ship length. It is proved that our proposed system is capable to efficiently design desired wake field for the given hull form without trial and error, and provide equivalent to or more precise results than the expert designer’ design. Additionally, we also confirm that the propulsive performance of the new design hull form is improved. In our careful comparison of the effectiveness of the ESD, it is indicated that the new design shows 2.2% reduction of horsepower compared to the original hull form both for ESD installed case.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

A wake field design for a given hull form is deeply related to improvement of propulsive performance with/without energy saving device (ESD) [1,2,3], and also noise characteristics of propeller. For the latter, in recent years, there are glowing social demands for the reduction of underwater ship radiated noise in terms of mariners’ comfort and environmental protection [4]. Propeller cavitation is one of the main sources of the noise and that should be reduced. A conventional countermeasure against severe cavitation is an increase in propeller development area; however, this approach causes lowering of propeller efficiency according to an increase in propeller development area. Apparently, the most direct and efficient approach is designing wake field generated by the hull form.

In fact, traditional approach for wake field design is not a systematic but rather a trial and error method based on expert’s tacit knowledge using the measurement results of towing tank tests [5]. To highlights the underlying issues and obtain important essence for development of the future systematic approach, several research projects had been performed [6,7,8]. For example, a domestic Japan research project in 1983 [9] investigated the wake flow distribution and resistance by theoretical and experimental tests for six different hull forms with a considerable frame line. There, a frame line was found so that it generates the wake flow distribution concentric to the propeller axis. The studies carried out in those projects were very beneficial, and became a strong motivation to the present study.

The aforementioned ESD is very common in modern ship design. The recent progress of optical flow field measurement methods, such as PIV [10, 11], and flow field analysis by computational fluid dynamics (CFD) [12,13,14,15,16], is going to reveal some working principle of ESD and interference effects between hull and ESD. For example, the energy saving effect of a duct type ESD is strongly influenced by the circumferential distribution of inflow angle to wing section of duct, which is generated by hull form [1,2,3]. Therefore, the optimum design of wake field generated by hull form often leads to a significant improvement in ESD performance, rather than the design effort of the ESD itself. Although, some studies were performed to optimize hull form including ESD effects [17, 18], those studies are not directly related to the systematic wake field design method.

On the other hand, to realize such a wake field design system, introduction of high fidelity simulation method, e.g., CFD based on Reynolds averaged Naiver Stokes (RaNS) equation method, appears to be promising, since recent advancement of CFD enables to create a large set of wake field database with considerably low cost as compared to experimental approach. Some tentative approached of such CFD based studies are: for example, work done by the present authors [19] or Van der Ploeg et al. [20], which successfully demonstrates an optimization of a hull form for minimum required power and best wake field quality. Other examples are also seen in Chen et al. [21], who firstly presents wake field design system by solving the inverse problems; and Stuck et al. [22], who proposes a design system for wake optimization using different numerical approach. Results seen in those studies are very promising, but an important drawback of utilization of time-consuming high-fidelity CFD solver is apparent in application to practical design work. It is clear that the effective utilization of CFD-based database type approach along with a scheme to analyze the database will solve the issue, where the database comprehensively includes hull form geometrical information together with flow field information.

The purpose of this paper is to propose the above-mentioned wake field design system and to demonstrate capability and effectiveness of the method through a practical design project of hull form design considering the interference effect of ESD and propeller. Our wake field design system outputs a hull form which achieves desired input wake distribution utilizing hull form and wake field database. In the system, the database is analyzed by a method for the first time proposed in the present study, that is, a scheme using the Euclidean distance and hull form blending(morphing). To validate our system, the one-leave-out cross validation is performed, which is widely used for the validation of the database analysis. There, it is confirmed that the proposed method has practical accuracy.

Next, a practical demonstration is performed, where a 749 gross tonnage cargo ship is selected as object ship. This is a hull form investigated in a project of the Japan society of naval architects and ocean engineers [23, 24], where main focus was on fully utilization of the SBD approach and the present authors were also participated. In the project, we developed a considerably promising bare hull form which achieves 38.1% reduction of CO2 emission from an averaged ship built in the 1990s. This hull form is defined as the original design in this study, then we try to further modify the design to reduce delivered horse power in a condition of hull with duct type ESD. Importantly, we design a new hull form to improve wake field suitable for the duct along with consideration of reduction of cavitation. To confirm the effectiveness of our proposed system, the towing tank test is conducted to measure the wake distribution, using 2 model ships (original and new design) with 6.8 m ship length. It is proved that our proposed system is capable to efficiently design desired wake field for the given hull form without trial and error, and provide equivalent to or more precise results than the expert designer’ design. Additionally, we also confirm that the propulsive performance of the new design hull form is improved. In our careful comparison of the effectiveness of the ESD, it is indicated that the new design shows 2.2% reduction of horsepower compared to the original hull form both for ESD installed case.

2 Overview of wake field design system

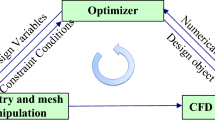

The proposed wake field design system is a system that outputs a hull form which achieves desired input wake distribution. Figure 1 shows an overview of the wake field design system.

The wake field design system consists of the following three technical elements.

-

1.

Hull form and wake field database.

-

2.

Wake field analysis method based on the Euclidean distance.

-

3.

Hull form generation method by hull form blending (morphing).

The input data of this system is a desired specific wake distribution on propeller plane. For example, this input wake is a wake to maximize energy saving devices effect or to reduce propeller cavitation. The desired specific wake distribution will be discussed later part in this paper. On the other hand, the output of this system is a hull form generates wake distribution closed to the input data. This output hull form is systematically generated from three hull forms in the hull form and wake field database, and it is not a hull form in the database.

The process of the system will be explained step by step. First, to analysis the given specific wake distribution, the system transforms the input wake distribution, which composed by velocity vector (u, v, w) to polar coordinate system of 10 points on the radial direction and 36 points on the circumferential direction:

Here, the data in a propeller boss is excluded from the analysis target.

Next, the Euclidean distances (\({d_{\text{k}}}\)) between a wake distribution on the database (\(\overrightarrow {{p_{ri\theta {j_k}}}}\)) and the input wake distribution (\(\overrightarrow {{q_{ri\theta j}}}\)) is evaluated by the Euclidean distance, expressed as Eq. 2.

where the Euclidean distance has a role as an evaluation function and a dimensionality reduction method of the database. Note that the Scipy [25] which is a Python-based ecosystem of open-source software is used for analysis of the database in anticipation of carrying out data mining to hull form and wake field database in the future.

Based on this Euclidean distance, the wake filed design system selects multiple similar wake field data which is defined as closer wake field data of the Euclidian distance from the input wake distribution, and in the present study we select three hull form data named as HF1, HF2, HF3, respectively. The output hull form, which yields wake distribution closed to the input data, is generated by hull form blending (morphing) method using the selected hull forms with similar wake fields. The hull form blending method is a method of generating a hull form from some basic hull forms [24], and its effectiveness for design is confirmed in hull form optimization in our previous research activities. When the N-th basic hull forms are represented by resolvable discrete surface points (\(\overrightarrow {{P_i}}\))—for example, grid points on hull surface in CFD—new hull form (\(\vec {P}\)) is obtained by the operation of Eq. 3 in the hull form blending method.

For third basic hull forms (HF1, HF2, HF3) in this study, Eq. 3 is expressed as Eq. 4.

where in the proposed method, the weighting factor (ai) is obtained from the Euclidean distances (d1, d2, d3) of the selected hull form and wake field data by Eq. 5,

Based on the Eq. 4 and Eq. 5, the output hull form is generated by hull form blending method using the aforementioned selected three hull forms in the database.

3 Validation of the proposed system

As a validation of the proposed method, leave-one-out cross validation method [27] is conducted for hull form and wake field database of 749 gross tonnage cargo ship [23, 24]. We construct two type databases for validation (DB1) and design verification (DB2), respectively. DB1 is used for validation on the present system and hull form database is parameterized with some hull form parameters that is easy to recognize the quantitative difference of hull forms. DB1 has 358 individual hull forms data with constant displacement and different ship length (LPP), breadth (B), draft (d) and block coefficient (CB). On the other hands, DB2 is a more general database and hull forms in DB2 cannot be expressed with certain hull form parameters. In this paper, DB2 is used for a practical design demonstration utilizing the proposed system. DB2 has 2,730 individual hull forms data with practically constant displacement and same hull form in fore part, and different aft-profiles, frame lines and sectional area curve. Note that the proposed system assumes that the DB stores all past design data of each shipyards. As for reference, calculation time for constructing DB2 (2,730 data) takes 6.1 days with 400 cases parallel calculations using 5 computers with 2 CPUs (Intel Xeon Gold 6148 (20 core 2.2 GHz) Broadwell-EP).

The Leave-one-out cross validation method is often used in statistics to estimate that how accurately a model will perform in practice. Based on this method, we extract one sample in the database and rebuild the model of the database without the sample. Then we predict the sample as a target with rebuilt model and show how accurately the model will predict the target hull form in practical aspects. To simplify the validation, we focus only on the axial flow velocity in wake distribution at propeller plane in Eq. 2.

3.1 Hull form and wake field database, DB1

For validation, we use DB1 which has 358 individual hull forms and CFD flow filed data with constant displacement and different ship length (LPP), breadth (B), draft (d) and block coefficient (CB) in the range in Table 1. Figure 2 shows the design space of DB1. All hull forms in DB1 is produced by systematic deformation method, which keeps frame lines of a basic hull form and moves ship-length-directional position of the frame lines to the corresponding position in the sectional area curve which is obtained by 1 − CP method, which is generally used to adjust CB in practical design. DB1 is parameterized by LPP, B, d. For simplicity, these parameters were nondimensionalized by the design parameters ξ, η, ζ of [0, 1], respectively. Nondimensionalization is performed by a linear mapping corresponding to the conditions shown in Table 2. Hull form data in nondimensionalized DB1 is shown in Fig. 3.

CFD flow filed database is produced by a structured-grid-based RaNS solver, NAGISA [28] developed at NMRI, and the turbulence model used in the present work is modified Spalart–Allmaras (MSA) [29] one equation model without wall function. This solver and turbulence model are normally used for hull form design at NMRI to estimate model-scale flow filed. The calculation grids of basic hull forms without any appendages at full loads and even keels were generated with HO topology, 1.8 million cells (i × j × k = 174 × 128 × 80: both sides) at model scale as shown in Fig. 4. The minimum spacing normal to wall is set to be y+<1.0 for constant Re = 1.0 × 107. The effect of free surface is considered to be small and ignored in all cases. An investigation on gird uncertainty for this calculative configuration was carried out in in the previous study [24], and we judged that the present grids have the same acceptable uncertainty level as in previous research.

The wake distributions at propeller planes in the database is very varied as shown in Fig. 5.

3.2 Validation result

Leave-one-out cross validation method is applied to the proposed wake field design system. The target hull form data is left from the DB1, and the wake distribution of this target hull form shown in Fig. 6. This target wake distribution is input to the proposed system, and then the system selects the three hull forms (HF1, HF2, HF3) from the database.

Table 3 shows Euclidean distance and the design parameters of selected hull forms in the DB1, which is also shown in Fig. 3—red: target, blue: HF1, HF2, HF3 (ID 283, 68, 14, respectively) green: ID 203 (The ship for reference, the Euclidean distance of which is placed in 4th). As you can see, HF1, HF2, HF3 are simply selected by the Euclidean distance of wake distribution, and at the same time, the hull form parameters are also close. This is the key fact of this proposed wake field design system, that is, there is a correlation between the Euclidean distance obtained from the wake distributions and the design parameters of the hull forms.

Figure 7 shows the frame lines of the hull form outputted by the proposed system (blue), target hull form (red) and sample hull forms in the database. As Fig. 7 indicates, the hull form newly outputted by the proposed system (blue) coincides with the target hull form very well. (blue and red lines cannot be distinguished because they are overlapped in Fig. 7.) This agreement is practically sufficient accuracy.

The present validation shows the proposed system can systemize the expert craftsmen’s tacit knowledge, or at least the system can suggest the possible idea of hull modification to the hull form designer. Since such a system has not existed in the past, this system is a very useful system for the designer.

4 Example of application and verification

In the following, a practical demonstration is performed to show the effectiveness of the proposed wake field design system.

In this research, we focus on a duct type ESD, called WAD, shown in Fig. 8. Some studies [1,2,3] have claimed that the thrust generated by the duct is a main working principal of the energy saving performance and wake field yield by bare hull form dominates fundamental performance of the duct. Hence, the inflow angle to wing section of the duct in the circumferential direction is a key parameter of interaction design of hull form and duct. In Fig. 9, inflow angle to wing section of the duct is defined. From the viewpoint of construction of a device, it is desirable that the opening angle of the duct is constant in the circumferential direction. Therefore, it is actually expected that circumferential distribution of the inflow angle had better be as uniform as possible to maximize the thrust and energy saving effect of the duct, and it is important to focus more on the improvement of wake field yielded by bare hull to enhance the duct performance.

The design purpose in this demonstration is to further improve the total propulsive performance by designing the bare hull form considering the influence of interference with the duct. In this paper, we will systematically achieve this goal using the proposed system. Meanwhile, the conventional wake field design considering interference with the duct is often done using the knowledge of expertise or just trial and error based procedure.

4.1 Hull form and wake field database, DB2

The object ship for verification is 749 gross tonnage cargo ship as same as abovementioned validation. The principal dimension of the object ship is shown in Table 4. In this demonstration, we use DB2 which has 2,730 individual hull form data practically constant displacement and same hull form in fore part, and different aft-profiles, frame lines and sectional area curve.

As mentioned above, the original hull form for this demonstration was investigated in a project of the Japan society of naval architects and ocean engineers in fully utilizing the conventional SBD [23, 24], where the present authors were also participated. In the project, we developed a considerably promising bare hull form which achieves 38.1% reduction of CO2 emission from an averaged ship built in the 1990s. Figure 10 shows the measured wake distribution of the original hull form (MS No.869) in towing tank test (Figs. 11, 12).

Figures 13 and 14 shows same examples of hull form variation. As you can see, this database is sufficiently varied about profiles, frame lines and sectional area curve (so-called CP curve). In constructing the database, we made full use of the hull form blending method and especially paid attention to the selection of the basic hull form for hull form blending in a practical point of view. Importantly, selection of this basic hull form has a large freedom, i.e., this does not have to be systematic base but designer’s free will.

Wake field database is constructed using the RaNS solver NAGISA [28] under the same calculation conditions as in validation. Before applying the turbulence model, we compared several turbulence models of EASM k-ω, SST k-ω, Modified SA and compared it with the tank test results of the original hull form (MS No. 869). As a result, modified SA (Cvor = 20) is applied to the construction of wake flow field database. An investigation on gird uncertainty for this computational configuration was carried out in in the previous study [24], and it is judged to have the same acceptable uncertainty level as in previous research.

Figure 15 shows an example of the wake flow database (wake distribution on propeller disk). As shown in Fig. 15, the database has various kinds of wake flows include strong hook shape.

The design purpose of this demonstration is hull form design considering the influence of interference with the duct. The proposed system does not require a database related to ESD. However, the desired wake distribution suitable for ESD is necessary that is discussed in the next section.

4.2 Design of desired wake distribution

In this demonstration, a desire wake distribution is designed to achieve following two design objectives.

-

1.

Improvement of duct type ESD performance.

-

2.

Reduction of cavitation.

The energy saving effect of the duct type ESD is strongly influenced by the circumferential distribution of the inflow angle. Therefore, it is important to improve wake distribution yielded by the bare hull form. According to constructional reason of the duct, the duct having the same opening angle in the circumferential direction. It is known that a higher energy saving effect can be obtained as the inflow angle to the wing section is constant [1,2,3]. Especially, the range of 0 to 80 degrees in the circumferential position of duct, where the duct thrust is strongly generated, must be carefully designed so that inflow angle is constant. Meanwhile, the inflow angle of the lower part of the duct is negative, hence that does not contribute to generation of the thrust of the duct; but, that contributes to improvement of the wake. In addition, the design of lower side of the duct has more freedom as compared to that of the upper side of the duct; hence, our focus of the discussion below is on the upper side of the duct. As mentioned earlier, to improve duct performance, it desirable to make circumferential distribution of inflow angle wing section of the duct as uniform as possible.

On the other hand, regarding the reduction of cavitation, it is important that the reduction of the fluctuation in the flow velocity in the x-axis direction in the circumferential direction of each radius (in particular the 0.7 R position where the propeller produces more thrust). Van der Ploeg et al. [20] demonstrates multi-objective optimization of a bare hull form to minimize resistance and the fluctuation which is defined by the L2-norm of the derivative of axial wake in circumferential direction. In the study, we use the maximum difference of axial wake at 0.7R as the value to be minimized, aiming at reduction of cavitation.

To achieve these two objectives, first we select the wake distribution for the duct (data with the smallest circumferential variation of the inflow angle in the design range of 0 to 80 degrees), and next, we also select the wake distribution for cavitation (data with the smallest difference between the maximum value and the minimum value in the x-axial flow velocity at 0.7R position). And then, we average these two flow fields to design the desired wake distribution.

Figure 16 shows the desired wake distribution. From the empirical design point of view [e.g., see Ref. 1,2,3], we focus on the center position of the hook shape in the wake distribution, which is core of longitudinal vortex. As compared to the original hull form’s calculated wake distribution in Figs. 17, 18 the center position of the hook shape in the desired wake locates lower than that of the original hull form. This movement of the center of hook shapes yields the improvement of the circumferential inflow angle to the wing section of the duct. We will discuss this contribution in wake field in detail at later section.

4.3 The system output hull form

From the desired wake distribution designed in the previous section, the wake field design system automatically creates a system output hull form to realize the desired wake.

Figures 19 and 20 show comparison of original hull form and system output hull form. To lower the center of the hook shape to the same height as the propeller axis, the volume of hull moves to around S.S. 2.0 from S.S. 1.0 compared to the original hull. The difference between the volume of the original and the system output hull forms is 0.02%.

The calculated wake distribution of the system output hull is shown in Fig. 18. A comparison of the wake distributions of the system output hull form (Fig. 18) and designed (input) wake distribution (Fig. 16) shows that the position of the center of hook shapes is well reproduced by the proposed system. Figure 21 shows the quantitative comparison of wake velocity (u) between the desired wake (Fig. 16) and the system output hull form (Fig. 18) at radial position r/R at 0.6, 0.7, 0.8. The wake velocity (u) of the system output hull agrees very well with that of the desired wake compared to that of original hull form in any circumferential position (\(\theta\)), especially for the duct-inflow-angle design range of 0 to 80 degrees position and these areas are also important for propeller cavitation. The maximum difference is only about 0.05 at \(\theta\) = 180°. Hence, we confirmed in calculation results that the proposed system can move the center of the hook shape lower as same as intended by the designer.

In fact, the trends of this change on hull is opposite to our original expectation, that is to move the separation line to the stern side, the volume just before the propeller plane must be moved. We initially expected that these would lower the center of the vortex considering the influence of stern upward flow; however, the system output hull form indicate actually different trend of volume movement is also promising, which is apparently beyond the conventional knowledge and considered to be very valuable information.

4.4 Verification by towing tank test

To verify the effectiveness of the proposed system, a large model ship with length 6.8 m of the original hull form (MS No. 869) and the system output hull form (MS No. 875) were manufactured. And we conducted flow measurement and resistance/propulsion test at 400 m towing tank in NMRI (Figs. 11, 22).

Figures 10 and 12 show the wake distributions of the original hull and the system output hull, respectively. Those results prove that the proposed system can systematically design a desired wake field also from the measurement point of view.

We also confirmed the energy saving effect which was our original objective using the towing tank. As Fig. 23 and Table 5 show, the system output hull with optimum duct (opening angle 8 deg.) achieves 2.2% improvement of BHP compared to the original hull with optimum duct. That is, despite the increase in BHP of the system output bare hull (0.4%), the total performance is higher due to the larger effect of the duct. The horsepower reduction effect (energy savings) of the duct for the system output hull achieves 4.5% (calculated as 1.0–643/673 in the table) against 1.9% for the original hull. In addition, even with ducts of the same shape (Duct 6°), the energy saving effect was higher in the system output hull. Incidentally, assuming that form factor (1 + k) of the system output hull form (MS No. 875) is the same as the original hull form (MS No. 869), the both EHP become 503 kw and DHP of the system output hull form (MS No. 875) became 659 kW. Therefore, the energy saving ratio of the system output hull form is increased by 2.2%, both with and without the duct. From these demonstration results, we confirmed the effectiveness of the wake field design system in the actual design in collaboration with bare hull optimization technique.

On the other hand, we also discuss reduction of circumferential fluctuation of axial wake to reduce cavitation. Figures 24 and 25 compare the measured distribution of the axial flow velocity of the original hull form and the system output hull form with the calculation results, respectively. In the calculation results, we achieve minimization of the difference between the maximum value and the minimum value of the axial wake flow velocity at the intended 0.7 R. However, the intended result was not obtained in the tank test results, and the circumferential distribution change more than the calculation assumption, where the intended increase in the flow velocity of 0 degrees to 20 degrees and the deceleration about 120 degrees are obtained.

As far as the computation is concerned, the wake distribution of the system output hull agrees well with the desired wake distribution; therefore, the proposed system is proved to indicate the ability of the systematic wake field design. On the other hands, it is seen that there are some differences in the comparison with the measured wake distribution (i.e., Figs. 12, 18) of the system output hull form. That is, we point out the difference of the x-axial flow velocity around 20–40° position. A primary reason of this difference is likely the geometry simplifications done while computational grid is generated, i.e., a stern tube for propeller shaft actually exists in the experimental model is smoothed out in the computational grid. However, we concluded that this is not basic problem of our proposed system and obtained results are apparently meaningful.

5 Discussion

In this section, we discuss the wake filed from a physical point of view about the deformation of hull forms.

Figures 26 and 27 compare the distribution of the circumferential inflow angle to the wing section of the duct and compare with the calculation results, respectively. In the system output hull, the circumferential fluctuation of the inflow angle in the design range of 0°–80 position is aimed to be smaller as compared to that for the original hull, that is actually achieved as shown in the figure. As a result, the thrust of the duct is improved, and the 2.2% total improvement is obtained.

To reduce the fluctuation of the inflow, the center of the hook shape locates on the same height as the propeller axis, as shown in Fig. 16. Here, a focus of discussion is how to move the center of the hook shape by a deformation of hull form. According to comparison between the original hull and the system output hull in Fig. 19, the volume moves from S.S. 1.0 to S.S. 2.0 and frame lines changes to blunt shape at the bottom (generally called U type frame line), especially at S.S. 1.0. form the original hull to the system output hull. Figures 28 and 29 show limiting streamlines, pressure distribution on hull surface and wake distribution at propeller plane for the original hull and the system output hull. Those figures indicate that in the system output hull, the enlargement at bottom of S.S. 2.0 yields a deeper pressure pocket (lower pressure area) and this strong reverse pressure gradient causes stronger separation line, which generated the strong axial vortex. As a result, this strong axial vortex leads to the lower center of the hook shape.

6 Concluding remarks

In this paper, we presented the wake field design system which outputs a hull form realizing desired input wake distribution utilizing hull form and wake field database. In the system, the database is analyzed by a method for the first time proposed in the present study, that is, a scheme using the Euclidean distance and hull form blending(morphing). Validation of our proposed system shows that that is capable to systemize the expert craftsmen’s tacit knowledge, or at least the system can suggest the possible idea of hull modification to the hull form designer. Since such a system has not been reported as far as our survey concerns, the system we proposed here may be a pioneer work and will be a very useful design tool for hull-form designers.

A practical demonstration is also performed in this paper, where a 749 gross tonnage cargo ship is selected as object ship. The initial (original) hull form in this research was developed in a project of the Japan society of naval architects and ocean engineers as a considerably promising bare hull form. This hull form is defined as the original design in this study, then we try to further modify the design to reduce delivered horse power in a condition of hull with duct type ESD. Importantly, we design a new hull form to improve wake field suitable for the duct along with consideration of reduction of cavitation. To confirm the effectiveness of our proposed system, the towing tank test is conducted to measure the wake distribution, using 2 model ships (original and new design) with 6.8 m ship length. It is proved that our proposed system is capable to efficiently design desired wake field for the given hull form without trial and error, and provide equivalent to or more precise results than the expert designer’ design. Additionally, we also confirm that the propulsive performance of the new design hull form is improved. In our careful comparison of the effectiveness of the ESD, it is indicated that the new design shows 2.2% reduction of horsepower compared to the original hull form both for ESD installed case. From these demonstration results, we confirmed the effectiveness of our proposed system in the practical design demonstration.

Finally, we discuss the wake filed associated with deformation of hull forms from a flow physical point of view. We found that the enlargement at bottom of S.S. 2.0 yields a lower pressure area than that on the original hull form and this strong reverse pressure gradient causes stronger separation line, which generated the strong axial vortex. Consequently, this strong axial vortex contributes to improvement of ESD performance.

For the future work, we are going to expand our hull form and wake field database to other ship type and wake field in various Reynolds number including the full scale. We believe that this tool is not only the one to realize automatic design, but to help the hull-form designer to explore his new idea and make his division in practical design.

Change history

11 September 2019

The original publication Table 2 has been published incorrectly.

Abbreviations

- L PP :

-

Length between perpendiculars (m)

- B :

-

Breadth (m)

- d :

-

Draft (m)

- x, y, z :

-

Non-dimensional Cartesian coordinates, normalized by LPP

- S.S.:

-

Square station, station number start from 0: A.P. to 10: F.P.

- ∇:

-

Displacement (m3)

- \({C_{\text{B}}}=\nabla /\left( {{L_{{\text{PP}}}}{\text{Bd}}} \right)\) :

-

Block coefficient

- V S :

-

Ship speed (m/s)

- \({{\varvec{\upnu}}}\) :

-

Kinematic viscosity (m/s)

- \({R_{\text{n}}}={V_{\text{S}}}{L_{{\text{PP}}}}/\nu\) :

-

Reynolds number

- u, v, w :

-

Non-dimensional velocity vector component, normalized by VS

- r :

-

Radial position in propeller coordinate

- \(\theta\) :

-

Circumferential position in propeller coordinates, 0° indicates the top position

- R :

-

Propeller radius (m)

- ξ, η, ζ :

-

Nondirectional design parameters for hull form variation

- \(\overrightarrow {{q_{{\text{ri}}\theta {\text{j}}}}}\) :

-

Velocity vector of input wake distribution

- \(\overrightarrow {{p_{{\text{ri}}\theta {{\text{j}}_{\text{k}}}}}}\) :

-

Velocity vector of a wake distribution in the database

- \({d_{\text{k}}}\) :

-

Euclidean distances between input wake and wake database

- \(\overrightarrow {{P_{\text{k}}}}\) :

-

Discrete points on hull surface

- a i :

-

Weighting factor for hull form blending (morphing) method

- \(\alpha\) :

-

Inflow angle to wing section of duct

- y + :

-

Non-dimensional distance to the wall, normalized by friction velocity

- 1 + k :

-

Form factor

- C W :

-

Wave resistance coefficient

- R T :

-

Total resistance (N)

- T :

-

Propeller thrust (N)

- \(Q\) :

-

Propeller torque (N m)

- \(Q\left( O \right)\) :

-

Propeller torque in open water (N m)

- \({\eta _{\text{R}}}=Q/Q\left( O \right)\) :

-

Relative rotative efficiency

- EHP:

-

Effective horsepower (kW)

- DHP:

-

Delivered horsepower (kW)

References

Kawashima H, Kume K, Sakamoto N (2014) Study of weather adapted duct (WAD). Papers of National Maritime Research Institute, vol 17, no. 1, pp 73–86. https://www.nmri.go.jp/en/_src/26595/pnm21170103-00%20%282%29.pdf. Accessed 1 Aug 2018 (in Japanese)

Sakamoto N, Kawanami Y, Hinatsu M, Uto S (2014) Viscous CFD analysis of stern duct installed on panamax bulk carrier in model and full scale. In: 15th International conference on computer and IT applications in the maritime industries

Ichinose Y, Kume K, Tahara Y (2018) A development and analysis of the new energy saving device “USTD”. In: Proceedings of the 19th numerical towing tank symposium

Renillson M, Leaper R, Boisseau O (2013) Hydro-acoustic noise from merchant ships—impacts and practical mitigation techniques. In: Proceedings of the third international symposium on marine propulsors, smp’13, pp. 201–208, Launceston, Tasmania, Australia

Mori M (1997) Hull form design. Ship Technology Association, Tokyo (in Japanese)

Bessho M (1967) Study into frame line configuration. J Soc Naval Arch Jpn 122:43–65 (in Japanese)

Project EFFORT. http://www.marin.nl/web/JIPs-Networks/Archive-JIPs-public/Effort.htm. Accessed 1 Aug 2018

Schweighofer J, Regnstrom B, Starke AR, Tzabiras G (2005) Viscous flow computational of two existing vessels at model- and full-scale ship Reynolds numbers—a study carried out within the European Union Project, EFFORT. In: International conference on computational methods in marine engineering MARINE

The 183th Research Committee (1985) SR 183 Report, study of propeller and stern shape for the purpose of reducing stern vibration and noise, The Ship Building Research Association of Japan. https://www.jstra.jp/html/PDF/SR183-5803.pdf(in Japanese)

Dang J, Chen H, Dong G, Van der Ploeg A, Hallmann R, Mauro F (2011) An exploratory study on the working principles of energy saving devices (ESDs). In: Proceedings of symposium of international symposium on green ship technology, Green ship’ 2011, Wuxi, China

Dang J, Dong G, Chen H (2012) An exploratory study on the working principles of energy saving devices (ESDs)—PIV, CFD investigations and ESD design guidelines. In: Proc. of the 31th OMAE, OMAE2012-83053, Rio De Janeiro, Brazil

Inukai Y, Kaneko T, Nagaya S, Ochi F (2011) Energy-saving principle of the IHIMU semicircular duct and its application to the flow field around full scale ships, IHI Eng Rev 44(1)

Shin HJ, Lee JS, Lee KH (2013) Numerical and experimental investigation of conventional and un-conventional preswirl duct for VLCC. Int J Naval Archit Ocean Eng 5:414–430

Kim K, Leer-Anderson M, Orych M (2014) Hydrodynamic optimization of energy saving devices in full scale. In: Proceedings of 30th symposium on naval hydrodynamics, Tasmania, Australia

Falkenhorst A, Kruger S, Steinbach CM (2015) Application of energy saving fins on rudders In: Proc. of the 34th OMAE, OMAE2015-41896, Newfoundland, Canada

Xing-Kaeding Y, Streckwall H, Gatchell S (2017) ESD design and analysis for a validation bulk carrier. Int Shipbuild Prog 63:137–168

Tahara Y, Shingo S, Kanai A (2017) CFD based optimal design method for energy saving devices by using overset grid technique and nonlinear optimization theory. J Jpn Soc Naval Arch Ocean Eng 26:1–16 (in Japanese)

Okamoto N, Suzuki K, Hino T, Masuda S (2017) An optimization method of stern hull form to minimize brake horse power (2nd report—optimization of hull form with super stream duct as energy saving device. J Jpn Soc Naval Arc Ocean Eng 26:27–34 (in Japanese)

Tahara Y, Ichinose Y, Kaneko A, Kasahara Y (2018) Variable decomposition approach applied to multi-objective optimization for minimum powering of commercial ships. J Mar Sci Technol. https://doi.org/10.1007/s00773-018-0551-5

Van der Ploeg A, Raven HC (2010) CFD-based optimization for minimal power and wake field quality. In: 11th International symposium on practical design of ships and other floating structures, Rio de Janeiro, Brazil

Chen PF, Huang CH (2002) An inverse hull design problem in optimizing the desired wake of a ship. J Ship Res 46(2):138–147

Stuck A, Kroger J, Rung T (2011) Adjoint-based Hull Design for wake optimization. Ship Technol Res 58(1):34–44

P-51 Research Committee (2017) Final report of Research Committee for Development of Eco-hull form Variation for Domestic Shipping, The Japan Society of Naval Architects and Engineers O. https://www.jasnaoe.or.jp/research/dl/PM-P51-17.pdf(in Japanese)

Ichinose Y, Tahara T, Kume K (2017) A construction and evaluation of hull form database for domestic vessels with regulation on gross tonnage—development of a prototype for 749GT-type domestic general cargos. J Jpn Soc Naval Arch Ocean Eng 26:51–62 (in Japanese)

SciPy.org: https://www.scipy.org/. Accessed 1 Aug 2018

Tahara Y, Peri D, Campana EF, Stern F (2011) Single- and multi-objective design optimization of a fast multihull ship: numerical and experimental results. J Mar Sci Technol 16(4):412–433

Kohavi R (1995) A study of cross-validation and bootstrap for accuracy estimation and model selection. In: Proceedings of the fourteenth international joint conference on artificial intelligence 2 (12):1137–1143, Morgan Kaufmann, San Mateo

Ohashi K, Kobayashi H (2016) Performance improvement of flow computations with an overset-grid method including body motions using a full multigrid method. In: ECCOMAS congress

Hirata N, Hino T (2000) A comparative study of zero- and one-equation turbulence models for ship flows. J Kansai Soc Naval Arch 234:17–24

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

This article is published under an open access license. Please check the 'Copyright Information' section either on this page or in the PDF for details of this license and what re-use is permitted. If your intended use exceeds what is permitted by the license or if you are unable to locate the licence and re-use information, please contact the Rights and Permissions team.

About this article

Cite this article

Ichinose, Y., Tahara, Y. A wake field design system utilizing a database analysis to enhance the performance of energy saving devices and propeller. J Mar Sci Technol 24, 1119–1133 (2019). https://doi.org/10.1007/s00773-018-0611-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00773-018-0611-x