Abstract

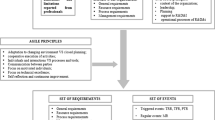

The implementation of a quality assurance system is fraught with difficulties. However, these difficulties may be overcome if the laboratory uses suitable means to facilitate the process. It is necessary to mobilise the intelligence and energy of all members of the laboratory. In order to command adherence, the project must be shared, and this necessitates a major effort by all concerned. Communication is a major factor in obtaining the support of all parties. Six important steps must be distinguished:

– Defining quality policy

– Creating awareness, information, training

– Creating a quality structure

– Establishing a deadline for obtaining accreditation

– Progressive implementation

– Experimentation and validation.

Even if the task of obtaining and maintaining accreditation remains difficult, it clearly promotes a minimum level of organisation and stepwise progress in quality assurance. The laboratory must keep improving its quality system, using European Standard EN 45001 as an effective management model.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Received: 9 April 1997 · Accepted: 11 September 1997

Rights and permissions

About this article

Cite this article

Mouillet, L. Key requirements for introducing quality assurance in measurement laboratories. Accred Qual Assur 3, 11–13 (1998). https://doi.org/10.1007/s007690050175

Issue Date:

DOI: https://doi.org/10.1007/s007690050175