Abstract

Classic saturates, aromatics, resins, and asphaltenes (SARA) analysis has long enabled the chromatographic separation of complex hydrocarbon-containing products into these four families. This simplification often does not provide sufficient or correct information on the relationship between the composition of the products and the process variables studied. The obtention of profiles by gradient automated multiple development (AMD) is an interesting alternative to obtain extended SARA separations with increasing level of complexity for heavy petroleum products that adequately represent the entirety of the sample. An optimized 20-step gradient based on tetrahydrofuran (THF)‒dichloromethane‒n-heptane over a total migration distance of 83 mm is proposed here to characterize all types of heavy oil products. The combination of ultraviolet (UV)–densitometry (at 201, 228, and 273 nm), fluorescence detection by intensity changes using berberine cation, together with on-plate recording of UV spectra of separated peaks and the comparison with those of standards, allow for a deep characterization of chemical families. In the apolar zone of the chromatogram saturates, naphthenes, naphteno-aromatics, alkyl-aromatics, and aromatics with different degrees of condensation are detected. The use of THF, both in the plate precleaning stage and in the first stages of the gradient, is responsible for the satisfactory resolution of the resins in the polar zone. AMD chromatographic zones can be related to peaks from hydrocarbon groups in classical SARA. The application of this gradient to different types of products allowed for the relation of the profiles of bitumen to their origin, differentiation of the resin part trapped in asphaltenes, control performance of deasphalting in hydrorefining products, and the control of the composition of base oils.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Heavy petroleum fuels consist of complex mixtures of thousands of high-boiling nonpolar and polar compounds that include different molecule structures and sizes, polarities, chemical families, and also metals [1]. The degree of complexity of these products increases with their boiling point. It is hard to imagine the number of compounds present. For example, a long, saturated hydrocarbon such as C167H336 has more than 1080 isomers. With 15 hexagons of benzene, 74,107,910 condensed structures can be built [2].

The most powerful technique for petroleum characterization is Fourier-transform ion cyclotron resonance mass spectrometry (FT–ICR MS). Recently, the development of temporally stable high-field (> 7 T) high-homogeneity magnets has led to the development of ultrahigh-resolution FT–ICR MS. With a high mass resolving power (m/Δm50%) > 300,000 and sub-parts-per-million mass accuracy, FT–ICR MS is able to characterize thousands of species in petroleum products without any separation step [3]. Although this approach also presents some problems and not all fuel components have been identified, its inherent high resolving power and high mass accuracy allow for baseline resolution of closely spaced isobaric species, as well as molecular formula assignment through accurate mass determination.

However, this technique is not operational for quality control. A complete molecular identification of heavy petroleum products based using this technique is not feasible. There is little equipment available for this technique and not everyone can have the necessary equipment in their laboratory. Likewise, the experiments and data analysis are very complex, expensive, and time-consuming. But, regardless of this, industry needs rapid and straightforward techniques for quality control.

At present, fuels are characterized in terms of chemical family composition, using a simple classical hydrocarbon group type analysis such as SARA [4, 5], the acronym of saturates (Sat), aromatics (Ar), resins (Res), and asphaltenes (Asph).

In petrochemistry, SARA has been useful for: obtaining information on the conversion of raw material and the quality of the conversion product, evaluating the variables of conversion processes, elucidating reaction pathways and kinetics, linking the stability of the product to the composition, diagnosing the source of plant upsets, and evaluating the effect of changes in composition on product performance properties [4, 5].

There are different techniques and methods developed for SARA, mostly based on chromatographic techniques. As the repartition of compounds in SARA groups is depending on the procedure, SARA must be performed by strictly following the selected experimental conditions for a reliable comparison of results.

However, a problem is that classical SARA has been performed in the past by techniques that present important practical limitations. The reference is ASTM D2007, an open-column chromatography method based on preferential adsorption of Asph and Res on clay, and Ar on silica gel [6]. These fractions are recovered using appropriate solvents, and Sat are eluted using n-pentane. The separated fractions are determined gravimetrically after evaporation of solvents. This method is laborious, time-consuming, not always providing pure fractions, and there is an incomplete recovery of them from the adsorbents. Likewise, it needs deasphalting of the starting product before the start.

Thin-layer chromatography with flame ionization detection (TLC‒FID, better known as Iatroscan) is carried out on 10-cm silica gel glass sinterized chromarods, and is therefore limited from the point of view of separation, sufficient for a simple SARA analysis but insufficient to achieve a higher degree of resolution if necessary [7, 8]. Likewise, FID supposed quantitativity (constant response factor for the different separated groups) has been questioned [9, 10]. Moreover, the sample is destroyed during FID detection. Another problem is its limited availability in terms of instrumentation, associated consumables, and repair.

High-performance liquid chromatography (HPLC) was also used for SARA [11]. Its use has, among other limitations, quantification problems linked to the irreversible adsorption of a substantial part of Asph and Res into the columns, a good part of which are not eluted. Moreover, detection of Sat using differential refractometry has a low sensitivity. The number of samples per day to be processed is necessarily low due to the inherent complexity associated with HPLC manipulation and calibration of these type of samples.

Although high-performance thin-layer chromatography (HPTLC) has been scarcely used for analyzing heavy petroleum products, the inherent advantages of HPTLC, such as high sample throughput, minimal sample preparation, and the presence of the whole sample on the layer, together with recent development of reliable instruments, make it a technique with a future for the characterization of fuels, either from petroleum or other renewable biosources (e.g., biomass) [12, 13].

An important general problem to develop HPTLC-based SARA methods was how to detect and quantify saturates on the plate. Our group has been studying some phenomena related to fluorescence enhancements due to apolar molecules for some time [14, 15]. Specifically, we developed an HPTLC-based method for classic SARA of heavy petroleum products [16]. This method is based on a conventional sequential elution using three solvents: n-heptane (C7), dichloromethane (DCM), and tetrahydrofuran (THF), in order of increasing polarity, to separate Sat, Ar, Res, and Asph. In this way, Ar, Res, and Asph were detected by UV‒densitometry. Saturates were detected and quantified by induced fluorescence using berberine-impregnated plates. Long hydrocarbon chains of Saturates induce an increase in berberine fluorescence through nonspecific noncovalent ion–dipole interactions [14, 15]. In consequence, saturates are detected and quantified by fluorescence densitometry with regard to the fluorescent baseline provided by berberine fluorophore. This detection technique is suitable for non-absorbing or poorly absorbing molecules, such as Sat.

Nevertheless, the main problem with the SARA analysis is conceptual. The classic SARA scheme is severely flawed for its use as a predictive tool because it uses only four pseudocomponents for a fuel. Therefore, it is not surprising that on many occasions it does not provide sufficient or correct information to correlate the chemical differences of the products with the variables studied. It would be necessary, and it is the objective of this paper, to develop detailed SARA methods to obtain separations with a higher degree of complexity, with densitometric techniques that allow that the product is detected in its entirety.

Automated multiple development (AMD) is a fully automated technique for HPTLC development that combines incremental multiple development solvent gradient in short steps (1–2 mm) and repetition of elemental steps [17]. This provides band focusing and improves sample separation. The use of AMD in combination with a robotic, spray-on, and fully automatic sample applicator contributes to improve the repeatability and sensitivity. AMD is especially adequate for samples that comprise a wide range of polarity and therefore appears as an interesting alternative to obtain different separations with increasing level of complexity for heavy petroleum products with regard to those provided by simple SARA. In this paper, different possibilities of gradient separations using AMD were explored.

2 Experimental

2.1 Materials

Berberine hemisulfate (> 95%; CAS number: 633-66-9) was from Sigma-Aldrich (Steinheim, Germany). HPLC-grade n-heptane (C7, 99.1%), dichloromethane (DCM, 99.9%), methanol (MeOH, 99.9%), tetrahydrofuran (THF, 99.9%), and toluene (99.7%) were from Panreac (Barcelona, Spain).

THF was used without stabilizer. It was passed through a column of activated carbon with a FeSO4 indicator before doing the HPTLC analysis, to avoid the peroxide formation, and then was kept under nitrogen.

2.2 Samples and standards

Samples include ten bitumen from different sources and, within each source, obtained at different distillation temperatures, and two Asphaltenes, three hydrorefined vacuum gas oils, one heavy crude and its hydrorefined derivative, and one base oil. They all were provided by TOTAL RM (France).

The following model compounds were used as migration distance (m.d.) qualitative standards: n-tetracosane C24 (≥ 99%; [646-31-1] CAS), n-octacosane C28 (≥ 98%; [630-02-4] CAS), and n-dotriacontane C32 (≥ 96%; [544-85-4] CAS) as paraffins; 1-octadecene (≥ 99.5%; [112-88-9] CAS) and cis-9-tricosene (97%; [27519-02-4] CAS) as olefins; ethyl-benzene (99.8%; [100-41-4] CAS), pentyl-benzene (99%; [538-68-1] CAS), and 2-ethylnaphthalene (≥ 99%; [939-27-5] CAS) as alkyl-aromatics; cis-decahydronaphthalene (99%; [439-01-6] CAS), 1,2,3,4-tetrahydronaphthalene (99%; [119-64-2] CAS), 9,10- dihydro-phenanthrene (≥ 94%; [776-35-2] CAS), perhydrofluorene ([5744-03-6] CAS), and 5-α (H)-androstane ([438-22-2] CAS) as naphthenes; naphthalene (≥ 99.7%; [91-20-3] CAS), phenanthrene (≥ 98%; [85-01-8] CAS), anthracene (≥ 99%; [120-12-7] CAS), pyrene (≥ 99%; [129-00-0] CAS), benzo[k]fluoranthene (98%; [207-08-9] CAS), benzo[e]pyrene (99%; [192-97-2] CAS), benzo[ghi]perylene (98%; [191-24-2] CAS), and coronene (99%; [191-07-1] CAS) as condensed hydro- and polyaromatics; and quinolin-65 (80%; [834884-59-2] CAS), violanthrone-79 ([85652-50-2] CAS), perylene-66 (40%; [MFCD07785507] MDL), violanthrone-78 ([82145-74-2] CAS) as condensed heterocyclic compounds. All standards were purchased from Sigma-Aldrich Inc. (St. Louis, MO, USA), except for perhydrofluorene and androstane, which were purchased from Chiron AS (Trondheim, Norway).

Standards were dissolved in toluene.

Although the above listed standards do not necessarily have to be in the studied products, we intend to cover the presence of most types of compounds that may be present, with regard to functional groups, aromaticity/hydroaromaticity, heteroatomic content, and molecular weight. Combined data on their migration (m.d. or RF) and UV spectra on silica gel can be found in the Supplementary Information.

2.3 Chromatographic plates

HPTLC silica gel plates (10 cm × 20 cm, pore size 60 Å, layer thickness 0.20 mm) were used from Merck (Darmstadt, Germany). They were precleaned by developing 90 mm with THF in a vertical developing chamber.

2.4 Sample application

Samples were dissolved in THF and applied using the Automatic TLC Sampler 4 (CAMAG, Muttenz, Switzerland) as 4-mm bands. A total of 25 bands of samples were applied on the same plate with a distance of 2.9 mm between tracks. Two additional tracks were always kept free of application as blank runs. The first application position was 10 mm (x coordinate), and the distance from lower edge of plate was 10 mm (y coordinate). Typical application volumes for petroleum samples were between 0.2 and 0.8 μL. Typical effective masses applied were between 0.5 and 3 μg for UV, and between 3 and 10 μg for fluorescence evaluation.

2.5 Chromatography

Chromatographic development was performed with an AMD2 system (CAMAG) using different conditions. Gradient composition in each step, number of steps, distance per step (mm step‒1), and total developing distance (mm) are detailed in Tables 1, 2, 3, and 4: a three solvent (C7‒DCM‒THF) classic SARA sequence (Table 1), a 23-step, THF‒DCM‒C7 gradient (Table 2), a 20-step, THF‒DCM‒C7 gradient (Table 3), and a 20-step DCM‒C7 gradient (Table 4). Migration of standards under different conditions and their recorded on-silica gel UV spectra can be found in the Supplementary Information.

2.6 UV and fluorescence densitometry

A TLC Scanner 3 (CAMAG) was used in UV and fluorescence modes. First, UV‒densitometry at different wavelengths (201, 228, and 273 nm) was recorded, as well as UV spectra of separated peaks. Subsequently, HPTLC silica gel plates were postimpregnated with a 60 mg L−1 solution of berberine hemi-sulphate in MeOH, using a CAMAG Chromatogram Immersion Device 3. Fluorescence mode was then used for peak detection by excitation at 365 nm. Emission was collected at longer wavelengths than 400 nm. This detection was referred to as fluorescence detection by intensity changes (FDIC).

3 Results and discussion

3.1 Classic SARA and SARA expanded by gradient

Figure 1A and B show a classic SARA chromatogram of a Canadian bitumen, using a sequence of several elution solvents in order of increasing polarity. In this case, the AMD instrument was used as a conventional developing chamber. As detailed in Table 1, saturates (Sat) were first separated (with C7 at 60 mm m.d.), then aromatics (Ar, with DCM at 40 mm m.d.), resins (Res, with THF at 20 mm), and asphaltenes (Asph, non-developed peak at the application point). Sat were detected after plate impregnation by berberine-induced fluorescence (λexc = 365 nm; λem > 400 nm) (Fig. 1B). Ar, Res, and Asph were detected by UV at 273 nm, the wavelength that provided maximum absorption for each of these groups (Fig. 1A).

When a 23-step AMD gradient based on the same eluents (THF‒DCM‒C7, see conditions in Table 2) was applied on the same sample, the resulting chromatogram is shown in Fig. 1C and D. As we can observe, the simplicity of the classical SARA chromatogram (Fig. 1A) is deceptive. The 23-stage SARA (Fig. 1C) gives us a clearer idea of the complexity of the sample.

AMD operates in successive elemental elution steps (of several millimeters each), which are performed with decreasing solvent strength, in our case THF > DCM > C7, in combination with increasing developing distance. The composition of the mobile phase in each step does not have to be the same and usually is of lower polarity that than of the previous one, adjusted by mixing of different proportions of the three selected solvents. The stepwise gradient formed allows narrow peaks and more efficient separations to be obtained in a highly reproducible way (± 0.45 mm). Repetitions of elemental steps (twice) were performed to provide band refocusing.

3.2 Gradient optimization: from 23-step SARA to 20-step SARA

Figure 2 shows the 23-step chromatogram (Table 2) of a hydrorefined vacuum gas oil at different UV wavelengths and FDIC. AMD chromatographic zones can be related to peaks from hydrocarbon groups in classical SARA. The peak in the gradient chromatogram appearing in the 100 vol% THF development zone (up to 14 mm m.d.; one step) can be considered as asphaltenes (non-developed by THF). The peaks eluted in the 18‒58 mm m.d. zone (10 steps, from 100 vol% DCM to 20:80, V/V, DCM‒heptane), correspond to resins. This zone is particularly well resolved using the described gradient conditions and may provide more useful information than that obtained using classical methods. The peaks eluted in the 58‒83 mm zone, from 15:85, V/V, DCM‒heptane to 100 vol% n-heptane, are usually considered aromatics and saturates.

An inefficient zone with regard to separation (57–67 mm, m.d.) was identified in this chromatogram. As in general AMD practice, an unresolved chromatogram can be superimposed with the corresponding diagram of the gradient employed, changes in solvent composition can be made, and a number of steps can be done to improve gradient separation. In this way, the gradient conditions were modified to 20 steps (see Fig. 2B and conditions in Table 3) to optimize separation zones on the plate. Thus, separation can be fine-tuned and amplified for each segment of the chromatogram. In our case, the separation in the apolar zone was improved without losing resolution in the asphaltenes‒resins zone and by removing the inefficient plate zone. To do this, steps 12 to 17, which included DCM‒C7 gradient, were removed, and seven final steps of C7 (100%) were added. In total, the sequence went from having 23 to 20 steps. Details of both gradients are described in Tables 2 and 3.

The saving of three steps in the chromatographic development involved going from 5 h and 20 min to 5 h of analysis time. Regardless of the final number of steps and despite the duration of these analyses, the number of substances processed per plate compensates the time invested with regard to other chromatographic techniques. The AMD instrument can be left programmed to perform the analysis overnight in automatic mode.

3.3 Heavy product characterization using optimized 20-step THF‒DCM‒C7 SARA gradient

Figure 2B shows the chromatogram of the mentioned hydrorefined vacuum gas oil under these AMD conditions at different UV wavelengths and FDIC. On-silica UV spectra of standards are similar to those obtained in dissolution and provide useful information for selecting densitometric conditions. UV spectra of several standards are shown in the Supplementary Information.

The most polar and heaviest compounds (Asph) remain at the application point (m.d. = 10 mm) and are directly detected on the plate by UV‒densitometry. Resins zone (18‒58 mm m.d. zone, 10 steps, from 100 vol% DCM to 20:80, V/V, DCM‒C7) is particularly well resolved using the described gradient conditions. As we will show below, the role of THF is crucial to achieve an adequate resolution of this zone.

Peaks eluted in the 58‒83 mm zone, seven steps at 100 vol% C7, are Aromatics and Saturates. This zone is especially interesting and rich in aromatic and saturated compounds in hydro-refining products such as this one, as can be seen by comparing the profile of this product with that of a bitumen in Fig. 1B.

Figure 2C shows a detailed view of different chemical families in this zone of the chromatogram where several peaks are coeluted. Identification of component groups has been possible by using selective detection, direct recording of UV spectrum of each separated peak, and comparing UV spectra of peaks with those of standards that were eluted on the plate under the same gradient conditions.

The peak eluted at 83.3 mm with the front of solvent is due to saturated hydrocarbons. This peak has no UV response and is detected by FDIC‒berberine [5]. An ion-induced dipole interaction between n-alkanes and berberine cation is responsible for an increase in berberine emission in the presence of alkanes [5]. The shoulder at 81 mm in the FDIC‒berberine chromatogram, which coelutes with saturated hydrocarbons and has a response in the presence of berberine, may be attributed to naphthenes. This shoulder is encompassed in the peak eluted at 80.3 mm, which has been selectively detected by UV at 201 nm. UV spectrum suggests that this peak consists of naphthenic and naphthene‒aromatic structures.

The inspection of the chromatogram obtained by UV detection at 228 nm, and the UV spectrum of the peak eluted at 78.2 mm, are coherent with the presence of alkyl-aromatic structures in this peak. Likewise, the chromatogram obtained by UV at 273 nm together with UV spectra of peaks eluted at 73.2, 68.5, and 64.3 mm suggest the presence of aromatic structures, probably with different degrees of condensation. Migration distances of standards under these conditions and the corresponding UV spectra are given in Supplementary Information.

Therefore, this optimized 20-step THF‒DCM‒C7 gradient can be used for profiling a variety of samples that covers the whole range of petroleum heavy products.

3.4 Applications of expanded SARA gradient

The application of multi-step gradient sequence to different heavy products provides qualitatively different chromatograms among products. Although this separation does not provide a complete molecular resolution of heavy petroleum products, the resulting profiles adequately represent the complexity of the analyte, and can provide a useful information for evaluating the effect of process variables on products. We show here some specific applications to different heavy products.

3.4.1 Bitumen

Bitumen is a black, viscous mixture of hydrocarbons obtained naturally or as a residue from petroleum distillation [18]. It is is too thick to be pumped from the ground or through pipelines.

Different qualitative profiles were obtained by application of 20-step expanded SARA gradient (THF‒DCM‒C7) in the function of their origin, regardless of their distillation cut temperature (DCT; in degrees celsius, °C). Figure 3 shows different profiles for bitumen from Iran (Norooz, DCT at +420, +450, and +490 °C), Gabon (Oguendjo/Olende, DCT at +495, +520, and +560 °C), and Cameroon (Lokele, DCT at +440, +470, and +490 °C).

It seems possible to obtain fingerprints for bitumen characterization by HPTLC in a similar way to those obtained in the case of characterization of plants, therefore relating bitumen composition and properties.

3.4.2 Asphaltenes

The structure of asphaltenes is still a challenge for analytical chemistry. From the point of view of solubility, asphaltenes are insoluble in C7 and soluble in toluene. This is the way to obtain them gravimetrically. Recent research suggests that they are “hand” shaped entities, with a central core consisting of a hydro/polyaromatic system (for example, around seven cores with a few N and S heteroatoms) with peripheral alkanes [19]. The molecular masses of the asphaltenes are between 300 and 1400 Da, with the majority of species between 400 and 800 Da.

Chromatographically, asphaltenes are associated with the undeveloped peak that remains at the point of application (in Iatroscan and in HPTLC) [13], or with the part that remains irreversibly retained in the stationary phase of chromatographic columns (in the case of HPLC and open column chromatography, as in the D2007 standard [6]).

When Asph are gravimetrically isolated they tend to “catch” some Res, structures that resemble those of Asph with a lower molecular weight and that are strongly attracted by them. Figure 4 shows that the 23-step gradient reveals different “resinic part” in two different types of Asph. This gradient is also useful to detect trapped Sat in Asph structures (not shown).

3.4.3 Hydrorefining products

Hydrorefining is a process for improving the quality of a petroleum product by hydrogenating in the presence of a catalyst at a temperature below that at which decomposition takes place [20]. This improves the H/C ratio of the product. Thus, a consequence of hydrorefining, deasphalting is observed (a decrease in the Asph peak), and also an increase in the Saturates fraction. This can be observed in Fig. 5 where the 23-step gradient chromatograms of a heavy Canadian oil and its derived hydrorefined product are shown.

3.4.4 Base oils

Base oils, produced from refining crude oil, are used in the formulation of lubricant products. They are complex mixtures containing hydrocarbon families of very different polarity, such as paraffins, isoparaffins, naphthenes (cycloparaffins), hydroaromatics, aromatics with different condensation degrees, and a variety of S-, O-, and N-heterocyclic structures, with molecular weight distributions ranging from 300 to 600 Da, although in general, they are asphaltene-free and have a lower polarity than other heavy products [21]. Base oils only have compounds in the apolar zone of the 20-step chromatogram (Fig. 6).

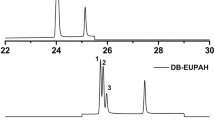

Under the 20-step AMD conditions, it is possible to distinguish the families of naphthenes, naphthenoaromatics, and alkylaromatics between 75 and 83 mm, with a degree of detail. This zone corresponds to the last seven stages of the gradient, with a composition 100% C7, according to Table 3. The families in base oil D were detected by UV detection at 201, 228, and 273 nm and FDIC, and UV spectra of the separate peaks were consistent with those of the model compounds studied (Supplementary Information).

Although aromatic compounds present some coelution in this zone of chromatogram, a selective UV detection at different wavelengths and the UV spectra of obtained peaks allowed us to identify several types of compounds in base oil D: saturates (m.d. = 84.3 mm), naphthenes (m.d. = 82.5 mm, a shoulder in saturates peak), heavy naphthene/naphthene-aromatics (m.d. = 80.4 mm), and alkyl-aromatics (m.d. = 78.3 mm). In the case of the peak at 80.4 mm, there would be a greater contribution from heavy naphthenes than from aromatics, since little absorbance is observed at 273 nm.

3.5 The role of THF in the separation

We have found that THF plays a crucial role in the degree of resolution of extended separations of heavy petroleum products, and particularly in the good separation obtained in the resins zone.

When THF is used either as a plate precleaning solvent in preconditioning step, or as a mobile phase in the gradient, good resolutions are obtained in the resulting chromatograms. On the contrary, when THF is neither used as a washing solvent nor as a mobile phase, profiles completely lose their resolution.

For evaluating the effect of THF as a mobile phase in the gradient, a 20-step DCM‒C7 gradient was used (Table 4) to compare with the gradient containing THF (Table 3). Therefore, the first two steps eluted with THF were changed to two steps eluted with DCM. Moreover, the effect of DCM as plate preconditioning solvent was compared with that of THF. The sample studied was a vacuum gas oil.

Figure 7 summarizes the results obtained for DCM‒C7 gradient. When THF was not present in the chromatographic system, i.e., using DCM‒C7 gradient, and DCM was the washing solvent, resolved peaks disappeared, and resins compounds were eluted to the apolar part of the chromatogram (Fig. 7A). Using this same gradient, resolved peaks in the resins zone are present when THF has been used in the preconditioning, washing step (Fig. 7B).

Figure 7C shows that a low-resolution chromatogram, similar to that of Fig. 7A, is obtained when THF is used in the washing step but is removed from the plate heating (heating for 30 min at 105 °C) before sample application. Likewise, Fig. 7D gives an idea of the importance of the precleaning operation. When no washing step is included, an intense peak of impurities is eluted by the gradient at a migration distance of 72 mm.

Results obtained from the 20-step THF‒DCM‒C7 gradient from the same vacuum oil sample are given in Fig. 8A–D. In all cases, resolved chromatographic profiles were obtained, with an adequate degree of resolution for the compounds eluted in the resins zone when THF was present either in the gradient mobile phase or as a washing solvent.

The effect of washing with DCM (Fig. 8A) or THF (Fig. 8B) gives a different distribution proportion of developed compounds. Likewise, the removal of THF by heating (Fig. 8C) shows a chromatogram similar to that of Fig. 8A (with DCM as the precleaning solvent). Moreover, Fig. 8D shows that using the plate with previous cleaning provided different repartition and proportion of resins onto the silica gel plate.

It is well known that THF adsorbs on silica gel surfaces, and that distinct mechanisms of adsorption (nonspecific, specific, molecular, and chemical adsorption) were observed [22]. Likewise, it has been found that adsorption isotherms of polar solvents on silica gel does fit abi-layer adsorption equation rather than the mono-layer one [23]. According to Scott [23], such layers can impede the interaction of the solute directly with the stationary phase as in sorption.

A combined and interactive mechanism of sorption and displacement was proposed by Scott when the silica surface was covered with a layer of molecules from one or more different solvents (Fig. 9).

Mechanism of sorption and displacement of THF on silica gel surface (

In our case, THF is the solvent that interacts directly with the silica surface in the precleaning step, and consequently constitutes the first layer. Thus, elution began using pure THF, and the next layer was a second layer of THF. Thus, a monolayer or bilayer of THF may be formed on the silica surface with which the solute interacts by sorption (mechanisms a and b). In general, the stronger the polarity of the solute, the more likely it is to interact with the surface by displacement (mechanism c), even to the extent of displacing both layers of THF (mechanism d). This influences the separation of the resins in the petroleum products studied.

4 Conclusion

Extended SARA profiles (20 and 23 AMD steps) of any type of heavy petroleum product were obtained under fixed conditions by AMD gradient on a silica gel HPTLC plate. These gradients are based on 20 (optimal) or 23 steps with different proportions of C7‒DCM‒THF over a total migration distance of 83 mm. Each step is repeated twice for refocusing the HPTLC bands. UV detection at several selected wavelengths and berberine-induced fluorescence, combined with on-silica recording of UV spectra of separated peaks and standards, allowed obtaining qualitative information of interest on the composition of these heavy petroleum products (bitumen, base oils, hydrorefining products, asphaltenes, etc.) and the variables involved in the corresponding processes.

Expansion of separation of selected zones of the chromatograms can be achieved by simple modification of AMD development conditions. The use of THF, coming from the plate precleaning step or from the AMD gradient is crucial to improve separation in the resins zone.

In addition to the inherent advantages of HPTLC (e.g., complete detection of the sample avoiding column irreversible adsorptions), a high number of samples on the same plate were processed, under strictly identical conditions, with minimal solvent requirements, reduced labor times, and important cost savings.

References

Altgelt KH, Boduszinski M (2014) Composition and analysis of heavy petroleum fractions. Taylor & Francis, Boca Raton

Elguero J (2021) Algunas reflexiones sobre el futuro de la quimica computacional. An Quím 117(3):203–208

Rodgers RP, Marshall AG (2007) Petroleomics: advanced characterization of petroleum-derived materials by Fourier Transform Ion Cyclotron Resonance Mass Spectrometry (FT-ICR MS). In: Mullins OC, Sheu EY, Hammami A, Marshall AG (eds) Asphaltenes, heavy oils, and petroleomics. Springer, New York. https://doi.org/10.1007/0-387-68903-6_3

Barman BN, Cebolla VL, Membrado L (2000) Chromatographic techniques for petroleum and related products. Crit Rev Anal Chem 30:75–120. https://doi.org/10.1080/10408340091164199

Hammami A, Ratulowski J (2007) Precipitation and deposition of Asphaltenes in production systems: a flow assurance overview. In: Mullins OC, Sheu EY, Hammami A, Marshall AG (eds) Asphaltenes, heavy oils, and petroleomics. Springer, New York. https://doi.org/10.1007/0-387-68903-6_23

ASTM D2007–19 (2020) Standard test method for characteristic groups in rubber extender and processing oils and other petroleum-derived oils by the clay-gel absorption chromatographic method. American Society for Testing and Materials, West Conshohocken

Ranny M (1987) Thin-layer chromatography with flame ionization detection. D. Reidel Publishing Company, Dordrecht

Barman BN (1996) Hydrocarbon-type analysis of base oils and other heavy distillates by thin-layer chromatography with flame-lonization detection and by the clay-gel method. J Chromatogr Sci 34:219–225. https://doi.org/10.1093/chromsci/34.5.219

Vela J, Membrado L, Cebolla VL, Ferrando AC (1998) Suitability of thin-layer chromatography-flame ionization detection with regard to quantitative characterization of different fossil fuel products. II. Calibration methods concerning quantitative group-type analysis. J Chromatogr Sci 36:487–493. https://doi.org/10.1093/chromsci/36.10.487

Jiang CQ, Larter SR, Noke KJ, Snowdon LR (2008) TLC–FID (Iatroscan) analysis of heavy oil and tar sand simples. Org Geochem 39:1210–1214. https://doi.org/10.1016/j.orggeochem.2008.01.013

Pei P, Britton J Jr, Hsu S (1983) Hydrocarbon type separation of lubricating base oil in multigram quantity by preparative HPLC. J Liq Chromatogr 6:627–645. https://doi.org/10.1080/01483918308076073

Cebolla VL, Membrado L, Matt M, Gálvez EM, Domingo MP (2002) Thin-layer chromatography for hydrocarbon characterization in petroleum middle distillates. In: Hsu CS (ed) Analytical advances for hydrocarbon research. Kluwer Academic/Plenum Press, New York, pp 95–112. https://doi.org/10.1007/978-1-4419-9212-3_5

Matt M, Gálvez EM, Cebolla VL, Membrado L, Bacaud R, Pessayre S (2003) Improved separation and quantitative determination of hydrocarbon types in gas oil by normal phase high-performance TLC with UV and fluorescence scanning densitometry. J Sep Sci 26:1665–1674. https://doi.org/10.1002/jssc.200301465

Cossío FP, Arrieta A, Cebolla VL, Membrado L, Domingo MP, Henrion P, Vela J (2000) Enhancement of fluorescence in thin-layer chromatography induced by the interaction between n-alkanes and an organic cation. Anal Chem 72:1759–1766. https://doi.org/10.1021/ac991302q

Cebolla VL, Mateos E, Garriga R, Membrado L, Cossío FP, Gálvez EM, Matt M, Delgado-Camón A (2012) Changes in fluorescent emission due to non-covalent interactions as a general detection procedure for thin-layer chromatography. ChemPhysChem 13:291–299. https://doi.org/10.1002/cphc.201100590

CAMAG Application Note A-101.1. Determination of SARA (Saturates, Aromatics, Resins and Aaphaltenes) in bitumen by HPTLC. Muttenz

Membrado L, Cebolla VL, Jarne C, Garriga R, Bernard-Savary P, Vela J (2023) Automated multiple development. In: Poole CF (ed) Instrumental thin-layer chromatography. Handbook of separation science, 2nd edn. Elsevier, Amsterdam, pp 81–110. https://doi.org/10.1016/C2021-0-01004-4

Holýa M, Remisováa E (2019) Analysis of influence of bitumen composition on the properties represented by empirical and viscosity test. Transp Res Procedia 40:34–41. https://doi.org/10.1016/j.trpro.2019.07.007

Sharma A, Mullins OC (2007) Insights into molecular and aggregate structures of Aaphaltenes using HRTEM. In: Mullins OC, Sheu EY, Hammami A, Marshall AG (eds) Aaphaltenes, heavy oils, and petroleomics. Springer, New York. https://doi.org/10.1007/0-387-68903-6_8

Fahim MA, Alsahhaf TA, Elkilani A (2010) Hydroconversion. In: Fahim MA, Alsahhaf TA, Elkilani A (eds) Fundamentals of petroleum refining. Elsevier, Amsterdam, pp 153–198

Abdul Jameel AG, Sarathy SM (2018) Lube products: molecular characterization of base oils. Petroleum and liquid fossil fuels analysis. Encyclopedia of analytical chemistry. Wiley, Hoboken

Merkku P, Yliruusi J, Vuorela H, Hiltunen R (1994) Determination of specific heats and adsorption energies of ternary TLC eluents and silica gel. J Planar Chromatogr 7:305–308

Scott RPW (1980) The silica gel surface and its interactions with solvent and solute in liquid chromatography. J Chromatogr Sci 18:297–306. https://doi.org/10.1093/chromsci/18.7.297

Acknowledgements

Authors thank TOTAL RM (France) for financial support for this project.

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest. The second author, V.L.C., is a member of the editorial board of the journal. Therefore, the submission was handled by a different member of the editorial board, and V.L.C. did not take part in the review process in any capacity.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jarne, C., Cebolla, V.L., Membrado, L. et al. Gradient high-performance thin-layer chromatography for characterizing complex hydrocarbon-containing products. JPC-J Planar Chromat 36, 335–349 (2023). https://doi.org/10.1007/s00764-023-00256-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00764-023-00256-x