Abstract

Bamboo tableware became popular as ecofriendly material. However, industrial tableware products made of bamboo-melamine–formaldehyde resin material are not biodegradable. In addition, harmful compounds were detected if such consumer articles were used with hot drinks or hot food, and risk assessment found that maximum daily dosages of melamine and formaldehyde were exceeded. High-performance thin-layer chromatography (HPTLC) methods for analysis of such samples have not been demonstrated so far, despite available HPTLC methods for the mentioned analytes. In this work, the potential and limitation of HPTLC analysis for bamboo-melamine–formaldehyde resin tableware was studied regarding the extractable presence of melamine, formaldehyde and genotoxins. The bamboo tableware was extracted with a food simulant, i.e. aqueous acetic acid simulating hot beverages, and analyzed neutralized and non-neutralized, directly without sample preparation to ensure sample integrity and to avoid loss of sample components. As a result, melamine was not detected in the acidic food simulant. Unfortunately, the existing formaldehyde method was not applicable due to the acidic milieu of the food simulant. The non-target HPTLC−(S9)-SOS-Umu-C bioassay with and without simulated S9 liver enzyme metabolization found no genotoxic substances in 50 µL food simulant, which volume and thus acidity was the maximum tolerated by the Salmonella cells.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

For industrial bamboo-melamine–formaldehyde resin consumer articles, melamine and formaldehyde have been identified as hazards that can be released into hot food. The release of melamine after repeated use is not necessarily a threat for adults but for infants, which can ingest up to three times the daily limit of 0.189 mg melamine/infant/day [1] if the bamboo–melamine articles are used for hot food. On average, investigated bamboo ware released two times the amount of melamine into food and drinks compared to other melamine–formaldehyde resin ware [2]. Formaldehyde can be released into hot food, too. For some articles, the formaldehyde limits were exceeded by a factor of 30–120 [1]. Because of these reasons the Netherlands, Belgium, Luxembourg and further EU member states have banned these products from their markets.

High-performance thin-layer chromatography (HPTLC) analysis of melamine, formaldehyde or genotoxins in bamboo-melamine–formaldehyde resin consumer articles has not been shown so far, although HPTLC methods exist to detect melamine [3], formaldehyde [4] and genotoxins [5]. For the latter, the HPTLC−(S9)-SOS-Umu-C bioassay [5] including simulated metabolic activation or deactivation in the liver [6] was demonstrated to detect genotoxins at low amounts. Hence, this work studied the potential and limitations of these existing HPTLC methods for the analysis of bamboo tableware regarding the extractable presence of melamine, formaldehyde and genotoxins.

2 Experimentals

2.1 Materials and chemicals

Purities were stated if available. Formaldehyde solution (37% in water equal to 37 mg/mL, stabilized with 10% methanol), lysogenic broth (Lennox) powder (including 5 g/L sodium chloride), ampicillin sodium salt, D-(+)-glucose (99.5%), melamine (≥ 99%), aflatoxin B1 (AfB1, > 98%) and fluorescein-di-(β-D-galactopyranoside) (FDG) were bought from Sigma-Aldrich (Steinheim, Germany). Dimedone (≥ 99.0%), and HPTLC plates silica gel 60 with and without fluorescence indicator F254 were delivered by Merck (Darmstadt, Germany). The genetically modified strain Salmonella typhimurium TA1535/pSK1002 was obtained from Trinova Biochem (Giessen, Germany). The S9 rat liver enzymes (phenobarbital/ß-naphthoflavone-induced), nicotinamide adenine dinucleotide phosphate, D-glucopyranose 6-phosphate and buffer salt solution were purchased from Xenometrix (Allschwil, Switzerland). Methanol (gradient grade), dimethyl sulfoxide (≥ 99.5%), chloroform (≥ 99%), ethyl acetate (HPLC), dichloromethane (≥ 99.8) and sodium hydroxide (≥ 98%) were bought from Carl Roth (Karlsruhe, Germany). 4-Nitroquinoline-1-oxide (4-NQO, 98.0%) was purchased from TCI (Eschborn, Germany). Diethyl ether (≥ 99%, stabilized with 2,6-di-tert-butyl-4-methylphenol) and iso-propanol were delivered by Honeywell Riedel-de-Haën (Seelze, Germany). Purified water was prepared by a Destamat Bi 18E (Heraeus, Hanau, Germany). Bamboo tableware was from La Playa Outdoor products & Sporting Goods Company (Swinoujscie, Poland).

2.2 Cell suspension, substrate and standard solutions

Culture medium was prepared by solving lysogenic broth (20 g) in 1 L water, followed by autoclavation. Ampicillin sodium salt (106 mg) and D-(+)-glucose (1 g) were dissolved in 5 mL water and afterwards transferred into the sterile lysogenic broth via a sterilizing syringe filter. An overnight Salmonella culture was prepared by inoculating 20 µL cell cryostock in culture medium (35 mL), which was then incubated (16 h, 37 °C, 100 rpm). Salmonella assay suspension was prepared by diluting the overnight culture of Salmonella cells using fresh culture medium to reach an optical density of 0.2 measured at 660 nm. The FDG substrate solution was prepared by solving 5 mg FDG in 1 mL dimethyl sulfoxide. An aliquot of this solution (25 µL) was transferred into buffer salt solution (2.5 mL). Melamine was dissolved in methanol (1 mg/mL) and further diluted to 10 ng/µL with methanol. Dimedone (2 mg/mL food simulant) and formaldehyde (2 mg/mL food simulant; 5.4 µL of 37% formaldehyde solution dissolved in 995 µL food simulant containing 10% methanol) solutions were prepared, and an aliquot of each standard solution was also neutralized with solid sodium hydroxide. Positive control solutions of 4-NQO and AfB1 (1 mg/mL each) were prepared in dimethyl sulfoxide and diluted with methanol to 1 µg/mL and 0.5 µg/mL, respectively.

2.3 Tableware extraction via food simulant

A representative 250-mL mug of the bamboo-melamine–formaldehyde resin tableware was filled up to the edge with food simulant simulating hot beverages (250 mL of 3% aqueous acetic acid [7]) and closed with aluminum foil (50 μm thickness, Korff, Oberbipp, Switzerland). After extraction with this food simulant at elevated temperature (70 °C, clean heating chamber) for a prolonged time (2 h), the extract was cooled down to room temperature. An aliquot (30 mL) was neutralized with solid sodium hydroxide (2 small spoon spatulas) to pH 6.8. As blank, the mere food simulant was used and also neutralized in the same way.

2.4 Melamine analysis

For all following HPTLC analyses, instrumentation (Automated TLC Sampler 4, Twin Trough Chamber, Derivatizer, Visualizer 2 and TLC Scanner 3, visionCATS software version 3.0) was used from CAMAG, Muttenz, Switzerland. The extract (30 µL/band) was applied next to the melamine solution (30 ng/band, 3 µL of 10 ng/µL solution) and food simulant blank (30 µL/band, 3% aqueous acetic acid) on the HPTLC plate silica gel 60 F254, developed up to 70 mm using iso-propanol–ethyl acetate–water 10:5:6, V/VV (according to [3] but dichloromethane was substituted with ethyl acetate), documented at FLD 254 nm and densitometrically detected via absorption measurement at 202 nm. On each track at the analogous melamine position (hRF 50), the respective UV spectrum (190−400 nm) was recorded.

2.5 Formaldehyde analysis

Eight acidic and eight neutralized solutions were applied analogously on two HPTLC plates silica gel 60 F254, separated with chloroform–dichloromethane–diethyl ether 4:5:6, V/V/V up to 70 mm and detected at UV 254 nm [4]. The following solutions were applied (mixtures were obtained by overspraying), i.e., of formaldehyde (F, 20 µg/band, 10 µL of 2 µg/µL solution), formaldehyde−dimedone mixture (FD, 20 µg/band each, 10 µL of each 2 µg/µL solution), dimedone (D, 20 µg/band, 10 µL of 2 µg/µL solution), dimedone−mug extract sample mixture (DS, 10 µL/band each), mug extract sample (S, 10 µL/band), mug extract sample−formaldehyde mixture (SF, 10 µL/band, 2 µg/µL formaldehyde in extract), mug extract sample−formaldehyde−dimedone mixture (SFD, 20 µL/band, plus 10 µL of each 1 µg/µL solution of formaldehyde and dimedone in extract), and the food simulant blank, which is 3% aqueous acetic acid used for extraction (B, 10 µL/band).

2.6 Genotoxin analysis

The acidic and neutralized mug extract sample (each 50, 30, and 10 µL) and corresponding blank solutions (50 µL each) were applied on the HPTLC plate silica gel 60, developed up to 70 mm using chloroform–dichloromethane–diethyl ether 4:5:6, V/V/V [4]. Thereafter positive control solutions (1 µL/band 4-NQO, and for metabolization control, 0.5 µL/band AfB1) were applied. The planar SOS-Umu-C bioassay was performed as described elsewhere [4, 5]. Briefly, Salmonella assay suspension (2.8 mL, yellow nozzle, level 4) were sprayed onto the chromatogram, incubated (3 h, 37 °C) in a humid polypropylene box (26.5 cm × 16 cm × 10 cm, KIS, ABM, Wolframs-Eschenbach, Germany), and dried in a cold airstream (4 min). Then, FDG substrate solution was applied (2.5 mL, yellow nozzle, level 4). After incubation (15 min, 37 °C) in a humid box, the plate was dried in a cold airstream (4 min) and documented at FLD 254 nm. The whole experiment was repeated using a Salmonella suspension containing the S9 mixture system (2.8 mL of a mixture of 3334 µL Salmonella assay suspension 500 µL S9 liver enzyme mixture, 162 µL nicotinamide adenine dinucleotide phosphate, 42 µL D-glucopyranose 6-phosphate and 953 µL buffer salt solution).

3 Results and discussion

As a sample, a commercially available bamboo tableware was selected. Melamine and formaldehyde are harmful compounds used in the manufacturing process of the industrial tableware products made of bamboo-melamine–formaldehyde resin material. Their extraction aimed at a realistic consumer use by extracting the inside of the mug, i.e., the surface that comes into contact with beverages such as tea or coffee during daily use [7]. Hence, a food simulant, i.e. 3% acetic acid, was used [7] which represents acidic and hot beverages, e.g., tea and coffee. Such an acidic food simulant was found to be more stressing for the tableware than other regulated food simulant solvents. A 250 mL mug of the bamboo-melamine–formaldehyde resin tableware was filled up to the edge with 3% aqueous acetic acid. After extraction at elevated temperature (70 °C) for a prolonged time (2 h), the colorless transparent cooled down extract was investigated. The mobile phase system for melamine analysis according to [3] was immiscible, and also to avoid chlorinated solvents, ethyl acetate was used instead of dichloromethane. The mobile phase system for formaldehyde analysis was used as reported [4], and as it is a medium polar mobile phase system, taken over for the genotoxin analysis.

3.1 Melamine analysis

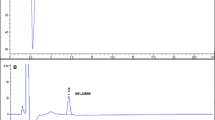

The absorption measurement of melamine at its absorption maximum of 202 nm [2] proved the absence of melamine in the mug extract sample and also in the food simulant blank (Fig. 1a). In contrast, the melamine signal was detected on the melamine reference track, which confirmed the position and detectability of melamine in the chromatogram via this method. As further proof of melamine absence in the sample, UV spectra were recorded at the position of the melamine and analogous positions on each track. The absorption maximum at 202 nm was only observed for the melamine reference, again proving the absence of melamine in the mug extract sample (Fig. 1b). The applied 30 µL mug extract sample was equivalent to 30 µL hot beverage. Higher sample volumes could not be applied bandwise without damaging the layer. However, there is potential to apply the mug extract as area to lower the detection limit.

Melamine analysis: Absorption densitograms at 202 nm (a) and respective UV spectra from 190 to 400 nm (b; recorded on each track at the melamine position and analogous positions) of the mug extract sample (30 µL/band), melamine standard (30 ng/band) and food simulant blank (30 µL/band) separated on the HPTLC plate silica gel 60 F254 with iso-propanol–ethyl acetate–water 10:5:6

3.2 Formaldehyde analysis

The volatile formaldehyde can be detected by its reaction with dimedone to a non-volatile product according to [3], supposedly detectable as UV-absorbing dark band in the UV 254 nm chromatogram. As expected, the formaldehyde − dimedone reaction product was detected as band 2 in the chromatogram (Fig. 2a, F versus FD). However, the results were inconsistent under acidic conditions. Dimedone dissolved in food simulant (3% acetic acid) was expected to show one band (1) but instead showed two bands (1 + 2) in the chromatogram (Fig. 2a, D). Since dimedone is already transformed under acidic conditions into the reaction product (band 2), a quantification of formaldehyde in the acidic mug extract sample was impossible. The same reaction result was observed when dimedone was dissolved in the acidic mug extract sample (DS). In contrast, the formaldehyde (F), mug extract sample (S), formaldehyde dissolved in mug extract sample (SF), and food simulant blank (B) did not show any dark bands, which was expected due to the absence or volatility of formaldehyde. As proof, formaldehyde and dimedone dissolved in the acidic mug extract sample (SFD) showed both bands with the reaction product (band 2) clearly pronounced.

Formaldehyde analysis: Chromatograms at UV 254 nm of the acidic (a) and neutralized mug extract sample (b) along with respective controls: formaldehyde (F, 20 µg/band), formaldehyde and dimedone (FD, 20 µg/band each), dimedone (D, 20 µg/band), dimedone and mug extract sample (DS, 10 µL/band each), mug extract sample (S, 10 µL/band), mug extract sample and formaldehyde (SF, 10 µL/band each), mug extract sample and formaldehyde and dimedone (SFD, 20 µL/band each) and food simulant blank (B, 10 µL), separated as in Fig. 1

To proof, whether an additional neutralization step can be helpful with regard to the unwanted dimedone reaction result under acidic conditions, the study was repeated under neutralized conditions. Therefore, the acidic solutions were neutralized via sodium hydroxide (Fig. 2b). The neutralization salts caused comparatively darker application zones because the resulting salt layer blocked the fluorescence indicator. The hRF value of the band 2 was higher under neutralized conditions, which was explained by the salt load present at the application zone, which increased in these tracks the polarity of the mobile phase (consisting of solvents known to contain traces of water, in which the salts are soluble). Again, the reaction product of dimedone and formaldehyde (FD) showed only one band (2), but for the neutralized dimedone (D) the band 1 did not show up in the chromatogram, only the reaction product band 2 was formed. This result suggested in comparison to the neutralized DS that the most likely still too acidic mug extract sample matrix (pH 6.8 in case of neutralized samples) had an influence and interfered with the reaction of dimedone and formaldehyde. Thus, formaldehyde could not be determined in the given acidic mug extract sample milieu by this method.

3.3 Genotoxin analysis

For the detection of genotoxins, the acidic and neutralized mug extract samples were applied at different volumes (10, 30 and 50 µL) along with respective food simulant blanks (50 µL) on the respective HPTLC plate without fluorescence indicator to avoid interference with the signal measurement of the formed fluorescent end-product of the enzyme-substrate reaction. The neutralized mug extract sample was used and applied because acidic conditions could have interfered with the on-surface applied Salmonella cells. The plate was developed and subjected to the HPTLC-SOS-Umu-C bioassay. An analogously prepared plate was subjected to the corresponding planar bioassay, in which the S9 enzyme mixture system was added to the cell suspension to simulate the metabolization in the liver (HPTLC−S9-SOS-Umu-C bioassay). The on-surface metabolization via the S9 mixture system was included because non-genotoxic compounds can enzymatically be metabolized and converted to genotoxic compounds. Both positive controls showed active green fluorescent bands, which proved the proper bioassay performance. However, no genotoxic responses were observed for the applied 50-µL sample volumes (Fig. 3), equivalent to 50 µL hot acidic beverage. Recently published studies on packaging migrates [5, 6, 8] that used the same planar bioassay were able to detect a variety of unknown genotoxins by applying 2 µL of an ethanolic migrate which was 50-fold concentrated. That was equivalent to an investigation of 100 µL non-concentrated ethanolic migrate. This study investigated a sample volume of 50 µL, which is meaningful and approximately 50% of the volume tested in the other migration studies. Since this study used an acidic extraction, higher sample volumes could not be applied bandwise without damaging the layer; however, area application could be studied to reach higher application volumes. Acidic conditions have a negative impact on Salmonella cells and salt is responsible for the bright halo around the application bands on the start zone (Fig. 3, neutralized 30 µL and 50 µL samples). Concentration of the samples before use cannot be carried out without enrichment of the acid content in the sample since water is more volatile. This would increase the negative effect of the acid on the Salmonella cells.

Genotoxin analysis via HPTLC−(S9)-SOS-Umu-C bioassay: Bioautograms at FLD 254 nm of the acidic and neutralized mug extract samples and respective food simulant blanks (*neutralized) without and with simulated S9 system metabolization in the liver, separated on the HPTLC plate silica gel 60 with chloroform–dichloromethane–diethyl ether 4:5:6, V/V/V, and detected at FLD 254 nm after the planar (S9)-SOS-Umu-C bioassay

4 Conclusion

Industrial tableware products made of bamboo-melamine–formaldehyde resin material is in many EU countries an illegal product if its use is supposed for food contact. Especially for hot food and hot drinks, migration of melamine and formaldehyde can exceed limits. For the studied bamboo tableware product, no melamine was found via absorption scan. Thus, the mug extract sample was safe in terms of melamine. The current HPTLC formaldehyde method was not applicable to the acidic nature of the investigated food simulant since the formaldehyde results were inconsistent. The sensitive HPTLC−(S9)-SOS-Umu-C bioassay showed that no genotoxins were extracted into the 50-µL food simulant representing hot acidic beverage.

References

US Food and Drug Administration (2008) Update interim safety and risk assessment of melamine and its analogues in food for humans. US Food and Drug Administration. https://wayback.archive-it.org/7993/20170111174251/http://www.fda.gov/Food/FoodborneIllnessContaminants/ChemicalContaminants/ucm164520.html. Accessed 31 Oct 2022

Bundesinstitut für Risikobewertung (2019) Gefäße aus Melamin-Formaldehyd-Harz wie „Coffee to go“ Becher aus „Bambusware“ können gesundheitlich bedenkliche Stoffe in heiße Lebensmittel abgeben. https://mobil.bfr.bund.de/cm/343/gefaesse-aus-melamin-formaldehyd-harz.pdf. Accessed 12 Dec 2022

Rani R, Medhe S, Srivastava M (2015) HPTLC-MS analysis of melamine in milk: standardization and validation. Dairy Sci & Technol 95:257–263. https://doi.org/10.1007/s13594-014-0204-3

Rani R, Srivastava MM (2016) Development and validation of HPTLC method for the estimation of formaldehyde in milk. Nat Acad Sci Lett. 39:21–24. https://doi.org/10.1007/s40009-015-0414-0

Meyer D, Marin-Kuan M, Debon E, Serrant P, Cottet-Fontannaz C, Schilter B, Morlock GE (2021) Detection of low levels of genotoxic compounds in food contact materials using an alternative HPTLC-SOS-Umu-C assay. ALTEX 38:387–397. https://doi.org/10.14573/altex.2006201

Debon E, Rogeboz P, Latado H, Morlock GE, Meyer D, Cottet-Fontannaz C, Scholz G, Schilter B, Marin-Kuan M (2022) Incorporation of metabolic activation in the HPTLC-SOS-Umu-C bioassay to detect low levels of genotoxic chemicals in food contact materials. Toxics 10. https://doi.org/10.3390/toxics10090501

Commission E (1985) Council directive of 19 December 1985. OJEC 372:14–21

Meyer D, Marin-Kuan M, Mayrhofer E, Kirchnawy C, Debon E, Latado H, Patin A, Schilter B, Morlock G (2023) Effect-detection by planar SOS-Umu-C genotoxicity bioassay and chemical identification of genotoxins in packaging migrates, proven by microtiter plate assays SOS-Umu-C and Ames-MPF. Food Control 147:109546. https://doi.org/10.1016/j.foodcont.2022.109546

Acknowledgements

Instrumentation was partially funded by the Deutsche Forschungsgemeinschaft (DFG, German Research Foundation) - INST 162/536-1 FUGG.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they do not have a conflict of interest.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Meyer, D., Morlock, G. High-performance thin-layer chromatography analysis of industrial bamboo tableware for genotoxins, melamine and formaldehyde. JPC-J Planar Chromat 36, 71–76 (2023). https://doi.org/10.1007/s00764-023-00233-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00764-023-00233-4