Abstract

A simple and sensitive thin-layer chromatography (TLC) method coupled with an image analysis technique was developed for the simultaneous quantitative determination of L-proline and L-lysine in dietary supplement with good precision and accuracy. Separation was performed on silica gel plates using ethanol‒toluene (2:3, V/V) as the mobile phase. The visualization of chromatograms was based on iodine–azide reaction; therefore, pre-chromatographic derivatization reaction of amino acids with phenyl isothiocyanate was performed. Digital images of TLC plate chromatograms were converted into peak chromatograms, and quantitative analysis was conducted using TLSee software.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In recent years, a growing interest in dietary supplements that contain ingredients other than vitamins and minerals has been observed. A significant group of such supplements are those containing amino acids necessary for the proper synthesis of collagen, such as L-proline (PR) and L-lysine (LY) [1, 2]. Therefore, in order to ensure the optimal level of collagen in the body, the combination of these two amino acids is very popular among people for whom their supplementation is indicated.

The growing interest in this type of supplements implies an increase in their production, and hence, it is necessary to control the declared content of active substances. An overview of the available literature showed that no method of the simultaneous determination of the two amino acids using thin-layer chromatography (TLC) has yet been developed. A method combining TLC with densitometry using ninhydrin as the visualization reagent had been previously developed for the determination of LY in dietary supplements [3].

In this paper, we propose a TLC method for the simultaneous quantitative determination of PR and LY in a dietary supplement. Quantitative determination was carried out using the image analysis technique. The basis of such analysis is the conversion of spots to the peak chromatogram and its analysis using some commercially available software (TLSee—Alfatech S.p.A., Genova, Italy; JustTLC—Sweday, Lund, Sweden) or freeware license (ImageJ—National Institutes of Health, Bethesda, MD, USA). The image analysis technique, although not often used, is a very good alternative to densitometry [4,5,6,7]. Previously conducted researches confirm the compliance of the results obtained with both techniques [8].

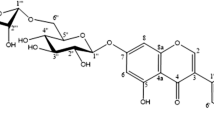

The visualization of the chromatograms was based on the iodine‒azide reaction. It is known that reaction between iodine and azide ions proceeds, as shown in Scheme 1, only in the presence of bivalent sulfur atom in the analyzed molecule [9].

Since PR and LY do not have it in their molecules, it is necessary to convert them to sulfur-containing derivatives. For this purpose, phenyl isothiocyanate (PITC) was used, and amino acids were transformed into their phenylthiocarbamyl (PTC) derivatives: PTC-PR and PTC-LY, respectively. The derivatization reaction proceeds as presented in Scheme 2 [10].

The use of TLC to separate the two amino acids as PTC derivatives contained in a dietary supplement in combination with the image analysis technique allowed to develop a cheap, simple, accurate and precise method for their quantitative determination.

2 Experimental

2.1 Reagents and solutions

PR (99%), LY (98%) and PITC (98%) were from Sigma-Aldrich (Poznań, Poland), analytical grade sodium azide was from CHEMPUR (Piekary Śląskie, Poland), and analytical grade potassium iodide, starch, hydrochloric acid, toluene, anhydrous ethanol and 2-propanol were from POCH (Gliwice, Poland). Deionized water (Polwater, Kraków, Poland) was used in the preparation of solutions. Dietary supplement in the form of capsules with label specification of 150 mg of PR and 330 mg of LY was purchased from Hanoju Deutschland GmbH (Damme, Germany).

2.1.1 Standard amino acid solution at concentration 0.01 mol/L

A specified amount of a particular amino acid was introduced into a 5-mL volumetric flask, and dissolved in 1 mL of 0.1 mol/L sodium hydroxide solution. The solution in the flask was diluted with water to the mark and shaken well.

2.1.2 Supplement stock solution

The contents of 10 capsules were mixed, and an aliquot of 48 mg of the powder was weighed, then introduced into a 10-mL volumetric flask and completely dissolved in 2 mL of 0.1 mol/L sodium hydroxide solution. The solution in the flask was diluted with water to the mark and shaken well.

2.1.3 Derivatization reagent

2-propanol, PITC and phosphate buffer (0.01 mol/L, pH 12) were mixed in volume ratio 7:1:1.

2.1.4 Phosphoric buffer (0.01 mol/L, pH 12)

An aliquot of 0.3582 g of disodium hydrogen phosphate was dissolved in 50 mL of water, and the pH was adjusted to 12 using 0.1 mol/L sodium hydroxide solution. The mixture was transferred to a 100-mL volumetric flask, and next the solution was diluted with water to the mark and shaken well.

2.1.5 Spraying solution (4% sodium azide, 0.5% starch, pH 5.5)

An aliquot of 2.0 g of sodium azide was dissolved in 20 mL of water. To this, an amount of 25 mL of 1% starch solution was added, and the pH was adjusted to 5.5 using hydrochloric acid (1:1, V/V). The mixture was transferred to a 50-mL volumetric flask, which was diluted with water to the mark and shaken well.

2.2 Procedure of derivatization of amino acids

The appropriate amount of standard amino acids solutions, 525 µL of 2-propanol, 75 µL of PITC and 75 µL of phosphate buffer were placed in an Eppendorf tube, and shaken well. The mixture was let to stand for 30 min. After the reaction was completed, the sample was diluted to 1 mL with methanol.

In the same manner, the derivatization of amino acids contained in the capsule of the dietary supplement was carried out.

2.3 General chromatographic and image analysis procedure, instrumentation and software

TLC analysis was performed using 5 × 10 cm or 7.5 × 10 cm silica gel TLC F254 aluminum plates (Sigma-Aldrich). Amino acids derivatives solutions were applied using a Linomat V semi-automatic applicator (CAMAG, Muttenz, Switzerland), in a volume of 1 µL, in the form of 4-mm bands, spaced 10 mm apart. The application rate was 250 nL/s.

The plates were developed with ethanol‒toluene (2:3, V/V) mobile phase, to a distance of 8.0 cm in a horizontal DS chamber (Chromdes, Lublin, Poland). The developed plates were air-dried and then sprayed with spraying solution using SG1 chromatography sprayer (DESAGA, Wiesloch, Germany). Slightly wet plates were exposed to iodine vapors for 20 s in amber glass container containing iodine (iodine chamber), and after being removed outside they were left for 2 min to let the iodine–azide reaction proceed (white spots appear on violet–blue background). The visualized plates were scanned at 300 dpi with an HP ScanJet G4010 office scanner (Hewlett-Packard, Budapest, Hungary). TLSee software was used to proceed the conversion of spots to peaks.

2.4 Linearity, precision and accuracy

The samples to be applied onto the plates were prepared according to the described derivatization procedure in the range of amino acids concentration 0.1‒1.5 nmol/band. For each amount, six replicate experiments were performed as described in the previous sections.

Based on the results obtained, linearity, precision (relative standard deviation, RSD) and accuracy (percent recovery) were calculated.

2.5 Determination of proline and lysine in dietary supplement

The content of amino acids in supplement capsule was established using the calibration curve method. For calibration plot derivatization, mixtures containing standard solution of PR in the range of concentration 11.5‒173 ng/band, and LY in the range of concentration 14.6‒219 ng/band were prepared. Next, a mixture-containing supplement sample (PR 99.0 ng/band, LY 45 ng/band) was prepared.

The supplement samples were analyzed on the same plates as the standard samples. Six replicate experiments were performed as previously described.

3 Results and discussion

Based on the results of the conducted laboratory experiments, the optimal conditions of the method procedure were established. Under these conditions, the spots of PTC derivatives appeared as white spots on violet–blue background, in proper for image analysis shape, without blurred edges.

The polar silica gel stationary phase for the determination of amino acids was chosen, according to the literature results [9]. The best separation of PTC derivatives, and derivatization reagent enabled the mobile phase consisting of ethanol and toluene mixed in a volume ratio 2:1. Using this phase system, the RF values for PTC-PR and PTC-LY were found to be 0.32 and 0.67, respectively. It was also stated that prior chamber saturation did not affect the yield of separation.

The derivatization conditions were selected and adapted based on previously conducted and described studies [11].

Quantitative determination using the image analysis technique requires the post-separation spots to be as round as possible, and without blurred edges. The corresponding peaks are narrow and symmetrical and, consequently, the obtained peak area values are higher and more repeatable. Considering the fact that solutions were applied using a TLC applicator, it was necessary to choose an optimal application rate and band width. In the most of cases, the solution application in the form of 0-mm band (dots) gives proper for image analysis shape of spots. In the case of PTC-PR and PTC-LY derivatives, the resulting spots had irregular and tailed shapes. It was observed that increasing of band width above 1 mm resulted in more rounding and less tailing spots. The best results were obtained when solutions were applied in the form of 4-mm band. The increase in band width did not affect the appearance of the PTC-LY spots, but the PTC-PR spots became flattened. Influence of application rate on the peak area values in the range 250‒350 nL/s was not observed. When the solutions were applied slower than 250 nL/s, lower values of peak areas were obtained. It can be explained by too fast solvent evaporation in relation to solution delivery onto the plate. An application rate of 250 nL/s was chosen as optimal.

The high contrast between the spots and the light blue background results in peak chromatograms characterized by a low signal-to-noise ratio. This kind of chromatograms can be easily analyzed, with good precision and accuracy. In order to ensure high contrast, the visualization conditions should be optimized. At first, the influence of sodium azide and starch concentration in spraying solution as well as its pH was investigated. In the next step, time of exposition to iodine vapors and time of iodine‒azide reaction were examined.

The influence of sodium azide concentration on the results was tested for 2%, 4% and 6% solutions. It was observed that spots on TLC chromatograms and thus peak areas were practically the same for 2% and 4% solutions. At the same time, it was observed that the use of sodium azide at a concentration of 6% resulted in a decrease in the values of the peak areas for both derivatives.

The next studied effect was the influence of the concentration of starch in solution (0.25%, 0.5%, 0.75% and 1.0%). At concentration 0.25%, the spots were small and the background color was unstable. At concentration 1.0%, the spots were light blue in color and, as a result, a contrast between them and the background was decreased. The best results were observed when visualization mixtures with a starch concentration of 0.50% and 0.75% were used. Finally, a mixture containing 0.5% of starch was chosen, due to the better stability of the background color.

In order to select optimal pH of the spraying solution, mixtures at pH values 5.5, 6.0 and 6.5 were prepared. In the tested pH range, no significant changes in the spot areas were observed. The pH 5.5 was chosen as the best because of slightly higher values of peak areas for PTC-LY.

Spots become visible after exposition of the developed plates to iodine vapor. It is therefore necessary to establish the time of exposition as well as the time after which iodine‒azide reaction is completed and the contrast between spots and the background is the highest. In the case of analyzed amino acids, the plates were placed in iodine chamber for 20 s, and then, after being removed outside they were left for 2 min to let the reaction to proceed. Then, the visualized chromatograms were scanned at resolution of 300 dpi. When the exposure time to iodine vapor was shorter than 20 s, the background faded rapidly. It was also observed that, for the reaction time of 2‒5 min, the peak area values were the highest and comparable. When the reaction time was longer than 5 min, the background was fading, and consequently, it was difficult to determine peak areas with good precision and accuracy.

Quantitative determination was based on the proportional correlation between peak areas and the amount of compound in the corresponding spot applied onto the plate. As shown in Fig. 1, the area of spots on plates and the corresponding peak areas increased proportionally with the amount of amino acids applied. Thus, the calibration plots between the peak area y and the amount x of PR or LY in derivatization mixture were constructed. Linearity was evaluated using the least square linear regression method. The regression equations y = ax + b (a is the slope of the calibration curve, b is the intercept), the determination coefficients R2 as well as the standard deviations of the intercept sb were calculated. Based on those data, the limits of detection (LOD = 3·sb/a) were also calculated. The results obtained for PR were:

y = 40310x + 18,335, R2 = 0.9990, sb = 634.7, LOD = 0.05 nmol/band.

The results obtained for LY were:

y = 55607x + 28,837, R2 = 0.9987, sb = 995.1, LOD = 0.05 nmol/band.

The intra-day and inter-day precision and recovery of the method and recovery at different concentrations within the linear range are presented in Table 1.

The estimation of amino acids in dietary supplement was established using the calibration curve method. Calibration curves were constructed to reflect the relationship between peak areas and the amounts of PR and LY standards contained in bands applied onto the plate. The regression equation for PR was y = 346.21x + 20,210 with the correlation coefficient R2 = 0.9983. The regression equation for LY was y = 374.49x + 27,612 with the determination coefficient R2 = 0.9985. The results of amino acids estimation in dietary supplement samples are presented in Table 2. As can be seen, good compliance of the determined content with that declared by the manufacturer was obtained.

4 Conclusion

The results show that the presented combination of TLC with the image analysis technique enables the simultaneous quantitative determination of PR and LY in dietary supplements. It is also relatively fast and the results are characterized by good precision and accuracy. The main advantage of image analysis is its simplicity and low cost resulting from application of computer equipped with scanner and suitable software for quantification. The disadvantage of the method is the fact that the precision and accuracy of the results depend on the duration of the derivatization reaction and the individual steps of chromatograms visualization. Thus, it is important to accurately measure the specific time, established as optimal, while these stages of analysis are carried out.

To our knowledge, the method presented in this paper is the first that uses not densitometric TLC technique for quantification of the investigated amino acids.

References

Karna E, Szoka L, Huynh TYL, Palka JA (2020) Proline-dependent regulation of collagen metabolism. Cell Mol Life Sci 77:1911–1918

Van Slyke DD, Sinex FM (1958) Hydroxylysine in collagen of lysine to form the course of hydroxylation. J Biol Chem 232:797–806

Pachuski J, Sherma J (2002) Quantification of lysine in dietary supplement tablets and capsules by reversed phase high performance thin layer chromatography with visible mode densitometry. J Liq Chromatogr Relat Technol 25:1633–1639

Skowron M, Zakrzewski R, Ciesielski W (2016) Application of image analysis technique for the determination of organophosphorus pesticides by thin-layer chromatography. J Planar Chromatogr 29:221–226

Skowron M, Zakrzewski R, Ciesielski W (2018) Application of image analysis technique for the determination of thiophanate methyl by thin-layer chromatography. Int J Environ Anal Chem 98:286–294

Olech M, Komsta Ł, Nowak R, Cieśla Ł, Waksmundzka-Hajnos M (2012) Investigation of antiradical activity of plant material by thin-layer chromatography with image processing. Food Chem 132:549–553

Rembisz Ż, Zakrzewski R, Skowron M, Ciesielski W (2016) Image analysis of phenylisothiocyanate derivatised and charge-couple device-detected glyphosate and glufosinate in food samples separated by thin-layer chromatography. Int J Environ Anal Chem 96:320–331

Ciesielski W, Dyńska-Kukulska K, Zakrzewski R, Hekner A (2010) Analysis of sulfide ions by densitometric thin-layer chromatography and use of TLSee software. J Planar Chromatogr 23:343–347

Zakrzewski R, Ciesielski W (2007) Iodine–azide detection system in planar chromatography. Trends Chromatogr 3:1–10

Zakrzewski R, Ciesielski W, Kaźmierczak D (2003) Detection of proline, arginine and lysine using iodine-azide reaction in TLC and HPTLC. J Sep Sci 26:1063–1066

Kaźmierczak D, Ciesielski W, Zakrzewski R, Żuber M (2004) Application of iodine–azide reaction for detection of amino acids in thin-layer chromatography. J Chromatogr A 1059:171–174

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Skowron, M., Zakrzewski, R. & Ciesielski, W. Application of the TLC image analysis technique for the simultaneous quantitative determination of L-proline and L-lysine in dietary supplement. JPC-J Planar Chromat 34, 197–202 (2021). https://doi.org/10.1007/s00764-021-00093-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00764-021-00093-w