Abstract

The use of nuclear magnetic resonance (NMR) is an appropriate tool for studying colloids in a non-invasive manner. Droplet size distributions and one-dimensional sample profiles are readily produced to characterize an emulsion, its stability, the size distribution of the dispersed phase, and rheological behavior with respect to parameters as temperature and/or water cut. Here, we present pulsed field Grgdient NMR methods that improve the performance as compared to existing methods. In particular, the so-called multi-echo approach is introduced to enhance the signal-to-noise ratio significantly making it possible to characterize emulsions in a minute or less. Thus, any evolution that takes place in the order of just a few minutes can be monitored. In addition to the multi-echo approach, an improved method for determining the droplet size distribution from a residual emulsion, i.e., in the presence of a bulk water phase, is presented.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

51 years ago, Packer and Rees [1] presented their method for determining droplet size distributions of water in oil emulsions by NMR. Over the years, improvements have been made to improve the characterization of the emulsions [2,3,4,5,6,7], and common for most of these methods is that the oil signal is removed using an inversion recovery sequence. In 2010, an approach was presented [8], which did not assume a pre-determined shape of the droplet size distribution and did not require a single component T1 to suppress the NMR signal from the oil phase. This method combines diffusion with surface relaxation measurements to produce the droplet size distribution. To suppress the oil phase, a stimulated echo sequence was used as a preparatory sequence where the z-storage time, Δ, was set so long that the oil phase would relax back to thermal equilibrium. Then one assumes a significant difference in relaxation times between the water and oil phase, where the oil phase is assumed to have a shorter relaxation time than the water phase. This approach was also applied by Fridjonson et.al [9] to suppress the signal from crude oils with shorter relaxation times from the stimulated echo part of the NMR sequence while using the T1 nulling from the inversion recovery part of the NMR sequence to get rid of the main component in the crude with the longest relaxation time.

When the difference in the relaxation times is small, the water signal intensity, from which the droplet size distributions (DSD) and profiles are extracted, is less intense especially for emulsions of low water content. Consequently, it may take on the order of 10–30 min to achieve a proper signal-to-noise ratio to determine the DSD and/or the 1D-image (profile) of the water phase, which is quite lengthy for a sample undergoing time-dependent morphological changes. If one is interested in characterizing unstable emulsions on the path to separated water and oil phases, it would not be possible with the existing methods [7,8,9,10,11] if the difference in the relaxation times of the oil and water phases was too close. One solution could be to add a relaxation agent to one of the phases, but this would perturb the emulsion prior to its characterization.

Our solution to the challenge of poor signal-to-noise ratio in the low-resolution NMR measurements is to introduce a multi-echo approach for improving the signal to noise significantly, both for the profile and DSD experiments. This can be done because the encoding parts of the profile and DSD sequences are run in just a few milliseconds while the relaxation time of the water phase is of the order of hundreds of milliseconds. Thus, the pulse sequence can be looped so that the acquisition can be repeated several times and signal to noise is reduced by combining the acquisitions before processing. As will be shown in the following, this may reduce the acquisition time to the order of less than a minute for systems where there is a significant overlap in the relaxation times between the oil and water phases.

2 Theory

In Sects. 2.1–2.3, the theory for characterization of emulsions with respect to determining one-dimensional image and droplet size distributions [7, 8, 10, 11] is recaptured and the improvements of the methods using the multi-echo approach are found in Sects. 2.2.1, 2.3.1, and 2.4 using a synthetic emulsion of 10% water cut. The synthetic emulsion was composed by a high viscous model oil (Primol 352 from Brenntag Nordic A/S) mixed with a surfactant (Span 80 from Fluka) and water to form stable emulsion with a water cut of 10%.

2.1 Suppression of the Oil Phase and Quantification of the Water Phase

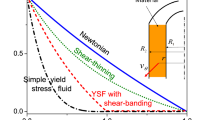

In low-resolution NMR, there is no spectral resolution between the oil and water phase, as the Fourier transform of the NMR signal following a 90-degree radio frequency (RF)-excitation pulse produces a relatively broad peak that includes both the oil and water signals from the emulsion. There are several options for resolving the water signal from the oil signal making use of the significant differences in relaxation times, diffusion coefficient, and/or their temperature dependencies [7]. Here, a significant difference in the longitudinal relaxation time, T1, of the two phases is assumed and then a stimulated echo (STE) sequence can be used to suppress the oil phase with the shorter T1.The z-storage delay between the second and third 90-degree pulses in the STE sequence (Fig. 1) is then increased until the signal from the oil phase has relaxed back to thermal equilibrium. Thereafter, the remaining water signal is brought back to the transverse plane and the emulsion characterization sequences can be applied on the water phase only. Figure 2 shows the T2 distribution from the CPMG data acquired from two types of butter using two z-storage delays, one short (0.010 s) and one long (1 s and 1.5 s). At the shorter delay, there is both signal from the oil and water phase, but as the delay is set long enough, the oil signal vanishes. As can be seen from the position of the oil peak, the suppression time (z-storage delay) must be set differently for the two types of butter. Also, significant amounts of water signal are lost, so the lesser difference there is in T1 values between the two phases, the noisier the data for emulsion characterization will be. Other techniques may be applied in cases where the water signal becomes too weak and there is too much overlap between the two phases. One way is to apply the significant difference in the root mean squared displacement between the water trapped inside a droplet and the oil phase that may diffuse over much larger distances in comparison [7].

The combined spoiler recovery delay–stimulated echo–Carr Purcell Meiboom Gill (SRD–STE–CPMG) sequence. The SRD part of the sequence is used to reduce the recycle delay of 5 times T1, the STE is used for suppressing the signal from the oil phase, and the CPMG part of the sequence is used for determining the attenuation due to T2 relaxation

To be able to characterize the emulsions properly, the oil and water phases should be quantified. This is done by applying the ordinary CPMG sequence on the emulsion which is cooled down to a temperature where the T2 distributions from the two phases are clearly separated. In Fig. 3, the T2 distributions arising from the two emulsions tempered to 0 °C are shown. From the areas of the two separated peaks, it is found that the FB emulsion contains 21.0% of water while the SB emulsion contains 19.5% of water. The ~ 2% of solid components dissolved in the water phase (protein and carbohydrates) are then accounted for.

To resolve the water phase from the oil phase, the suppression time Δ must be found for each temperature the emulsions is to be characterized. This is shown in Fig. 2, where the Δ is increased from 0.010 s until the oil phase vanishes in the T2 distribution. At a temperature of 20 °C, the Δ is found to be 1.0 s for the FB emulsion while it is 1.5 s for the SB emulsion. Δ will have to be increased when increasing the temperature at which the emulsions are to be characterized.

2.2 Determining the One-Dimensional Image Using the Multi-Echo Approach

The one-dimensional profile of the water in the emulsion is measured by acquiring a spin echo signal in the presence of a read gradient. Consider the spectral function \({\mathrm{f}}_{(\upomega )}\) that reflects the normalized Fourier transform of the NMR signal and the normalized spin density projection along the direction of the magnetic field gradient g, \({\uprho }_{\mathrm{z}}\), as follows [12]

When applying a magnetic field gradient during the acquisition of the NMR signal, we are then able to produce a position-dependent NMR signal by applying the Fourier transform on the acquisition as indicated in Fig. 4.

The principle of measuring a one-dimensional image /profile. The sample is subjected to an acquisition of a spin echo signal during the application of a constant magnetic field gradient. The Fourier transform of this signal, \(f\left(\omega \right)\), will produce a spectrum where the frequency-dependent signal correlates to the position of the signal in the sample

2.2.1 The Multi-Echo Profile Approach

Figure 5 shows the multi-echo approach where the sequence combines three parts of different motivation. The SRD part is used to excite the sample without the need for spending five times the longest T1 between the accumulating scans. When studying unstable systems, one may apply a spoiler recovery delay (SRD) that may be less than 5T1, for example, T1 to gain 73.2% (single T1 value) of the initial NMR signal to be applied in the two last parts of the sequence. The SRD duration will depend on the other two parts of the sequence with the STE of particular importance. The suppression time Δ, the STE part of the sequence, will further reduce the NMR signal available for emulsion characterization. For the FB and SB emulsions, the remaining signal after suppression of the oil phase was 38% and 35%, respectively. Using an SRD of T1 leaves 27.8% and 25.6% of the initial water signal from emulsions FB and SB, respectively. Then the remaining water signal available for emulsion characterization is approximately a quarter of the initial water signal.

The third part consists of the multi gradient spin echo (MESE) sequence. After acquiring the first spin echo during a constant gradient, a gradient pulse (G3) of opposite polarity is applied before the gradient spin echo sequence is repeated. The strength of G3 is adjusted such that the second and the following echoes are centered at the right position and with maximum intensity. Then if eight echoes are acquired and combined to form one echo, the signal intensity should in principle equal that of an ordinary profile experiment with recycle delay of 5T1 and suppression time Δ set to 0. In Fig. 6, the spin echoes acquired with the SRD–STE–MGSE are shown. To produce the water phase profile, eight spin echoes are added point by point, and then subjected to a Fourier transform.

In Fig. 7, the result from the application of the SRD–STE–MGSE sequence on a system with poor signal-to-noise ratio is shown. With one echo only, a region slightly above the noise level can be identified. When recording 48 echoes, the water profile is easily identified and well above the noise level. This shows the power of the multi-echo approach: where an ordinary profile experiment cannot resolve the profile from the noise, the multi-echo approach can using approximately the same acquisition time.

2.3 Determining the Droplet Size Distribution via Surface Relaxivity

The size determination of water droplets in an emulsion presented here is based on the combined diffusion and T2 relaxation time experiments [7, 8, 10, 11]. Diffusion experiment at short observation times may provide a measure of the average surface-to-volume ratio, S/V, as given by Mitra et.al. [13]

where \(\mathrm{D}\left(\mathrm{t}\right)\) is the time-dependent apparent restricted diffusion coefficient, \({\mathrm{D}}_{0}\) is the unrestricted diffusion coefficient in bulk fluid, \(\mathrm{t}\) is the observation time, and \(\mathrm{S}/\mathrm{V}\) is the surface-to-volume ratio. The latter term correlates to the droplet radius \(\mathrm{R}\) when assuming spherically shaped droplets. From a CPMG experiment, a distribution of relaxation times can be found for the water droplets, and the T2 value may relate to the product of the surface relaxivity, \(\uprho\), and \(\mathrm{S}/\mathrm{V}\)

Combining these two experiments, we get a distribution F(d) for the droplet diameter

where \({\upxi }_{\mathrm{i}}\) is the fractional intensity at a given diameter \(d_{i}\) and \({\overline{\mathrm{T}}}_{2}\) is the average value of the relaxation time found from the T2 distribution and\(\overline{\frac{S}{V}}\) is the surface-to-volume ratio as found from the diffusion experiment at short observation times. Higher order terms of the expansion in Eq. 5 are required in the case of small droplets. Alternatively, one can then perform a diffusion experiment at longer observation times, where the attenuation of the NMR signal can be written as

For this equation to be valid, the unrestricted root of mean squared displacement must be much larger than the droplet radius \(\mathrm{R}\)

It can then be shown that the distribution for the droplet diameter is written as

Here \(\overline{\frac{1}{{T }_{2}^{2}}}\) is the average value of the inverse of the square of the T2 distribution and \(\overline{{T }_{2}^{2}}\) is the average value of the square of the T2 distribution.

Equations 5 and 8 resolve the average value for the droplet size from the surface relaxivity term. Then it becomes possible to produce a distribution of droplet sizes by combining the PFG NMR diffusion experiment with the T2 relaxation time experiment. We have chosen to make use of the bipolar pulsed field gradient spin echo sequence [14] to reduce the impact from eddy current transients and having as short an observation time as possible. The latter is important for the Mitra expansion given in Eq. 5 to be valid. Also, in the attenuation of the echo signal due to the incrementing pulsed field gradients, we focus on the initial decay where we may apply the second cumulant approximation [15] and leaving out the higher order terms of the applied gradient when determining the apparent diffusion coefficient.

2.3.1 The Multi-Echo DSD Method

In Fig. 8, the combined SRD–pulsed field gradient spin echo (PFGSE)–STE–CPMG sequence is shown. The PFGSE part of the sequence is applied to determine the apparent diffusion coefficient which may relate to the droplet size according to Eq. 5. The STE part of the sequence is applied to suppress the signal from the oil phase by applying an appropriately long Δ. The CPMG part of the sequence is applied to enhance signal-to-noise ratio of the apparent diffusion experiment. Several echoes are acquired with several data points and the echoes are added. This improves the accuracy of the determination of the apparent diffusion coefficient significantly. This is demonstrated in Fig. 9 where the normalized single peak is compared with the normalized peak arising from the sum of 32 echoes plus a small shift, so they do not overlap.

The combined SRD–PFGSE–STE–CPMG sequence. The SRD part of the sequence excites the system using a SRD value that can be set shorter than five times Δ, the PFGSE part of the sequence performs a diffusion decoding of the NMR signal, STE part of the sequence with Δ allows the oil phase to relax back to thermal equilibrium and the CPMG part of the sequence improves the signal to noise

Using either 1 or 32 echoes, the procedure for determining the average droplet size and the DSD was repeated 20 times. The result is shown in Fig. 10, where the average droplet size found from a stable synthetic emulsion of 10% water cut is found to be much more stable using 32 echoes than 1 echo. The impact of this variation is demonstrated in the DSD, where the DSD is rather stable using 32 echoes while it varies a lot when using only 1 echo.

Comparing the determination of the average droplet size and its DSD when using 1 (C) and 32 (B) echoes in the SRD–PFGSE–STE–CPMG experiment. The experiment is repeated 20 times (A). Average droplet size is 18.1 ± 7.5 µm with 1 echo and 16.6 ± 1.5 µm using 32 echoes. The emulsion used was a synthetic emulsion using a high viscous model oil (Primol 352 from Brenntag Nordic A/S) mixed with a surfactant (Span 80 from Fluka) and water to form stable emulsion with low water cut 10%

2.4 The Slice Selective Multi-Echo DSD Method

There are situations where a bulk phase of water is present simultaneously with the emulsion. This could be an unstable emulsion where coalescence and separation have taken place leaving a bulk phase at the bottom and a residual emulsion phase at the top. In such a situation, it is not possible to determine the average droplet size using the sequence shown in Fig. 8, as the apparent diffusion coefficient will be a combination of the water from the emulsion phase and the bulk phase. Thus, the method for determining the average droplet size from the apparent diffusion coefficient will be biased toward larger droplet sizes due to the interference from the bulk diffusion.

To avoid the bulk phase, one may apply a shaped RF pulse in combination with a slice gradient to select the region of interest, i.e., a slice selective sequence as shown in Fig. 11. After having run the SRD–PFGSE–STE part of the sequence shown in Fig. 8, the 90-degree RF pulse brings the magnetization back into the detection plane (\(xy\)). The slice gradient ensures that the acquired signal arises from the emulsion phase only. The slice gradient and the frequency can then be chosen such that the emulsion phase is the only region contributing the acquired signal, and the oil phase has already vanished due to the long Δ delay. The slice gradient is so weak that there will be insignificant motional encoding and decoding as compared to the PFGSE part of the sequence.

3 Experimental

For characterizing emulsions, two types of butter were used: one full fat butter (FB), and one soft butter where rape seed oil (FS) was added as an ingredient. Both systems contained approximately 20% water, 78% fat, and 2% of macromolecules as protein and carbohydrates. The samples were contained in 18 mm NMR tubes and measured by a R4 20 MHz permanent magnet spectrometer supplied by Applied Magnetic Resonance Ltd., UK. The spectrometer has the option of running pulsed magnetic field gradients where the maximum gradient strength is approximately 350 Gauss/cm and the duration of the 90-degree RF pulse is 8 µs. The gradient pulse length was 1.0 ms, the eddy current dead time was 1.0 ms, and the inter-echo spacing of the PFGSE part of the sequence was 4 ms (τ = 2 ms). The eddy current dead time of 1 ms was applied for the whole range of applied gradient strengths up to 300 Gauss/cm. With the given gradient pulse duration and eddy current dead time, the observation time in the PFGSE part of the sequence is 2.7 ms, which is then used in Eq. 5 to find the average surface-to-volume ratio. The sample could be heated or cooled by flowing air around the sample tube in the spectrometer. The phase cycle applied in the stimulated echo part of the sequences is the one proposed by Fauth et.al [16] while keeping the phase of the 180-degree RF pulses fixed.

In the multi-profile sequence, a τ-value of 1.5 ms was applied and the strength of the read gradient (G2) was 4.3 Gauss/cm. As each echo was acquired with 128 data points using a filter of 100 kHz, this resulted in a resolution of 0.4 mm for the profile.

To verify the slice selective determination of the DSD, a sample of 50% bulk water and 50% butter was studied. The butter was in a liquid state at 4 °C to produce a homogeneous emulsion phase with a water content of approximately 20% on top of the bulk water phase.

Finally, the breakup of a foam was studied, which has different characteristics from a liquid–liquid dispersion and is an unstable emulsion. Pure water with small amounts of dodecylbenzene sulfonic acid and 0.5% Star San (Five Star Chemicals & Supply Inc.) was mixed with a propeller. The produced foam was placed in NMR tubes of 38 mm with a sample height of ~ 40 mm and immediately characterized in a 2 MHz permanent magnet spectrometer supplied by Applied Magnetic Resonance Ltd., UK. The RF probe was a high sensitivity probe supplied by MRF Innovations. This system also delivered magnetic field gradient pulses. The applied strength can be up to approximately 35 Gauss/cm.

4 Results and Discussion

Here, the multi-echo approach is applied on systems where it is vital to enhance the signal-to-noise ratio in particular for systems that are foam-like or become unstable, e.g., heating of butter from 20 °C to 30 °C. As examples for the characterization of emulsions, two types of butter have been applied, one full fat butter (FB) emulsion and one where rape seed oil has been added to the full fat butter phase to produce a butter (SB) emulsion that is more smooth at storage temperature (~ 4 °C).

4.1 Characterizing two types of butter

The full fat butter (FB) and soft butter (FS) were first characterized at 0 °C to determine the quantity of the water. Figure 3 shows the separated water signal that was quantified to 21.0% for the FB and 19.5 for the SB. This is close to the declaration of 20% water as extracted from the list of nutrients (water content = 100 minus percentage of nutrients per 100 g). A small variation in proton density between fat and water is disregarded as these values are estimates only. The samples were then heated to room temperature (20 °C) and the DSD was determined using the SRD–PFGSE–STE–CPMG sequence shown in Fig. 8. As the apparent diffusion at an observation time of 2.7 ms was found to be \(2.4\times {10}^{-10}\) m2/s (FB) and \(1.6\times {10}^{-10}\) m2/s (SB), the root mean squared distance is much less than the root mean squared distance of bulk diffusion. Consequently, the asymptotic limit given in Eq. 9 was applied to find the average droplet size and to determine the DSD from the Inverse Laplace Transform of the CPMG attenuation. With the measured apparent diffusion coefficients, the average droplet sizes were then found to be 3.7 ± 0.4 µm for FB and 3.0 ± 0.3 µm for SB. These values are in accordance with average droplet size measurements (d33) reported elsewhere [17, 18]. After determination of the DSD of the FB and SB, the temperature of the air flow was set to 30 °C, and the water profiles were determined repeatedly for an hour. Due to the multi-echo profile approach with the recording of 60 echoes, the number of scans could be set to 4 and the SRD to 1 s. Then the profiles could be recorded every 27 s for FB (Δ = 1.5 s) and every 31 s for SB (Δ = 2 s).

In Fig. 12, the development of the butter emulsions during heating from 20 °C to 30 °C is shown. The upper plots (C) show the initial profile versus the final profile after 1 h of heating. While FB remains unaltered in water content along the direction of gravity, the SB changes shape of the water profile significantly. After 1 h, there is a 10 mm region with a water content of ~ 45% while the water content is negligible above this region.

Two butter samples—(left side) full fat butter (FB) and (right side) soft butter (SB)—characterized at 20 °C and during heating up to 30 °C. A shows the measured water profile at 20 °C (initial) and after heating up to 30 °C (final). B shows the evolution of the water profiles as contour plots during heating from 20 °C to 30 °C (final). C shows the measured DSD at 20 °C (initial) and after heating up to 30 °C (final)

The evolution of the profiles is shown as two-dimensional contour plots in the middle (B) of Fig. 12. Here, it is seen that the FB does not change its water profile during the 1-h acquisition (135 profiles) while there is a clear evolution of SB as it is heated (120 profiles acquired in one our). Up to 15 min, the approximate time it takes to heat the sample, the profile remains unaltered, then the profile intensity starts to increase in the lower region of the emulsion and consequently that water intensity becomes less in the upper region of the emulsion. After 1 h, the water content has increased to around 45% in the lower region of the emulsion with negligible water above this region. The upper region resembles the oil phase while the lower region does not express a water bulk phase as the local viscosity is higher than that of pure water.

The two samples were then cooled down to 20 °C and the DSD was re-measured. The apparent diffusion coefficients were found to be 1.2 10–9 m2/s (FB) and 2.0 10–9 m2/s (SB), and to determine the DSD, the short observation time approach was employed. With the measured apparent diffusion coefficients, the average droplet sizes were then found to be 7.6 ± 0.7 µm for FB and 56.0 ± 5.6 µm for SB. In the lower plots (C) of Fig. 12, the DSD acquired at 20 °C (initial) and heated to 30 °C for 1 h (final) are shown. For the SB, both the water profile and the DSD indicate sedimentation and coalescence of the droplets to form bigger droplets. However, the value of the water cut of 30 ~ 45% from the bottom up to 10 mm indicates that a more densely packed layer of water droplets is formed where the droplets are not necessarily spherical. For the FB, the water profile indicates no change while the DSD indicates that coalescence is occurring but has not yet formed droplets large enough to observe a change in the water profile due to sedimentation.

4.2 Characterizing Emulsions in the Presence of a Bulk Phase

There are situations of a residual emulsion where the emulsion only partly separates into bulk phases [19, 20] and has residual water droplets in the oil phase. A multi-echo approach for measuring the residual emulsion has been proposed in Sect. 2.4. To verify the approach, a sample with liquid butter on the top of a bulk water phase was measured. For comparison, a sample of liquid butter was measured as well. The slice selective method was used to determine the DSD in addition to the method without slice selection. In Fig. 13, the normalized DSD is shown for the two samples. The solid line represents the DSD determined with the slice selective method on the butter/water sample while the dashed line represents the DSD determined with the method without slice selection on butter only. The distributions do not overlap exactly but they are very similar in both position and width of the DSD. One may conclude that the bulk water does not contribute significantly to the DSD. By comparison, the DSD achieved with the method without slice selection on the butter/water sample is shown (‘x’ marked). Here, the DSD is shifted toward much larger droplets This is expected since the apparent measured diffusion will have contributions from both the bulk diffusion and restricted diffusion and will consequently be biased toward bigger droplets.

There are other ways to target the water droplets in the oil while there is a bulk phase at the bottom. One way could be to apply the PFGSTE diffusion experiment with observation time of 1 s. Then if the water droplets are of the order of 10 µm, one could suppress the bulk water as the apparent diffusion coefficient will be of the order of 10–9 m2/s while the apparent diffusion coefficient of water confined in the droplets will be of the order of 10–11 m2/s. The root mean squared displacement for bulk water with an observation time of 1 s is more than 100 µm, and then the asymptotic limit is reached for droplets of 10 µm size and can be used to determine DSD while the bulk water signal is suppressed.

Diffusion weighted profile experiments can also be applied to determine the average droplet sizes of the emulsion in the presence of bulk water at the bottom [7].

4.3 Characterization of Foam

The breakup of foam could be a separation of air bubbles from a water phase, and the speed at which this takes place can be high. Then it is crucial to have a fast method for determining the water profile with proper signal-to-noise ratio. A foam was made according to the description provided in Sect. 4, and profiles of the water signal were recorded every 16 s for 7 min using the 2 MHz spectrometer with sample diameter and height of 40 mm.

Figure 14 shows the measured initial water profile and final water profile after 6 min, and the evolution of the water profiles as a contour plot. As it took some time to place the foam in the NMR tube and start the profile measurements, the first profile was measured approximately 45 s after the end of foam production. Already by 45 s, a small peak starts to evolve at the bottom indicating a fast breakup of the foam. In the contour plot in Fig. 14, less than 5 min elapsed to accumulate the bulk water phase at the bottom (< 10 mm) while there were some minor quantities of foam from 10 and up to 20 mm.

5 Conclusion

New methods for characterizing emulsions have been presented along with example applications to determine the evolution of the vertical distribution of water, and the water droplet size distribution. These methods apply the multi-echo approach to significantly improve signal to noise in the NMR experiments for systems that are more unstable or foam-like. For these unstable emulsions with rapidly evolving phase separation, such as emulsions undergoing heating, the spoiler recovery delay– stimulated echo–Carr Purcell Meiboom Gill (SRD–PFGSE–STE–CPMG) sequence accurately determined the evolving water profile. The methods were also used to determine the dispersed phase DSD in the presence of the fully separated bulk phase layer. These methods provide new applications that use NMR to characterize emulsions with low water content, low viscosity oil or being unstable.

Data and Materials Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request

References

K.J. Packer, C. Rees, Pulsed NMR studies of restricted diffusion .I. Droplet size distributions in emulsions. J. Colloid. Interface. Sci. 40(2), 206–218 (1972)

B. Balinov, O. Söderman, T. Wärnheim, Determination of water droplet size in margarines and low-calorie spreads by nuclear magnetic resonance self-diffusion. J. Am. Oil Chemist. Soc. 71(5), 513–518 (1994)

A.A. Peña, G.J. Hirasaki, Enhanced characterization of oilfield emulsions via NMR diffusion and transverse relaxation experiments. Adv. Coll. Interface. Sci. 105(1–3), 103–150 (2003)

C.P. Aichele et al., Water in oil emulsion droplet size characterization using a pulsed field gradient with diffusion editing (PFG-DE) NMR technique. J. Colloid Interface Sci. 315(2), 607–619 (2007)

J.P.M. van Duynhoven et al., Scope of droplet size measurements in food emulsions by pulsed field gradient NMR at low field. Magn. Reson. Chem. 40(13), S51–S59 (2002)

G. Guthausen, Analysis of food and emulsions. TrAC, Trends Anal. Chem. 83, 103–106 (2016)

G. Sørland, Dynamic Pulsed-field-gradient NMR, Springer Series in Chemical Physiscs 110 (Springer, Heidelberg, 2014)

Sørland, G. H. Characterization of Emulsions by PFG-NMR. In The 10th International Bologna Conference on Magnetic Resonance in Porous Media, Sept. 12−16, 2010, Leipzig, Germany; pp 27−31

E.O. Fridjonsson et al., Optimized droplet sizing of water-in-crude oil emulsions using nuclear magnetic resonance. Energy Fuels 28, 1756–1764 (2014)

N.V.D.T. Opedal, G. Sørland, J. Sjöblom, J Methods for droplet size distribution determination of water-in-oil emulsions using low-field NMR. Diffusion-FundamentalsOrg 9(7), 1–29 (2009)

Debora Salomon Marques, Geir Sørland, simone less, regis vilagines, the application of PFG-NMR methods to characterize the efficiency of separation of water-in-crude oil emulsions. J. Colloid Interface Sci. 512, 361–368 (2018)

Slichter, C.P., Principles of Magnetic Resonance. 3rd enlarged and updated edition ed. 1990: Springer Verlag.

P.P. Mitra, P.N. Sen, L.M. Schwartz, Short-time behavior of the diffusion coefficient as a geometrical probe of porous media. Phys. Rev. B 47(14), 8565–8574 (1993)

G.H. Sørland, D. Aksnes, L. Gjerdåker, A pulsed field gradient spin-echo method for diffusion measurements in the presence of internal gradients. J. Magn. Reson. 137(2), 397–401 (1999)

J. Stepišnik, Validity limits of gaussian approximation in cumulant expansion for diffusion attenuation of spin echo. Phys. B 270(1–2), 110–117 (1999)

J.M. Fauth et al., (1986) Elimination of unwanted echoes and reduction of dead time in three-pulse electron spin-echo spectroscopy. J. Magnet. Res. 66(1), 74–85 (1969)

I. Fourel et al., Determination of water droplet size distributions by low resolution PFG-NMR II “solid” emulsions. J. Colloid Interface Sci. 169, 119–124 (1995)

K. Van Lent et al., Determination of water droplet size distribution in butter: Pulsed field gradient NMR in comparison with confocal scanin laser microscopy. Int. Dairy J. 18, 12–22 (2008)

Tomas Nordeide Hjartnes, Geir humborstad Sørland, Sébastien Simon, and Johan Sjöblom, demulsification of crude oil emulsions tracked by pulsed field gradient (PFG) Nuclear Magnetic Resonance (NMR). Part I: Chem. Demulsification, Industrial. Eng. Chem. Res. 58(6), 2310–2323 (2019)

Hjartnes, Tomas., Mhatre, Sameer., Gao, Bicheng., Sørland, Geir ., Simon, Sébastien ., Sjöblom, Johan., (2019) Demulsification of crude oil emulsions tracked by pulsed field gradient NMR. Part II: Influence of chemical demulsifiers in external AC electric field. Colloids and Surfaces A: Physicochemical and Engineering Aspects. 586. 124188.

Funding

Open access funding provided by NTNU Norwegian University of Science and Technology (incl St. Olavs Hospital - Trondheim University Hospital). There is no external funding supporting this work.

Author information

Authors and Affiliations

Contributions

Corresponding author wrote the main manuscript text and prepared all figures. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors have no competing interests as defined by Springer, or other interests that might be perceived to influence the results and/or discussion reported in this paper.

Ethical Approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sørland, G.H., Less, S., Alkhabbaz, S. et al. Improved Methods for Characterizing Emulsions by Low-Resolution Nuclear Magnetic Resonance via Surface Relaxation and One-Dimensional Images. Appl Magn Reson 54, 619–635 (2023). https://doi.org/10.1007/s00723-023-01535-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00723-023-01535-w