Abstract

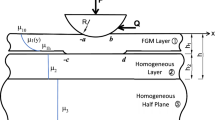

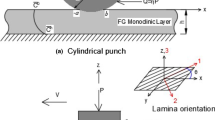

The object of this work was to describe the behavior of sliding friction on gradient nanostructured material coating by considering the material gradient and size effect. A multi-layer couple stress elasticity model is proposed to simulate gradient nanostructured material coating with arbitrarily varying modulus. The singular integral equation of second kind is obtained to describe the sliding friction problem for gradient nanostructured material coating indented by a cylindrical punch with the help of the Fourier integral transform technology and transfer matrix method. The Gauss-Jacobi quadrature formula is applied to solve the singular integral equation numerically. A parametric study for the influence of characteristic material length, friction coefficient, and material gradient is conducted to investigate the sliding frictional contact problem of gradient nanostructured material coating. The results provide a way to improve the mechanical response in frictional contact by using the gradient nanostructured material coating.

Similar content being viewed by others

References

Yang, Y.T., Ekinci, K.L., Huang, X., Schiavone, L.M., Roukes, M.L., Zorman, C.A., Mehregany, M.: Monocrystalline silicon carbide nanoelectromechanical systems. Appl. Phys. Lett. 78(2), 162–164 (2001). https://doi.org/10.1063/1.1338959

Liao, F., Girshick, S.L., Mook, W.M., Gerberich, W.W., Zachariah, M.R.: Superhard nanocrystalline silicon carbide films. Appl. Phys. Lett. 86(17), 171913 (2005). https://doi.org/10.1063/1.1920434

Bei, P., Locascio, M., Zapol, P., Li, S., Mielke, S.L., Schatz, G.C., Espionsa, H.D.: Measurements of near-ultimate strength for multiwalled carbon nanotubes and irradiation-induced crosslinking improvements. Nat. Nanotechnol. 3(10), 626–631 (2008). https://doi.org/10.1038/nnano.2008.211

Dong, Q., Liu, W.K., Zheng, Q.: Concurrent quantum/continuum coupling analysis of nanostructures. Comput. Method. Appl. M. 197(41–42), 3291–3323 (2008). https://doi.org/10.1016/j.cma.2008.01.007

Bisheh, H.K., Wu, N.: Analysis of wave propagation characteristics in piezoelectric cylindrical composite shells reinforced with carbon nanotubes. Int. J. Mech. Sci. 145, 200–220 (2018). https://doi.org/10.1016/j.ijmecsci.2018.07.002

Bisheh, H.K., Wu, N.: Wave propagation in smart laminated composite cylindrical shells reinforced with carbon nanotubes in hygrothermal environments. Compos. Part B-Eng. 162, 219–241 (2019). https://doi.org/10.1016/j.compositesb.2018.10.064

Lu, K.: Making strong nanomaterials ductile with gradients. Science 345(6203), 1455–1456 (2014). https://doi.org/10.1126/science.1255940

Huang, S.Q., Tang, P.J., Hou, P.F., Zhang, W.H.: A method of coating analysis based on cylindrical indenter loading on coated structure. Acta Mech. 234(5), 2223–2267 (2023). https://doi.org/10.1007/s00707-022-03434-w

Çömez, İ: Frictional moving contact problem between a functionally graded monoclinic layer and a rigid punch of an arbitrary profile. Acta Mech. 233(4), 1435–1453 (2022). https://doi.org/10.1007/s00707-022-03178-7

Yilmaz, K.B., Sabuncuoglu, B., Yildirim, B.: Investigation of stress distributions between a frictional rigid cylinder and laminated glass fiber composites. Acta Mech. 232, 4379–4403 (2021). https://doi.org/10.1007/s00707-021-03021-5

Çömez, İ: Dynamic contact problem for a viscoelastic orthotropic coated isotropic half plane. Acta Mech. 233(12), 5241–5253 (2022). https://doi.org/10.1007/s00707-022-03366-5

Liu, Z., Zhang, H., Feng, H., Yan, Z., Dong, P.: Effects of surface gradient nanostructuring on the fatigue behavior of the friction stir welded AlZnMgCu alloy. Mater. Lett. 252, 329–332 (2019). https://doi.org/10.1016/j.matlet.2019.05.120

Liu, C., Liu, D., Zhang, X., Ao, N., Xu, X., Liu, D., Yang, J.: Fretting fatigue characteristics of Ti-6Al-4V alloy with a gradient nanostructured surface layer induced by ultrasonic surface rolling process. Int. J. Fatigue 125, 249–260 (2019). https://doi.org/10.1016/j.ijfatigue.2019.03.042

Zhao, Y.Y., Liang, M.T., Liu, S.J., Zhang, W.H.: Enhanced fatigue property by fabricating a gradient nanostructured surface layer in a reduced-activation steel. Prog. Nat. Sci-Mater. 32, 385–391 (2022). https://doi.org/10.1016/j.pnsc.2022.03.009

Wei, Y., Du, Y., Shu, S., Zhu, C.: Size effect characterization for nanostructured material in nanoindentation test. Mat. Res. Soc. Symp. Proc. 788, L8.2 (2003). https://doi.org/10.1557/PROC-788-L8.2

Ma, Q., Clarke, D.R.: Size dependent hardness of silver single crystals. J. Mater. Res. 10(4), 853–863 (1995). https://doi.org/10.1557/jmr.1995.0853

Zhao, M., Slaughter, W.S., Li, M., Mao, S.X.: Material-length-scale-controlled nanoindentation size effects due to strain-gradient plasticity. Acta Mater. 51(15), 4461–4469 (2003). https://doi.org/10.1016/S1359-6454(03)00281-7

Durst, K., Backes, B., Franke, O., Göken, M.: Indentation size effect in metallic materials: modeling strength from pop-in to macroscopic hardness using geometrically necessary dislocations. Acta Mater. 54(9), 2547–2555 (2006). https://doi.org/10.1016/j.actamat.2006.01.036

Pharr, G.M., Herbert, E.G., Gao, Y.: The Indentation size effect: a critical examination of experimental observations and mechanistic interpretations. Annu. Rev. Mater. Res. 40(1), 271–292 (2010). https://doi.org/10.1146/annurev-matsci-070909-104456

Raineesh, K.P., Prasad, K.E.: Indentation size effect in magnesium single crystals of different crystallographic orientations. J. Mater. Res. 37(3), 728–736 (2022). https://doi.org/10.1557/s43578-021-00480-3

Mindlin, R.D., Tiersten, H.F.: Effects of couple-stresses in linear elasticity. Arch. Ration. Mech. Anal. 11, 415–448 (1962). https://doi.org/10.1007/BF00253946

Zisis, T., Gourgiotis, P.A., Baxevanakis, K.P., Georgiadis, H.G.: Some basic contact problems in couple stress elasticity. Int. J. Solids Struct. 51(11–12), 2084–2095 (2014). https://doi.org/10.1016/j.ijsolstr.2014.02.016

Zisis, T., Gourgiotis, P.A., Corso, F.D.: A contact problem in couple stress thermoelasticity: the indentation by a hot flat punch. Int. J. Solids Struct. 63, 226–239 (2015). https://doi.org/10.1016/j.ijsolstr.2015.03.002

Gourgiotis, P., Zisis, T.: Two-dimensional indentation of microstructured solids characterized by couple-stress elasticity. J. Strain. Anal. Eng. 51(4), 318–331 (2016). https://doi.org/10.1177/0309324715611524

Zisis, T., Gourgiotis, P.A., Georgiadis, H.G.: Contact mechanics in the framework of couple stress elasticity. Gener Models Non-Class Approach. Complex Mater. 2, 279–306 (2018). https://doi.org/10.1007/978-3-319-77504-3_14

Zisis, T.: Burmister’s problem extended to a microstructured layer. J. Mech. Mater. Struct. 13(2), 203–223 (2018). https://doi.org/10.2140/jomms.2018.13.203

Karuriya, A.N., Bhandakkar, T.K.: Plane strain indentation on finite thickness bonded layer in couple stress elasticity. Int. J. Solids Struct. 108, 275–288 (2017). https://doi.org/10.1016/j.ijsolstr.2016.12.027

Song, H.X., Ke, L.L., Wang, Y.S.: Sliding frictional contact analysis of an elastic solid with couple stresses. Int. J. Mech. Sci. 133, 804–816 (2017). https://doi.org/10.1016/j.ijmecsci.2017.09.037

Çömez, I., El-Borgi, S.: Sliding frictional contact problem of a layer indented by a rigid punch in couple stress elasticity. Math. Mech. Solids 28(3), 730–747 (2023). https://doi.org/10.1177/10812865221080551

Çömez, İ, El-Borgi, S.: Frictional contact problem of a coated half plane pressed by a rigid punch with coupled stress elasticity. Arch. Appl. Mech. (2023). https://doi.org/10.1007/s00419-023-02452-x

Song, H.X., Ke, L.L., Wang, Y.S., Jiang, H.: Two-dimensional frictionless contact of a coated half-plane based on couple stress theory. Int. J. Appl. Mech. 10(05), 1850049 (2018). https://doi.org/10.1142/s1758825118500497

Gourgiotis, P.A., Zisis, T., Giannakopoulos, A.E., Georgiadis, H.G.: The Hertz contact problem in couple-stress elasticity. Int. J. Solids Struct. 168, 228–237 (2019). https://doi.org/10.1016/j.ijsolstr.2019.03.032

Wang, Y., Zhang, X., Shen, H., Liu, J., Zhang, B.: Couple stress-based 3D contact of elastic films. Int. J. Solids Struct. 191, 449–463 (2020). https://doi.org/10.1016/j.ijsolstr.2020.01.005

Peng, C., Zeng, F., Yuan, B., Wang, Y.: An approximate model to describe the size effects of spherical contact tests, based on a modified couple stress elasticity. Acta Mech. 232(11), 4363–4377 (2021). https://doi.org/10.1007/s00707-021-03054-w

Li, P., Liu, T.J.: The size effect in adhesive contact on a gradient nanostructured coating. Nanotechnology 32(23), 235704 (2021). https://doi.org/10.1088/1361-6528/abe9e6

Li, P., Liu, T.J.: Axisymmetric adhesive contact of multi-layer couple-stress elastic structures involving graded nanostructured materials. Appl. Math. Model. 111, 501–520 (2022). https://doi.org/10.1016/j.apm.2022.06.044

Wongviboonsin, W., Le, T.M., Lawongkerd, J., Gourgiotis, P.A., Rungamornrat, J.: Microstructural effects on the response of a multi-layered elastic substrate. Int. J. Solids Struct. 241, 111394 (2022). https://doi.org/10.1016/j.ijsolstr.2021.111394

Wongviboonsin, W., Gourgiotis, P.A., Van, C.N., Limkatanyu, S., Rungamornrat, J.: Size effects in two-dimensional layered materials modeled by couple stress elasticity. Front. Struct. Civ. Eng. 15(2), 425–443 (2021). https://doi.org/10.1007/s11709-021-0707-y

Nikolopoulos, S., Gourgiotis, P.A., Zisis, T.: Analysis of the tilted shallow wedge problem in couple-stress elasticity. J. Elasticity. 144(2), 205–221 (2021). https://doi.org/10.1007/s10659-021-09844-6

Zisis, T.: Anti-plane loading of microstructured materials in the context of couple stress theory of elasticity: half-planes and layers. Arch. Appl. Mech. 88, 97–110 (2018). https://doi.org/10.1007/s00419-017-1277-2

Krenk, S.: On quadrature formulas for singular integral equations of the first and the second kind. Q. Appl. Math. 33(3), 225–232 (1975). https://doi.org/10.1090/qam/448967

Acknowledgements

The authors are grateful for the financial support by the National Natural Science Foundation of China (Project no. 12062019) and by the Natural Science Foundation of Inner Mongolia (Project no. 2020MS01022).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, P., Liu, TJ. Frictional sliding of cylindrical punch on gradient nanostructured material coating. Acta Mech 234, 6589–6606 (2023). https://doi.org/10.1007/s00707-023-03725-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-023-03725-w