Abstract

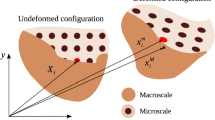

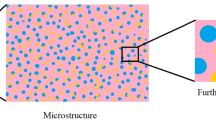

Porous elastomeric materials have wide applications in aerospace, electronics, biomedicine, and other fields. However, closed-form analytical solutions for macroscopic strain energy density of high-order porous elastomers have not been well resolved. In this work, we propose a new approach for constitutive modeling of porous elastomeric materials under large deformation, mainly relying on expressing the macroscopic strain energy density function of the composite material as a function of the strain energy of elastomer matrix via a strain-amplification relation. Such amplification relation, as constructed through a thick-walled sphere volume element model, is utilized in a mapping of the macroscopic deformation to the average deformation of elastomer matrix in the sense of the first invariant by a scaling coefficient–amplification factor, which depends on both the initial void volume fraction and the macroscopic volumetric deformation ratio. The analytical stress–stretch relation is then derived and given in simple form of only three material parameters. Discussions on how the factors affect the amplification factor are made and the behavior of the model is shown in several deformation simulations. The prediction results of this model are compared with those of existing models, and reasonable agreement is obtained.

Similar content being viewed by others

References

Ba, A., Kovalenko, A., Aristegui, C., Mondain-Monval, O., Brunet, T.: Soft porous silicone rubbers with ultra-low sound speeds in acoustic metamaterials. Sci. Rep. 7, 40106 (2017)

Xu, Y., Sun, B., Ling, Y., Fei, Q., Chen, Z., Li, X., Guo, P., Jeon, N., Goswami, S., Liao, Y.: Multiscale porous elastomer substrates for multifunctional on-skin electronics with passive-cooling capabilities. Proc. Natl. Acad. Sci. 117, 205–213 (2020)

Gerecht, S., Townsend, S.A., Pressler, H., Zhu, H., Nijst, C.L., Bruggeman, J.P., Nichol, J.W., Langer, R.: A porous photocurable elastomer for cell encapsulation and culture. Biomaterials 28, 4826–4835 (2007)

Clough, E.C., Plaisted, T.A., Eckel, Z.C., Cante, K., Hundley, J.M., Schaedler, T.A.: Elastomeric microlattice impact attenuators. Matter 1, 1519–1531 (2019)

Xiong, J., Thangavel, G., Wang, J., Zhou, X., Lee, P.S.: Self-healable sticky porous elastomer for gas-solid interacted power generation. Sci. Adv. 6, eabb4246 (2020)

Jiang, Y., Wang, Q.: Highly-stretchable 3D-architected mechanical metamaterials. Sci. Rep. 6, 34147 (2016)

Traugutt, N.A., Mistry, D., Luo, C., Yu, K., Ge, Q., Yakacki, C.M.: Liquid-crystal-elastomer-based dissipative structures by digital light processing 3D printing. Adv. Mater., e2000797 (2020)

Wirth, D.M., Jaquez, A., Gandarilla, S., Hochberg, J.D., Church, D.C., Pokorski, J.K.: Highly Expandable Foam for Lithographic 3D Printing. ACS Appl Mater Interfaces 12, 19033–19043 (2020)

Mu, X., Bertron, T., Dunn, C., Qiao, H., Wu, J., Zhao, Z., Saldana, C., Qi, H.J.: Porous polymeric materials by 3D printing of photocurable resin. Mater. Horiz. 4, 442–449 (2017)

Hensleigh, R.M., Cui, H., Oakdale, J.S., Ye, J.C., Campbell, P.G., Duoss, E.B., Spadaccini, C.M., Zheng, X., Worsley, M.A.: Additive manufacturing of complex micro-architected graphene aerogels. Mater. Horiz. 5, 1035–1401 (2018)

Lewis, J.A.: Direct ink writing of 3D functional materials. Adv. Func. Mater. 16, 2193–2204 (2006)

Feng, W., Christensen, R.: Nonlinear deformation of elastomeric foams. Int. J. Non Linear Mech. 17, 355–367 (1982)

Danielsson, M., Parks, D., Boyce, M.: Constitutive modeling of porous hyperelastic materials. Mech. Mater. 36, 347–358 (2004)

Hang-Sheng, H., Abeyaratne, R.: Cavitation in elastic and elastic-plastic solids. J. Mech. Phys. Solids 40, 571–592 (1992)

Guo, Z., Caner, F., Peng, X., Moran, B.: On constitutive modelling of porous neo-Hookean composites. J. Mech. Phys. Solids 56, 2338–2357 (2008)

Chen, Y., Guo, W., Yang, P., Zhao, J., Guo, Z., Dong, L., Zhong, Z.: Constitutive modeling of neo-Hookean materials with spherical voids in finite deformation. Extreme Mech. Lett. 24, 47–57 (2018)

Drozdov, A.D., Christiansen, J.D.: Modeling the elastic response of polymer foams at finite deformations. Int. J. Mech. Sci. 171, 105398 (2020)

Hashin, Z.: Large isotropic elastic deformation of composites and porous media. Int. J. Solids Struct. 21, 711–720 (1985)

Castañeda, P.P.: Exact second-order estimates for the effective mechanical properties of nonlinear composite materials. J. Mech. Phys. Solids 44, 827–862 (1996)

Lopez-Pamies, O., Ponte Castañeda, P.: Second-order estimates for the macroscopic response and loss of ellipticity in porous rubbers at large deformations. J. Elastic., 76, 247–287 (2004)

Shrimali, B., Lefèvre, V., Lopez-Pamies, O.: A simple explicit homogenization solution for the macroscopic elastic response of isotropic porous elastomers. J. Mech. Phys. Solids 122, 364–380 (2019)

Gent, A.N.: A new constitutive relation for rubber. Rubber Chem. Technol. 69, 59–61 (1996)

Arruda, E.M., Boyce, M.C.: A three-dimensional constitutive model for the large stretch behavior of rubber elastic materials. J. Mech. Phys. Solids 41, 389–412 (1993)

Singh, V., Racherla, V.: Deformation behavior of fluid-filled porous elastomers: analytical estimates and validation. J. Mech. Phys. Solids 163, 104835 (2022)

Mullins, L., Tobin, N.: Theoretical model for the elastic behavior of filler-reinforced vulcanized rubbers. Rubber Chem. Technol. 30, 555–571 (1957)

Govindjee, S., Simo, J.: A micro-mechanically based continuum damage model for carbon black-filled rubbers incorporating Mullins’ effect. J. Mech. Phys. Solids 39, 87–112 (1991)

Jörgen S. Bergström, M.C.B.: Mechanical Behavior of Particle Filled Elastomers, Rubber Chemistry and Technology, 72 (1999) 633–656.

Qi, M.C.B.H.J.: Constitutive model for stretch-induced softening of the stress-stretch behavior of elastomeric materials. J. Mech. Phys. Solids 52, 2187–2205 (2004)

Hill, R.: On constitutive macro-variables for heterogeneous solids at finite strain, Proceedings of the Royal Society of London. A. Math. Phys. Sci. 326, 131–147 (1972)

Gurson, A.L.: Continuum theory of ductile rupture by void nucleation and growth: part I—yield criteria and flow rules for porous ductile media. J. Eng. Mater. Technol. 99, 2–15 (1977)

Lopez-Pamies, O., Nakamura, T., Idiart, M.I.: Cavitation in elastomeric solids: II—onset-of-cavitation surfaces for Neo-Hookean materials. J. Mech. Phys. Solids 59, 1488–1505 (2011)

Acknowledgements

This research was supported by National Natural Science Foundation of China (12202190), Joint Fund of Advanced Aerospace Manufacturing Technology Research (U1937601), National Natural Science Foundation of China for Creative Research Groups (No. 51921003), Outstanding Postdoctoral program in Jiangsu Province (2022ZB233), and Nanjing University of Aeronautics and Astronautics (90YAH21131).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Danielsson–Parks–Boyce (DPB) model

According to Danielsson et al. [13], in order to obtain the macroscopic Cauchy stress tensor \({\overline{\mathbf{T}}}\), one first needs to calculate the macroscopic principal Cauchy stress tensor \(\left[ {{\tilde{\overline{\mathbf{T}}}}} \right]_{i}\) through

where \({{\partial W^{\text{m}} } \mathord{\left/ {\vphantom {{\partial W^{\text{m}} } {\partial I_{1}^{\text{m}} }}} \right. \kern-0pt} {\partial I_{1}^{\text{m}} }}\) is given by

and \({{\partial I_{1}^{\text{m}} } \mathord{\left/ {\vphantom {{\partial I_{1}^{\text{m}} } {\partial \overline{\lambda }_{i} }}} \right. \kern-0pt} {\partial \overline{\lambda }_{i} }}\) is given by

After calculating \(\left[ {{\tilde{\overline{\mathbf{T}}}}} \right]_{i}\), the macroscopic Cauchy stress tensor \({\overline{\mathbf{T}}}\) is then obtained through the rotation of \({\tilde{\overline{\mathbf{T}}}}\) by \({\overline{\mathbf{Q}}}\), i.e., \({\overline{\mathbf{T}}} = {\overline{\mathbf{Q}}}{\overline{\tilde{\mathbf{T}}}}\overline{Q}^{\text{T}}\), where \({\overline{\mathbf{Q}}}\) is the orthogonal rotation tensor that decomposes \({\overline{\mathbf{B}}}\) into a diagonal tensor \({\tilde{\overline{\mathbf{B}}}}\) via \({\overline{\mathbf{B}}} = \overline{Q}\overline{\tilde{B}}\overline{Q}^{\text{T}}\). For the DPB model, it is observed that the integrand of Eq. (15) is rather complex and \(\left[ {{\tilde{\overline{\mathbf{T}}}}} \right]_{i}\) may only be solved through numerical integration methods. In addition, the lack of an explicit relationship between the macroscopic Cauchy stress tensor and deformation makes it inconvenient for application, especially in nonlinear problems (e.g., indentation). In this work, we use ten-order Gaussian quadrature for each of the integration variables \(\left\{ {\Theta ,\Phi ,R} \right\}\) to generate data for comparison with the results obtained from our model (Fig. 2).

Appendix B: Jacobian matrix

The consistent, closed-form hyperelastic tangent operator (the Jacobian matrix), \({\overline{\mathbf{C}}}\), can be obtained by evaluating

where \(\overline{C}_{ijkl}\) is the tangent operator. To simplify derivations, we first make some useful definitions, i.e.,

Then using the identities

we obtain

Considering \(\overline{J}\overline{T}_{ij}\) can be expressed as

it is straightforward to obtain the derivative of \(\overline{J}\overline{T}_{ij}\) with respect to \(\overline{F}_{km}\) as

Substituting Eq. (20) and Eq. (21) in Eq. (23) gives the final expression of \({{\partial \left( {\overline{J}\overline{T}_{ij} } \right)} \mathord{\left/ {\vphantom {{\partial \left( {\overline{J}\overline{T}_{ij} } \right)} {\partial \overline{F}_{km} }}} \right. \kern-0pt} {\partial \overline{F}_{km} }}\); for brevity, we do not write it down here. Once the expression of \({{\partial \left( {\overline{J}\overline{T}_{ij} } \right)} \mathord{\left/ {\vphantom {{\partial \left( {\overline{J}\overline{T}_{ij} } \right)} {\partial \overline{F}_{km} }}} \right. \kern-0pt} {\partial \overline{F}_{km} }}\) is known, one can immediately obtain \(\overline{C}_{ijkl}\) by using Eq. (18).

Appendix C: Shrimali–Lefèvre–Lopez-Pamies (SLLP) model

According to Shrimali et al. [21], the approximate solution for \(\overline{W}\) for the general case of porous elastomers with any choice of stored-energy function \(\psi_{\text{m}}\) for the elastomeric matrix is given by

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Q., Shi, Y. & Gao, C. An analytical stress–stretch relation for porous elastomeric materials with large deformation. Acta Mech 234, 6069–6081 (2023). https://doi.org/10.1007/s00707-023-03697-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-023-03697-x