Abstract

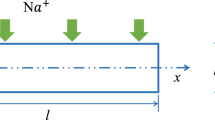

An analytical calculation of diffusion-induced stress in a layered electrode composed of a current collector and a nanocomposite active plate for lithium-ion batteries is proposed. The active plate of the bilayer nanocomposite anode is reinforced by graphene nanosheets (GNSs), whose mechanical properties are predicted by the Mori–Tanaka micromechanical method. The reinforced GNSs will make agglomeration in the matrix, which has a certain obstacle to reducing the overall stress level of the anode. The size effect of a single GNS also affects the corresponding material properties, and the Halpin–Tsai equation can be used to acquire the reliable prediction results. The analytical solutions of the diffusion-induced stress and strain of the nanocomposite anode under galvanostatic charging operation are derived, and then, the elastoplastic stress distribution in the interior of the anode is obtained. In addition, the effect of GNS’s thickness on the migration of the plastic interface is also evaluated.

Similar content being viewed by others

References

Scrosati, B., Hassoun, J., Sun, Y.K.: Lithium-ion batteries. A look into the future. Energy Environ. Sci. 4, 3287–3295 (2011). https://doi.org/10.1039/C1EE01388B

Zuo, X., Zhu, J., Müller-Buschbaum, P., Cheng, Y.J.: Silicon based lithium-ion battery anodes: a chronicle perspective review. Nano Energy 31, 113–143 (2017). https://doi.org/10.1016/j.nanoen.2016.11.013

McDowell, M.T., Lee, S.W., Nix, W.D., Cui, Y.: 25th anniversary article: understanding the lithiation of silicon and other alloying anodes for lithium-ion batteries. Adv. Mater. 25, 4966–4985 (2013). https://doi.org/10.1002/adma.201301795

Wang, C.M., Li, X., Wang, Z., et al.: In situ TEM investigation of congruent phase transition and structural evolution of nanostructured silicon/carbon anode for lithium ion batteries. Nano Lett. 12, 1624–1632 (2012). https://doi.org/10.1021/nl204559u

Feng, H.P., et al.: Carbon-based core–shell nanostructured materials for electrochemical energy storage. J. Mater. Chem. A 6, 7310–7337 (2018). https://doi.org/10.1039/C8TA01257A

Yen, Y.C., et al.: Study on solid-electrolyte-interphase of Si and C-coated Si electrodes in lithium cells. J. Electrochem. Soc. 156, A95 (2009). https://doi.org/10.1149/1.3032230

Wang, H., Liu, Y., Luo, S., et al.: Effect of TiO2 on the sintering temperature and dielectric properties of Li2O–MgO–ZnO–B2O3–SiO2 ceramic composites for LTCC applications. J. Mater. Sci. Mater Electron. 33, 1000–1007 (2022). https://doi.org/10.1007/s10854-021-07370-8

Yu, H., Liu, X., Li, D.: Experimental measurement of stress evolution in silicon carbide composite electrode during electrochemical cycling. Mater. Sci. Semiconductor Process. 138, 106275 (2022). https://doi.org/10.1016/j.mssp.2021.106275

Gao, X., et al.: Unlocking multiphysics design guidelines on Si/C composite nanostructures for high-energy-density and robust lithium-ion battery anode. Nano Energy 81, 105591 (2021). https://doi.org/10.1016/j.nanoen.2020.105591

Li, G.D., Tang, Z.Y.: Noble metal nanoparticle and metal oxide core/yolk–shell nanostructures as catalysts: recent progress and perspective. Nanoscale 6, 3995–4011 (2014). https://doi.org/10.1039/C3NR06787D

Ng, S.H., et al.: Highly reversible lithium storage in spheroidal carbon-coated silicon nanocomposites as anodes for lithium-ion batteries. Angew. Chem. Int. Ed. 45, 6896–6899 (2006). https://doi.org/10.1002/anie.200601676

Li, X.L., et al.: Hollow core–shell structured porous Si–C nanocomposites for Li-ion battery anodes. J. Mater. Chem. 22, 11014–11017 (2012). https://doi.org/10.1039/C2JM31286G

Liu, N., et al.: A pomegranate-inspired nanoscale design for large-volume-change lithium battery anodes. Nat. Nanotech 9, 187–192 (2014). https://doi.org/10.1038/nnano.2014.6

Huang, X., et al.: Graphene-based electrodes. Adv. Mat. 24, 5979–6004 (2012). https://doi.org/10.1002/adma.201201587

Liang, B., et al.: Silicon-based materials as high capacity anodes for next generation lithium ion batteries. J. Power Sources 267, 469–490 (2014). https://doi.org/10.1016/j.jpowsour.2014.05.096

Li, D.W., Wang, Y.K., Hu, J.Z., et al.: In situ measurement of mechanical property and stress evolution in a composite silicon electrode. J. Power Sources 366, 80–85 (2017). https://doi.org/10.1016/j.jpowsour.2017.09.004

Li, D.W., Wang, Y.K., Hu, J.Z., et al.: Role of polymeric binders on mechanical behavior and cracking resistance of silicon composite electrodes during electrochemical cycling. J. Power Sources 387, 9–15 (2018). https://doi.org/10.1016/j.jpowsour.2018.03.048

Shao, G.S., et al.: Mechanical properties of graphene nanoplates reinforced copper matrix composites prepared by electrostatic self-assembly and spark plasma sintering. Mater. Sci. Eng. A 739, 329–334 (2019). https://doi.org/10.1016/j.msea.2018.10.067

Gao, X., et al.: Three-dimensional modeling of electrochemical behavior in sio/graphite composite anode for high energy density lithium-ion battery. J. Electrochem. En. Conv. Stor. 19, 041004 (2022). https://doi.org/10.1115/1.4054649

Franco, A.A.: Multiscale modelling and numerical simulation of rechargeable lithium ion batteries: concepts, methods and challenges. RSC Adv. 3, 13027 (2013). https://doi.org/10.1039/c3ra23502e

Pouyanmehr, R., Hassanzadeh-Aghdam, M.K., Ansari, R.: Effect of graphene nanosheet dispersion on diffusion-induced stresses in layered Sn-based nanocomposite electrode for lithium-ion batteries. Mech. Mater. 145, 103390 (2020). https://doi.org/10.1016/j.mechmat.2020.103390

Liu, B., et al.: A simultaneous multiscale and multiphysics model and numerical implementation of a core-shell model for lithium-ion full-cell batteries. ASME. J. Appl. Mech. 86, 041005 (2019). https://doi.org/10.1115/1.4042432

Yang, J., Tse, J.S.: Li ion diffusion mechanisms in LiFePO4: an ab initio molecular dynamics study. J. Phys. Chem. A 115, 13045 (2011). https://doi.org/10.1021/jp205057d

Shi, D.L., Feng, X.Q., Huang, Y.Y., Hwang, K.C., Gao, H.J.: The effect of nanotube waviness and agglomeration on the elastic property of carbon nanotube-reinforced composites. J. Eng. Mater. Technol. 126, 250–257 (2004). https://doi.org/10.1115/1.1751182

de Vasconcelos, L.S., et al.: Chemomechanics of rechargeable batteries: status, theories, and perspectives. Chem. Rev. (2022). https://doi.org/10.1021/acs.chemrev.2c00002

Prussin, S.: Generation and distribution of dislocations by solute diffusion. J. Appl. Phys. 30, 1876–1881 (1961). https://doi.org/10.1063/1.1728256

Christensen, J., Newman, J.: Stress generation and fracture in lithium insertion materials. J. Solid State Electrochem. 10, 293–319 (2006). https://doi.org/10.1007/s10008-006-0095-1

Li, J., Dozier, A.K., Li, Y., et al.: Crack pattern formation in thin film lithium-ion battery. J. Electrochem. Soc. 158, A689–A694 (2011). https://doi.org/10.1149/1.3574027

Li, Y., Zhang, K., Zheng, B.L.: Stress Analysis in spherical composition-gradient electrodes of lithium-ion battery. J. Electrochem. Soc. 162, A223–A228 (2015). https://doi.org/10.1149/2.1021501jes

Zhang, X.C., Shyy, W., Sastry, A.M.: Numerical simulation of intercalation-induced stress in Li-ion battery electrode particle. J. Electrochem. Soc. 154, A910–A916 (2007). https://doi.org/10.1149/1.2759840

Lim, C., Yan, B., Yin, L., et al.: Simulation of diffusion-induced stress using reconstructed electrodes particle structures generated by micro/nano-CT. Electrochim. Acta 75, 279–287 (2012). https://doi.org/10.1016/j.electacta.2012.04.120

Zhu, M., Park, J., Sastry, A.M.: Fracture analysis of the cathode in Li-ion batteries: a simulation study. J. Electrochem. Soc. 159, A492–A498 (2012). https://doi.org/10.1149/2.045204jes

Gao, X., et al.: Insights into the Li diffusion mechanism in Si/C composite anodes for lithium-ion batteries. ACS Appl. Mater. Interfaces 13, 21362–21370 (2021). https://doi.org/10.1021/acsami.1c03366

Gao, X., et al.: Mechanics-driven anode material failure in battery safety and capacity deterioration issues: a review. ASME. Appl. Mech. Rev. AMR-21-1061 (2022). https://doi.org/10.1115/1.4054566.

Xu, C.J., Weng, L., Chen, B.B., et al.: Modeling of the ratcheting behavior in flexible electrodes during cyclic deformation. J. Power Sources 446, 227353 (2020). https://doi.org/10.1016/j.jpowsour.2019.227353

Shi, Y.T., Weng, L., Zhang, Y.D., et al.: Chemo-mechanical analysis of ratcheting deformation in silicon particle electrode under cyclic charging and discharging. Mech. Mater. 162, 104062 (2021). https://doi.org/10.1016/j.mechmat.2021.104062

Zhou, X.S., et al.: Spin-coated silicon nanoparticle/graphene electrode as a binder-free anode for high-performance lithium-ion batteries. Nano Res. 12, 845–853 (2012). https://doi.org/10.1007/s12274-012-0268-4

Deshpande, R., et al.: Modeling diffusion-induced stress in nanowire electrode structures. J. Power Sources 195, 5081–5088 (2010). https://doi.org/10.1016/j.jpowsour.2010.02.021

Crank, J.: The Mathematics of Diffusion. Oxford (1979)

Barai, P., Weng, G.J.: A theory of plasticity for carbon nanotube reinforced composites. Int. J. Plasticity 27, 539–559 (2011). https://doi.org/10.1016/j.ijplas.2010.08.006

Hill, R.: A self-consistent mechanics of composite materials. J. Mech. Phys. Solids 13, 213–222 (1965). https://doi.org/10.1016/0022-5096(65)90010-4

Affdl, J.C.H., Kardos, J.L.: The Halpin-Tsai equations: a review. Polymer Eng. Sci. 16, 344–352 (1976). https://doi.org/10.1002/pen.760160512

Rafiee, M.A., Rafiee, J., Wang, Z., et al.: Enhanced mechanical properties of nanocomposites at low graphene content. ACS Nano 3, 3884–3890 (2009). https://doi.org/10.1021/nn9010472

Lu, Y.J., Zhang, P.L., Wang, F.H., et al.: Reaction-diffusion-stress coupling model for Li-ion batteries: the role of surface effects on electrochemical performance. Electrochim. Acta 274, 359–369 (2018). https://doi.org/10.1016/j.electacta.2018.04.105

Hao, F., Fang, D.N.: Reducing diffusion-induced stresses of electrode–collector bilayer in lithium-ion battery by pre-strain. J. Power Sources 242, 415–420 (2013). https://doi.org/10.1016/j.jpowsour.2013.05.098

Liu, D.Y., Chen, W.Q., Shen, X.D.: Diffusion-induced stresses in graphene-based composite bilayer electrode of lithium-ion battery. Compos. Struct. 165, 91–98 (2017). https://doi.org/10.1016/j.compstruct.2017.01.011

Acknowledgements

This work was supported by the Guizhou Provincial General Undergraduate Higher Education Technology Supporting Talent Support Program (KY (2018)043), Postgraduate Research & Practice Innovation Program of Jiangsu Province (KYCX20_1074), the National Natural Science Foundation of China (10502025, 10872087, 11272143), the Key University Science Research Project of Jiangsu Province (17KJA130002).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A

When yield failure occurs in plastic materials, von Mises stress is generally used as the failure criterion. The von Mises stress is calculated according to the principal stress in three directions, and the formula is as follows:

where \(\sigma_{Y}\) is the von Mises stress and \(\sigma_{1}\), \(\sigma_{2}\), \(\sigma_{3}\) are the first, second, and third principal stresses, respectively. Based on the generalized plane strain theory of thin plates, there are \(\sigma_{1} = \sigma_{{{{x}}x}}\), \(\sigma_{2} = \sigma_{yy}\), and \(\sigma_{3} = \sigma_{{{{zz}}}}\). Obtained by Eq. (2), \(\sigma_{1} = \sigma_{2}\), \(\sigma_{3} = 0\), so on the yield surface, the stress can be expressed as:

Appendix B

For elastoplastic materials, there is \(\Delta \sigma = C_{T} \Delta \varepsilon\), where

The physical meaning of \(E\) and \(\sigma_{Y}\) is consistent with the paper, and \(E_{t}\) is the strain hardening modulus. As shown in Fig.

9, the strain increment in the plastic stage is divided into elastic and plastic parts, namely

Integrate the above equation to obtain

where \(\varepsilon_{xx}\) is the total strain in the plastic stage, and the superscripts \(e\) and \(p\) represent the elastic and plastic parts of the plastic stage, respectively. Likewise, the stress increment \(\Delta \sigma\) in the plastic stage can be expressed in any of the three moduli, namely

Therefore, in the plastic domain, the stress distribution can be expressed as

Substituting Eqs. (1) and (A.5) into Eq. (A.7) yields

Appendix C

The representative volume element model for GNSs agglomeration is shown in Fig.

10. As has been illustrated in the paper, the composite matrix volume \(V\) is consisting of two parts: the hypothetical matrix volume \(V_{m}\) which is made of the silicon initial matrix and the GNSs dispersed in random direction, and the agglomeration domain volume \(V_{a}\), namely

According to the volume relationship of each component of the composite material, the following can be obtained:

where \(\phi_{m}\) is the volume fraction of the hypothetical matrix, and \(\phi_{a}\) is the volume fraction of the agglomeration domain. Suppose the volume of the additive in the composite is \(V_{r}\), the volume of the additive in the hypothetical matrix is \(V_{r}^{m}\), and the volume of the additive in the agglomeration domain is \(V_{r}^{a}\), then there is \(V_{r} = V_{r}^{m} + V_{r}^{a}\). According to the volume conservation relationship, it can be obtained

where \(\phi_{r}\) is the average volume fraction of GNSs, \(\phi_{r}^{m}\) is the volume fraction of GNSs in the hypothetical matrix, and \(\phi_{r}^{a}\) is the volume fraction of GNSs in the agglomeration domain.

Overall, the agglomeration parameters \(\xi\) and \(\lambda\) introduced in the paper are defined as

It should be noted that for a given average volume fraction of GNSs, \(\phi_{r}^{a}\) must be less than \(\xi\), that is, \(\lambda < \frac{\xi }{{\phi_{r} }}\). Similarly, for the agglomeration domain, the volume occupied by GNSs \(\frac{{V_{r}^{a} }}{{V_{a} }}\) should be larger than the average volume fraction of GNSs \(\phi_{r}\), i.e., \(\frac{{\phi_{r} \lambda }}{\xi } > \phi_{r}\). To sum up, it can be concluded that \(0 < \xi < \lambda < 1\).

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gao, C., Guan, L., Shi, Y. et al. An analytical multiscale modeling of a nanocomposite anode with graphene nanosheets for lithium-ion battery. Acta Mech 233, 5265–5281 (2022). https://doi.org/10.1007/s00707-022-03379-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-022-03379-0