Abstract

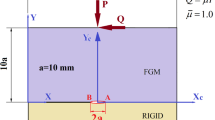

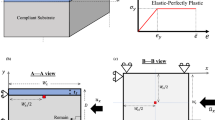

In this paper, a semi-analytic solution is developed to investigate the plastic deformation of a film-substrate with inhomogeneous inclusions subjected to contact loading. In this solution, the surface pressure distribution and contact area can be determined by solving a set of governing equations via a modified conjugate gradient method. The inhomogeneous inclusions and the coating material are modeled as homogeneous inclusions with known initial eigenstrains plus unknown equivalent eigenstrains, according to the Eshelby’s equivalent inclusion method. A plasticity loop and an incremental loading process are used to obtain the accumulative plastic strain iteratively. This model considers not only the interactions among the contact loading body, embedded inhomogeneous inclusions and film materials, but also the plastic deformation of the film-substrate system. This solution is of great significance to understand the plastic deformation mechanism of a film-substrate with inhomogeneous inclusions under contact loading.

Similar content being viewed by others

References

Askari, D., Ghasemi-Nejhad, M.N.: Effects of vacancy defects on mechanical properties of graphene/carbon nanotubes: a numerical modeling. J. Comput. Theor. Nanosci. 8(4), 783–794 (2011)

Hao, F., et al.: Mechanical and thermal transport properties of graphene with defects. Appl. Phys. Lett. 99(4), 041901 (2011)

Jin, M.Z., et al.: The effects of micro-defects and crack on the mechanical properties of metal fiber sintered sheets. Int. J. Solids Struct. 51(10), 1946–1953 (2014)

Zhou, K., et al.: A fast method for solving three-dimensional arbitrarily shaped inclusions in a half space. Comput. Methods Appl. Mech. Eng. 198(9–12), 885–892 (2009)

Zhou, K., et al.: Multiple 3D inhomogeneous inclusions in a half space under contact loading. Mech. Mater. 43(8), 444–457 (2011)

Zhou, K., et al.: Semi-analytic solution for multiple interacting three-dimensional inhomogeneous inclusions of arbitrary shape in an infinite space. Int. J. Numer. Methods Eng. 87(7), 617–638 (2011)

Zhou, K.: Elastic field and effective moduli of periodic composites with arbitrary inhomogeneity distribution. Acta Mech. 223(2), 293–308 (2012)

Dong, Q.B., Zhou, K.: Elastohydrodynamic lubrication modeling for materials with multiple cracks. Acta Mech. 225(12), 3395–3408 (2014)

Zhou, K., Wei, R.B.: Modeling cracks and inclusions near surfaces under contact loading. Int. J. Mech. Sci. 83, 163–171 (2014)

Zhou, K., Wei, R.B.: Multiple cracks in a half-space under contact loading. Acta Mech. 225(4–5), 1487–1502 (2014)

Dong, Q.B., Zhou, K.: Multiple inhomogeneous inclusions and cracks in a half space under elastohydrodynamic lubrication contact. Int. J. Appl. Mech. 7(1), 1550003 (2015)

Dong, Q.B., Zhou, K.: Modeling heterogeneous materials with multiple inclusions under mixed lubrication contact. Int. J. Mech. Sci. 103, 89–96 (2015)

Dong, Q.B., et al.: Analysis of fluid pressure, interface stresses and stress intensity factors for layered materials with cracks and inhomogeneities under elastohydrodynamic lubrication contact. Int. J. Mech. Sci. 93, 48–58 (2015)

Zhou, K., et al.: Semi-analytic solution of multiple inhomogeneous inclusions and cracks in an infinite space. Int. J. Comput. Methods 12(1), 1550002 (2015)

Dong, Q.B., et al.: Heterogeneous structures with inhomogeneous inclusions under elastohydrodynamic lubrication contact with consideration of surface roughness. Proc. Inst. Mech. Eng. Part J-J. Eng. Tribol. 230(5), 571–582 (2016)

Fang, Q.H., Zhang, L.C.: Coupled effect of grain boundary sliding and dislocation emission on fracture toughness of nanocrystalline materials. J. Micromech. Mol. Phys. 1(2), 1650008 (2016)

Long, X., et al.: Mechanical effects of isolated defects within a lead-free solder bump subjected to coupled thermal-electrical loading. J. Micromech. Mol. Phys. 1(1), 1650004 (2016)

Markenscoff, X.: On the dynamic generalization of the anisotropic Eshelby ellipsoidal inclusion and the dynamically expanding inhomogeneities with transformation strain. J. Micromech. Mol. Phys. 1(3–4), 1640001 (2016)

Mikata, Y.: Analytical treatment on the effective material properties of a composite material with spheroidal and ellipsoidal inhomogeneities in an isotropic matrix. J. Micromech. Mol. Phys. 1(3–4), 1640012 (2016)

Ren, H., et al.: A new peridynamic formulation with shear deformation for elastic solid. J. Micromech. Mol. Phys. 1(2), 1650009 (2016)

Shi, C., et al.: An interphase model for effective elastic properties of concrete composites. J. Micromech. Mol. Phys. 01(01), 1650005 (2016)

Wei, R.B., et al.: Modeling surface pressure, interfacial stresses and stress intensity factors for layered materials containing multiple cracks and inhomogeneous inclusions under contact loading. Mech. Mater. 92, 8–17 (2016)

Yang, S., Sharma, P.: Eshelby’s tensor for embedded inclusions and the elasto-capillary phenomenon. J. Micromech. Mol. Phys. 1(3–4), 1630002 (2016)

Zhou, K., Dong, Q.B.: A three-dimensional model of line-contact elastohydrodynamic lubrication for heterogeneous materials with inclusions. Int. J. Appl. Mech. 8(2), 1650014 (2016)

Burbery, N.B., et al.: Dislocation dynamics in polycrystals with atomistic-informed mechanisms of dislocation–grain boundary interactions. J. Micromech. Mol. Phys. 2(1), 1750003 (2017)

Kuroda, M.: Interpretation of the behavior of metals under large plastic shear deformations: a macroscopic approach. Int. J. Plast. 13(4), 359–383 (1997)

Kiritani, M., et al.: Plastic deformation of metal thin films without involving dislocations and anomalous production of point defects. Radiat. Eff. Defects Solids 157(1–2), 3–24 (2002)

Richmond, O., Alexandrov, S.: The theory of general and ideal plastic deformations of Tresca solids. Acta Mech. 158(1–2), 33–42 (2002)

Bucher, A., et al.: A material model for finite elasto-plastic deformations considering a substructure. Int. J. Plast. 20(4–5), 619–642 (2004)

Guo, L.G., et al.: Research on plastic deformation behaviour in cold ring rolling by FEM numerical simulation. Model. Simul. Mater. Sci. Eng. 13(7), 1029–1046 (2005)

Shi, J., et al.: Damage criteria based on plastic strain energy intensity under complicated stress state. Int. J. Appl. Mech. 7(6), 1550089 (2015)

Chen, J., et al.: Interaction between dislocation and subsurface crack under condition of slip caused by half-plane contact surface normal force. Eng. Fract. Mech. 114, 115–126 (2013)

Wei, R., et al.: Fatigue crack propagation in heterogeneous materials under remote cyclic loading. J. Micromech. Mol. Phys. 1(01), 1650003 (2016)

Bo, L., et al.: Study of transformation toughening behavior of an edge through crack in zirconia ceramics with the cohesive zone model. Int. J. Appl. Mech. 10, 1850066 (2018)

Hui, L., et al.: An implicit coupling finite element and peridynamic method for dynamic problems of solid mechanics with crack propagation. Int. J. Appl. Mech. 10(10), 1850037 (2018)

Mamalis, A.G., et al.: The effect of porosity and micro-defects on plastically deformed porous materials. J. Mater. Process. Technol. 96(1–3), 117–123 (1999)

Pettermann, H.E., et al.: A thermo-elasto-plastic constitutive law for inhomogeneous materials based on an incremental Mori–Tanaka approach. Comput. Struct. 71(2), 197–214 (1999)

von Blanckenhagen, B., et al.: Discrete dislocation simulation of plastic deformation in metal thin films. Acta Mater. 52(3), 773–784 (2004)

Cleja-Tigoiu, S.: Elasto-plastic materials with lattice defects modeled by second order deformations with non-zero curvature. Int. J. Fract. 166(1–2), 61–75 (2010)

Ellers, J., Driessen, G.: Genetic correlation between temperature-induced plasticity of life-history traits in a soil arthropod. Evol. Ecol. 25(2), 473–484 (2011)

Bose, T., Rattan, M.: Modeling creep analysis of thermally graded anisotropic rotating composite disc. Int. J. Appl. Mech. 10, 1850063 (2018)

Jiang, Y.Y., et al.: Three-dimensional elastic-plastic stress analysis of rolling contact. J. Tribol.-Trans. ASME 124(4), 699–708 (2002)

Shao, Y.F., et al.: Multiscale simulations on the reversible plasticity of Al (0 0 1) surface under a nano-sized indenter. Comput. Mater. Sci. 67, 346–352 (2013)

Shi, S., et al.: Elastic-plastic response of clamped square plates subjected to repeated quasi-static uniform pressure. Int. J. Appl. Mech. 10(6), S1758825118500679 (2018)

Wang, H., et al.: Effects of detwinning on the inelasticity of AZ31B sheets during cyclic loading and unloading. Int. J. Appl. Mech. 10(9), 1850095 (2018)

Mazarei, Z., et al.: Thermo-elasto-plastic analysis of thick-walled spherical pressure vessels made of functionally graded materials. Int. J. Appl. Mech. 8(4), 1650054 (2016)

Soyarslan, C., et al.: A thermomechanically consistent constitutive theory for modeling micro-void and/or micro-crack driven failure in metals at finite strains. Int. J. Appl. Mech. 8(1), 1650009 (2016)

Jacq, C., et al.: Development of a three-dimensional semi-analytical elastic–plastic contact code. J. Tribol.Trans. ASME 124(4), 653–667 (2002)

Chen, W.W., et al.: Modeling elasto-plastic indentation on layered materials using the equivalent inclusion method. Int. J. Solids Struct. 47(20), 2841–2854 (2010)

Mura, T.: Micromechanics of Defects in Solids. Springer, Dordrecht (1982)

Wang, Z.J., et al.: A numerical elastic–plastic contact model for rough surfaces. Tribol. Trans. 53(2), 224–238 (2010)

Osullivan, T.C., King, R.B.: Sliding contact stress-field due to a spherical indenter on a layered elastic half-space. J. Tribol.-Trans. ASME 110(2), 235–240 (1988)

Acknowledgements

The authors acknowledge financial support by Singapore Maritime Institute (Grant No: SMI-2014-MA11) and the National Natural Science Foundation of China (Grant No: 11472200).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A

Based on the previous study of Zhou et al. [5] regarding the elastic behaviors of a half-space with arbitrary inhomogeneous inclusions under contact loading, the stress field when considering the plastic deformation can be obtained using the EIM and stress superposition:

where \(p_{\xi ,\zeta }\) represents the pressure in a discretized surface area centered at (\(x_{\xi },y_{\zeta },0)\), respectively;\( M_{\alpha -\xi ,\beta -\zeta ,\gamma }^{n}\) and \(M_{\alpha -\xi ,\beta -\zeta ,\gamma }^{f}\) are \(6\times 1\) matrix forms of the influence coefficients induced by \(p_{\xi ,\zeta }\) and \(f_{\xi ,\zeta }\) on a surface element, respectively; \(A_{\alpha -\xi ,\beta -\zeta ,\gamma -\varphi }\) is a \(6\times 6\) matrix form of the influence coefficients which relate the eigenstresses \(\sigma _{\alpha ,\beta ,\gamma }^{p}\) and \(\sigma _{\alpha ,\beta ,\gamma }^{*}\) at the observation point (\(x_{a},y_{a},z_{a})\) in the cuboid [\(\alpha ,\beta ,\gamma \)] to the initial eigenstrains \(\varepsilon _{\xi ,\zeta ,\varphi }^{p}\) and equivalent eigenstrains \(\varepsilon _{\xi ,\zeta ,\varphi }^{*}\) plus plastic strain \(\varepsilon _{\xi ,\zeta ,\varphi }^{**}\) in the cuboid [\(\xi ,\zeta ,\varphi ,\)], respectively, and the detailed expressions of \(M_{\alpha -\xi ,\beta -\zeta ,\gamma }^{n}\), \(M_{\alpha -\xi ,\beta -\zeta ,\gamma }^{f}\) and \(A_{\alpha -\xi ,\beta -\zeta ,\gamma -\varphi }\) can be found in the work by Zhou et al. [5]; the value of \(\varepsilon _{\xi ,\zeta ,\varphi }^{**}\) equals zero when the elastic deformation has just occurred and it would be nonzero when plastic deformation happens.

The surface u(x, y) can be decomposed into two parts: (1) the elastic displacement \(u^{0}(x,y)\) due to contact loading and (2) the eigendisplacement \( u^{*}(x,y)\) due to the subsurface eigenstrains (the initial eigenstrain \(\varepsilon _{\xi ,\zeta }^{p}\), the equivalent eigenstrains \(\varepsilon _{\xi ,\zeta ,\varphi }^{*}\) and the accumulated plastic strain \(\varepsilon _{\xi ,\zeta ,\varphi }^{**})\). It can be written as

where \(Q_{\alpha -\xi ,\beta -\zeta ,\gamma }^{n}\) and \(Q_{\alpha -\xi ,\beta -\zeta ,\gamma }^{f}\) are the influence coefficients induced by \(p_{\xi ,\zeta }\) and \(f_{\xi ,\zeta }\) on a surface element, respectively; \(S_{\xi -\alpha ,\zeta -\beta ,\varphi }\) are the coefficients relating to the surface displacement to the initial eigenstrain \(\varepsilon _{\xi ,\zeta }^{p}\), equivalent eigenstrain \(\varepsilon _{\xi ,\zeta }^{*}\) and effective equivalent plastic strain \(\varepsilon _{\xi ,\zeta }^{**}\). The detailed expressions of \(Q_{\alpha -\xi ,\beta -\zeta ,\gamma }^{n}\), \(Q_{\alpha -\xi ,\beta -\zeta ,\gamma }^{f}\) and \(S_{\xi -\alpha ,\zeta -\beta ,\varphi }\) can be found in the work by Zhou et al. [5].

Appendix B

The linear isotropic hardening law describing the size of the yield surface as a function of the accumulated plastic strain p is given as

where \(\sigma _{\mathrm{Y}}\) is the initial yield stress, \(E_{S}\) is the Young’s modulus, and \(E_{\mathrm{t}}\) is the plastic tangential modulus.

The current study follows the notion postulated by Nelias et al. [43] to calculate the increment in plastic strain. Yielding occurs when the condition \(f\left( p+{\varDelta } p \right) =0\) is satisfied in the plastic zone. The actual increment in the accumulated plastic strain \(\Delta p\) can be obtained through the Newton–Raphson iteration scheme. The yield function can be expanded and approximated as

Between two consecutive iterative steps, the correction of the accumulated plastic strain \({{\varDelta } p}^{(n)}\) can be expressed as

All of the related variables are updated as follows:

Here, \(p^{(1)}\), \(\sigma _{VM}^{\left( 1 \right) }\) and \(\sigma _{ij}^{\left( 1 \right) }\) are the initial effective plastic strain, the equivalent von Mises stress and the Cauchy stress components, respectively. The calculation ends if the convergence condition is satisfied:

The steps indicated in Eqs. (B2)–(B4) are repeated until the iteration converges. According to the plastic flow rule, the estimation of the plastic strain increment is determined:

Rights and permissions

About this article

Cite this article

Yang, J., Fang, Q., Kang, G. et al. Plastic deformation of a film-substrate with inhomogeneous inclusions under contact loading. Acta Mech 230, 4463–4479 (2019). https://doi.org/10.1007/s00707-019-02518-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-019-02518-4