Abstract

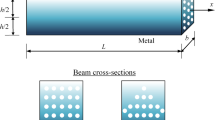

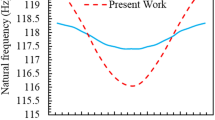

In this paper, the evaluation procedures of the natural frequency and the stress intensity factor in the opening mode are established for the Euler–Bernoulli cracked beam by using (a) a technique in the framework of the finite element method, (b) a group method of data handling (GMDH), and (c) the software ABAQUS software. In the first one, the stiffness and mass matrices of the beam are enriched according to the depth and location of the crack for the determination of the natural frequency. A discrete spring model is used to simulate the crack in the structure based on the energy release rate. The continuity conditions in a cracked element are applied to connect two sub-elements of both sides of the crack. In the second method, the natural frequency and the stress intensity factor are determined using the GMDH algorithm. Design of experiments technique is employed to create an optimum arrangement for the application in the GMDH neural network. A few case studies are examined to investigate the results of the analysis, in addition, to identify the priority and the comparison of the three methods. The procedure of the analysis explains the advantages and limitations of the finite element-based technique, the GMDH method, and ABAQUS.

Similar content being viewed by others

Abbreviations

- a :

-

Crack depth

- \(a_{i}\) :

-

Constant coefficients of GMDH

- A :

-

Cross-sectional area

- b :

-

Width of the beam

- \({\varvec{D}}_{L\left( R \right) }\) :

-

Conversion matrix of left (right) sub-element

- E :

-

Young’s modulus

- \(EI_{0}\) :

-

Flexural stiffness

- h :

-

Height of the beam

- \(I_{0}\) :

-

Moment of inertia in perfect section

- \(I_{c}\) :

-

Moment of inertia in cracked section

- \(k_{sp}\) :

-

Stiffness factor of rotational spring

- \(K_{I}\) :

-

Stress intensity factor

- \({\varvec{K}}_{0}\) :

-

Stiffness matrix of perfect element

- \({\varvec{K}}_{L(R)}\) :

-

Stiffness matrix of left (right) sub-element

- \({\varvec{K}}_{L(R)}^{c}\) :

-

Enriched stiffness matrix of left (right) sub-element

- \({\varvec{K}}_{sp}^{c}\) :

-

Enriched stiffness matrix of rotational spring

- \({\varvec{K}}_{t}^{c}\) :

-

Stiffness matrix of cracked element

- \(l_{e}\) :

-

Length of the element

- L :

-

Length of the beam

- m :

-

Number of output variables of GMDH

- M :

-

Bending moment

- \({\varvec{M}}_{0}\) :

-

Mass matrix of perfect section

- \({\varvec{M}}_{L(R)}\) :

-

Mass matrix of left (right) sub-element

- \({\varvec{M}}_{L(R)}^{c}\) :

-

Enriched mass matrix of left (right) sub-element

- \({\varvec{M}}_{t}^{c}\) :

-

Enriched total mass matrix

- n :

-

Number of input variables of GMDH

- \({\varvec{N}}\) :

-

Shape function

- q :

-

Distributed load

- T :

-

Kinetic energy

- \(T_{L(R)}\) :

-

Kinetic energy of left (right) sub-element

- \(T_{L(R)}^{c}\) :

-

Enriched kinetic energy of (right) sub-element

- \(T_{t}^{c}\) :

-

Total kinetic energy of a cracked element

- \({\varvec{u}}\) :

-

Displacement vector

- \({\dot{{\varvec{u}}}}\) :

-

Time derivative of displacement vector

- \({\varvec{u}}_{L(R)}\) :

-

Displacement vector of left (right) sub-element

- \({\dot{{{\varvec{u}}}}}_{L(R)}\) :

-

Time derivative of displacement vector of left (right) sub-element

- U :

-

Strain energy

- \(U_{L(R)}\) :

-

Strain energy in left (right) sub-element

- \(U_{L(R)}^{c}\) :

-

Enriched strain energy in left (right) sub-element

- \(U_{sp}\) :

-

Absorbed potential energy in rotational spring

- \(U_{t}^{c}\) :

-

Total potential energy of a cracked element

- V :

-

Shear force

- w :

-

Deflection

- \({\dot{w}}\) :

-

Time derivative of deflection

- \({\dot{w}}_{L(R)}\) :

-

Time derivative of the left sub-element deflection

- x :

-

Axial direction

- \(x{}_{i}\) :

-

Input variables of GMDH

- \(x_{0}\) :

-

Crack location in the beam

- \(x_{c}\) :

-

Crack location in the element

- \({\varvec{X}}\) :

-

Input vector of GMDH

- \(y_{i}\) :

-

Output variables of GMDH

- \({\varvec{Y}}\) :

-

Output vector of GMDH

- z :

-

Transverse direction

- \(\Delta \phi \) :

-

Change in slope

- \(\varepsilon _{x}\) :

-

Axial strain

- \(\lambda _{mm}\) :

-

Compliance for bending moment

- v :

-

Poisson’s ratio

- \(\rho \) :

-

Density

- \(\sigma _{x}\) :

-

Axial stress

- \(\phi \) :

-

Slope

- \({\dot{\phi }}\) :

-

Time derivative of slop

- \(\omega \) :

-

Natural frequency

References

Mohamadi, M.: Extended Finite Element Method For Fracture Analysis of Structures. Blackwell Publishing, Oxford (2008)

Irwin, G.R., Kies, J.A.: Critical energy rate analysis of fracture strength. J. Weld. 33, 193–198 (1954)

Irwin, G.R.: Analysis of stresses and strains near the end of a crack traversing a plate. J. Appl. Mech. 24, 361–364 (1957)

Kienzler, R., Herrmann, D.: On material forces in elementary beam theory. J. Appl. Mech. 53, 561–564 (1986)

Ngo, D., Scordelis, A.C.: Finite element analysis of reinforced concrete beams. J. Am. Concr. Inst. 64, 52–163 (1967)

Cundall, P.A., Strack, O.D.L.: A discrete numerical model for granular assemblies. J. Geotech. 29, 47–65 (1979)

Owen, D.R.J., Fawkes, A.J.: Engineering Fracture Mechanics: Numerical Methods and Applications. Pine Ridge Press, Swansea (1983)

Owen, D.R.J.: Hinton E Finite Element Plasticity, Theory and Practice. Pine Ridge Press, Swansea (1980)

Bazant, Z.P., Planas, J.: Fracture and Size Effect in Concrete and Other Quasi Brittle Materials. CRC Press Publishing, London (1998)

Moes, N., Dolbow, J., Belytschko, T.: A finite element method for crack growth without remeshing. J. Numer. Methods Eng. 46, 131–150 (1999)

Belytschko, T., Black, T.: Elastic crack growth in finite elements with minimal remeshing. J. Numer. Methods Eng. 45, 601–620 (1999)

Sih, G.C.: Handbook of stress intensity factors for researchers and engineerings. Lehigh University, Bethlehem (1973)

Chang, R.: Static finite element stress intensity factors for annular cracks. J. Nondestr. Eval. 2, 119–124 (1981)

Tada, H., Paris, P.C., Irwin, G.R.: The stress analysis of crack handbook. Paris Productions & (Del Research Corp.) (1985)

Kienzler, R., Herrmann, G.: An elementary theory of defective beams. J. Acta Mech. 62, 37–46 (1986)

Ricci, P., Viola, E.: Stress intensity factors for cracked T-sections and dynamic behavior of T-beams. J. Eng. Fract. Mech. 73, 91–111 (2006)

Kumar, P.: Elements of Fracture Mechanics. McGraw-Hill, McGraw Hill Education (India) Private Limited, Bengaluru (2009)

Qian, G.L., Gu, S.N., Jiang, J.S.: The dynamic behavior and crack detection of a beam with a crack. J. Sound Vib. 2, 233–243 (1990)

Leissa, A.W., Qatu, M.S.: Vibrations of Continuous Systems. McGraw-Hill, New York (2011)

Rao, S.S.: Mechanical vibrations. Prentice Hall, New York (2011)

Logan, D.L.: A First Course in the Finite Element Method. Chris Carson, Toronto (2007)

Yokoyama, T., Chen, M.C.: Vibration analysis of edge-cracked beams using a line-spring model. J. Eng. Fract. Mech. 59, 403–409 (1998)

Gudmundsun, P.: The dynamic behavior of slender structures with cross-sectional cracks. J. Mech. Phys. Solids 1, 329–345 (1983)

Pandey, A.K., Biswas, M., Samman, M.M.: Damage detection from change in curvature mode shapes. J. Sound Vib. 145, 321–335 (1994)

Lele, S.P., Maiti, S.K.: Modelling of transverse vibration of short beams for crack detection and measurement of crack extension. J. Sound Vib. 257, 559–583 (2002)

Silva, J.M., Gomes, A.J.: Experimental dynamic analysis of cracked free-free beams. J. Exp. Mech. 30, 20–25 (1990)

Kim, J.T., Stubbs, N.: Crack detection in beam-type structures using frequency data. J. Sound Vib. 259, 145–160 (2003)

Swamidas, A.S.J., Yang, X.F., Seshadri, R.: Identification of cracking in beam structures using Timoshenko and Euler formulations. J. Eng. Mech. 130, 1297–1308 (2004)

Dobeling, S.W., Farrar, C.R., Prime, M.B.: A summary review of vibration-based damage identification methods. J. Shock Vib. Dig. 30, 91–105 (1998)

Cawly, P., Adams, R.D.: The locations of defects in structures from measurements of natural frequencies. J. Strain Anal. 14, 49–57 (1979)

Friswell, M.I., Penny, J.E.T., Wilson, D.A.L.: Using vibration data and statistical measures to locate damage in structures. J. Anal. Exp. Modal Anal. 9, 239–254 (1994)

Narkis, Y.: Identification of crack location in vibrating simply supported beams. J. Sound Vib. 172, 549–558 (1994)

Pandey, A.K., Biswas, M.: Damage detection in structures using changes in flexibility. J. Sound Vib. 169, 3–17 (1994)

Ratcliffe, C.P.: Damage detection using a modified Laplacian operator on mode shape data. J. Sound Vib. 204, 505–517 (1997)

Ostachowicz, W.M., Krawczuk, M.: Analysis of the effect of cracks on the natural frequencies of a cantilever Beam. J. Sound Vib. 150, 191–201 (1991)

Binici, B.: Vibration of beam with multiple open cracks subjected to axial force. J. Sound Vib. 287, 277–295 (2005)

Sergio, H.S., Daniel, J.I.: Continuous model for the transverse vibration of cracked Timoshenko beams. J. Trans. ASME 124, 310–320 (2002)

Shafiei, M., Khaji, N.: Analytical solutions for free and forced vibrations of a multiple cracked Timoshenko beam subject to a concentrated moving load. J. Acta Mech. 221, 79–97 (2011)

Neves, A.C., Simões, F.M.F., Pinto da Costa, A.: Vibrations of cracked beams: discrete mass and stiffness models. J. Comput. Struct. 168, 68–77 (2016)

Ivakhnenko, A.G.: Heuristic self-organization in problems of engineering cybernetics. J. Automat. 6, 207–219 (1970)

Ivakhnenko, A.G.: Polynomial theory of complex systems. J. Trans. Syst. 1, 364–378 (1971)

Kutuk, M.A., Atmaca, N., Guzelbey, I.H.: Explicit formulation of SIF using neural networks for opening mode of fracture. J. Eng. Struct. 29, 2080–2086 (2007)

Nariman-zadeh, N., Darvizeh, A., Darvizeh, M., Gharababaei, H.: Modelling of explosive cutting process of plates using GMDH-type neural network and singular value decomposition. J. Mater. Process. Technol. 128, 80–87 (2002)

Besarati, S.M., Myers, P.D., Covey, D.C., Jamali, A.: Modelling friction factor in pipeline flow using a GMDH-type neural network. J. Cogent Eng. 2, 1–14 (2015)

Montgomery, D.: Design and Analysis of Experiments. Wiley, New York (2013)

Box, G., Hunter, J., Hunter, W.: Statistics for Experiments. Wiley, New York (2005)

Ranjit, K.R.: A Primer on the Taguchi Method. Society of Manufacturing Engineers, Michigan (2010)

Eriksson, M., Andersson, P., Burman, A.: Using design of experiments techniques for an efficient finite element study of the influence of changed. International ANSYS Conference, vol. 2, pp. 63–72 (1998)

Alijani, A., Mastan Abadi, M., Darvizeh, A., Kh. Abadi, M.: Theoretical approaches for bending analysis of founded Euler–Bernoulli cracked beams. J. Arch. Appl. Mech. 88: 875–895 (2018)

Mottaghian, F., Darvizeh, A., Alijani, A.: A novel finite element model for large deformation analysis of cracked beams using classical and continuum-based approaches. J. Arch. Appl. Mech. (2018). https://doi.org/10.1007/s00419-018-1460-0

Zarrinzadeh, H., Kabir, M.Z., Deylami, A.: Extended finite element fracture analysis of a cracked isotropic shell repaired by composite patch. J. Fatigue. Fract. Eng. Mater. Struct. 39, 1352–1365 (2016)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A

The components of the conversion matrix of the left sub-element:

The components of the conversion matrix of the right sub-element:

Appendix B

The polynomial equation derived from GMDH method relevant to Table 2c in the determination of the natural frequency for C-F boundary condition:

in which

and

The polynomial equation derived from GMDH method relevant to Table 3c in the determination of the stress intensity factor for C-F boundary condition:

in which

and

Appendix C

Modeling differences between ABAQUS and the finite element in a more accurate representation:

ABAQUS | Finite element-based technique | |

|---|---|---|

Assumptions | 2D analysis of the beam | 1D analysis of the beam |

2D modeling of the crack | 1D modeling of the crack | |

Using C-Integral for the crack modeling | Using rotational spring for the crack modeling | |

Plane stress state | Neglecting transverse shear deformation | |

Global steps | Drawing model | Using cubical Hermit functions |

Definition of material properties | Definition of strain–displacement and stress–strain relationships | |

Assembling the model | Derivation of the standard stiffness and mass matrices | |

Definition of the static/vibration solver | Derivation of the enriched stiffness and mass matrices | |

Creating an interaction for the crack modeling | Assembling the stiffness and mass matrices and the force vector | |

Applying loads and boundary conditions | Applying boundary conditions | |

Meshing | Determination of displacements | |

Definition of job | ||

Advantages | Implementation of a relatively complete modeling for the beam and the crack | The short time of preparation and processing |

No need to derive equations | Flexibility in changing material and geometric characteristics and boundary conditions | |

2D Graphical display of stress contours in the region around the crack tip | ||

Disadvantages | The necessity of re-meshing and repartitioning for every new model | The decrease in the accuracy of results in crack depths higher than .8h |

Time-consuming in the preparation and processing | Un-capability in the illustration of stress contours in the region around the crack tip |

Rights and permissions

About this article

Cite this article

Alijani, A., Abadi, M.K., Razzaghi, J. et al. Numerical analysis of natural frequency and stress intensity factor in Euler–Bernoulli cracked beam. Acta Mech 230, 4391–4415 (2019). https://doi.org/10.1007/s00707-019-02492-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-019-02492-x