Abstract

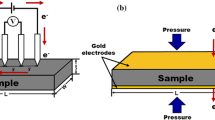

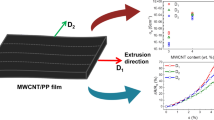

In this paper, the electrical conductivity and mechanical properties such as elastic modulus of multiwalled carbon nanotubes (MWCNTs) reinforced polypropylene (PP) nanocomposites were investigated both experimentally and theoretically. MWCNT-PP nanocomposites samples were produced using injection mold at different injection velocities. The range of the CNT fillers is from 0 up to 12 wt%. The influence of the injection velocity and the volume fraction of CNTs on both electrical conductivity and mechanical properties of the nanocomposites were studied. The injection speed showed some effect on the electrical conductivity, but no significant influence on the mechanical properties such as elastic modulus and stress-strain relations of the composites under tensile loading. Parallel to the experimental investigation, for electrical conductivity, a percolation theory was applied to study the electrical conductivity of the nanocomposite system in terms of content of nanotubes. Both Kirkpatrick (Rev Mod Phys 45:574–588, 1973) and McLachlan et al. (J Polym Sci B 43:3273–3287, 2005) models were used to determine the transition from low conductivity to high conductivity in which designates as percolation threshold. It was found that the percolation threshold of CNT/PP composites is close to 3.8 wt%. For mechanical properties of the system, several micromechanical models were applied to elucidate the elastic properties of the nanocomposites. The results indicate that the interphase between the CNT and the polymers plays an important role in determining the elastic modulus of the system.

Similar content being viewed by others

References

Kirkpatrick S.: Percolation and conduction. Rev. Mod. Phys. 45, 574–588 (1973)

McLachlan D.S., Chiteme C., Park C., Wise K.E., Lowther S.E., Lillehei P.T., Siochi E.J., Harrison J.S.: AC and DC percolative conductivity of single wall carbon nanotube polymer composites. J. Polym. Sci. B 43, 3273–3287 (2005)

Iijima S.: Helical microtubules of graphitic carbon. Nature 354, 56–58 (1991)

Cho J.W., Paul D.R.: Nylon 6 nanocomposites by melt compounding. Polymer 42(3), 1083–1094 (2001)

Dennis H.R., Hunter D.L., Chang D., Kim S., White J.L., Cho J.W., Paul D.R.: Effect of melt processing conditions on the extent of exfoliation in organoclay-based nanocomposites. Polymer 42(23), 9513–9522 (2001)

Anderson, P.G.: Twin screw extrusion guidelines for compounding nanocomposites. In: Proceedings of Annual Technical Conference of the Society of Plastics Engineers, vol. 48, pp. 1–5 (2002)

Dolgovskij, M.K., Fasulo, P.D., Lortie, F., Macosko, C.W., Ottaviani, R.A., Rodgers, W.R.: Effect of mixer type on exfoliation of polypropylene nanocomposites. In: Proceedings of Annual Technical Conference of the Society of Plastics Engineers, vol. 49, pp. 2255–2259 (2003)

Fasulo P.D., Rodgers W.R., Ottaviani R.A., Hunter D.L.: Extrusion processing of TPO nanocomposites. Polym. Eng. Sci. 44, 1036–1045 (2004)

Xia H., Wang Q., Li K., Hu G.: Preparation of polypropylene/carbon nanotube composite powder with a solid-state mechanochemical pulverization process. J. App. Polym. Sci. 93(1), 378–386 (2004)

Potschke P., Kretzschmar B., Janke A.: Use of carbon nanotube filled polycarbonate in blends with montmorillonite filled polypropylene. Comp. Sci. Tech. 67, 855–860 (2007)

Chen L., Pang X.-J., Yu Z.-L.: Study on polycarbonate-multiwalled carbon nanotubes composite produced by melt processing. Mater. Sci. Eng. A 457, 287–291 (2007)

Yang J., Xu T., Lu A., Zhang Q., Fu Q.: Electrical properties of poly(phenylene sulfide)/multiwalled carbon nanotube composites prepared by simple mixing and compression. J. App. Polym. Sci. 109(2), 720–726 (2008)

Masuda J., Torkelson J.M.: Dispersion and major property enhancements in polymer/multiwall carbon nanotube nanocomposites via solid-state shear pulverization followed by melt mixing. Macromolecules 41, 5974–5977 (2008)

Prashantha K., Soulestin J., Lacrampe M.F., Krawczak P., Dupin G., Claes M.: Masterbatch-based multiwalled carbon nanotube filled polypropylene nanocomposites: assessment of rheological and mechanical properties. Comp. Sci. Tech. 69, 1756–1763 (2009)

Wu D., Sun Y., Zhang M.: Kinetics study on melt compounding of carbon nanotube/polypropylene nanocomposites. J. Polym. Sci. 47, 608–618 (2009)

Pan Y., Li L., Chan S.H., Zhao J.: Correlation between dispersion state and electrical conductivity of MWCNTs/PP composites prepared by melt blending. Composites A 41, 419–426 (2010)

Morishita T., Matsushita M., Katagiri Y., Fukumori K.: Noncovalent functionalization of carbon nanotubes with maleimide polymers applicable to high-melting polymer-based composites. Carbon 48, 2308–2316 (2010)

Lertwimolnun W., Vergnes B.: Influence of compatibilizer and processing conditions on the dispersion of nanoclay in a polypropylene matrix. Polymer 46(10), 3462–3471 (2005)

Kim D., Lee J.S., Barry C.F., Mead J.L.: Evaluation and prediction of the effects of melt processing conditions on the degree of mixing in alumina/poly (ethylene terephthalate) nanocomposites. J. App. Polym. Sci. 109(5), 2924–2934 (2008)

Manas-Zloczower I., Nir A., Tadmor Z.: Dispersive mixing in internal mixers. A theoretical model based on agglomerate rupture. Rubber Chem. Tech. 55, 1250–1285 (1982)

Manas-Zloczower I., Nir A., Tadmor Z.: Dispersive Mixing in Roll-Mills. Polym. Compos. 6(4), 222–231 (1985)

Gong X., Liu J., Baskaran S., Voise R., Young J.: Surfactant-assisted processing of carbon nanotube/polymer composites. Chem. Mater. 12, 1049–1052 (2000)

Zhu J., Kim J., Peng H., Margrave J., Khabashesku V., Barrera E.: Improving the dispersion and integration of single-walled carbon nanotubes in epoxy composites through functionalization. Nano Lett. 3(8), 1107–1113 (2003)

Malloy R.A.: Plastics Part Design for Injection Molding. Hanser/Gardner Publications, Cincinnati, OH (1994)

Liang G.D., Bao S.P., Tjong S.C.: Microstructure and properties of polypropylene composites filled with silver and carbon nanotube nanoparticles prepared by melt-compounding. Mater. Sci. Eng. B 147, 55–61 (2007)

Hwa So H., Cho J.W., Sahoo N.G.: Effect of carbon nanotubes on mechanical and electrical properties of polyimide/carbon nanotubes nanocomposites. Eur. Polym. J. 43, 3750–3756 (2007)

Mamunya Y., Boudenne A., Lebovka N., Ibos L., Candau Y., Lisunova M.: Electrical and thermophysical behavior of PVC-MWCNT nanocomposites. Comp. Sci. Tech. 68, 1981–1988 (2008)

Eshelby J.D.: The determination of the elastic field of an ellipsoidal inclusion and related problems. Proc. R. Soc. Lond. Ser. A 241, 376–396 (1957)

Hill R.: A self-consistent mechanics of composite materials. J. Mech. Phys. Solids 13, 189–198 (1965)

Budiansky B., O’Connell R.J.: Elastic moduli of a cracked solid. Int. J. Solids Struct. 12, 81–97 (1976)

Hoenig A.: Elastic moduli of a non-randomly cracked body. Int J. Solids Struct. 15, 137–154 (1979)

Laws N., Brockenbrough J.R.: The effect of microcrack systems on loss of stiffness of brittle solids. Int. J. Solids. Struct. 23, 1247–1268 (1987)

Laws N., Dvorak G.J.: The effect of fiber breaks and aligned penny-shaped cracks on the stiffness and energy release rates in unidirectional composites. Int. J. Solids Struct. 23, 1269–1283 (1987)

Christensen R.M., Lo K.H.: Solutions for effective shear properties in three phase sphere and cylinder models. J. Mech. Phys. Solids 27, 315–330 (1979)

Huang Y., Hu K.X., Chandra A.: A generalized self-consistent mechanics method for microcracked solids. J. Mech. Phys. Solids 42, 1273–1291 (1994)

Huang Y., Chandra A., Jiang Z.Q., Wei X., Hu K.X.: The numerical calculation of two-dimensional effective moduli for microcracked solids. Int. J. Solids Struct. 33, 1575–1586 (1994)

Salganik R.L.: Mechanics of bodies with many cracks. J. Mech. Phys. Solids 8, 135–143 (1973)

Norris A.N.: A differential method for the effective moduli of composites. Mech. Mater. 4, 1–16 (1985)

Zimmerman R.W.: The effect of microcracks on the elastic moduli of brittle materials. J. Mater. Sci. Lett. 4, 1457–1460 (1985)

Zimmerman R.W.: Elastic moduli of a solid containing spherical inclusions. Mech. Mater. 12, 17–24 (1991)

Hashin Z.: The differential method and its application to cracked materials. J. Mech. Phys. Solids 36, 719–734 (1988)

Mori T., Tanaka K.: Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall. 21(5), 571–574 (1973)

Weng G.J.: Some elastic properties of reinforced solids, with special reference to isotropic ones containing spherical inclusions. Int. J. Eng. Sci. 22, 845–856 (1984)

Weng G.J.: The theoretical connection between Mori–Tanaka’s theory and the Hashin–Shtrikman–Walpole bounds. Int. J. Eng. Sci. 28, 1111–1120 (1990)

Shen L., Li J.: Effective elastic moduli of composites reinforced by particle or fiber with an inhomogeneous interphase. Int. J. Solids Struct. 40, 1393–1409 (2003)

Shen L., Li J.: Homogenization of a fiber/sphere with an inhomogeneous interphase for the effective elastic moduli of composites. Proc. Roy. Soc. A 461, 1475–1504 (2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ngabonziza, Y., Li, J. & Barry, C.F. Electrical conductivity and mechanical properties of multiwalled carbon nanotube-reinforced polypropylene nanocomposites. Acta Mech 220, 289–298 (2011). https://doi.org/10.1007/s00707-011-0486-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00707-011-0486-y