Abstract

Radiolabeled 1,2,4,5-tetrazines are powerful heterocyclic agents for bioorthogonal PET imaging due to their fast cycloaddition with trans-cyclooctenes. However, fluorine-18 radiolabeling of highly reactive tetrazines is often not feasible due to limited compound stability. We demonstrate that post-radiolabeling oxidation of thioether functionalities is a viable and transferable strategy to avoid these limitations, enabling the synthesis of highly reactive 18F-tetrazines.

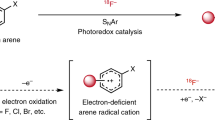

Graphical abstract

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

1,2,4,5-Tetrazines (Tz) react rapidly and selectively with alkenes and alkynes in a cycloaddition/cycloreversion cascade reaction first described by Carboni and Lindsey [1]. Exceptionally high second order rate constants can be reached using strained alkenes, such as trans-cyclooctene (TCO) [2]. In 2008, the group of Joseph M. Fox demonstrated that the reactions between tetrazines and TCOs are biocompatible and can be used as bioorthogonal ligation reactions [3].

While this type of click chemistry has emerged as a valuable tool for a variety of applications [4, 5], it is of particular interest to the field of radiolabeling and molecular imaging [6]. Here, high reaction rates and selectivity are crucial, given the diminutive concentrations of radiolabeled compounds and short half-lives of commonly used radioisotopes, such as fluorine-18. Enabled by bioorthogonal chemistry, pretargeting strategies decouple accumulation kinetics from the physical half-life of radionuclides: a tagged marker compound is administered and given sufficient time to accumulate in the desired target tissues. Following accumulation and subsequent excretion of non-bound marker, a radiolabeled agent is administered that rapidly binds to the pre-administered compound via a bioorthogonal reaction [4, 7,8,9,10]. Although a variety of bioorthogonal reactions have been reported, the ligation between 1,2,4,5-tetrazines and strained dienophiles proved to be especially suitable for radiolabeled agents owing to exceptionally high ligation rates of up to 107 M−1 s−1 [9, 11].

Early radiofluorination attempts of tetrazines conducted by Fox and coworkers resulted in degradation and led to the conclusion that 1,2,4,5-tetrazines are unstable under typical 18F-labeling conditions [12]. In 2014, the first radiofluorinated tetrazine, [18F]1, was developed in our lab [13] utilizing a dialkyl-scaffold that improves Tz stability to allow for direct fluorine-18 labeling. However, due to the lower reactivity the in vivo applicability of this probe proved to be limited. Since our first report of an 18F-labeled Tz, several such compounds have been reported by us and others using different labeling methods and scaffolds [14,15,16,17,18].

Here we investigated a series of derivatives of our original fluorine-18 labeled tetrazine with improved reactivity. Limitations in radiolabeling, caused by high reactivity of some of the tetrazines, can be circumvented by post-radiolabeling modification that boosts the reactivity after the radiolabeling step. We translate this concept of post-radiolabeling activation to highly reactive mono-substituted tetrazines, resulting in an 18F-labeled tetrazine with exceptional high reactivity.

Results and discussion

To improve on our previously reported tetrazine scaffold, 3-(3-fluoropropyl)-6-methyl-1,2,4,5-tetrazine (1), we exchanged the methyl group against different aryl substituents to enhance click reactivity (Fig. 1a). A range of electron withdrawing and electron donating substituents were chosen to cover a range of different reactivities and polarities, both of which were shown to influence in vivo performance of tetrazines [16].

First, 19F-labeled tetrazines 2–8 were synthesized applying the procedure developed by Devaraj and coworkers (Fig. 1b) [19]. 4-Fluorobutanenitrile (9) was used to directly produce the fluorinated compounds. Consecutively, their click reactivity with trans-cyclooctene (10) was investigated in anhydrous 1,4-dioxane at 25 °C using stopped-flow spectrophotometry. Second order rate constants were determined to range from 1.0 to 15 M−1 s−1 (Fig. 1c). As expected, the reactivity of aryl-substituted tetrazines modified with electron-donating groups (Me, OMe, SMe) was found to be similar to previously reported 1. In contrast, electron-withdrawing (trifluoromethyl)phenyl and 4-(methylsulfonyl)phenyl substituents accelerate the reaction by 3- to 5-fold. The highest reactivity is observed for the 2-pyridyl derivative where a combined electronic and distortion lowering effect is at play as recently revealed by our group [20]. A computational investigation on the click reactivity of alkyl-aryl substituted tetrazines 2–8 was published previously [21].

Having investigated the reaction rates of the fluorinated aryl–alkyl tetrazines, we next turned to radiolabeling. For direct nucleophilic 18-fluorine labeling of the tetrazines we used the corresponding tosylated precursors 17–22 which were prepared from tetrazine alcohols 11–16 (Fig. 2a). Synthesis of 11–16 was carried out using the same methodology as used for 2–8 [19]. Applying this method, the tosylated sulfone 24 could not be obtained. Therefore, this tetrazine was synthesized by oxidation of 21 to 23 using dimethyldioxirane (DMDO) [22] and subsequent tosylation. The p-tolyl tosylate 18 was used for optimization of the radiofluorination method. As the standard [2.2.2]cryptand/K2CO3 method proved to be most suitable for the preparation of [18F]1, the same procedure was applied for [18F]3 resulting in 11.2% yield (determined by radio-HPLC). DMSO as solvent or the use of KHCO3 instead of potassium carbonate resulted in lower yields (< 6%). When tetrabutylammonium (TBA) hydrogen carbonate in dry acetonitrile was used for labeling a significantly improved radiochemical yield of [18F]3 (22.9%) was noted. Further optimization of the reaction solvent revealed an increased yield of 56% when a 1:1 (v/v) mixture of acetonitrile and 2,3-dimethyl-2-butanol (thexyl alcohol) was used as solvent, which is in agreement with previous reports documenting the positive effect of tertiary alcohols on fluorine-18 radiolabeling (Fig. 2b) [23, 24]. This method was transferred onto an automated synthesis module (TRACERlab FXFDG synthesis module, GE Healthcare) housed in a shielded hot cell, where in a non-optimized sequence 10 GBq of [18F]3 could be obtained from 181 GBq cyclotron produced fluorine-18 (9.5% decay-corrected radiochemical yield). In this automated procedure, purification of the compounds was achieved by preparative RP-HPLC using 10 mM PO4-buffer (pH 6) and acetonitrile as eluents. The HPLC eluate was monitored in series for radioactivity and UV absorption, the product fraction was collected, diluted with water, and passed over a preactivated C18 Sep-Pak Plus cartridge (Waters, Milford, MA, USA). The cartridge was then eluted with 2.5 cm3 ethanol to obtain the respective [18F]tetrazines.

Applying the optimized radiolabeling conditions to phenyl-Tz-precursor 17, a radiochemical yield of 40% was achieved as determined by radio-TLC and radio-HPLC. As a result, 8.9 GBq of [18F]2 with a specific activity of 99 GBq/µmol were obtained using the automated synthesizer (6.3% isolated radiochemical yield). All attempts of nucleophilic fluorination with 4-CF3-phenyl Tz 19 as precursor failed to obtain at least 1% incorporation yield of [18F]4. Starting from 20, [18F]5 could be isolated in 15.8% decay-corrected radiochemical yield (18% yield as investigated by radio-HPLC) using the TBA-HCO3/thexyl-alcohol/acetonitrile system. Attempts to further optimize the reaction conditions for this particular derivative resulted in diminished yields. Using the automated synthesizer, 7.0 GBq of [18F]5 could be obtained, corresponding to a decay-corrected radiochemical yield of 4.9%. For the thiomethyl derivative [18F]6 up to 47.5% incorporation yield were measured by radio-HPLC. 11.5 GBq of [18F]6 (8.6% decay-corrected radiochemical yield) with high specific activity (230 GBq/µmol) were obtained using the automated TRACERlab FXFDG synthesis module. Attempts of preparing sulfone [18F]7 by direct radiofluorination of tosylate 24 failed due to decomposition of the tetrazine observed by HPLC analysis. We assume that the high reactivity of this tetrazine derivative renders direct 18F-labeling impossible. Despite excessive optimization attempts, we were not able to prepare the pyridyl derivative [18F]8 by nucleophilic fluorination of precursor 22 (radiochemical yields < 1%). In addition to the successful preparation of novel radio-tetrazines [18F]2, [18F]3, and [18F]4–6, the radiosynthesis of already described dialkyltetrazine [18F]1 could also be significantly improved to a decay-corrected isolated radiochemical yield of 35% (vs. previously reported 5%, [4]) using the TBA-HCO3, thexyl alcohol, and acetonitrile labeling system (Fig. 2c).

In conclusion, while showing lower reactivity, more electron-rich tetrazines can be radiolabeled by direct nucleophilic 18F-fluorination. Access to radiolabeled tetrazines with higher reactivity is not possible using this method. To address this limitation, we employed a different strategy in which the high reactivity of the tetrazine is established after the radiolabeling step. This post-radiolabeling activation allows stable but lower reactivity tetrazines to be used in the radiolabeling step, but still yields highly reactive radiolabeled compounds after additional activation. Using sulfide [18F]6, which can be radiolabeled in good yields, we prepared the more reactive [18F]7 by oxidation with DMDO (Fig. 3). A solution of [18F]6 in ethanol, as obtained by automated radiosynthesis, was concentrated to dryness, and redissolved in acetone (1 cm3) containing DMDO (~ 40 mM). After short reaction time (60–80 s) volatiles were removed on the rotary evaporator and the residue was purified using RP-HPLC to obtain [18F]7 in 56% radiochemical yield and a specific activity of 56 GBq/µmol thus bypassing the inaccessibility through direct radiolabeling.

Having demonstrated the applicability of post-radiolabeling activation through sulfide oxidation, we turned towards even more reactive compounds. Recently, we described the synthesis of fluorine-18 labeled tetrazines using a two-step reaction sequence in which an azide is first radiofluorinated and then connected to an alkyne-modified tetrazine by copper-catalyzed azide-alkyne cycloaddition (Fig. 4a) [16]. Using this strategy, highly reactive 18F-labeled tetrazines could be prepared with second order rate constants of up to 230 times higher than tetrazine 1. During that study we found that the copper-catalyzed azide-alkyne cycloaddition between the reactive sulfone-tetrazine 25 and 2-fluoroethylazide is not possible (Fig. 4b). However, we aimed to obtain the highly reactive sulfone Tz 26 by post-radiolabeling oxidation of sulfide 30 (Fig. 5).

a Two-step radiolabeling approach applying copper-catalyzed azide-alkyne cycloaddition [16]; b Failed attempt for the synthesis of Tz 26

a Synthesis of alkyne-modified tetrazine 29; b synthesis of 30 and subsequent DMDO oxidation to 31 and 26 (i: CuSO4 · 5 H2O, sodium ascorbate, sodium bathophenanthrolinedisulfonate); c second order rate constants for the reactions of 30 (X = SO), 31 (X = S), and 26 (X = SO2) with TCO (10) in 1,4-dioxane at 25 °C

The 19F-labeled reference compound 30 was prepared using Pinner salt 28, formamidine acetate, and hydrazine monohydrate, followed by oxidation with sodium nitrite under acidic conditions to obtain 29 (Fig. 5a), which was modified by copper-catalyzed click reaction with 2-fluoroethylazide. 30 could be selectively oxidized to the sulfoxide 31 and eventually to the sulfone 26 (Fig. 5b). As expected, reaction kinetics investigations revealed an increase in second order rate constants in correlation with increased sulfur oxidation state, ranging from 90 M−1 s−1 and 190 M−1 s−1 for 30 and 31, respectively, to 370 M−1 s−1 for 26 (Fig. 5c).

To test the post-radiolabeling activation strategy, 29 was coupled to fluorine-18 labeled [18F]2-fluoroethylazide (Fig. 6a), which was obtained starting from 2-azidoethyl nosylate using a fully automated procedure previously described by our group [25]. The highly volatile [18F]-fluoroethylazide was distilled into a vial already containing tetrazine 29 and a catalytic mixture of copper sulfate, sodium ascorbate, and disodium bathophenanthroline disulfonate (Na2BPDS) in dry DMF. The reaction was carried out for 103 min at room temperature until the mixture was diluted with DMSO/water (v/v, 1/1), purified by HPLC and the collected fraction was trapped on a Sep-Pak C18 plus cartridge which was eluted with acetonitrile. 41.4 mCi of [18F]30 were obtained, corresponding to 1.1% non-decay-corrected radiochemical yield. Further optimization of the click radiolabeling step was not carried out, as we focused on showing subsequent post-radiolabeling oxidation to the respective sulfone [18F]26 and sulfoxide [18F]31. Therefore, [18F]30 was treated with DMDO solution in acetone (~ 60 mM). After 1 min reaction time at room temperature, the mixture was concentrated, and the residue redissolved in acetonitrile. Radio-TLC revealed that the radiofluorinated sulfide [18F]30 already contained traces of the sulfoxide and sulfone tetrazines [18F]31 and [18F]26, respectively, most likely due to air oxidation. Analysis of the DMDO-treated mixture confirmed complete conversion of the sulfide [18F]31 to a mixture of the sulfoxide [18F]31 and the sulfone [18F]26 after a reaction time of 1 min (Fig. 6b).

Conclusion

We show that post-radiolabeling activation via rapid sulfur oxidation is a viable strategy for the synthesis of highly reactive 18F-tetrazines, in particular if the respective Tz scaffold/precursor cannot be directly radiofluorinated. To demonstrate this concept, 18F-labeled phenyl-substituted tetrazines were prepared, including Tz scaffolds with high bioorthogonal reactivity.

Experimental

Unless otherwise noted, reactions were carried out under an atmosphere of argon in air-dried glassware with magnetic stirring. Air- and/or moisture-sensitive liquids were transferred via syringe. All reagents were purchased from commercial sources and used without further purification. Dichloromethane, methanol, THF, diethyl ether, and 1,4-dioxane were dried using PURESOLV-columns (Inert Corporation, USA). Solvents used for flash column chromatography were purchased from Donau Chemie AG (Austria). Dry acetonitrile and dry DMF were obtained from Sigma-Aldrich (Germany) and ACROS Organics (Belgium), respectively, and stored under argon. Thin layer chromatography was performed using TLC plates on aluminum support (Merck, silica gel 60, fluorescent indicator 254). Column chromatography was performed using a BUCHI Sepacore Flash System (2 × BUCHI Pump Module C-605, BUCHI Pump Manager C-615, BUCHI UV Photometer C-635, and BUCHI Fraction Collector C-660) and a Reveleris® X2 Flash Chromatography/Prep Purification Systems (BUCHI). Silica gel 60 (40–63 µm) was obtained from Merck. A Kinetex® 5 µm C18 100 Å, AXIA LC column (100 × 30.0 mm, Phenomenex) was used for preparative HPLC. HPLC grade solvents were purchased from VWR (USA).

1H, 13C, and 19F NMR spectra were recorded on a Bruker AC 200 MHz, Bruker Avance UltraShield 400 MHz, or Bruker Avance III 600 MHz spectrometer at 20 °C. Chemical shifts are reported in ppm (δ) relative to tetramethylsilane and calibrated using solvent residual peaks. Data is shown as follows: chemical shift, multiplicity (s = singlet, d = doublet, t = triplet, q = quartet, quint = quintet, m = multiplet, b = broad signal), coupling constants (J, Hz), and integration.

GC/MS experiments were done with a Thermo Finnigan GC 8000 Top gaschromatograph on a BGB5 column (l = 30 m, di = 0.32 mm, 1 µm coating thickness) coupled to a Voyager Quadrupol mass spectrometer (electron ionization, 70 eV). HPLC analysis was performed on a Nexera X2® UHPLC system (Shimadzu®) comprised of LC-30AD pumps, SIL-30AC autosampler, CTO-20AC column oven and DGU-20A5/3 degasser module. Detection was done using an SPD-M20A photo diode array, an RF-20Axs fluorescence detector, and ELS-2041 evaporative light scattering detector (JASCO®) and an LCMS-2020 mass spectrometer (ESI/APCI). If not stated otherwise, all separations were performed using a Waters® XSelect® CSH™ C18 2,5 µm (3.0 × 50 mm) column XP at 40 °C, and a flowrate of 1.7 cm3/min with water/acetonitrile + 0.1% formic acid gradient elution.

HRMS analysis was carried out using methanol solutions (concentration: 10 ppm) on an Agilent 6230 LC TOFMS mass spectrometer equipped with an Agilent Dual AJS ESI-Source. The mass spectrometer was connected to a liquid chromatography system of the 1100/1200 series from Agilent Technologies (Palo Alto, CA, USA). The system consisted of a 1200SL binary gradient pump, a degasser, column thermostat, and an HTC PAL autosampler (CTC Analytics AG, Zwingen, Switzerland).

trans-Cyclooctene (TCO, 10) [26], 4-mercaptobenzonitrile [27], as well as DMDO [22] were prepared following known procedures. Dry hydrazine was prepared by the vacuum thermolysis of hydrazine cyanurate [28]. 2-fluoroethylazide was synthesized according to known procedure [29].

4-Fluorobutanenitril (9)

Warning: Alkylfluorides are potentially highly toxic! NaCN is highly toxic! A mixture of 1-bromo-3-fluoropropane (14.1 g, 100 mmol), powdered NaCN (6.12 g, 125 mmol), and triethylene glycol (20 cm3) was slowly heated to 130 °C. Care must be taken due to an exothermic reaction setting in at ~ 40 °C. The mixture was kept between 120–140 °C for 2 h. After cooling to room temperature, the mixture was distilled to obtain the desired product as a colorless liquid (5.5 g, 63%). 1H NMR (200 MHz, CDCl3): δ = 1.86–2.14 (m, 2H), 2.47 (t, J = 7.0 Hz, 2H), 4.51 (dt, J = 47.0 Hz, 5.5 Hz, 2H) ppm; 13C NMR (50 MHz, CDCl3): δ = 13.2 (d, J = 5.06 Hz), 26.2 (d, J = 20.7 Hz), 81.2 (d, J = 166.8 Hz), 118.7 ppm.

General procedure A for the synthesis of compounds 1–6 and 8

A well-blended mixture of 4-fluorobutanenitrile (9, 1–2 eq.), a nitrile (1–7 eq.), and Zn(OTf)2 (5 mol%) or NiCl2 (5 mol%) was treated dropwise with hydrazine monohydrate (6–36 eq.) while cooled in an ice bath. The mixture was allowed to warm up to room temperature and stirred at the specified temperature for the specified time. The crude reaction mixture was poured onto ice-water (50 cm3). After addition of NaNO2 (4 eq.) the solution was acidified with aqueous 2 N HCl solution. The mixture was extracted with EtOAc or Et2O, dried over MgSO4, filtered and concentrated. The crude product was purified by column chromatography.

3-(3-Fluoropropyl)-6-methyl-1,2,4,5-tetrazine (1)

Synthesis was performed according to general procedure A using 4-fluorobutanenitrile (9, 100 mg, 1.15 mmol), dry acetonitrile (423 mm3, 8 mmol), Zn(OTf)2 (192 mg, 0.53 mmol), and hydrazine monohydrate (1.25 cm3, 41.1 mmol). After stirring at 42 °C for 24 h the reaction mixture was oxidized using NaNO2 (550 mg, 8 mmol) and 2 N HCl, and extracted with Et2O (4 × 150 cm3). Purification was performed by column chromatography (Et2O in hexanes, gradient elution) to give the desired product as a red oil (67.3 mg, 38%). Spectroscopic data matched previously reported [13].

3-(3-Fluoropropyl)-6-phenyl-1,2,4,5-tetrazine (2, C11H11FN4)

Synthesis was performed according to general procedure A using benzonitrile (237 mg, 2.3 mmol), 4-fluorobutanenitrile (9, 400 mg, 4.6 mmol), NiCl2 (45 mg, 0.35 mmol), and hydrazine monohydrate (1.1 cm3, 21 mmol). After stirring at 52 °C for 16 h the reaction mixture was oxidized using NaNO2 (2.54 g, 37 mmol) and 2 N HCl, and extracted with EtOAc (4 × 100 cm3). Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to give the desired product as a purple solid (83 mg, 17%). 1H NMR (400 MHz, CDCl3): δ = 2.36–2.50 (m, 2H), 3.53 (t, J = 7.8 Hz, 2H), 4.65 (dt, J = 47.2 Hz, 5.9 Hz, 2H), 7.57–7.66 (m, 3H), 8.57–8.63 (m, 2H) ppm; 13C NMR (101 MHz, CDCl3): δ = 28.5 (d, J = 20.5 Hz), 30.9 (d, J = 4.9 Hz), 82.8 (d, J = 166.7 Hz), 127.9, 129.2, 131.7, 132.6, 164.3, 169.2 ppm; 19F NMR (377 MHz, CDCl3): δ = − 219.9 ppm; HRMS: m/z calcd. for C11H12FN4+ ([M + H]+) 219.1041, found 219.1048.

3-(3-Fluoropropyl)-6-(p-tolyl)-1,2,4,5-tetrazine (3, C12H13FN4)

Synthesis was performed according to general procedure A using 4-methylbenzonitrile (404 mg, 3.44 mmol), 4-fluorobutanenitrile (9, 560 mg, 6.43 mmol), NiCl2 (68 mg, 0.52 mmol), and hydrazine monohydrate (1.5 cm3, 31 mmol). After stirring at 65 °C for 20 h the reaction mixture was oxidized using NaNO2 (2.85 g, 41 mmol) and 2 N HCl, and extracted with EtOAc (4 × 100 cm3). Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to give the desired product as red crystals (51 mg, 6%). 1H NMR (400 MHz, CDCl3): δ = 2.33–2.50 (m, 5H), 3.51 (t, J = 7.60 Hz, 2H), 4.64 (dt, J = 47.1 Hz, 5.6 Hz, 2H), 7.39 (d, J = 8.2 Hz, 2H), 8.48 (d, J = 8.2 Hz, 2H) ppm; 13C NMR (101 MHz, CDCl3): δ = 21.6, 28.5 (d, J = 20.7 Hz), 30.8 (d, J = 5.4 Hz), 82.9 (d, J = 166.4 Hz), 127.9, 128.9, 130.0, 143.3, 164.3, 168.9 ppm; 19F NMR (377 MHz, CDCl3): δ = − 219.9 ppm; HRMS: m/z calcd. for C12H14FN4+ ([M + H]+) 233.11970, found 233.11922.

3-(3-Fluoropropyl)-6-[4-(trifluoromethyl)phenyl]-1,2,4,5-tetrazine (4, C12H10F4N4)

Synthesis was performed according to general procedure A using 4-trifluoromethylbenzonitrile (500 mg, 2.92 mmol), 4-fluorobutanenitrile (9, 509 mg, 5.84 mmol), NiCl2 (57 mg, 0.44 mmol), and hydrazine monohydrate (1.3 cm3, 26 mmol). After stirring at 65 °C for 24 h the reaction mixture was oxidized using NaNO2 (1.2 g, 18 mmol) and 2 N HCl, and extracted with EtOAc (4 × 100 cm3). Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to give the desired product as purple crystals (39 mg, 5%). 1H NMR (400 MHz, CDCl3): δ = 2.38–2.53 (m, 2H), 3.58 (t, J = 7.8 Hz, 2H), 4.67 (dt, J = 46.8 Hz, 5.5 Hz, 2H), 7.87 (d, J = 8.2 Hz, 2H), 8.75 (d, J = 8.2 Hz, 2H) ppm; 13C NMR (101 MHz, CDCl3): δ = 28.5 (d, J = 19.8 Hz), 31.1 (d, J = 4.9 Hz), 82.8 (d, J = 166.0 Hz), 123.7 (q, J = 272.7 Hz), 126.2 (q, J = 3.5 Hz), 128.3, 134.2 (q, J = 33.2 Hz), 163.5, 169.9 ppm; 19F NMR (377 MHz, CDCl3): δ = − 219.9 (1F), − 63.1 (3F) ppm; HRMS: m/z calcd. for C12H11F4N4+ ([M + H]+) 287.09144, found 287.09058.

3-(3-Fluoropropyl)-6-(3,4,5-trimethoxyphenyl)-1,2,4,5-tetrazine (5, C14H17FN4O3)

Synthesis was performed according to general procedure A using 3,4,5-trimethoxybenzonitrile (444 mg, 2.3 mmol), 4-fluorobutanenitrile (9, 400 mg, 4.6 mmol), NiCl2 (45 mg, 0.35 mmol), and hydrazine monohydrate (1.1 cm3, 21 mmol). After stirring at 52 °C for 16 h the reaction mixture was oxidized using NaNO2 (2.54 g, 37 mmol) and 2 N HCl, and extracted with EtOAc (4 × 100 cm3). Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to give the desired product as a red solid (13 mg, 2%). 1H NMR (400 MHz, CDCl3): δ = 2.35–2.51 (m, 2H), 3.53 (t, J = 7.8 Hz, 2H), 3.98 (s, 3H), 4.00 (s, 6H), 4.66 (dt, J = 46.8 Hz, 5.9 Hz, 2H), 7.90 (s, 2H) ppm; 13C NMR (101 MHz, CDCl3): δ = 28.4 (d, J = 20.5 Hz), 30.8 (d, J = 4.9 Hz), 56.3, 61.0, 82.9 (d, J = 166.0 Hz), 105.1, 126.6, 142.1, 153.9, 163.8, 168.9 ppm; 19F NMR (377 MHz, CDCl3): δ = − 219.9 ppm; HRMS: m/z calcd. for C14H18FN4O3+ ([M + H]+) 309.1357, found 309.1359.

3-(3-Fluoropropyl)-6-[4-(methylthio)phenyl]-1,2,4,5-tetrazine (6, C12H13FN4S) and 3-(3-fluoropropyl)-6-[4-(methylsulfinyl)phenyl]-1,2,4,5-tetrazine (32, C12H13FN4OS)

Synthesis was performed according to general procedure A using 4-(methylthio)benzonitrile (443 mg, 2.3 mmol), 4-fluorobutanenitrile (9, 400 mg, 4.6 mmol), NiCl2 (45 mg, 0.35 mmol), and hydrazine monohydrate (1.1 cm3, 21 mmol). After stirring at 42 °C for 18 h the reaction mixture was oxidized using NaNO2 (2.54 g, 37 mmol) and 2 N HCl, and extracted with EtOAc (4 × 100 cm3). Purification was performed by column chromatography (DCM in hexanes, gradient elution) to give 6 as a red solid (8 mg, 1.3%) and the oxidized sulfoxide 3-(3-fluoropropyl)-6-[4-(methylsulfinyl)phenyl]-1,2,4,5-tetrazine (32) as purple solid (2 mg, 0.4%).

6: 1H NMR (400 MHz, CDCl3): δ = 2.35–2.51 (m, 2H), 2.58 (s, 3H), 3.52 (t, J = 7.8 Hz, 2H), 4.66 (dt, J = 47.2 Hz, 5.5 Hz, 2H), 7.42 (dt, J = 8.6 Hz, 2.0 Hz, 2H), 8.52 (dt, J = 8.9 Hz, 2.0 Hz, 2H) ppm; 13C NMR (101 MHz, CDCl3): δ = 14.9, 28.5 (d, J = 20.5 Hz), 30.6 (d, J = 5.67 Hz), 82.9 (d, J = 166.7 Hz), 125.9, 127.8, 128.1, 145.4, 164.1, 168.9 ppm; 19F NMR (377 MHz, CDCl3): δ = − 219.9 ppm; HRMS: m/z calcd. for C12H14FN4S+ ([M + H]+) 265.0918, found 265.0923.

33: 1H NMR (600 MHz, CDCl3): δ = 2.40–2.50 (m, 2H), 2.83 (s, 3H), 3.58 (t, J = 7.6 Hz, 2H), 4.67 (dt, J = 46.9 Hz, 5.6 Hz, 2H), 7.89 (dt, J = 8.8 Hz, 1.8 Hz, 2H), 8.79 (dt, J = 8.8 Hz, 1.8 Hz, 2H) ppm; 13C NMR (151 MHz, CDCl3): δ = 28.4 (d, J = 19.6 Hz), 31.0 (d, J = 5.5 Hz), 43.9, 82.9 (d, J = 166.8 Hz), 124.4, 128.8, 134.3, 150.6, 163.6, 169.8 ppm; 19F NMR (377 MHz, CDCl3): δ = − 219.9 ppm.

3-(3-Fluoropropyl)-6-[4-(methylsulfonyl)phenyl]-1,2,4,5-tetrazine (7, C12H13FN4O2S)

3-(3-fluoropropyl)-6-[4-(methylsulfinyl)phenyl]-1,2,4,5-tetrazine (6, 20 mg, 0.07 mmol) was treated with an ice-cold solution of dimethyl dioxirane (DMDO) in acetone (10 cm3, ~ 40 mM). The pink reaction mixture was allowed to warm to room temperature and stirred for 40 min. The mixture was concentrated and the residue purified by column chromatography (EtOAc in hexanes, gradient elution) to afford the desired product as a pink solid (13 mg, 63%). 1H NMR (400 MHz, CDCl3): δ = 2.39–2.54 (m, 2H), 3.14–3.17 (m, 3H), 3.60 (t, J = 7.8 Hz, 2H), 4.67 (dt, J = 46.8 Hz, 5.5 Hz, 2H), 8.20 (dt, J = 8.5 Hz, 2.0 Hz, 2H), 8.84 (dt, J = 8.6 Hz, 2.0 Hz, 2H) ppm; 13C NMR (101 MHz, CDCl3): δ = 28.5 (d, J = 20.5 Hz), 31.2 (d, J = 5.7 Hz), 44.4, 82.8 (d, J = 166.7 Hz), 128.3, 128.8, 136.7, 144.1, 163.25, 170.1 ppm; 19F NMR (377 MHz, CDCl3): δ = − 219.8 ppm; HRMS: m/z calcd. for C12H14FN4O2S+ ([M + H]+) 297.0816, found 297.0816.

3-(3-Fluoropropyl)-6-(pyridin-2-yl)-1,2,4,5-tetrazine (8, C10H10FN5)

Synthesis was performed according to general procedure A using 2-pyridinecarbonitrile (561 mg, 5.4 mmol), 4-fluorobutanenitrile (9, 470 mg, 5.4 mmol), NiCl2 (70 mg, 0.54 mmol), and hydrazine monohydrate (1.6 cm3, 32 mmol). After stirring at 60 °C for 24 h the reaction mixture was oxidized using NaNO2 (1.52 g, 22 mmol) and 2 N HCl, and extracted with EtOAc (4 × 100 cm3). Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to give the desired product as a red oil (128 mg, 11%). 1H NMR (400 MHz, CDCl3): δ = 2.29–2.44 (m, 2H), 3.52 (t, J = 7.7 Hz, 2H), 4.58 (dt, J = 47.2 Hz, 5.9 Hz, 2H), 7.46–7.52 (m, 1H), 7.92 (td, J = 7.9 Hz, 1.8 Hz, 1H), 8.56 (d, J = 7.7 Hz, 1H), 8.87 (d, J = 4.03 Hz, 1H) ppm; 13C NMR (101 MHz, CDCl3): δ = 28.3 (d, J = 20.7 Hz), 30.9 (d, J = 4.6 Hz), 82.7 (d, J = 166.4 Hz), 123.8, 126.2, 137.3, 150.0, 150.7, 163.6, 169.9 ppm; 19F NMR (377 MHz, CDCl3): δ = − 219.9 ppm; HRMS: m/z calcd. for C10H11FN5+ ([M + H]+) 220.09930, found 220.09865.

General procedure B for the synthesis of compounds 11–16

A well-blended mixture of a nitrile (1 eq.), 4-hydroxybutanenitrile (2 eq.), and NiCl2 (5 mol%) was treated dropwise with hydrazine monohydrate (9–12 eq.) while cooling in an ice bath. The mixture was allowed to warm up to room temperature and stirred at the specified temperature for the specified time. The crude reaction mixture was poured onto ice-water (50 cm3). After addition of NaNO2 (4–6 eq.) the solution was acidified with aqueous 2 N HCl solution. The mixture was extracted with EtOAc, dried over MgSO4, filtered and concentrated. The crude product was purified by column chromatography.

3-(6-Phenyl-1,2,4,5-tetrazin-3-yl)propan-1-ol (11, C11H12N4O)

Synthesis was performed according to general procedure B using benzonitrile (4 g, 38.8 mmol), 4-hydroxybutanenitrile (6.6 g, 77.6 mmol), NiCl2 (753 mg, 5.8 mmol), and hydrazine monohydrate (16.9 cm3, 350 mmol). After stirring at 42 °C for 72 h the reaction mixture was oxidized using NaNO2 (16 g, 233 mmol) and 2 N HCl, and extracted with EtOAc (4 × 250 cm3). Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to give the desired product as a purple solid (3.6 g, 42%). 1H NMR (400 MHz, CDCl3): δ = 1.73 (bs, 1H), 2.24–2.33 (m, 2H), 3.52 (t, J = 7.4 Hz, 2H), 3.85 (t, J = 6.1 Hz, 2H), 7.57–7.67 (m, 3H), 8.58–8.63 (m, 2H) ppm; 13C NMR (101 MHz, CDCl3): δ = 30.6, 31.5, 61.8, 127.9, 129.2, 131.8, 132.6, 164.2, 169.9 ppm; HRMS: m/z calcd. for C11H13N4O+ ([M + H]+) 217.1084, found 217.1089.

3-[6-(p-Tolyl)-1,2,4,5-tetrazin-3-yl]propan-1-ol (12, C12H14N4O)

Synthesis was performed according to general procedure B using 4-methylbenzonitrile (1 g, 8.54 mmol), 4-hydroxybutanenitrile (1.45 g, 17.1 mmol), NiCl2 (166 mg, 1.28 mmol), and hydrazine monohydrate (3.7 cm3, 77 mmol). After stirring at 65 °C for 23 h the reaction mixture was oxidized using NaNO2 (3.5 g, 51 mmol) and 2 N HCl, and extracted with EtOAc (4 × 100 cm3). Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to afford the desired product as purple crystals (620 mg, 32%). 1H NMR (400 MHz, CDCl3): δ = 2.25 (quin, J = 7.3 Hz, 2H), 2.41 (bs, 1H), 2.44 (s, 3H), 3.46 (t, J = 7.5 Hz, 2H), 3.82 (t, J = 6.1 Hz, 2H), 7.36 (d, J = 8.2 Hz, 2H), 8.43 (d, J = 8.2 Hz, 2H) ppm; 13C NMR (101 MHz, CDCl3): δ = 21.6, 30.6, 31.4, 61.6, 127.8, 128.9, 129.9, 143.2, 164.2, 169.5 ppm; HRMS: m/z calcd. for C12H15N4O+ ([M + H]+) 231.12404, found 231.12349.

3-[6-[4-(Trifluoromethyl)phenyl]-1,2,4,5-tetrazin-3-yl]propan-1-ol (13, C12H9F3N4O)

Synthesis was performed according to general procedure B using 4-(trifluoromethyl)benzonitrile (500 mg, 2.92 mmol), 4-hydroxybutanenitrile (497 mg, 5.84 mmol), NiCl2 (57 mg, 0.44 mmol), and hydrazine monohydrate (1.3 cm3, 26 mmol). After stirring at 60 °C for 24 h the reaction mixture was oxidized using NaNO2 (1.2 g, 17.5 mmol) and 2 N HCl, and extracted with EtOAc (4 × 100 cm3). Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to afford the desired product as purple crystals (226 mg, 27%). 1H NMR (400 MHz, CDCl3): δ = 1.74 (bs, 1H), 2.30 (quin, J = 6.7 Hz, 2H), 3.55 (t, J = 7.5 Hz, 2H), 3.86 (t, J = 5.9 Hz, 2H), 7.86 (d, J = 8.2 Hz, 2H), 8.73 (d, J = 8.2 Hz, 2H) ppm; 13C NMR (101 MHz, CDCl3): δ = 30.6, 31.7, 61.7, 123.7 (q, J = 272.2 Hz), 126.2 (q, J = 3.8 Hz), 128.2, 134.1 (q, J = 32.9 Hz), 135.1, 163.3, 170.5 ppm; 19F NMR (377 MHz, CDCl3): δ = − 63.1 ppm; HRMS: m/z calcd. for C12H10F3N4O− ([M–H]−) 283.08122, found 283.08203.

3-[6-(3,4,5-Trimethoxyphenyl)-1,2,4,5-tetrazin-3-yl]propan-1-ol (14, C14H18F3N4O4)

Synthesis was performed according to general procedure B using 3,4,5-trimethoxybenzonitrile (1 g, 5.18 mmol), 4-hydroxybutanenitrile (881 mg, 10.4 mmol), NiCl2 (100 mg, 0.77 mmol), and hydrazine monohydrate (3.1 cm3, 63 mmol). After stirring at 50 °C for 72 h the reaction mixture was oxidized using NaNO2 (2.2 g, 31 mmol) and 2 N HCl, and extracted with EtOAc (4 × 100 cm3). Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to afford the desired product as a pink crystalline solid (198 mg, 13%). 1H NMR (400 MHz, CDCl3): δ = 2.22–2.32 (m, 2H), 3.50 (t, J = 7.4 Hz, 2H), 3.85 (t, J = 6.1 Hz, 2H), 3.97 (s, 3H), 4.00 (s, 6H), 7.89 (s, 2H) ppm; 13C NMR (101 MHz, CDCl3): δ = 30.6, 31.4, 56.3, 61.0, 61.8, 105.0, 126.7, 142.0, 153.9, 163.7, 169.6 ppm; HRMS: m/z calcd. for C14H19F3N4O4+ ([M + H]+) 307.1401, found 307.1406.

3-[6-[4-(Methylthio)phenyl]-1,2,4,5-tetrazin-3-yl]propan-1-ol (15, C12H14N4OS)

Synthesis was performed according to general procedure B using 4-(methylthio)benzonitrile (1 g, 6.7 mmol), 4-hydroxybutanenitrile (1.14 g, 13.4 mmol), NiCl2 (129 mg, 1 mmol), and hydrazine monohydrate (3 cm3, 60 mmol). After stirring at 52 °C for 18 h the reaction mixture was oxidized using NaNO2 (4 g, 54 mmol) and 2 N HCl, and extracted with EtOAc (4 × 100 cm3). Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to afford the desired product as a red solid (96 mg, 6%). 1H NMR (400 MHz, CDCl3): δ = 2.26 (tt, J = 7.4 Hz, 6.2 Hz, 2H), 2.57 (s, 3H), 3.48 (t, J = 7.4 Hz, 2H), 3.83 (t, J = 6.1 Hz, 2H), 7.40 (dt, J = 8.6 Hz, 2.3 Hz, 2H), 8.48 (dt, J = 8.6 Hz, 2.3 Hz, 2H) ppm; 13C NMR (101 MHz, CDCl3): δ = 14.8, 30.6, 31.4, 61.7, 125.9, 128.0, 145.2, 163.9, 169.5 ppm; HRMS: m/z calcd. for C12H15N4OS+ ([M + H]+) 263.0961, found 263.0970.

3-[6-(Pyridin-2-yl)-1,2,4,5-tetrazin-3-yl]propan-1-ol (16, C10H11N5O)

Synthesis was performed according to general procedure B using 2-pyridinecarbonitrile (1 g, 9.6 mmol), 4-hydroxybutanenitrile (1.6 g, 19.2 mmol), NiCl2 (188 mg, 1.44 mmol), and hydrazine monohydrate (4.2 cm3, 86 mmol). After stirring at 45 °C for 16 h the reaction mixture was oxidized using NaNO2 (4.1 g, 60 mmol) and 2 N HCl, and extracted with EtOAc (4 × 100 cm3). Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to afford the desired product as a red crystalline solid (130 mg, 6%). 1H NMR (400 MHz, CDCl3): δ = 2.23–2.32 (m, 2H), 3.55 (t, J = 7.4 Hz, 2H), 3.83 (t, J = 6.1 Hz, 2H), 7.55 (ddd, J = 7.7 Hz, 4.8 Hz, 1.2 Hz, 1H), 7.97 (td, J = 7.8 Hz, 1.9 Hz, 1H), 8.61–8.65 (m, 1H), 8.90–8.96 (m, 1H) ppm; 13C NMR (101 MHz, CDCl3): δ = 30.7, 31.7, 61.6, 123.9, 126.4, 137.5, 150.2, 150.8, 163.5, 170.8 ppm; HRMS: m/z calcd. for C10H12N5O+ ([M + H]+) 218.10364, found 218.10316.

3-[6-[4-(Methylsulfonyl)phenyl]-1,2,4,5-tetrazin-3-yl]propan-1-ol (23, C12H14N4O3S)

3-[6-[4-(Methylthio)phenyl]-1,2,4,5-tetrazin-3-yl]propan-1-ol (15, 40 mg, 0.15 mmol) was treated with an ice-cold solution of dimethyl dioxirane (DMDO) in acetone (25 cm3, approx. 40 mM). The pink reaction mixture was allowed to warm to room temperature and stirred for 30 min. The mixture was concentrated and the residue purified by column chromatography (MeOH in DCM, gradient elution) to afford the desired product as pink solid (34 mg, 75%). 1H NMR (600 MHz, DMSO-d6): δ = 2.06–2.13 (m, 2H), 3.39 (t, J = 7.6 Hz, 2H), 3.55–3.60 (m, 2H), 4.63 (t, J = 5.1 Hz, 1H), 8.22 (dt, J = 8.5 Hz, 1.8 Hz, 2H), 8.72 (dt, J = 8.8 Hz, 2.1 Hz, 2H) ppm; 13C NMR (151 MHz, DMSO-d6): δ = 30.6, 31.3, 43.3, 60.0, 128.0, 128.4, 136.6, 143.8, 162.6, 170.3 ppm; HRMS: m/z calcd. for C12H15N4O3S+ ([M + H]+) 295.0859, found 295.0873.

General procedure C for the synthesis of compounds 17–22 and 24

A mixture of respective butanol-tetrazine (1 eq.) and tosyl chloride (2–4 eq.) was dissolved in dry DCM and cooled in an ice-bath. Dry pyridine (2–4 eq.) was added dropwise, and the mixture was stirred at room temperature for the specified time. The crude reaction mixture was diluted with DCM, washed with water and aqueous 1 N HCl followed by aqueous NaHCO3 solution. Combined organic layer was dried over MgSO4, filtered and concentrated. The crude product was purified by column chromatography.

3-(6-Phenyl-1,2,4,5-tetrazin-3-yl)propyl 4-methylbenzenesulfonate (17)

Synthesis was performed according to general procedure C using 3-(6-phenyl-1,2,4,5-tetrazin-3-yl)propan-1-ol (11, 200 mg, 0.93 mmol), tosyl chloride (353 mg 1.85 mmol), and pyridine (146 mm3, 1.85 mmol) in DCM (30 cm3). After stirring for 24 h the reaction mixture the described workup was followed. Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to afford the desired product as a purple crystalline solid (250 mg, 73%). 1H NMR (400 MHz, CDCl3): δ = 2.36–2.44 (m, 5H), 3.44 (t, J = 7.4 Hz, 2H), 4.25 (t, J = 6.1 Hz, 2H), 7.30 (d, J = 8.2 Hz, 2H), 7.57–7.68 (m, 3H), 7.74–7.80 (m, 2H), 8.56–8.60 (m, 2H) ppm; 13C NMR (101 MHz, CDCl3): δ = 21.6, 26.6, 30.7, 68.9, 127.9, 128.0, 129.3, 129.8, 131.6, 132.7, 132.8, 144.9, 164.3, 168.6 ppm.

3-[6-(p-Tolyl)-1,2,4,5-tetrazin-3-yl]propyl 4-methylbenzenesulfonate (18, C19H20N4O3S)

Synthesis was performed according to general procedure C using 3-[6-(p-tolyl)-1,2,4,5-tetrazin-3-yl]propan-1-ol (12, 330 mg, 1.43 mmol), tosyl chloride (681 mg 3.6 mmol), and pyridine (350 mm3, 4.3 mmol) in DCM (8 cm3). After stirring for 16 h the reaction mixture the described workup was followed. Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to afford the desired product as a red crystalline solid (430 mg, 78%). 1H NMR (400 MHz, CDCl3): δ = 2.35–2.43 (m, 5H), 2.48 (s, 3H), 3.41 (t, J = 7.5 Hz, 2H), 4.24 (t, J = 6.1 Hz, 2H), 7.30 (d, J = 8.2 Hz, 2H), 7.40 (d, J = 8.2 Hz, 2H), 7.77 (d, J = 8.2 Hz, 2H), 8.46 (d, J = 8.2 Hz, 2H) ppm; 13C NMR (101 MHz, CDCl3): δ = 21.6, 21.7, 26.6, 30.7, 69.0, 127.8, 127.9, 128.8, 129.8, 130.0, 143.4, 144.9, 164.3, 168.3 ppm; HRMS: m/z calcd. for C19H21N4O3S+ ([M + H]+) 385.13289, found 385.13181.

3-[6-[4-(Trifluoromethyl)phenyl]-1,2,4,5-tetrazin-3-yl]propyl 4-methylbenzenesulfonate (19)

Synthesis was performed according to general procedure C using 3-[6-[4-(trifluoromethyl)phenyl]-1,2,4,5-tetrazin-3-yl]propan-1-ol (13, 100 mg, 0.35 mmol), tosyl chloride (134 mg 0.71 mmol), and pyridine (60 mm3, 0.71 mmol) in DCM (5 cm3). After stirring for 16 h the reaction mixture the described workup was followed. Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to afford the desired product as a purple crystalline solid (125 mg, 81%). 1H NMR (400 MHz, CDCl3): δ = 2.37–2.47 (m, 5H), 3.49 (t, J = 7.5 Hz, 2H), 4.26 (t, J = 5.9 Hz, 2H), 7.31 (d, J = 7.9 Hz, 2H), 7.77 (d, J = 8.2 Hz, 2H), 7.87 (d, J = 8.2 Hz, 2H), 8.71 (d, J = 8.2 Hz, 2H) ppm; 13C NMR (101 MHz, CDCl3): δ = 21.6, 26.6, 31.0, 68.9, 123.7 (q, J = 272.2 Hz), 126.2 (q, J = 3.1 Hz), 127.9, 128.3, 129.9, 132.7, 134.2 (q, J = 32.9 Hz), 135.0, 144.9, 163.4, 169.3 ppm.

3-[6-(3,4,5-Trimethoxyphenyl)-1,2,4,5-tetrazin-3-yl]propyl 4-methylbenzenesulfonate (20, C21H24N4O6S)

Synthesis was performed according to general procedure C using 3-[6-(3,4,5-trimethoxyphenyl)-1,2,4,5-tetrazin-3-yl]propan-1-ol (14, 100 mg, 0.33 mmol), tosyl chloride (124 mg 0.65 mmol), and pyridine (55 mm3, 0.65 mmol) in DCM (2 cm3). After stirring for 24 h the reaction mixture the described workup was followed. Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to afford the desired product as a red crystalline solid (142 mg, 95%). 1H NMR (400 MHz, CDCl3): δ = 2.36–2.44 (m, 5H), 3.43 (t, J = 7.4 Hz, 2H), 3.98 (s, 3H), 3.99–4.03 (m, 6H), 4.26 (t, J = 6.1 Hz, 2H), 7.32 (d, J = 7.8 Hz, 2H), 7.75–7.80 (m, 2H), 7.87 (s, 2H) ppm; 13C NMR (101 MHz, CDCl3): δ = 21.6, 26.6, 30.7, 56.4, 61.0, 69.0, 105.1, 126.5, 127.9, 129.9, 132.8, 142.2, 144.9, 153.9, 163.8, 168.3 ppm; HRMS: m/z calcd. for C21H25N4O6S+ ([M + H]+) 461.1489, found 461.1504.

3-[6-[4-(Methylthio)phenyl]-1,2,4,5-tetrazin-3-yl]propyl 4-methylbenzenesulfonate (21)

Synthesis was performed according to general procedure C using 3-[6-[4-(methylthio)phenyl]-1,2,4,5-tetrazin-3-yl]propan-1-ol (15, 54 mg, 0.21 mmol), tosyl chloride (156 mg 0.82 mmol), and pyridine (70 mm3, 0.82 mmol) in DCM (3 cm3). After stirring for 24 h the reaction mixture the described workup was followed. Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to afford the desired product as a red crystalline solid (57 mg, 67%). 1H NMR (400 MHz, CDCl3): δ = 2.35–2.43 (m, 5H), 2.58 (s, 3H), 3.41 (t, J = 7.41 Hz, 2H), 4.25 (t, J = 6.05 Hz, 2H), 7.31 (d, J = 7.8 Hz, 2H), 7.42 (dt, J = 8.6 Hz, 2.3 Hz, 2H), 7.78 (dt, J = 8.2 Hz, 2.0 Hz, 2H), 8.49 (dt, J = 8.9 Hz, 2.0 Hz, 2H) ppm; 13C NMR (101 MHz, CDCl3): δ = 14.9, 21.6, 26.6, 30.7, 69.0, 125.9, 127.7, 127.9, 128.1, 129.9, 132.8, 144.9, 145.5, 164.1, 168.3 ppm.

3-[6-(Pyridin-2-yl)-1,2,4,5-tetrazin-3-yl]propyl 4-methylbenzenesulfonate (22, C17H17N5O3S)

Synthesis was performed according to general procedure C using 3-[6-(pyridin-2-yl)-1,2,4,5-tetrazin-3-yl]propan-1-ol (16, 64 mg, 0.29 mmol), tosyl chloride (115 mg 0.6 mmol), and pyridine (55 mm3, 0.6 mmol) in DCM (3 cm3). After stirring for 3 days the reaction mixture the described workup was followed. Purification was performed by column chromatography (EtOAc in hexanes, gradient elution) to afford the desired product as a pink crystalline solid (72 mg, 67%). 1H NMR (400 MHz, CDCl3): δ = 2.35–2.45 (m, 5H), 3.48 (t, J = 7.3 Hz, 2H), 4.23 (t, J = 6.0 Hz, 2H), 7.30 (d, J = 8.1 Hz, 2H), 7.56 (dd, J = 7.5 Hz, 4.9 Hz, 1H), 7.76 (d, J = 8.1 Hz, 2H), 7.98 (t, J = 7.5 Hz, 1H), 8.61 (d, J = 8.1 Hz, 1H), 8.94 (d, J = 4.8 Hz, 1H) ppm; 13C NMR (101 MHz, CDCl3): δ = 21.5, 26.6, 30.9, 68.9, 123.9, 126.4, 127.8, 129.8, 132.7, 137.4, 144.9, 150.1, 150.8, 163.7, 169.5 ppm; HRMS: m/z calcd. for C17H18N5O3S+ ([M + H]+) 372.11249, found 372.11156.

3-[6-[4-(Methylsulfonyl)phenyl]-1,2,4,5-tetrazin-3-yl]propyl 4-methylbenzenesulfonate (24)

Synthesis was performed according to general procedure C using 3-[6-[4-(methylsulfonyl)phenyl]-1,2,4,5-tetrazin-3-yl]propan-1-ol (28, 27 mg, 90 µmol), tosyl chloride (69 mg, 0.36 mmol), and pyridine (50 mm3, 0.45 mmol) in DCM (4 cm3). After stirring for 16 h the reaction mixture the described workup was followed. Purification was performed by column chromatography (MeOH in DCM, gradient elution) to afford the desired product as a pink crystalline solid (32 mg, 79%). 1H NMR (600 MHz, CDCl3): δ = 2.39–2.46 (m, 5H), 3.15 (s, 3H), 3.51 (t, J = 7.5 Hz, 2H), 4.26 (t, J = 5.9 Hz, 2H), 7.33 (d, J = 7.92 Hz, 2H), 7.77 (dt, J = 8.5 Hz, 2.1 Hz, 2H), 8.19 (dt, J = 8.5 Hz, 1.8 Hz, 2H), 8.81 (dt, J = 8.8 Hz, 1.8 Hz, 2H) ppm; 13C NMR (151 MHz, CDCl3): δ = 21.6, 26.7, 31.1, 44.4, 68.9, 127.9, 128.3, 128.8, 129.9, 132.7, 136.6, 144.0, 145.0, 163.2, 169.5 ppm.

4-(But-3-ynylthio)benzonitrile (27)

4-Mercaptobenzontitrile (550 mg, 4.07 mmol) and K2CO3 (845 mg, 6.1 mmol) were dissolved in dry DMF (20 cm3) and the mixture was stirred at 85 °C for 15 min under an atmosphere of argon. 4-Bromobutyne (402.5 mm3, 4.48 mmol) was added dropwise and the reaction mixture was stirred at 85 °C for 72 h. The resulting brownish solution was diluted with DCM (100 cm3) and filtered. The filtrate was extracted with aq. 5% LiCl solution (4 × 80 cm3), dried over Na2SO4, filtered, and concentrated. Purification by column chromatography (EtOAc in hexanes, gradient elution) gave the desired product as a colorless oil (305 mg, 40%). 1H NMR (400 MHz, CDCl3): δ = 7.54 (d, J = 8.4 Hz, 2H), 7.33 (d, J = 8.4 Hz, 2H), 3.16 (t, J = 7.4 Hz, 2H), 2.56 (dd, J = 7.6 Hz, 2.7 Hz, 2H), 2.08 (t, J = 2.5 Hz, 1H) ppm; 13C NMR (100 MHz, CDCl3): δ = 143.6, 132.5, 127.5, 118.8, 108.9, 81.5, 70.5, 31.1, 19.1 ppm.

3-[4-(But-3-yn-1-ylthio)phenyl]-1,2,4,5-tetrazine (29, C12H10N4S)

4-(But-3-ynylthio)benzonitrile (27, 210 mg, 1.12 mmol) was dissolved in dry ethanol (1.2 cm3) and the mixture was cooled in an ice bath. Acetyl chloride (640 mm3, 9 mmol) was added dropwise within 10 min, the reaction mixture was allowed to warm to room temperature and stirred for 24 h. The suspension was cooled to -20 °C and allowed to stand for 48 h for further crystallization. The mixture was concentrated to give the corresponding Pinner salt (28, 310 mg, 99%) as a white solid.

A well-blended mixture of Pinner salt (310 mg, 1.17 mmol) and formamidine acetate salt (428 mg, 4.1 mmol) was treated dropwise with hydrazine monohydrate (2.7 cm3, 55.7 mmol) under cooling in an ice bath. The resulting dark purple suspension was allowed to warm to room temperature and stirred for 20 h. The mixture was poured onto ice-water (30 cm3), sodium nitrite (325 mg, 4.7 mmol) was added, and the solution acidified to pH 5 using acetic acid (120 cm3) causing a color change to bright purple-red. The colorful mixture was extracted with EtOAc (3 × 90 cm3), the combined organic layer washed with aq. NaHCO3 solution (2 × 200 cm3) and brine (200 cm3). The clear red solution was dried over Na2SO4, filtered, and concentrated. Purification by column chromatography (5–35% EtOAc in hexanes, gradient elution) afforded the product as a red crystalline solid (83 mg, 30%). 1H NMR (600 MHz, CDCl3): δ = 10.12 (s, 1H), 8.47 (d, J = 8.3 Hz, 2H), 7.42 (d, J = 8.3 Hz, 2H), 3.16 (t, J = 7.4 Hz, 2H), 2.54 (dd, J = 7.4 Hz, 2.6 Hz, 2H), 2.03 (t, J = 2.6 Hz, 1H) ppm; 13C NMR (151 MHz, CDCl3): δ = 166.3, 157.8, 143.5, 128.8, 128.0, 81.8, 70.4, 31.3, 19.3 ppm; ESI–MS: m/z calcd. for C12H11N4S+ ([M + H]+) 243.07, found 242.90.

3-[4-(But-3-yn-1-ylsulfonyl)phenyl]-1,2,4,5-tetrazine (25, C12H10N4O2S)

Tetrazine 29 (14 mg, 57.8 µmol) was dissolved in dry DCM (2 cm3) and the solution was cooled in an ice bath. DMDO solution (0.08 M in dry acetone; 3 cm3, 173 µmol) was added dropwise and the reaction mixture was warmed up to room temperature and stirred for 40 min. The colorful solution was concentrated to afford the desired product as a red solid (15.8 mg, 99%) without further purification needed. 1H NMR (400 MHz, CDCl3): δ = 10.27 (s, 1H), 8.79 (d, J = 8.6 Hz, 2H), 8.10 (d, J = 8.6 Hz, 2H), 3.33 (t, J = 7.7 Hz, 2H), 2.63 (dd, J = 7.7 Hz, 2.8 Hz, 2H), 1.88 (t, J = 2.5 Hz, 1H) ppm; 13C NMR (151 MHz, CDCl3): δ = 165.5, 158.4, 142.7, 137.0, 129.4, 129.3, 79.1, 71.1, 54.7, 13.4 ppm; ESI–MS: m/z calcd. for C12H11N4O2S+ ([M + H]+) 275.06, found 274.90.

3-[4-[[2-[1-(2-Fluoroethyl)-1H-1,2,3-triazol-4-yl]ethyl]thio]phenyl]-1,2,4,5-tetrazine (30, C14H14FN7S)

Tetrazine 29 (23 mg, 94.9 µmol) was dissolved in dry DMF (600 mm3) and 2-fluoroethylazide (1.5 mmol/cm3 solution in DMF; 140 mm3, 189.8 µmol) was added. Catalyst solution containing aq. sodium ascorbate (300 mg/cm3 solution; 40 mm3), aq. copper sulfate pentahydrate (112 mg/cm3 solution; 40 mm3), and aq. bathophenantrolinedisulfonic acid disodium salt hydrate (Na2BPDS) (50 mg/cm3 solution; 80 mm3) was added and the brownish-red mixture was stirred at room temperature for 90 min. Purification by column chromatography (H2O/MeCN gradient elution, 0.1% formic acid) gave the desired click product as a bright purple solid (14.4 mg, 47%). 1H NMR (600 MHz, CDCl3): δ = 10.11 (s, 1H) 8.46 (d, J = 8.7 Hz, 2H), 7.46 (s, 1H), 7.41 (d, J = 8.6 Hz, 2H), 4.75 (t, J = 4.6 Hz, 1H), 4.68 (t, J = 4.6 Hz, 1H), 4.61 (t, J = 4.5 Hz, 1H), 4.56 (t, J = 4.5 Hz, 1H), 3.35 (t, J = 7.3 Hz, 2H), 3.10 (t, J = 7.4 Hz, 2H) ppm; 13C NMR (151 MHz, CDCl3): δ = 166.3, 157.8, 145.9, 144.0, 128.7, 128.5, 127.7, 122.7, 82.3 (1J13C-19F = 172.1 Hz), 50.8 (2J13C-19F = 20.6 Hz), 31.7, 25.6 ppm; 19F NMR (376 MHz, CDCl3): δ = − 221.4 ppm; ESI–MS: m/z calcd. for C14H15FN7S+ ([M + H]+) 332.11, found 331.95.

3-[4-[[2-[1-(2-Fluoroethyl)-1H-1,2,3-triazol-4-yl]ethyl]sulfinyl]phenyl]-1,2,4,5-tetrazine (31, C14H14FN7OS)

Tetrazine 30 (5.9 mg, 17.8 µmol) was dissolved in dry DCM (300 mm3) and the mixture was cooled in an ice bath. DMDO solution (0.075 M in dry acetone; 237 mm3, 17.8 µmol) was added dropwise and the reaction mixture was warmed to room temperature and stirred for 20 min. The colorful solution was concentrated and purified by column chromatography (H2O/MeCN gradient elution, 0.1% formic acid) to afford the desired product as a dark purple solid (6.2 mg, 99%). NMR (400 MHz, CDCl3): δ = 10.29 (s, 1H), 8.81 (d, J = 8.3 Hz, 2H), 7.90 (d, J = 8.3 Hz, 2H), 7.56 (s, 1H), 4.84 (t, J = 4.6 Hz, 1H), 4.72 (t, J = 4.6 Hz, 1H), 4.68 (t, J = 4.5 Hz, 1H), 4.62 (t, J = 4.5 Hz, 1H), 3.50–3.43 (m, 1H), 3.38–3.31 (m, 1H), 3.27–3.20 (m, 1H), 3.15–3.08 (m, 1H) ppm; 13C NMR (151 MHz, CDCl3): δ = 166.0, 158.2, 149.1, 144.8, 134.2, 129.1, 125.1, 122.8, 82.2 (1J13C-19F = 172.4 Hz), 55.7, 50.8 (2J13C-19F = 20.7 Hz), 18.5 ppm; 19F NMR (376 MHz, CDCl3): δ = − 221.6 ppm; ESI–MS: m/z calcd. for C14H15FN7OS+ ([M + H]+) 348.10, found 347.90.

3-[4-[[2-[1-(2-Fluoroethyl)-1H-1,2,3-triazol-4-yl]ethyl]sulfonyl]phenyl]-1,2,4,5-tetrazine (26, C14H14FN7O2S)

Tetrazine 30 (5.1 mg, 15.4 µmol) was dissolved in dry DCM (500 mm3) and the mixture was cooled in an ice bath. DMDO solution (0.075 M in dry acetone; 820 mm3, 61.6 µmol) was added dropwise and the reaction mixture was warmed to room temperature and stirred for 25 min. The colorful solution was concentrated to afford the desired product as a dark purple solid (15.8 mg, 99%) without further purification needed. 1H NMR (400 MHz, CDCl3): δ = 10.34 (s, 1H) 8.85 (d, J = 8.5 Hz, 2H), 8.17 (d, J = 8.5 Hz, 2H), 7.53 (s, 1H), 4.81 (t, J = 4.6 Hz, 1H), 4.70 (t, J = 4.6 Hz, 1H), 4.65 (t, J = 4.5 Hz, 1H), 4.58 (t, J = 4.5 Hz, 1H), 3.66 (t, J = 7.5 Hz, 2H), 3.26 (t, J = 7.6 Hz, 2H) ppm; 13C NMR (151 MHz, CDCl3): δ = 165.5, 158.4, 143.8, 143.1, 136.8, 129.2, 128.1, 122.7, 82.2 (1J13C-19F = 172.2 Hz), 55.2, 50.8 (2J13C-19F = 20.7 Hz), 19.4 ppm; 19F NMR (376 MHz, CDCl3): δ = − 221.6 ppm; ESI–MS: m/z calcd. for C14H15FN7O2S+ ([M + H]+) 364.10, found 363.96.

Click kinetics

Stopped-flow measurements were performed using an SX20-LED stopped-flow spectrophotometer (Applied Photophysics) equipped with a 535 nm LED (optical pathlength 10 mm, full width half-maximum 34 nm) to monitor the characteristic tetrazine visible light absorbance (520–540 nm). The reagent syringes were loaded with tetrazine and TCO (10) solutions and the instrument was primed. Subsequent data were collected in triplicate to sextuplicate for each tetrazine. Reactions were conducted at 25 °C and recorded automatically at the time of acquisition.

Data sets were analyzed by fitting an exponential decay using Prism 6 (Graphpad) to calculate the observed pseudo-first order rate constants that were converted into second order rate constants by dividing through the concentration of excess TCO.

TCO (10) was dissolved in dry 1,4-dioxane to reach an approximate concentration of 4 mM. The exact concentration was determined by absorbance titration with DMT tetrazine (extinction coefficient 510 M−1 cm−1 at 520 nm) [30], quantifying the decrease in tetrazine absorbance upon reaction with TCO.

Tetrazines (1–8, 26, 30, 31) were dissolved in dry 1,4-dioxane to reach an approximate concentration of 0.1 mM and used without further dilution for stopped-flow analysis with TCO.

Radiolabeling

Thin layer chromatography was performed using TLC alumina plates (Merck, silica gel 60, fluorescence indicator F254, or Merck, aluminum oxide neutral, fluorescence indicator F254). Detection in radio-TLC was performed by placing the TLC plates on multisensitive phosphor screens (Perkin-Elmer Life Sciences, Waltham, MA). The screens were scanned at 300 dpi resolution using a PerkinElmer Cyclone® Plus Phosphor Imager (Perkin-Elmer Life Sciences). [18F]Fluoride was produced via the 18O(p,n)18F nuclear reaction by irradiating oxygen-18 enriched water (IASON, Austria) using a PETtrace cyclotron equipped with high yield liquid target system (GE Healthcare, Uppsala, Sweden). HPLC analysis was performed on a 1200 series system (Agilent Technologies) using a reversed phase columns and acetonitrile/water or acetonitrile/phosphate buffer gradients. Analytical conditions: (A): Agilent Extend-C18 3.5 µm, 3 × 100 mm, gradient 10 mM phosphate-buffer pH 6/acetonitrile, 1.3 cm3/min, 0–1 min 15% acetonitrile, 1 → 8 min 15% → 85% acetonitrile, 8–9 min 85% acetonitrile. (B): Agilent ZORBAX SB-Aq 5 µm, 4.6 × 250 mm, water/acetonitrile, 1.2 cm3/min, 0–2 min 5% acetonitrile, 2 → 10 min 5% → 20% acetonitrile, 10–16 min 20% → 90%, 16–20 min 90% acetonitrile. For radio-HPLC a GABI star radioactivity detector (raytest Isotopenmessgeraete GmbH, Straubenhardt, Germany) was used. Preparative HPLC separations were done on the built in HPLC system on a synthesis module (TRACERlab™ FXFDG, General Electric Healthcare, Uppsala, Sweden) using a Macherey–Nagel EP 250/16 100–7 C-18 (10 µm, 16 × 250 mm) column and phosphate-buffer (10 mM, pH 6)/acetonitrile-gradient (flow rate: 5 cm3/min, 0–6 min 10% acetonitrile, 6.01 min 30% acetonitrile, 6.01 → 40 min 30% → 80% acetonitrile) in combination with a K-2001 UV detector (Knauer) and radioactivity detector.

General procedure for manual radiolabeling of [ 18 F]1, [ 18 F]2, [ 18 F]3, [ 18 F]5, and [ 18 F]6

A QMA light cartridge (Waters) was preconditioned with 0.5 M K2CO3 solution (7 cm3) followed by 15 cm3 water. Cyclotron produced 18F-fluoride in water (0.5–2.5 cm3) was passed over the cartridge, and the cartridge was eluted with a solution 0.075 M tetrabutylammonium hydrogen carbonate solution, followed by 1 cm3 of acetonitrile. Volatiles were removed in a stream of argon at 105 °C and residual water was removed by addition and subsequent evaporation of 700 mm3 dry acetonitrile. The azeotropic drying step was repeated two more times. Precursor was added in the labelling solvent, and the reaction mixture was heated to the indicated temperature for the indicated time span. After cooling of the reaction contents the incorporation yield was investigated by radio-HPLC and/or radio-TLC. In several cases the fluorine-18 tetrazine derivatives were additionally isolated using preparative HPLC.

[18F]1: 328 MBq 18F fluoride, 430 mm3 TBA-HCO3-Lsg (32.25 µmol), 10 mg (32.4 µmol) 3-(6-methyl-1,2,4,5-tetrazin-3-yl)propyl 4-methylbenzenesulfonate [13] in 400 mm3 thexyl alcohol/dry acetonitrile v/v = 1:1, 4.5 min; 95 °C: incorporation yield (HPLC) = 46.5%, incorporation yield (TLC) = 48.3%, isolated yield (decay-corrected) = 33.4%.

[18F]2: 356 MBq 18F fluoride, 250 mm3 TBA-HCO3-Lsg (18.75 µmol), 6.7 mg (18.1 µmol) of 17 in 400 mm3 thexyl alcohol/dry acetonitrile v/v = 1:1, 5 min; 95 °C: incorporation yield (HPLC) = 40%, incorporation yield (TLC) = 40.5%.

[18F]3: 363 MBq 18F fluoride, 500 mm3 TBA-HCO3-Lsg (37.5 µmol), 12.7 mg (33.0 µmol) of 18 in 500 mm3 thexyl alcohol/dry acetonitrile v/v = 1:1, 5 min, 107 °C: incorporation yield (HPLC) = 56.2%, isolated yield (decay-corrected) = 41.7%.

[18F]5: 355 MBq 18F fluoride, 250 mm3 TBA-HCO3-Lsg (18.75 µmol), 9.0 mg (19.5 µmol) of 20 in 400 mm3 thexyl alcohol/dry acetonitrile v/v = 1:1, 5 min; 95 °C: incorporation yield (HPLC) = 13.7%, incorporation yield (TLC) = 18%.

[18F]6: 481.7 MBq 18F fluoride, 166 mm3 TBA-HCO3-Lsg (12.5 µmol), 5.2 mg (12.5 µmol) of 21 in 400 mm3 thexyl alcohol/dry acetonitrile v/v = 1:1, 8 min; 97 °C: incorporation yield (HPLC) = 47.7%.

General procedure for manual radiolabeling of [ 18 F]2, [ 18 F]3, [ 18 F]5, and [ 18 F]6

A remote-controlled synthesis module (TRACERlab™ FXFDG, General Electric Healthcare, Uppsala, Sweden) with a 3 cm3 glass reactor housed in a hot cell was used for automated labeling experiments. Cyclotron produced no carrier added [18F] fluoride was trapped on a preconditioned (5 cm3 0.5 M K2CO3 followed by 15 cm3 water) Waters QMA light cartridge. The radioactivity was eluted with 500 mm3 0.075 M TBA-HCO3 solution followed by 1 cm3 acetonitrile. Volatiles were removed in vacuo at a temperature of 60–120 °C. After cooling to 50 °C a solution of precursor in a mixture of dry acetonitrile and thexyl alcohol was added. The reaction mixture was heated to 93 °C for 8 min followed by cooling to 45 °C and consequent transfer into a vial. The reactor was rinsed with 2 cm3 DMSO:water = 1:1 (v/v). Combined solutions were injected into a preparative HPLC column (Macherey–Nagel EP 250/16 100–7 C-18, 10 µm, 16 × 250 mm) and eluted using a gradient of phosphate buffer (10 mM pH 6) and acetonitrile at a flow rate of 5 cm3/min (0–6 min 10% acetonitrile, 6.01 min 30% acetonitrile, 6.01 → 40 min 30% → 80% acetonitrile). The product fraction was diluted with 50 cm3 water, prior to passage over a preconditioned (5 cm3 acetonitrile followed by 15 cm3 H2O) tc18 plus SepPak cartridge (Waters). The cartridge was eluted with 1.5 cm3 ethanol. 18F-species prepared by automated labeling matched HPLC retention times with authentic standards.

[18F]2: 246.4 GBq 18F fluoride, 12.2 mg (33 µmol) of 17 in a mixture of 200 mm3 thexyl alcohol and 300 mm3 dry acetonitrile yielded 8.88 GBq [18F]2 (6.3% decay-corrected), retention time on preparative HPLC: 29.0 min, radiochemical purity (analytical HPLC) = 95%. Specific activity (HPLC) = 99 GBq/µmol.

[18F]3: 181.3 GBq 18F fluoride, 12.0 mg (31.2 µmol) of 18 in a mixture of 300 mm3 thexyl alcohol and 300 mm3 dry acetonitrile yielded 9.99 GBq [18F]3 (9.5% decay-corrected), radiochemical purity (analytical HPLC) = 98.3%.

[18F]5: 233.2 GBq 18F fluoride, 11.7 mg (25.4 µmol) of 20 in a mixture of 200 mm3 thexyl alcohol and 300 mm3 dry acetonitrile yielded 6.98 GBq [18F]5 (4.9% decay-corrected), retention time on preparative HPLC: 28.1 min, radiochemical purity (analytical HPLC) = 94.4%.

[18F]6: 218.3 GBq 18F fluoride, 11.0 mg (26.4 µmol) of 21 in a mixture of 200 mm3 thexyl alcohol and 300 mm3 dry acetonitrile yielded 11.5 GBq [18F]6 (8.6% decay-corrected), retention time on preparative HPLC: 32.6 min, radiochemical purity (analytical HPLC) = 95.4%. Specific activity (HPLC) = 229.5 GBq/µmol.

Preparation of [ 18 F]7

5.3 GBq [18F]6 in 1.5 cm3 EtOH as obtained by automated labeling was evaporated to dryness on the rotary evaporator (40 °C, 20 mbar) in an 8 cm3 vial. The residue was treated with 0.5 cm3 of an ice-cold solution of dimethyldioxirane (DMDO) in acetone (~ 40 mM). After 60 s reaction time volatiles were removed on the rotary evaporator. The residue was re-dissolved in 2.5 cm3 DMSO:water = 1:1 (v/v) and injected into the preparative HPLC system described at the section automated labeling. 2.36 GBq [18F]7 (56% decay-corrected yield) eluted with a retention time of 23.1 min. Radiochemical purity (analytical HPLC) = 93.0%, specific activity (HPLC) = 56.2 GBq/µmol. HPLC retention time of [18F]7 matched with the retention time of authentic standard.

Preparation of [ 18 F]30

First, a solution for the copper catalyzed azide-alkyne cycloaddition (CuAAC) was prepared: An aqueous solution of CuSO4·5H2O (10 mm3, 100 mg/cm3) was mixed with an aqueous solution of sodium ascorbate (10 mm3, 300 mg/cm3). When the color of the mixture turned yellow a solution of Na2BPDS (40 mm3, 50 mg/cm3) in water was added.

[18F]Fluoroethylazide was prepared according to literature [29]: irradiated [18O]water containing [18F]F− was passed through an anion exchange resin cartridge (Sep-Pak Accell Plus QMA Plus Light, chloride form). [18F]Fluoride trapped on the QMA was then eluted with 1 cm3 of a Kryptofix222/K2CO3 solution (4,7,13,16,21,24-hexaoxa-1,10-diazabicyclo[8.8.8] hexacosane (330 mg), K2CO3 (100 mg), and water (0.8 cm3) in MeOH (19.2 cm3)) into a 4 cm3 glass vial. The resulting mixture was then gently concentrated to dryness at 90–110 °C via azeotropic drying using 2 × MeCN (1 cm3) and a stream of helium. The procedure took 25–30 min and yielded in the ready to react [18F]-K222 complex. To the dried residue containing [18F]fluoride (3884 mCi), precursor azidoethylnosylate (12.5 mg, 46 µmol) in dry MeCN (300 mm3) was added. The mixture was heated at 110 °C for 5 min. All volatiles in the reactor were distilled into a vial containing the alkyne-modified tetrazine 29 (0.9 mg) and the solution for the CuAAC. During the distillation in the TRACERlab™ FXFDG module, the temperature was gradually increased to 135 °C, and a second portion of MeCN (200 mm3) was added to the reactor during distillation, to enable most efficient transfer of [18F]fluoroethylazide into the CuAAC reaction mixture.

Following distillation and a 5 min reaction time at room temperature, the mixture was diluted with DMSO/water (1:1, 2 cm3) and purified by semi-preparative HPLC. The collected HPLC fraction was trapped on a Sep-Pak C18 plus short cartridge, which was eluted with 1 cm3 acetonitrile. 41.4 mCi of [18F]30 could be obtained (1.07% non-decay-corrected radiochemical yield) and synthesis duration was 103 min.

Preparation of [ 18 F]26 and [ 18 F]31

Volatiles of the [18F]30 solution in acetonitrile were removed by rotary evaporation, and the residue was treated with 0.5 cm3 DMDO solution in acetone. After 60 s reaction time, volatiles were removed, and the residue was taken up in 1 cm3 acetonitrile. Fractions pre- and post-oxidation were analyzed using radio-TLC (SiO2, 5% MeOH in DCM).

References

Carboni RA, Lindsey RV (1959) J Am Chem Soc 81:4342

Thalhammer F, Wallfahrer U, Sauer J (1990) Tetrahedron Lett 31:6851

Blackman ML, Royzen M, Fox JM (2008) J Am Chem Soc 130:13518

Knight JC, Cornelissen B (2014) Am J Nucl Med Mol Imaging 4:96

Patterson DM, Nazarova LA, Prescher JA (2014) ACS Chem Biol 9:592

Meyer J-P, Adumeau P, Lewis JS, Zeglis BM (2016) Bioconjug Chem 27:2791

Rossin R, Renart Verkerk P, van den Bosch SM, Vulders RCM, Verel I, Lub J, Robillard MS (2010) Angew Chem Int Ed 49:3375

Zeglis BM, Sevak KK, Reiner T, Mohindra P, Carlin SD, Zanzonico P, Weissleder R, Lewis JS (2013) J Nucl Med 54:1389

Rossin R, Robillard MS (2014) Curr Opin Chem Biol 21:161

Meyer J-P, Houghton JL, Kozlowski P, Abdel-Atti D, Reiner T, Pillarsetty NVK, Scholz WW, Zeglis BM, Lewis JS (2016) Bioconjug Chem 27:298

Darko A, Wallace S, Dmitrenko O, Machovina MM, Mehl RA, Chin JW, Fox JM (2014) Chem Sci 5:3770

Li Z, Cai H, Hassink M, Blackman ML, Brown RCD, Conti PS, Fox JM (2010) Chem Commun 46:8043

Denk C, Svatunek D, Filip T, Wanek T, Lumpi D, Fröhlich J, Kuntner C, Mikula H (2014) Angew Chem Int Ed 53:9655

Rashidian M, Keliher E, Dougan M, Juras PK, Cavallari M, Wojtkiewicz GR, Jacobsen J, Edens JG, Tas JM, Victora G, Weissleder R, Ploegh H (2015) ACS Cent Sci 1:142

Keinänen O, Li XG, Chenna NK, Lumen D, Ott J, Molthoff CF, Sarparanta M, Helariutta K, Vuorinen T, Windhorst AD, Airaksinen AJ (2016) ACS Med Chem Lett 7:62

Steen EJL, Jorgensen JT, Denk C, Battisti UM, Norregaard K, Edem PE, Bratteby K, Shalgunov V, Wilkovitsch M, Svatunek D, Poulie CBM, Hvass L, Simon M, Wanek T, Rossin R, Robillard M, Kristensen JL, Mikula H, Kjaer A, Herth MM (2021) ACS Pharmacol Transl Sci 4:824

Garcia-Vazquez R, Battisti UM, Jorgensen JT, Shalgunov V, Hvass L, Stares DL, Petersen IN, Crestey F, Loffler A, Svatunek D, Kristensen JL, Mikula H, Kjaer A, Herth MM (2021) Chem Sci 12:11668

Battisti UM, Bratteby K, Jorgensen JT, Hvass L, Shalgunov V, Mikula H, Kjaer A, Herth MM (2021) J Med Chem 64:15297

Yang J, Karver MR, Li W, Sahu S, Devaraj NK (2012) Angew Chem Int Ed 51:5222

Svatunek D, Wilkovitsch M, Hartmann L, Houk KN, Mikula H (2022) J Am Chem Soc 144:8171

Svatunek D, Denk C, Mikula H (2018) Monatsh Chem 149:833

Mikula H, Svatunek D, Lumpi D, Glöcklhofer F, Hametner C, Fröhlich J (2013) Org Process Res Dev 17:313

Lee SJ, Oh SJ, Chi DY, Lee BS, Ryu JS, Moon DH (2008) J Label Compd Radiopharm 51:80

Kim DW, Jeong H-J, Lim ST, Sohn M-H (2010) Nucl Med Mol Imaging 44:25

Denk C, Wilkovitsch M, Skrinjar P, Svatunek D, Mairinger S, Kuntner C, Filip T, Frohlich J, Wanek T, Mikula H (2017) Org Biomol Chem 15:5976

Svatunek D, Denk C, Rosecker V, Sohr B, Hametner C, Allmaier G, Frohlich J, Mikula H (2016) Monatsh Chem 147:579

Liu Y, Kim J, Seo H, Park S, Chae J (2015) Adv Synth Catal 357:2205

Nachbaur E, Leiseder G (1971) Monatsh Chem 102:1718

Denk C, Wilkovitsch M, Skrinjar P, Svatunek D, Mairinger S, Kuntner C, Filip T, Fröhlich J, Wanek T, Mikula H (2017) Org Biomol Chem 15:5976

Carlson JCT, Mikula H, Weissleder R (2018) J Am Chem Soc 140:3603

Acknowledgements

This project has received funding from the European Union’s EU Framework Programme for Research and Innovation Horizon 2020, under grant agreement no. 668532. DS is grateful to the Theodor Körner fund (Vienna, Austria) for financial support.

Funding

Open access funding provided by TU Wien (TUW).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wilkovitsch, M., Svatunek, D., Mikula, H. et al. Post-radiolabeling thioether oxidation to enhance the bioorthogonal reactivity of 18F-tetrazines. Monatsh Chem 154, 1441–1457 (2023). https://doi.org/10.1007/s00706-023-03140-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-023-03140-w