Abstract

The synthesis of novel pyrazolothienopyridinone derivatives as potential GABAA receptor modulators was performed and is herein described. A crucial step of the synthesis involving handling unstable aminothiophenes was managed via two different synthetic strategies delivering a set of 8 target compounds.

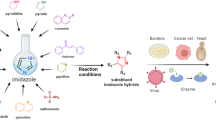

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

GABAA receptors are inhibitory chloride channels located in the mammalian central nervous system. They are targeted by many heavily used pharmaceuticals such as benzodiazepine-based sedatives, hypnotics, anxiolytics, barbiturate-based anticonvulsants, and general anesthetics of a broad range of chemotypes [1,2,3]. Structurally, these channels are pentamers, i.e. consisting of 5 subunits, which can be drawn from a pool of 19 different subtypes (α 1–6, β 1–3, γ 1–3, δ , ε , θ, π, and ρ). An example of a typical subunit arrangement is shown in Fig. 1.

Additionally, Fig. 1 shows the binding site of the endogenuous ligand GABA at the α-/β + binding site, besides alternative binding sites for benzodiazepines (Bz) and pyrazoloquinolinones (PQ). Besides those binding sites, additional possible binding sites have been identified which allow several ligand classes to interact with this family of receptors as well, making them highly promiscuous [1]. As a consequence, side effects are associated with all current therapies that target GABAA receptors; thus, there is still the need to further investigate and develop improved ligands with subtype selectivity [4].

The complex structure of this receptor makes it a challenging task to selectively target one of the binding sites or even more to target a specific subunit subtype selectively [2, 5]. To elucidate this problem, PQs have been in the center of our attention for some time [1, 3, 5,6,7,8,9], and > 100 compounds were prepared with different substitution patterns on the A and D ring.

In the present work, we targeted a more profound alteration of the scaffold, by exchanging the A ring with thiophene derivatives, since thiophene is a well-known bioisoster for the phenyl moiety [10]. The proposed derivatives would still maintain the same putative pharmacophores, as depicted in Fig. 2.

Results and discussion

Traditionally, the initial step of a PQ synthesis starts from the accordingly substituted aniline 1, which is condensed with diethyl ethoxymethylene malonate (DEEMM, 2) to obtain a phenylaminomethylenemalonate intermediate 3 (Scheme 1) [11].

However, this route is not feasible for electron-rich heterocycles, such as thiophene, since some required amines of these heterocycles are unstable [12]. Therefore, several alternatives were explored to overcome this obstacle and obtain the thiophenyl aminomethylenemalonate intermediates (Scheme 2, compounds 6 and 9 and Scheme 3, compounds 15, 16, and 20).

One of these compounds, namely 6, was already reported in literature [5]. The synthesis started from methyl 3-aminothiophene-2-carboxylate (4), which was hydrolyzed to the corresponding carboxylic acid 5 and subsequently, in a one-pot fashion, decarboxylated and condensed to the desired intermediate 6 at the same time (Scheme 2). This strategy is an attractive option, provided that such a starting material is obtainable, since three different transformations were done without the purification of each intermediate.

The regioisomeric product 9 had to be prepared via an alternative route. Hence, it was tried to start from 2-thiophenecarboxylic acid (7) and synthesize Boc-protected 2-aminothiopene (8) via a Curtius rearrangement as reported in literature [13]. Deprotection and reaction with DEEMM would provide the desired intermediate 9. Indeed, 8 could be obtained in 80% yield, however, deprotection attempts only led to a black precipitate which did not yield intermediate 9 after its treatment with dry pyridine and DEEMM. Consequently, a different method for the synthesis of intermediate 9 had to be chosen [12].

Reduction of 2-nitrothiophene 10 with SnCl2‧2H2O was carried out and the resulting hexachlorostannate salt 11 was isolated in a crude form. Subsequently, pyridine was added to transform 11 to 2-aminothiophene in situ followed by immediate condensation with DEEMM gave 9 in 93% yield.

For the remaining target compounds 15, 16, and 20 the strategy based on the Curtius rearrangement could be applied [14,15,16,17]. Substrates 12a, 12b, and 17 gave the Boc protected amines 13a, 13b, and 18 in 91%, 43%, and 50% yield, respectively. Subsequently, the corresponding hydrochloride salts of the amines 14a, 14b, and 19 were obtained in 64%, 73%, and 98% yield via water-free deprotection with 4 M HCl in dioxane (Scheme 3). The isolation consisted of a simple filtration step and compounds 14a, 14b, and 19 were subjected immediately to the next step, where pyridine was used both as a solvent and as a base to regenerate the desired aminothiophene in situ. Anhydrous conditions were selected for this step since it was observed that the amine hydrochlorides were unstable when exposed to air. The target compounds 15, 16, and 20 were isolated in 32%, 78%, and 88% yield, respectively. Generally, the method is very convenient for handling potentially unstable aminothiophenes. The obtained aminothiophene hydrochlorides 14a, 14b, and 19 are easy to handle, and the use of high temperatures for the condensation with DEEMM is unnecessary, in contrast to other reported literature procedures [18]. It is noteworthy to mention that characterization of intermediates 14a, 14b, and 19 was not possible. 1H NMR of these salts did not show the expected ammonium signal and only noise was observed, most likely due to instability of the salts in deuterated solvents where traces of water or HCl (in case of CDCl3) are typically present.

Having compounds 6, 9, 15, 16, and 20 in hand, the rest of the synthetic route was performed in a similar way to the classical synthesis of PQ derivatives [7] (Scheme 4). The aforementioned intermediates were thermally cyclized in Ph2O as solvent to give compounds 21, 22, and 25–27, which were then were chlorinated with phosphorous oxychloride, obtaining compounds 23, 24, and 28–30 (Scheme 4).

Afterwards, compounds 23, 24, and 28–30 underwent a nucleophilic aromatic substitution using 4-methoxyphenylhydrazine hydrochloride as the nucleophile adding NEt3 to generate the free hydrazine in refluxing EtOH overnight. Under these conditions, the hydrazine substituted compounds 31–33 were obtained, however in low yields (Scheme 5). For further cyclization to the final products 34–36, more forcing conditions had to be applied. These consisted of the stronger base potassium tert-butoxide and an increased temperature of 140 °C, which required DMAc as solvent (Scheme 5).

On the way to product 38, the intermediate hydrazine 37 was not isolated, but after nucleophilic substitution adding the stronger base potassium tert-butoxide to the NEt3 solution and increasing the temperature to 140 °C, which required DMAc as co-solvent, delivered 38 in a one-pot fashion in 19% yield (Scheme 6) as previously reported in literature [5].

In the case of substrate 30, the hydrazine intermediate could not be detected, since even with NEt3 in ethanol, the second cyclization towards the final product occurred immediately delivering 39 in 46% yield (Scheme 6).

In conclusion, several strategies towards the synthesis of regioisomeric (in respect to the position of the sulfur) pyrazolothienopyridinones derivatives was achieved, which will further enable the development of new pyrazoloquinolinone derivatives. The major challenge, handling extremely electron rich thiophene amines was solved, which can serve as a blurprint for further derivatives with such features. The obtained target molecules will be subjected to biological testing and these results will be reported in due course.

Experimental

All starting materials and reagents were purchased from commercial sources and used without further purification. Reactions were monitored by TLC on silica gel 60 F254 plates. Normal-phase column chromatography was performed on silica gel 60 (230 – 400 mesh). NMR spectra were recorded at 297 K in the solvent indicated, with 200, 400 and 600 MHz instruments, respectively, employing standard software provided by the manufacturer. 1H NMR and 13C NMR spectra were referenced to tetramethylsilane (TMS, δ = 0 ppm) by calibration with the residual organic solvent signals [19]. Accurate mass analysis (2 ppm mass accuracy) was carried out from 10 to 100 mg/dm3 solutions via LC-TOFMS measurements using an autosampler, an HPLC system with binary pumps, degasser, and column thermostat and ESI-TOF mass spectrometer. Melting points were determined with a Büchi Melting Point B-545 apparatus with a heating rate of 1 °C min−1 (70% onset point and 10% clear point) or on a Kofler Block apparatus. All melting points were obtained without additional recrystallization directly after flash column chromatography (FCC) with light petroleum (LP) and EtOAc and subsequent drying in high vacuum.

General procedure 1: synthesis of heterocyclic tert-butyl-carbamate derivatives / Boc-protected heterocyclic amine derivatives

Heterocyclic tert-butyl-carbamate derivatives were synthesized according to a literature procedure [14]. In a previously dried 25 cm3 three-necked round-bottomed flask equipped with a magnetic stirring bar, reflux condenser, septa, and in an argon atmosphere, 1 eq. of the corresponding heterocyclic carboxylic acid was added, which was subsequently dissolved in dry tert-butanol. Afterward, 1.1 eq. of triethylamine was added, followed by the addition of 1.01 eq. of diphenylphosphoryl azide. The mixture was heated to reflux (85 °C) and was kept at refluxing temperature overnight. The initially light brown colored mixture became dark during the reaction time. After full conversion was observed on a TLC (DCM/MeOH 95:5 + 3 drops AcOH) using bromocresol green as a staining agent, the reaction mixture was poured into water, extracted 3 times with EtOAc and dried over anhydrous magnesium sulfate. The solvent was evaporated under reduced pressure, and the resulting product of this procedure was subjected to flash column chromatography using LP:CHCl3 = 60:40 as mobile phase to obtain the corresponding heterocyclic tert-butyl carbamates 13a, 13b, and 18.

General procedure 2: synthesis of heterocyclic ammonium salts

Heterocyclic ammonium salts were synthesized according to a literature procedure [20, 21]. In a 10 cm3 dry reaction vial, equipped with a magnetic stirrer, septum, and an argon atmosphere, 1 eq. of the corresponding heterocyclic tert-butyl carbamate was added to a commercial solution of 4 N HCl in dioxane (13.8 eq.), and the mixture was stirred at room temperature until full consumption of the starting material was observed via TLC, using ninhydrin as a staining agent. Afterwards, a precipitate was observed in the reaction mixture. The reaction mixture was diluted with diethyl ether, and the product was collected by filtration, washed with diethyl ether, and dried in vacuo to afford the corresponding heterocyclic salts 14a, 14b, and 19 as a product.

General procedure 3: condensation with diethyl ethoxymethylenemalonate (DEEMM)

Diethylthiophenylamino methylene malonate derivatives were synthesized according to a literature procedure [14]. In a previously dried 30 cm3 reaction vial, equipped with a magnetic stirrer, septum, and an argon atmosphere, the corresponding heterocyclic salt was mixed with the required amount of diethyl ethoxymethylenemalonate, and afterwards, dry pyridine was added to the reaction vial. The reaction was heated at 40 °C and stirred overnight. After full conversion was observed via TLC using ninhydrin as a staining agent, water was added to the reaction mixture and extracted with chloroform. The organic phase was dried over magnesium or sodium sulfate and concentrated in vacuo, obtaining a crude material. The derivatives 9, 15, 16, and 20 obtained via this procedure were purified via flash column chromatography using PE/EtOAc as mobile phase.

General procedure 4: thermal cyclization

Ethylhydroxythienopyridine carboxylate derivatives were synthesized according to a literature procedure [3]. In a round-bottomed flask equipped with a magnetic stirrer and reflux condenser, the desired condensed substituted aniline derivate (1 eq.) was dispersed in approximately 2 cm3 of diphenyl ether and heated to 235 °C with a heating mantel. After full consumption was observed via TLC analysis using ninhydrin as a staining agent, the reaction mixture was adsorbed onto celite and purified via flash column chromatography, using mixtures of PE/EtOAc to yield the desired derivatives 21, 22, and 25–27.

General procedure 5: synthesis of chlorothienopyridine carboxylate derivatives

Chlorothienopyridine carboxylate derivatives were synthesized according to a literature procedure [3]. The desired hydroxythienopyridine carboxylate was suspended in POCl3 and heated to reflux. After full conversion was observed via TLC analysis, the reaction mixture was cooled in an ice bath. Some pieces of ice were added slowly to the reaction mixture, followed by the careful addition of distilled water, ensuring the reaction temperature did not rise. Afterward, the pH of the reaction mixture was adjusted to 8 by adding either a saturated solution of Na2CO3 or solid Na2CO3. Then, the reaction mixture was extracted using EtOAc, dried over Mg2SO4, and concentrated in vacuo. The crude material obtained from this procedure was purified via flash column chromatography, using mixtures of PE/EtOAc to yield the purified halogenated derivatives 23, 24, and 28–30.

General procedure 6: nucleophilic aromatic substitution of chlorothienopyridine carboxylates

Ethyl phenylhydrazineylthienopyridine carboxylate derivatives were synthesized according to a modified literature procedure [3]. In an 8 cm3 reaction vial equipped with a magnetic stirrer, 1.69 eq. of TEA, 4-methoxyphenylhydrazine hydrochloride (1.68 eq.), and 1 cm3 of dry EtOH were added and stirred for 2 min at room temperature. Afterward, 1 eq. of the desired chlorothienopyridine carboxylate was added, and the reaction mixture was heated to reflux and stirred overnight or until full consumption of the starting material was observed via TLC analysis. Afterward, distilled water was added to the reaction mixture, extracted 3 times with ethyl acetate, dried over magnesium sulfate, and concentrated in vacuo. The crude material was purified via flash column chromatography, using mixtures of PE/EtOAc as mobile phase to yield the desired derivatives 31–33 and 39.

General procedure 7: formation of pyrazolothienopyridinone derivatives

Pyrazolothienopyridinone derivatives were synthesized according to a literature procedure [22]. In a 50 cm3 flask with a septum, 1 eq. of the corresponding phenylhydrazineylthienopyridine carboxylate derivative and 1.5 eq. of t-BuOK were added and 3 times evacuated and flushed with argon. Afterward, 3 cm3 of the solvent were added to the flask. The reaction mixture was heated to 140 °C overnight. After full conversion was observed according to TLC analysis, the solvent was concentrated in vacuo. The product was purified via prep RP-HPLC. This procedure yielded derivatives 34–36.

Diethyl 2-[(thiophen-2-ylamino)methylene]malonate (9) [12, 17]

Compound 9 was synthesized according to general procedure 3, using 11 (1.82 g, 3.42 mmol) as starting material, 1 eq. of DEEMM (1.03 cm3, 3.42 mmol) and dry pyridine (20 cm3). After full consumption of the starting material was observed, water was added to the reaction mixture and in this particular reaction, a precipitate was formed during this step. The precipitate was filtered from the solvent and thoroughly washed with chloroform several times until obtaining a gray solid. Separately, the mother liquor was extracted with chloroform. Both chloroform phases were collected, dried over magnesium sulfate, and concentrated in vacuo. The crude product was purified via flash column chromatography, using a gradient of PE/EtOAc 95:5 to PE/EtOAc 90:10. Product 9 was obtained as yellow crystalline solid in 93% (0.86 g, 3.17 mmol) yield. M.p.: 40.3–40.5 °C (Ref. [12] 39–40 °C); Rf = 0.63 (PE/EtOAc = 9/1); HR-MS: m/z calcd. 270.0794 Da ([M + H]+), found 270.0795 Da, difference: 0.1 mDa = 0.35 ppm; 1H NMR (400 MHz, CDCl3): δ = 1.31 (t, J = 7.1 Hz, 3H, -CH3), 1.37 (t, J = 7.1 Hz, 3H, –CH3), 4.23 (q, J = 7.1 Hz, 2H, –CH2–), 4.30 (q, J = 7.1 Hz, 2H, –CH2–), 6.68 (ddd, J = 3.6, 1.5, 0.6 Hz, 1H, H5), 6.85–6.91 (m, 2H, H4 and H3), 8.24 (d, J = 13.2 Hz, 1H, NH–CH =), 11.11 (d, J = 13.2 Hz, 1H, –NH–) ppm; 13C NMR (101 MHz, CDCl3): δ = 14.4 (q, CH3), 14.5 (q, CH3), 60.3 (t, –CH2–), 60.7 (t, –CH2–), 94.0 (s, Cquat), 114.5 (d, C5), 118.3 (d, C3), 126.7 (d, C4), 144.0 (s, C2), 154.4 (d, NH–CH =), 165.4 (s, C = O), 169.2 (s, C = O) ppm; Ref. [12] provides NMR data in DMSO-d6 as solvent.

Bis(2-thienylammonium)hexachlorostannate (11) [12]

Intermediate 11 was synthesized according to a modified literature procedure. In a three-necked 50 cm3 round-bottomed flask, 2-nitrothiophene (10, 1.70 g, 13.2 mmol, 1 eq) was suspended in 20 cm3 of concentrated HCl and the mixture was heated to 50 °C and stirred until the substrate was dissolved. Afterwards, dihydrate stannous chloride (2 eq.) was added portionwise to the mixture, maintaining the reaction temperature between 40–45 °C by immersion in an ice bath. After the addition was complete, the cooling bath was removed, and the mixture was allowed to stir at 35 °C for 1.5 h. The reaction was monitored by TLC, showing full conversion at this point. The mixture was cooled overnight to 2 °C and 11 was obtained as a gray precipitate in 26% yield (1.82 g, 3.43 mmol). Due to the instability of this compound, it was further converted immediately without full characterization.

tert-Butyl (5-chlorothiophen-2-yl)carbamate (13a) [23, 24]

Compound 13a was synthesized according to general procedure 1, using 5-chlorothiophene-2-carboxylic acid (12a, 1.0 g, 6.05 mmol) as starting material. 13a was obtained as colorless crystalline solid in 75% (1.06 g, 4.54 mmol) yield. M.p.: 122.8–122.9 °C (Ref. [23] 142–143 °C); Rf = 0.38 (LP/CHCl3 = 6/4); 1H NMR spectral data is in accordance with literature data [24]; 13C NMR (101 MHz, CDCl3): δ = 28.0 (q, –(CH3)3), 80.4 (s, –C–CH3), 108.1 (d, C4), 117.9 (s, C5), 123.8 (d, C3), 139.4 (s, C2), 152.5 (s, C = O) ppm.

tert-Butyl 1-benzothiophen-2-ylcarbamate (13b) [15, 25]

Compound 13b was synthesized according to general procedure 1, using 12b (1 g, 5.50 mmol) as starting material. 13b was obtained as colorless crystalline solid in 43% (0.59 g, 2.36 mmol) yield. M.p.: 101.7–102.2 °C (Ref. [25] 100–101 °C); Rf = 0.71 (LP/CHCl3 = 6/4); 1H NMR spectral data is in accordance with literature data [15]; 13C NMR (101 MHz, DMSO-d6): δ = 28.0 (q, –(CH3)3), 80.4 (s, –C–CH3), 104.5 (d, C3), 121.5 (d, C7), 121.7 (d, C4), 122.1 (d, C5), 124.3 (d, C6), 133.9 (s, C3a), 137.9 (s, C7a), 141.6 (s, C2), 152.4 (s, C = O) ppm.

5-Chlorothiophen-2-aminium chloride (14a) [21]

Intermediate 14a was synthesized according to general procedure 2, 13a (107 mg, 0.46 mmol) as starting material. Product 14a was obtained as brown pearly solid in 64% (50 mg, 0.30 mmol) yield. Due to the instability of this compound, it was further converted immediately without full characterization.

1-Benzothiophen-2-aminium chloride (14b)

Intermediate 14b was synthesized according to general procedure 2, using 13b (108 mg, 0.43 mmol) as starting material. The product was obtained as colorless pearly solid in 73% (58 mg, 0.32 mmol) yield. Due to the instability of this compound, it was further converted immediately without full characterization.

Diethyl 2-[[(5-chlorothiophen-2-yl)amino]methylene]malonate (15, C12H14ClNO4S)

Compound 15 was synthesized according to general procedure 3, using 14a (0.62 g, 3.66 mmol) as starting material, 1 eq. of DEEMM (1.1 cm3, 3.66 mmol) and dry pyridine (10 cm3). The product was purified via flash column chromatography, using PE/EtOAc 90:10 as mobile phase and obtained as yellow oil in 31% (0.35 g, 1.15 mmol) yield. Rf = 0.58 (PE/EtOAc = 85/15); LC–MS: m/z calcd. 304.76 ([M + H]+), found 304.10; 1H NMR (400 MHz, CDCl3): δ = 1.28 (t, J = 7.1 Hz, 3H, –CH3), 1.34 (t, J = 7.1 Hz, 3H, –CH3), 4.20 (q, J = 7.1 Hz, 2H, –CH2–), 4.26 (q, J = 7.1 Hz, 2H, –CH2–), 6.44 (d, J = 4.0 Hz, 1H, H3), 6.67 (d, J = 4.0 Hz, 1H, H4), 8.07 (d, J = 13.0 Hz, 1H, NH-CH =), 10.96 (d, J = 13.0 Hz, 1H, –NH–) ppm; 13C NMR (101 MHz, CDCl3): δ = 14.3 (q, CH3), 14.4 (q, CH3), 60.3 (t, –CH2–), 60.7 (t, –CH2–), 94.7 (s, Cquat), 114.1 (d, C3), 123.1 (s, C5), 125.4 (d, C4), 141.4 (s, C2), 153.9 (d, NH–CH =), 165.0 (s, C = O), 169.0 (s, C = O) ppm.

Diethyl 2-[(1-Benzothiophen-2-ylamino)methylene]malonate (16, C16H17NO4S)

Compound 16 was synthesized according to general procedure 3, using 14b (0.17 g, 0.93 mmol) as starting material, 1 eq. of DEEMM (0.28 cm3, 0.93 mmol) and dry pyridine (5 cm3). The product was purified via flash column chromatography, using PE/EtOAc 90:10 as mobile phase. The product 16 was obtained as yellow crystalline solid in 77% (0.23 g, 0.72 mmol) yield. M.p.: 68.4–68.9 °C (Ref. [30] 69–70 °C); Rf = 0.39 (PE/EtOAc = 85/15); HR-MS: m/z calcd. 320.0951 Da ([M + H]+), found 320.0954 Da, difference: − 0.3 mDa = -1.06 ppm; 1H NMR (400 MHz, DMSO-d6): δ = 1.26 (t, J = 7.1 Hz, 6H, 2 -CH3), 4.18 (bs, 2H, 2 –CH2–), 7.22–7.30 (m, 2H, H3 and H6), 7.34 (t, J = 7.5 Hz, 1H, H5), 7.68 (d, J = 7.8 Hz, 1H, H4), 7.88 (d, J = 7.9 Hz, 1H, H7), 8.12 (s, 1H, NH-CH =), 11.06 (s, 1H, –NH-) ppm; 13C NMR (101 MHz, DMSO-d6): δ = 14.2 (q, 2 CH3), 59.8 (t, 2 –CH2–), 94.9 (s, Cquat), 109.0 (d, C3), 122.3 (d, C7), 122.8 (d, C4), 123.7 (d, C6), 125.1 (d, C5), 133.5 (s, C3a), 138.8 (s, C7a), 143.9 (s, C2), 151.1 (d, NH–CH =), 164.7 (s, C = O), 166.46 (s, C = O) ppm; Both carbonyl signals were only observable on HMBC but did not appear in the 13C NMR. 1H NMR spectral data are in accordance with literature data [26].

3-(tert-Butoxycarbonylamino)1-benzothiophen (18)

Compound 18 was synthesized according to general grocedure 1, using 17 (1 g, 5.51 mmol) as starting material. 18 was obtained as yellow crystalline solid in 50% (0.68 g, 2.74 mmol) yield. M.p.: 104.6–105.2 °C (Ref [25] 104–105 °C); Rf = 0.31 (LP/CHCl3 = 6/4); 1H NMR (400 MHz, DMSO-d6): δ = 1.52 (s, 9H, –C– (CH3)3), 7.32–7.42 (m, 2H, H5, H7), 7.59 (s, 1H, H2), 7.91 (ddt, J = 7.5, 4.0, 2.0 Hz, 1H, H6), 8.09–8.16 (m, 1H, H4), 9.58 (s, 1H, –NH–) ppm; 13C NMR (101 MHz, DMSO-d6): δ = 28.1 (q, – (CH3)3), 79.5 (s, –C–CH3), 108.7 (d, C2), 121.3 (d, C4), 122.8 (d, C6), 123.7 (d, C7), 124.6 (d, C5), 130.5 (s, C3), 133.0 (s, C7a), 137.2 (s, C3a), 153.5 (s, C = O) ppm.

1-Benzothiophen-3-aminium chloride (19)

Compound 19 was synthesized according to general procedure 2, using 18 (864 mg, 3.46 mmol) as starting material. Product 19 was obtained as colorless pearly solid in 97% (625 mg, 3.39 mmol) yield. Due to the instability of this compound, it was further converted immediately without full characterization.

Diethyl 2-[(1-Benzothiophen-3-ylamino)methylene]malonate (20, C16H17NO4S) [25]

Compound 20 was synthesized according to general procedure 3, using 19 (0.59 g, 3.20 mmol) as starting material, 1 eq. of DEEMM (0.96 cm3, 0.93 mmol) and dry pyridine (10 cm3). The product was purified via flash column chromatography, using PE/EtOAc 90:10 as mobile phase and obtained as yellow crystalline solid in 88% (0.89 g, 2.81 mmol) yield. M.p.: 100.9–101.4 °C; Rf = 0.51 (PE/EtOAc = 85/15); HR-MS: m/z calcd. 320.0951 Da ([M + H]+), found 320.0959 Da, difference: − 0.8 mDa = − 2.55 ppm; 1H NMR (400 MHz, DMSO-d6): δ = 1.27 (m, 6H, 2 –CH3), 4.14 (q, J = 7.2 Hz, 2H, –CH2–), 4.25 (q, J = 7.1 Hz, 2H, –CH2–), 7.47 (ddd, J = 7.5, 1.4 Hz, 1H, H6), 7.52 ddd, J = 7.5, 1.4 Hz, 1H, H5), 7.73 (d, J = 7.4 Hz, 1H, H7), 7.78 (s, 1H, H2), 8.04 (d, J = 7.4 Hz, 1H, H4), 8.46 (d, J = 10.9 Hz, 1H, NH-CH =), 11.06 (d, J = 10.7 Hz, 1H, –NH–) ppm; 13C NMR (101 MHz, DMSO-d6): δ = 14.2 (q, 2 –CH3), 59.0 (t, –CH2–), 59.9 (t, –CH2–), 93.5 (s, Cquat), 110.5 (d, C2), 119.7 (d, C7), 123.5 (d, C4), 124.8 (d, C5), 125.5 (d, C6), 132.0 (s, C3a), 132.4 (s, C3), 138.3 (s, C7a), 153.4 (d, NH–CH =), 164.7 (s, C = O), 167.8 (s, C = O) ppm.

Ethyl 7-hydroxythieno[3,2-b]pyridine-6-carboxylate (21) [26]

The title compound was prepared according to general procedure 4 starting using 6 (3.7 g, 14.5 mmol, 1 eq.) as starting material. Compound 21 was isolated via precipitation from the reaction mixture using LP (200 cm3). The precipitate was collected by filtration, washed with 2 × 50 cm3 of LP and dried in vacuo to give 1.57 g of 21 (48%). The washing liquids were found to contain residual starting materials. After evaporation of volatiles the residue (Ph2O, substrate and traces of product) was heated again for one hour. After the work-up described above additional 560 mg (17%) of product could be isolated. Overall, 2.13 g (65%) brown solid of 21 were obtained. M.p.: 242–245 °C (Ref. [17, 27] 259–262 °C); 1H NMR (400 MHz, DMSO-d6): δ = 1.26 (t, J = 7.1 Hz, 3H, CH2CH3), 4.20 (q, J = 7.1 Hz, 2H, CH2CH3), 7.29 (d, J = 5.4 Hz, 1H, ArH), 8.03 (d, J = 5.4 Hz, 1H, ArH), 8.49 (s, 1H, NCH), 12.78 (s, 1H, NH) ppm; 13C NMR (101 MHz, DMSO-d6): δ = 14.3 (q, CH2CH3), 59.7 (t, CH2CH3), 110.9 (s, C6), 118.8 (d), 130.7 (s), 133.6 (d), 143.1 (d, C5), 143.2 (s), 164.8 (s), 169.8 (COO) ppm.

Ethyl 4-hydroxybenzo[4,5]thieno[3,2-b]pyridine–3-carboxylate (22) [27]

Compound 22 was synthesized according to general procedure 4, using 20 (0.62 g, 1.94 mmol) and 2 cm3 of diphenyl ether. In this reaction, the purification via column chromatography was not performed since a precipitate appeared after adding PE to the reaction mixture. This precipitate was washed with LP and hexane several times and dried in vacuo. An analytical sample was recrystallized twice with DMSO, yielding 22 as colorless solid in 82% (0.44 g, 1.59 mmol) yield. No further purification was required. M.p.: > 230 °C (Ref. [26] 255–257 °C); Rf = 0.38 (PE/EtOAc = 85/15); HR-MS: m/z calcd. 274.0532 Da ([M + H]+), found 274.0523 Da, difference: 1 mDa = 3.51 ppm; 1H NMR (600 MHz, DMSO-d6): δ = 1.30 (t, J = 7.1 Hz, 3H -CH3), 4.26 (q, J = 7.1 Hz, 2H, -CH2-), 7.61 (ddd, J = 7.5, 7.1, 1.2 Hz, 1H, H7), 7.64 (ddd, J = 8.1, 7.6, 1.4 Hz, 1H, H8), 8.14 (d, J = 7.9 Hz, 1H, H6), 8.41 (dd, J = 8.0, 1.6 Hz, 1H, H9), 8.55 (s, 1H, H2), 13.37 (s, 1H, -OH) ppm; 13C NMR (151 MHz, DMSO-d6): δ = 14.3 (q, –CH3), 60.1 (t, –CH2–), 112.9 (s, broad signal, C3), 122.7 (d, C9), 124.1 (d, C6), 125.4 (d, C7), 128.6 (d, C8), 130.3 (s, broad signal, C5a), 139.5 (s, C9a), 1430 (s, broad signal, C9b), 164.901 (s, C = O) ppm, C2 and C4 missing.

Ethyl 7-chlorothieno[3,2-b]pyridine-6-carboxylate (23) [26]

Compound 23 was synthesized according to general procedure 5 using 21 (2.45 g, 11 mmol) and 15 cm3 of POCl3. The crude product was purified via flash column chromatography, using a gradient of PE/EtOAc 90:10 delivering 23 as brown solid in 66% (1.70 g, 7.0 mmol) yield. M.p.: 74–79 °C (Ref. [27] 82–83 °C); 1H NMR (200 MHz, CDCl3): δ = 1.44 (t, J = 7.1 Hz, 3H, CH2CH3), 4.46 (q, J = 7.1 Hz, 2H, CH2CH3), 7.60 (d, J = 5.5 Hz, 1H, ArH), 7.93 (d, J = 5.5 Hz, 1H, ArH), 9.14 (s, 1H, NCH) ppm; 13C NMR (50 MHz, CDCl3): δ = 14.4 (q, CH2CH3), 62.0 (t, CH2CH3), 120.0 (s, ArC), 125.9 (d, C2), 134.6 (s, ArC), 135.1 (d, C3), 139.2 (s, C7), 150.0 (d, C5), 158.3 (s, C8), 164.2 (s, COO) ppm. Spectral data were in agreement with those reported in the literature.

Ethyl 4-chlorobenzo[4,5]thieno[3,2-b]pyridine-3-carboxylate (24) [27]

Compound 24 was synthesized according to general procedure 5 using 22 (0.29 g, 1.12 mmol) and 1.5 cm3 of POCl3. The crude product was purified via flash column chromatography, using a gradient of PE/EtOAc 90:10 delivering 24 as colorless crystalline solid in 74% (0.32 g, 1.10 mmol) yield. M.p.: 84–85 °C (Ref. [28] 88–89 °C); Rf = 0.37 (PE/EtOAc = 9/1); HR-MS: m/z calcd. 292.0194 Da ([M + H]+), found 292.0199 Da, difference: − 0.6 mDa = – 1.94 ppm; 1H NMR (400 MHz, CDCl3): δ = 1.47 (t, J = 7.1 Hz, 3H, –CH3), 4.50 (q, J = 7.1 Hz, 2H, –CH2-), 7.59 (ddd, J = 8.2, 7.1, 1.2 Hz, 1H, H8), 7.65 (ddd, J = 8.0, 7.2, 1.5 Hz, 1H, H7), 7.91 (dd, J = 8.0, 1.0 Hz, 1H, H6), 8.51 (dd, J = 7.9, 0.7 Hz, 1H, H9), 9.20 (s, 1H, H2) ppm; 13C NMR (101 MHz, CDCl3): δ = 14.4 (q, –CH3), 62.2 (t, –CH2–), 122.3 (s, C3), 123.2 (d, C6), 124.4 (d, C9), 125.8 (d, C8), 130.1 (d, C7), 134.6 (s, C9a), 135.5 (s, C4), 138.8 (s, C4a), 141.2 (s, C5a), 149.4 (d, C2), 154.9 (s, C9b), 164.2 (s, C = O) ppm.

Ethyl 4-hydroxythieno[2,3-b]pyridine-5-carboxylate (25) [29]

Compound 25 was synthesized according to general procedure 4, using 9 (0.75 g, 2.78 mmol) as starting material and 2 cm3 of diphenyl ether. Monitoring this reaction using ninhydrin as a TLC staining agent is a crucial step, since both the starting material and the resulting product have identical Rf values. The crude product was purified via flash column chromatography, using a gradient of PE/EtOAc 99:1 to PE/EtOAc 90:10 delivering 25 as colorless solid in 66% (0.32 g, 1.83 mmol) yield. M.p.: 144.1–144.8 °C (Ref. [17] 152–153 °C); Rf = 0.63 (PE/EtOAc = 9/1); GC–MS: m/z = 223 (25, M+), 177 (100), 53 (45); HR-MS: m/z calcd. 224.0376 Da ([M + H]+), found 224.0378 Da, difference: − 0.2 mDa = − 0.74 ppm; 1H NMR (400 MHz, DMSO-d6): δ = 1.34 (t, J = 7.1 Hz, 3H, –CH3), 4.36 (q, J = 7.1 Hz, 2H, –CH2–), 7.48 (d, J = 5.9 Hz, 1H, H2), 7.68 (d, J = 5.9 Hz, 1H, H3), 8.70 (s, 1H, H6) ppm; 13C NMR (101 MHz, DMSO-d6): δ = 14.5 (q, –CH3), 61.6 (t, –CH2–), 108.2 (s, C5), 120.2 (d, C2), 125.5 (d, C3), 147.2 (d, C6), 161.9 (s, C7a), 164.4 (s, C3a), 167.9 (s, C = O) ppm, C4 missing. 1H NMR spectral data are in accordance with literature data [17]. C7a was only visible in HMBC, but not in 13C NMR.

Ethyl 2-chloro-4-hydroxythieno[2,3-b]pyridine-5-carboxylate (26, C10H8ClNO3S)

Compound 26 was synthesized according to general procedure 4, using 15 as substrate (1.14 g, 3.76 mmol) in 1 cm3 of diphenyl ether. The crude product was purified via flash column chromatography, using a gradient of PE/EtOAc 99:1 to PE/EtOAc 95:5 delivering 26 as colorless solid in 69% (0.32 g, 0.68 mmol) yield. M.p.: 168–170 °C; Rf = 0.4 (DCM/MeOH 95/5); LC–MS: m/z calcd. 257.99 ([M + H]+), found 257.90; 1H NMR (400 MHz, CDCl3): δ = 1.46 (t, J = 7.1 Hz, 3H, -CH3), 4.49 (q, J = 7.1 Hz, 2H, –CH2-), 7.33 (s, 1H, H3), 8.85 (s, 1H, H6), 11.85 (s, 1H, –OH) ppm; 13C NMR (101 MHz, CDCl3): δ = 14.3 (q, –CH3), 62.3 (t, –CH2–), 106.0 (s, C5), 117.9 (d, C3), 122.7 (s, C2), 131.1 (s, C4), 148.4 (d, C6), 162.2 (s, C7a), 165.3 (s, C3a), 170.1 (s, C = O) ppm.

Ethyl 4-hydroxybenzo[4,5]thieno[2,3-b]pyridine-3-carboxylate (27, C14H11NO3S) [30]

Compound 27 was synthesized according to general procedure 4, starting from 16 (0.07 g, 0.19 mmol) and 2 cm3 of diphenyl ether. The starting material had to be dissolved in this case with the aid of the ultrasound bath. The crude product was purified via flash column chromatography, using a gradient of PE/EtOAc 99:1 to PE/EtOAc 95:5 delivering 27 as beige solid in 47% (0.025 g, 0.09 mmol) yield. M.p.: 187.8–193.6 °C; Rf = 0.45 (PE/EtOAc 85/15); HR-MS: m/z calcd. 274.0532 Da ([M + H]+), found 274.0537 Da, difference: − 0.5 mDa = − 1.79 ppm; 1H NMR (400 MHz, CDCl3): δ = 1.49 (t, J = 7.1 Hz, 3H, –CH3), 4.52 (q, J = 7.1 Hz, 2H, –CH2–), 7.47–7.58 (m, 2H, H6 and H7), 7.76–8.00 (m, 1H, H8), 8.53–8.74 (m, 1H, H5), 8.98 (s, 1H, H2), 12.32 (s, 1H, –OH) ppm; 13C NMR (101 MHz, CDCl3): δ = 14.4 (q, –CH3), 62.3 (t, –CH2–), 106.3 (s, C3), 122.6 (s, C8), 125.7 (d, C6 or C7), 126.2 (d, C5), 127.2 (d, C6 or C7), 132.5 (s, C8a), 136.8 (s, C4b), 149.7 (d, C2), 164.4 (s, C9a), 167.2 (s, C4 or C4a), 167.5 (s, C4 or C4a), 170.4 (s, C = O) ppm.

Ethyl 4-chlorothieno[2,3-b]pyridine-5-carboxylate (28) [17]

Compound 28 was synthesized according to general procedure 5, starting from 25 (0.07 g, 0.31 mmol) and 1 cm3 of POCl3. For this product, the reaction time lasted 1 h and 28 was obtained as yellow crystalline solid in 79% (0.06 g, 0.25 mmol) yield. M.p.: 68.0–68.5 °C (Ref. [17] 60–70 °C); Rf = 0.66 (PE/EtOAc = 85/15); GC–MS: m/z = 241 (35, M+), 196 (100), 133 (38); HR-MS: m/z calcd. 242.0037 Da ([M + H]+), found 242.0038 Da, difference: − 0.1 mDa = -0.58 ppm; 1H NMR (400 MHz, CDCl3): δ = 1.45 (t, J = 7.1 Hz, 3H, –CH3), 4.48 (q, J = 7.1 Hz, 2H, –CH2–), 7.55 (d, J = 6.1 Hz, 1H, H3), 7.66 (dd, J = 6.1, 0.4 Hz, 1H, H2), 9.01 (s, 1H, H6) ppm; 13C NMR (101 MHz, CDCl3): δ = 14.3 (q, -CH3), 62.0 (t, –CH2–), 120.9 (d, C3), 121.6 (s, C5), 129.1 (d, C2), 132.4 (s, C3a), 139.3 (s, C4), 148.2 (d, C6), 163.9 (s, C7a), 164.3 (s, C = O) ppm.

Ethyl 2,4-dichlorothieno[2,3-b]pyridine-5-carboxylate (29, C10H7Cl2NO2S)

Compound 29 was synthesized according to general procedure 5, starting from 26 (0.29 g, 1.12 mmol) and 2 cm3 of POCl3. The crude product was purified via flash column chromatography, using a gradient of PE/EtOAc 99:1 to PE/EtOAc 95:5 to give 29 as beige solid in quantitative yield (0.33 g, 1.12 mmol). M.p.: 63–65 °C; Rf = 0.66 (PE/EtOAc = 9/1); 1H NMR (600 MHz, CDCl3): δ = 1.44 (t, J = 7.1 Hz, 3H, -CH3), 4.46 (q, J = 7.1 Hz, 2H, –CH2–), 7.39 (s, 1H, H3), 8.94 (s, 1H, H6) ppm; 13C NMR (151 MHz, CDCl3): δ = 14.4 (q, –CH3), 62.2 (t, –CH2–), 119.8 (d, C3), 122.4 (s, C5), 132.4 (s, C2), 135.1 (s, C3a), 137.7 (s, C4), 148.5 (d, C6), 162.7 (s, C7a), 164.2 (s, C = O) ppm.

Ethyl 4-chlorobenzo[4,5]thieno[2,3-b]pyridine-3-carboxylate (30, C14H10ClNO2S)

Compound 30 was synthesized according to general procedure 5, starting from 27 (1.4689 g, 5.37 mmol) and 10 cm3 of POCl3. The crude product was purified via flash column chromatography, using a gradient of PE/EtOAc 95:5 delivering 30 as yellow solid in 35% (0.55 g, 1.90 mmol) yield. M.p.: 70–72.3 °C; Rf = 0.45 (PE/EtOAc = 85/15); HR-MS: m/z calcd. 274.0532 Da ([M + H]+), found 274.0532 Da, difference: − 0.1 mDa = − 0.26 ppm; 1H NMR (400 MHz, DMSO-d6): δ = 1.39 (t, J = 7.1 Hz, 3H, –CH3), 4.42 (q, J = 7.1 Hz, 2H, –CH2–), 7.65 (ddd, J = 8.5, 7.2, 1.4 Hz, 1H, H6), 7.70 (ddd, J = 7.8, 7.5, 1.4 Hz, 1H, H7), 8.20 (dd, J = 7.8, 1.6 Hz, 1H, H8), 8.91 (dd, J = 7.9, 1.7 Hz, 1H, H5), 8.95 (s, 1H, H2) ppm; 13C NMR (101 MHz, DMSO-d6): δ = 14.0 (q, –CH3), 61.9 (t, –CH2–), 123.4 (s, C3), 123.6 (d, C8), 125.7 (s, C8a), 125.8 (d, C5), 126.0 (d, C6), 128.8 (d, C7), 131.4 (s, C4b), 137.4 (s, C4a), 138.0 (s, C4), 148.8 (d, C2), 163.8 (s, C = O), 164.7 (s, C9a) ppm.

Ethyl 4-[2-(4-methoxyphenyl)hydrazinyl]benzo[4,5]thieno[3,2-b]pyridine-3-carboxylate (31, C21H19N3O3S)

Compound 31 was synthesized according to general procedure 6, starting from 24 (0.063 g, 0.16 mmol). The crude product was purified via flash column chromatography, using a gradient of PE/EtOAc 95:5 to PE/EtOAc 85:15 and subsequently via RP-HPLC. Compound 31 was obtained as orange solid in 13% (0.008 g, 0.021 mmol) yield. M.p.: 85–86 °C; Rf = 0.26 (PE/EtOAc = 9/1); LC–MS: m/z calcd. 394.12 ([M + H]+), found 394.05; HR-MS: m/z calcd. 394.1220 Da ([M + H]+), found 394.1214 Da, difference: 0.6 mDa = 1.6 ppm; 1H NMR (400 MHz, DMSO-d6): δ = 1.38 (t, J = 7.1 Hz, 3H, –CH3), 3.94 (s, 3H, –OCH3), 4.48 (q, J = 7.1 Hz, 2H, –CH2-), 7.26 (d, J = 9.0 Hz, 2H, H3’, H5’), 7.65 (ddd, J = 7.4, 0.8 Hz, 1H, H8), 7.72 (ddd, J = 7.5, 1.4 Hz, 1H, H7), 8.09 (d, J = 8.9 Hz, 2H, H2’, H6’), 8.16 (d, J = 7.9 Hz, 1H, H6), 8.50 (d, J = 7.7 Hz, 1H, H9), 9.18 (s, 1H, H2) ppm; 13C NMR (101 MHz, DMSO-d6): δ = 14.3 (q, –CH3), 56.0 (q, –OCH3), 61.9 (t, –CH2–), 115.3 (d, C3´, C5´), 119.4 (s, C3), 123.0 (d, C9), 123.6 (d, C6), 124.1 (s, C4a), 125.7 (d, C2´, C6´), 125.9 (d, C8), 129.8 (d, C7), 132.5 (s, C9b), 143.6 (s, C5a), 145.8 (s, C1´), 147.6 (d, C2), 148.4 (s, C4), 155.9 (s, C9a), 164.2 (s, C4´), 165.6 (s, C = O) ppm.

Ethyl 4-[2-(4-methoxyphenyl)hydrazinyl]thieno[2,3-b]pyridine-5-carboxylate (32, C17H17N3O3S)

Compound 32 was synthesized according to general procedure 6, starting from 28 (0.096 g, 0.40 mmol). The crude product was purified via flash column chromatography, using a gradient of PE/EtOAc 90:10 delivering 32 as orange solid in 28% (0.038 g, 1.11 mmol) yield. M.p.: > 230 °C; Rf = 0.37 (PE/EtOAc = 85/15); LC–MS: m/z calcd. 342.09 ([M-H]−), found 342.17; HR-MS: m/z calcd. 342.0907 Da ([M]+), found 342.0904 Da, difference: + 0.3 mDa = + 0.8 ppm; 1H NMR (400 MHz, DMSO-d6): δ = 1.15 (t, J = 7.1 Hz, 3H, -CH3), 3.92 (s, 3H, –OCH3), 4.25 (q, J = 7.1 Hz, 2H, –CH2–), 7.22 (d, J = 9.0 Hz, 2H, H3 ‘, H5 ‘), 7.63 (d, J = 6.1 Hz, 1H, H3), 8.00 (d, J = 9.0 Hz, 2H, H2 ‘, H6 ‘), 8.10 (d, J = 6.0 Hz, 1H, H2), 8.94 (s, 1H, H6) ppm; 13C NMR (101 MHz, DMSO-d6): δ = 14.0 (q, –CH3), 55.9 (q, –OCH3), 61.4 (t, –CH2–), 114.9 (d, C3’, C5’), 115.7 (s, C5), 120.0 (d, C3), 123.6 (s, C3a), 125.7 (d, C2´, C4´), 131.0 (d, C2), 146.5 (s, C1’), 147.4 (d, C6), 152.4 (s, C4), 163.5 (s, C4´), 165.2 (s, 7a), 165.5 (s, C = O) ppm.

Ethyl 2-chloro-4-[2-(4-methoxyphenyl)hydrazinyl]thieno[2,3-b]pyridine-5-carboxylate (33, C17H16ClN3O3S)

Compound 33 was synthesized according to general procedure 6, starting from 29 (0.058 g, 0.21 mmol). The crude product was purified via flash column chromatography, using PE/EtOAc 90:10 delivering 33 as orange solid in 40% (0.032 g, 0.085 mmol) yield. M.p.: 126–127 °C; Rf = 0.47 (PE/EtOAc = 90/10); LC–MS: m/z calcd. 376.05 ([M + H]+), found 376.05; HR-MS: m/z calcd. 376.0517 Da ([M]+), found 376.0525 Da, difference: − 0.8 mDa = − 2.07 ppm; 1H NMR (400 MHz, CDCl3): δ = 1.25 (t, J = 7.1 Hz, 3H, –CH3), 3.93 (s, 3H, –OCH3), 4.33 (q, J = 7.1 Hz, 2H, –CH2–), 7.06 (d, J = 9.0 Hz, 2H, H3’, H5’), 7.40 (s, 1H, H3), 7.99 (d, J = 8.9 Hz, 2H, H2’, H6’), 8.97 (s, 1H, H6) ppm; 13C NMR (101 MHz, CDCl3): δ = 14.4 (q, –CH3), 55.9 (q, –OCH3), 61.9 (t, –CH2–), 114.7 (d, C3’, C5’), 117.2 (s, C5), 119.4 (d, C3), 123.8 (s, C3a), 126.0 (d, C2´, C4’), 147.2 (s, C1’), 148.2 (d, C6), 152.5 (s, C4), 163.9 (s, C4´), 164.6 (s, C7a), 165.9 (s, C = O) ppm.

2-(4-Methoxyphenyl)-2,5-dihydro-3H-benzo[4,5]thieno[3,2-b]pyrazolo[3,4-d]pyridin-3-one (34, C19H12N3O2S)

Compound 34 was synthesized according to general procedure 7, starting from 31 (0.19 g, 0.48 mmol). Water was added to the reaction mixture and a precipitate appeared, which was filtered. From this step, 20.6 mg of the product were obtained. It was observed that some precipitate got trapped within the glass filter of the funnel, thus, the filter was washed with DMSO until the precipitate completely dissolved and the DMSO was evaporated with high vacuum. Additionally, the water phase was extracted with EtOAc, dried over magnesium sulfate, and concentrated in vacuo. The desired reaction product was also found on the organic phase and the residue collected from the funnel. The three collected crude fractions were purified via RP-HPLC delivering 34 as yellow solid in 38% (0.064 g, 0.18 mmol) yield. M.p.: > 230 °C; Rf = 0.9 (DCM/MeOH = 9/1); LC–MS: m/z calcd. 348.08 ([M + H]+), found 348.15; HR-MS: m/z calcd. 348.0801 Da ([M + H]+), found 348.0809 Da, difference: 0.8 mDa = 2.29 ppm; 1H NMR (400 MHz, DMSO-d6): δ = 3.79 (s, 3H, –OCH3), 7.02 (d, J = 8.6 Hz, 2H, H3’, H5’), 7.62 (d, J = 8.1 Hz, 2H, H8, H7), 8.10 (d, J = 8.6 Hz, 2H, H2’, H4’), 8.19 (d, J = 9.0 Hz, 1H, H6), 8.48 (s, 1H, H9), 8.81 (s, 1H, H4), 13.74 (s, 1H, –NH–) ppm; 13C NMR (101 MHz, DMSO-d6): δ = 55.3 (q, –OCH3), 108.2 (s, C3a), 113.9 (d, C3’, C5’), 118.6 (s, C10a), 120.6 (d, C2’, C4’), 121.6 (d, C9), 124.0 (d, C6), 125.6 (d, C7), 127.6 (d, C8), 129.9 (s, C5b), 133.4 (s, C1’), 134.1 (s, C5a), 136.9 (s, C9a), 137.4 (d, C4), 141.8 (s, C10b), 156.1 (s, C4’), 160.5 (s, C = O) ppm; C5a only visible in HMBC.

2-(4-Methoxyphenyl)-2,5-dihydro-3H-pyrazolo[3,4-d]thieno[2,3-b]pyridin-3-one (35, C15H11N3O2S)

Compound 35 was synthesized according to general procedure 7, starting from 32 (0.07 g, 0.31 mmol) and 1 cm3 of POCl3. In this case, the crude product was only washed with petroleum ether and no further purification was required. The crude product was purified via flash column chromatography, using a gradient of PE/EtOAc 99:1 to PE/EtOAc 95:5 delivering 35 as red solid in 68% (0.009 g, 0.03 mmol) yield. M.p.: 181–182 °C; Rf = 0.3 (DCM/MeOH = 95/5); HR-MS: m/z calcd. 298.0645 Da ([M + H]+), found 298.0644 Da, difference: 0.1 mDa = 0.33 ppm; 1H NMR (400 MHz, DMSO-d6): δ = 3.91 (s, 3H, -OCH3), 7.21 (d, J = 8.9 Hz, 2H, H3’, H5’), 7.56 (d, J = 6.1 Hz, 1H, H8), 7.98 (d, J = 8.9 Hz, 2H, H2’, H6’), 8.06 (d, J = 6.1 Hz, 1H, H7), 8.95 (s, 1H, H4) ppm; 13C NMR (101 MHz, DMSO-d6): δ = 55.9 (q, –OCH3), 114.9 (d, C3’, C5’), 116.9 (s, C3a), 120.0 (d, C2’, C6’), 123.0 (s, C8a), 125.5 (d, C7), 130.8 (d, C8), 146.6 (s, C1´), 147.7 (d, C4), 152.8 (s, C8b), 163.4 (s, C4’), 165.0 (s, C5a), 166.6 (s, C = O) ppm.

7-Chloro-2-(4-methoxyphenyl)-2,5-dihydro-3H-pyrazolo[3,4-d]thieno[2,3-b]pyridin-3-one (36, C15H10ClN3O2S)

Compound 36 was synthesized according to general procedure 7, starting from 33 (0.02 g, 0.51 mmol). The crude product was purified via RP-HPLC delivering 36 as yellow solid in 23% (0.004 g, 0.012 mmol) yield. LC–MS: m/z calcd. 332.02 ([M + H]+), found 332.05; 1H NMR (600 MHz, DMSO-d6): δ = 3.77 (s, 3H, –OCH3), 6.98 (d, J = 8.6 Hz, 2H, H3’, H5’), 7.52 (s, 1H, H8), 8.07 (d, J = 8.5 Hz, 2H, H2’, H4’), 8.48 (s, 1H, H4) ppm; 13C NMR (151 MHz, DMSO-d6): δ = 55.3 (q, -OCH3), 108.3 (s, C3a), 113.7 (d, C3’, C5’), 114.9 (s, C3a), 118.9 (s, C8a), 119.3 (d, C8), 120.6 (d, C2’, C4’), 125.8 (s, C7), 133.9 (s, C1’), 141.8 (d, C4), 142.6 (s, C8b), 155.7 (s, C4’), 160.1 (s, C5a), 163.1 (s, C = O) ppm.

2-(4-Methoxyphenyl)-2,5-dihydro-3H-benzo[4,5]thieno[2,3-b]pyrazolo[3,4-d]pyridin-3-one (39, C19H13N3O2S)

Compound 39 was synthesized according to general procedure 6, starting from 30 (62.7 mg, 0.18 mmol). In this case, after full consumption of the starting material, a precipitate was observed in the reaction mixture, which was filtered. NMR analysis confirmed that said precipitate corresponds to the pure reaction product as yellow powder in 46% (0.029 g, 0.083 mmol) yield. No further purification was performed. M.p.: > 300 °C; Rf = 0.4 (DCM/MeOH = 95/5); HR-MS: m/z calcd. 348.0801 Da ([M + H]+), found 348.0801 Da, difference: 0.0 mDa = 0.06 ppm; 1H NMR (400 MHz, DMSO-d6): δ = 3.80 (s, 3H, -OCH3), 7.05 (d, J = 8.8 Hz, 2H, H3’, H5’), 7.56 (t, J = 7.6 Hz, 1H, H8), 7.66 (t, J = 7.5 Hz, 1H, H9), 8.14 (d, J = 8.1 Hz, 1H, H7), 8.19 (d, J = 8.7 Hz, 2H, H2’, H4’), 8.57 (d, J = 7.9 Hz, 1H, H10), 8.80 (s, 1H, H4), 13.57 (s, 1H, –NH–) ppm; 13C NMR (101 MHz, DMSO-d6): δ = 55.3 (q, –OCH3), 110.4 (s, C3a), 113.9 (d, C3’, C5’), 114.8 (s, C10b), 120.5 (d, C2’, C4’), 123.0 (d, C6), 124.3 (d, C10), 125.9 (d, C9), 126.1 (d, C8), 132.4 (s, C6a), 133.4 (s, C1’), 134.5 (s, C10a), 137.3 (d, C4), 142.1 (s, C10c), 156.0 (s, C4’), 160.1 (s, C = O) ppm; C5a missing, C4 barely visible in 13C NMR but visible in HMBC.

Data availability

NMR data of synthesized compounds are available in the supporting information.

References

Iorio MT, Vogel FD, Koniuszewski F, Scholze P, Rehman S, Simeone X, Schnürch M, Mihovilovic MD, Ernst M (2020) Int J Mol Sci 21:334

Alanis BAV, Iorio MT, Silva LL, Bampali K, Ernst M, Schnürch M, Mihovilovic MD (2020) Molecules 25:999

Simeone X, Iorio MT, Siebert DCB, Rehman S, Schnürch M, Mihovilovic MD, Ernst M (2019) Bioorg Med Chem 27:3167

Fabjan J, Koniuszewski F, Schaar B, Ernst M (2021) Front Neurosci 14:611953

Varagic Z, Wimmer L, Schnürch M, Mihovilovic MD, Huang S, Rallapalli S, Cook JM, Mirheydari P, Ecker GF, Sieghart W, Ernst M (2013) Br J Pharmacol 169:371

Mirheydari P, Ramerstorfer J, Varagic Z, Scholze P, Wimmer L, Mihovilovic MM, Sieghart W, Ernst M (2014) Neurochem Res 39:1057

Simeone X, Siebert DCB, Bampali K, Varagic Z, Treven M, Rehman S, Pyszkowski J, Holzinger R, Steudle F, Scholze P, Mihovilovic MD, Schnürch M, Ernst M (2017) Sci Rep 7:5674

Treven M, Siebert DCB, Holzinger R, Bampali K, Fabjan J, Varagic Z, Wimmer L, Steudle F, Scholze P, Schnürch M, Mihovilovic MD, Ernst M (2018) Br J Pharmacol 175:419

Iorio MT, Rehman S, Bampali K, Stoeger B, Schnürch M, Ernst M, Mihovilovic MD (2019) Eur J Med Chem 180:340

Patani GA, LaVoie EJ (1996) Chem Rev 96:3147

Yokoyama N, Ritter B, Neubert AD (1982) J Med Chem 25:337

Schnute ME, Cudahy MM, Brideau RJ, Homa FL, Hopkins TA, Knechtel ML, Oien NL, Pitts TW, Poorman RA, Wathen MW, Wieber JL (2005) J Med Chem 48:5794

Matsuno K, Nakajima T, Ichimura M, Giese NA, Yu J-C, Lokker NA, Ushiki J, Ide S-i, Oda S, Nomoto Y (2002) J Med Chem. 45:4513

Whittamore PRO, Addie MS, Bennett SNL, Birch AM, Butters M, Godfrey L, Kenny PW, Morley AD, Murray PM, Oikonomakos NG, Otterbein LR, Pannifer AD, Parker JS, Readman K, Siedlecki PS, Schofield P, Stocker A, Taylor MJ, Townsend LA, Whalley DP, Whitehouse J (2006) Bioorg Med Chem Lett 16:5567

Branum ST, Colburn RW, Dax SL, Flores CM, Jetter MC, Liu Y, Ludovici D, Macielag MJ, Matthews JM, McNally JJ, Qin N, Reaney LM, Russell RK, Wells KM, Youells SC, Youngman MA (2009) Sulfonamides as TRPM8 modulators. Patent WO2009012430A1, Jan 22, 2009; (2009) Chem Abstr 150:168153

Trullinger TK, Johnson TC, Hunter R (2014) Pesticidal pyrimidine compounds. Patent WO2014074333, May 15, 2014; (2014) Chem Abstr 160:718094

Khan MA, Guarçoni AE (1977) J Heterocycl Chem 14:807

Suen YF, Robins L, Yang B, Verkman AS, Nantz MH, Kurth MJ (2006) Bioorg Med Chem Lett 16:537

Gottlieb HE, Kotlyar V, Nudelman A (1997) J Org Chem 62:7512

Guzi TJ, Paruch K, Dwyer MP, Parry DA, Zhao L, Curran PJ, Belanger DB, Hamann B, Reddy PAP, Siddiqui MA, Tadikonda PK (2007) Imidazopyrazine compounds and their methods for inhibiting protein kinases, preparation, pharmaceutical compositions and use in the treatment of protein kinase-associated diseases. US Patent 20070105864, May 10, 2007; (2007) Chem Abstr 146:501082

Leenders RGG, Brinch SA, Sowa ST, Amundsen-Isaksen E, Galera-Prat A, Murthy S, Aertssen S, Smits JN, Nieczypor P, Damen E, Wegert A, Nazaré M, Lehtiö L, Waaler J, Krauss S (2021) J Med Chem 64:17936

Wimmer L (2016) Synthesis of bioactive molecules for the investigation of ion channels and transporters. Ph.D. Thesis, TU Wien

Binder D, Habison G, Noe CR (1977) Synthesis 1977:255

Ohta T, Komoriya S, Yoshino T, Uoto K, Nakamoto Y, Naito H, Mochizuki A, Nagata T, Kanno H, Haginoya N, Yoshikawa K, Nagamochi M, Kobayashi S, Ono M (2003) Diamine derivatives. Patent WO2003000657, Jan 03, 2003; (2005) Chem Abstr 142:176829

Gálvez C, Garcia F, Veiga M, Viladoms P (1983) Synthesis 1983:932

Muchiri DR, Midgley JM (1999) J Kenya Chem Soc 1:5

Barker JM (1982) J Chem Res, Synop 158

Görlitzer K, Meyer H, Walter RD, Jomaa H, Wiesner J (2004) Pharmazie 59:506

Forbes IT, Johnson CN, Jones GE, Loudon J, Nicholass JM, Thompson M, Upton N (1990) J Med Chem 33:2640

Février B, Dupas G, Bourguignon J, Quéguiner G (1993) J Heterocycl Chem 30:1085

Acknowledgements

We are grateful to the Austrian Science Fund FWF grant W1232 (graduate school program MolTag) for the financial support of this work.

Funding

Open access funding provided by Austrian Science Fund (FWF).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Vega Alanis, B.A., Wimmer, L., Ernst, M. et al. Novel pyrazolothienopyridinones as potential GABAA receptor modulators. Monatsh Chem 154, 1427–1439 (2023). https://doi.org/10.1007/s00706-023-03063-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-023-03063-6