Abstract

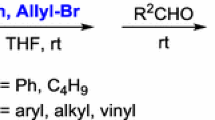

Ru-catalyzed synthesis of mixed alkyl–alkyl acetals via addition of primary alcohols to allyl ethers has been extended to include long-chain and/or functionalized substrates. The catalytic systems for these reactions were generated from RuCl2(PPh3)3 and [RuCl2(1,5-COD)]x and phosphines [PPh3 or P(p-chlorophenyl)3] or SbPh3. Of particular importance is the almost quantitative elimination of transacetalization. The addition proceeds through allyl complexes, not via isomerization of allyl ethers––subsequent addition of ROH to vinyl ethers.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Alkyl acetals R1CH(OR2)(OR3) (R1–R3 = alkyl) are widely used in synthetic organic chemistry as good protecting groups for aldehydes and ketones [1] in asymmetric synthesis [2], and also as “green solvents” in the lacquer and paint industry [3] or as diesel fuel additives [4]. Likewise, in the food (e.g., green pepper flavor) [5], fragrance (e.g., lemon or cardamom fragrance) [6, 7], and pharmaceutical [8] industries, acetals are used both as intermediates and as end products. There are many methods for the synthesis of symmetrical acetals reported in the literature. Also, synthesis of some mixed acetals (e.g., tetrahydropyranyl ethers, dioxane and dioxolane derivatives obtained from unsymmetrical diols) is quite simple because of the substrate structure. However, selective synthesis of mixed acetals of the type R1CH(OR2)(OR3) (where R1, R2, and R3 is alkyl group) is still difficult. Application of classical methods for the synthesis of these compounds is not satisfactory, as a concomitant transacetalization reaction leads to a mixture of symmetrical and unsymmetrical acetals, which can be difficult to separate. So far, only two reports describing a selective method for the preparation of several mixed acetals have been published. Fujioka and co-workers obtained mixed acetals by reaction of dimethyl acetals of the type R1CH(OMe)2 with TESOTf and 2,4,6-collidine and then by treating the salt obtained with R2OH [9, 10]. However, only alkyl methyl acetals were obtained with their method. Also a few attempts using transition metal complexes for the synthesis of mixed alkyl alkyl acetals have not been successful because of a transacetalization side reaction [11, 12]. Recently, we have obtained alkyl-aryl acetals via addition of alcohols and phenols to allyl ethers [13, 14] and cyclic acetals via cyclization of allyloxyalcohols [15]. In the present study, we wish to report an extension of this methodology to include more functionalized substrates.

Results and discussion

Mixed acetals of the type CH3CH2CH(OR1)(OR2) were obtained in the addition of alkyl alcohols to allyl alkyl ethers. Some of the starting allyl ethers were obtained under phase transfer catalysis (PTC) conditions, according to the procedure developed by us enabling practically quantitative conversion of alcohol into allyl ether. This is of particular importance in the case when ether and alcohol have similar boiling points. PTC methods described in the literature do not assure such a quantitative conversion of ROH into RO-allyl. The mixed acetals prepared from allyl butyl ether and several primary alcohols are presented in Table 1. Usually, the most effective catalyst for these transformations was RuCl2(PPh3)3–[Ru1], but sometimes better results were obtained in the presence of complexes generated in situ from [RuCl2(1,5-COD)]x and phosphines (PPh3–[Ru2] or P(p-chlorophenyl)3–[Ru3] or SbPh3–[Ru4]). We observed similiar effects during isomerization of allyl ethers and N-allyl amines: complexes generated in situ from [RuCl2(1,5-COD)]x and phosphines or phosphites were extremely effective [16, 17]. Other catalytic systems, [Ru3(CO)12, [RuCl2(1,5-COD)]x lacking outside ligands, Ru(acac)3], turned out to be ineffective. The reaction products were: mixed acetals (products of addition), symmetrical acetals (products of transacetalization), and (E)- and (Z)-butyl (1-propenyl) ethers (products of isomerization of BuO-allyl), and cyclic acetal (only for entry 4). Conversion of the allyl ethers was practically quantitative and reaction selectivity was very good (entries 4, 7, 8) or excellent (entries 1, 2, 3, 5, 6).

It is noteworthy that some of the acetals (e.g., 2 and 3) may be obtained alterable in the reaction of R1Oallyl with R2OH or R2Oallyl with R1OH.

As reported before [14, 15], addition of tertiary alcohol (t-BuOH and [Ru1] were investigated) does not occur at all––probably due to steric factors. In the case of addition of secondary alcohols, intensive transacetalization was observed. For example, in the reaction of pentan-2-ol with allyl butyl ether in the presence of [Ru1], 33% of mixed acetal and 67% of both symmetrical acetals were obtained (very similiar results were obtained for cyclohexanol). In the addition reaction of 9-decen-1-ol to allyl butyl ether, the stereoselective migration of the double bond in the chain was observed––but only from the terminal site 9 to the site 8 (8E), with 95% conversion (Table 1, entry 5). Moreover, the addition of (9Z)-9-octadecene-1-ol to allyl butyl ether was not accompanied by either double bond migration or Z/E isomerization (Table 1, entry 6). Obviously, those are kinetic effects. Significant prolongation of reaction time (5 times more) makes double bond migration along the chain and Z/E isomerization noticable. It is well known that double bond migration is much faster if the bond is terminal rather than internal [18–20]. Also, the Z/E isomerization is usually much slower than double bond migration [18–20].

Mixed acetals were also obtained in the addition reaction of butan-1-ol to allyl ethers of various structures (Table 2). The bulky allyl t-butyl ether was converted to the mixed acetal in high yield with good selectivity (Table 2, entry 9). In the case of synthesis of long chain acetals, the full conversion was achieved by raising the temperature from 120 to 130 °C (Table 2, entry 11).

It is also very interesting that the addition of R2OH (R2 = n-decyl, 9-decen-1-yl) to an ether of the type R1OCH2CH=CHCH2OR1 (R1 = n-Bu) was possible (Table 3).

What is of great importance is that we did not observe any transacetalization during these reactions and that the isomerized product could be separated from the addition product by simple distillation.

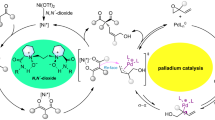

According to our previous reports [14, 15], the proposed mechanism of the studied reaction of the addition of alcohols to allyl ethers is presented in Scheme 1. The first step consists of the oxidative addition of the allyl ether to [Ru] through a C(allyl)–H bond, and the hydrido-π-allyl complex I1 is formed. Reductive elimination of allyl/H ligands generates the vinyl ether, while the reaction with R2OH results in the formation of the complex I2. Migration of R2O to the coordinated allyl ligand leads to the complex I3 containing the coordinated, unsaturated acetal and two hydride ligands. Rapid hydrogenation follows through the complex I4 and the mixed acetal P2 is formed. The complex I3 can also be formed directly from I1 through the transition state TS.

The proposed mechanism presented above is supported by the following observations: the addition of alcohols to vinyl butyl ether does not occur, and 2-vinyloxyethanol does not undergo cyclization towards 2-methyl-1,3-dioxolane (but 2-allyloxyethanol easily forms 2-ethyl-1,3-dioxolane [15]). In our opinion, the reaction runs through π-allyl complexes, which may occur from ROCH2CH=CH2 (or slowly from ROCH=CHCH3 [15]) but not from ROCH=CH2. Therefore, the reaction cannot be the two-step addition of R2OH to R1O-allyl: first, the isomerization of R1O-allyl to R1O-(1-propenyl), followed by the addition of R2OH to R1O-(1-propenyl).

What is worth mentioning is that we also developed methods for the separation of mixed acetals from the reaction mixtures. It turned out that ruthenium complexes can be almost quantitatively removed by sorption on the activated carbon Norit CN-1 (Acros). Traces of ruthenium were determined by the ICP-OES method. Less than 0.2 ppm of Ru was detected in the acetals. The removal of ruthenium complexes is of great consequence at higher temperatures (e.g., at distillation), because if they are not removed, they can catalyze the transacetalization reaction.

Experimental

Qualitative and quantitative analyses were performed by the following methods: nuclear magnetic resonance (1H, 13C NMR), gas chromatography, mass spectrometry, electrospray (ESI) mass spectrometry, and ICP-OES. NMR spectra were recorded at room temperature on Bruker Avance 400 and Varian Unity 300 apparatus. Chemical shifts of 1H and 13C NMR spectra were related to tetramethylsilane. GC and GC–MS analyses were performed on Thermo Finnigan apparatus equipped with a 30-m MDN 5S column and a mass detector (EI, 40/70 eV). Melting point measurements were conducted on a Stuart automatic melting point SMP40 apparatus. The sequential spectrometer with an excitation in the ICP plasma (Spectro Analytical Instruments, Germany) was used with the following parameters: frequency 27.12 MHz, power 1.1 kW, nebulizer concentric Meinhard, sample rate 1.0 cm3 min−1, analytical lines (integration time) Ru 240.272 nm (3 s). The standard calibration procedure using five standards (1 mg cm−3 solutions purchased from Merck, Germany) was adopted and all the measurements were done in triplicate. The relative standard deviation of the technique was 3–5%. Accurate mass measurements were performed using a Mariner ESI-TOF (Applied Biosystems) mass spectrometer at the resolving power 5,000. Samples were injected using a syringe pump as methanolic solutions also containing polyethylene glycol 200 or 400 as an internal standard. For all samples [M + Na]+ ions were measured. The accuracy of the mass measurements was better than 5 ppm.

Reagents and catalysts

Allyl t-butyl ether was synthesized according to [21]. Synthesis of 1,4-dibutoxy-(Z)-2-butene was described in our previous work [22]. Allyl ethers: allyl n-decyl, allyl n-octadecyl, and allyl geranyl ether were obtained in typical PTC method [23].

RuCl2(PPh3)3 [24] and [RuCl2(1,5-COD)]x [25] were synthesized according to the procedures described in the literature. 2-(1-Propenyloxy)-ethanol was prepared via isomerization of 2-allyloxyethanol with RuClH(CO)(PPh3)3, as we described in our previous paper [15]. All other chemicals are commercially available reagents (Acros, Aldrich, Merck).

Catalytic test reactions

All reagents (molar ratios of the reaction mixture components and the temperature are shown in the Tables and Schemes) were placed in a glass screw-capped ampoule, purged with argon (by bubbling through the solution for 10 min), then tightly capped and heated in an oil bath at given temperature (±0.5 °C) for a given period of time. Then, the ampoule was cooled to room temperature and the obtained residue was used in NMR (0.15 cm3 in 0.6 cm3 CDCl3) and GC and MS analyses. Before the GC, GC–MS, and MS analyses, ruthenium was removed from the samples using activated carbon (Norit CN-1, Acros; 1 g/10 mg Ru).

Reaction on preparative scale

Allyl ether, alcohol, and catalyst were placed in a thick round-bottomed flask. The mixture was purged with argon (by bubbling through the solution for 15 min), then tightly capped, heated, and vigorously stirred (Spinplus stir bar) in an oil bath at a given temperature (±0.5 °C) for a given period of time. After that, the flask was cooled to room temperature, and the obtained residue was diluted in hexane or petroleum ether and the mixture was cooled to −30 °C. After 24 h, the solid residue was quickly filtered off, and activated carbon (Norit CN-1, Acros; 1 g/10 mg Ru) was added. The mixture was stirred for 24 h, the sorbent was filtered off, and volatile fractions were evaporated. The content of Ru was <0.2 ppm. The crude acetals 1, 2, 4, 5, 7–9, and 11 were purified by vacuum distillation. In some cases (3, 6, 10, 12, 13), distillation was ineffective (decomposition of the acetal was observed).

1-(1-Butoxypropoxy)pentane (1, C12H26O2)

B.p.: 114–115 °C (20 mbar); 1H NMR (400 MHz, CDCl3): δ = 0.90 (t, J = 7.2 Hz, 3H), 0.91 (t, J = 7.5 Hz, 3H), 0.93 (t, J = 7.3 Hz, 3H), 1.28–1.45 (m, 6H), 1.51–1.67 (m, 6H), 3.38–3.44 (m, 2H), 3.54–3.61 (m, 2H), 4.39 (t, J = 5.8 Hz, 1H) ppm; 13C NMR (100 MHz, CDCl3): δ = 9.1, 13.9, 14.0, 19.5, 22.6, 26.6, 28.6, 29.7, 32.1, 65.3, 65.5, 104.4 ppm; GC–MS (70 eV): m/z (%) = 202 (<1), 173 (20), 129 (52), 115 (86), 103 (30), 71 (80), 59 (100), 57 (90), 43 (82); HRMS (ESI+): calcd for C12H26O2Na [M + Na]+ 225.1830, found 225.1825.

1-(1-Butoxypropoxy)decane (2, C17H36O2)

B.p.: 123 °C (0.45 mbar); 1H NMR (400 MHz, CDCl3): δ = 0.88 (t, J = 7.0 Hz, 3H), 0.91 (t, J = 7.5 Hz, 3H), 0.93 (t, J = 7.3 Hz, 3H), 1.21–1.44 (m, 16H), 1.50–1.67 (m, 6H), 3.36–3.46 (m, 2H), 3.53–3.60 (m, 2H), 4.39 (t, J = 5.7 Hz, 1H) ppm; 13C NMR (100 MHz, CDCl3): δ = 9.1, 13.9, 14.1, 19.5, 22.7, 26.4, 26.6, 29.6, 29.7, 29.7, 30.0, 32.0, 32.1, 65.3, 65.6, 104.3 ppm; GC–MS (70 eV): m/z (%) = 272 (<1), 243 (8), 199 (14), 141 (10), 115 (84), 102 (42), 85 (52), 71 (48), 59 (80), 57 (100), 43 (52), 41 (52); HRMS (ESI+): calcd for C17H36O2Na [M + Na]+ 295.2608, found 295.2614.

1-(1-Butoxypropoxy)octadecane (3, C25H52O2)

M.p.: 34.7 °C; 1H NMR (400 MHz, CDCl3): δ = 0.90 (t, J = 7.0 Hz, 3H), 0.91 (t, J = 7.5 Hz, 3H), 0.94 (t, J = 7.3 Hz, 3H), 1.24–1.46 (m, 32H), 1.53–1.70 (m, 6H), 3.39–3.47 (m, 2H), 3.52–3.65 (m, 2H), 4.41 (t, J = 5.7 Hz, 1H) ppm; 13C NMR (100 MHz, CDCl3): δ = 8.9, 13.8, 14.0, 19.4, 22.7, 25.8, 26.3, 29.4, 29.5, 29.6 (2C), 29.7 (7C), 29.9, 31.9, 32.0, 32.8, 65.11, 65.42, 104.23 ppm.

(E/Z)-1-[1-[2-(1-Prop-1-enyloxy)ethoxy]propoxy]butane (4, C12H24O3)

Mixture of isomers; b.p.: 91 °C (1.2 mbar); GC–MS (70 eV): m/z (%) = 187 (3), 115 (30), 77 (63), 59 (100), 57 (52), 46 (31), 41 (35), 29 (20); 187 (2), 115 (37), 77 (85), 59 (100), 57 (56), 46 (33), 41 (54), 29 (35).

(E)-isomer 1H NMR (400 MHz, CDCl3): δ = 0.89–0.93 (m, 3H), 0.94 (t, J = 7.5 Hz), 1.35–1.45 (m, 4H), 1.55 (dd, J = 6.7 Hz, J = 1,6 Hz, 3H), 1.64–1.71 (m, 2H), 3.62 (t, J = 6.5 Hz, 2H), 3.83–3.87 (m, 2H), 3.95–3.98 (m, 2H), 4.47 (t, J = 4.8 Hz), 4.75 (dq, J = 12.6 Hz, J = 6.7 Hz, 1H), 6.22 (dq, J = 12.6 Hz, J = 1.6 Hz, 1H) ppm; 13C NMR (100 MHz, CDCl3): δ = 9.2, 12.5, 13.9, 19.2, 26.3, 31.5, 65.5, 68.5, 71.3, 98.2, 104.4, 146.7 ppm;

(Z)-isomer 1H NMR (400 MHz, CDCl3): δ = 0.89–0.93 (m, 3H), 0.97 (t, J = 7.5 Hz), 1.35–1.45 (m, 4H), 1.58 (dd, J = 6.7 Hz, J = 1.7 Hz, 3H), 1.64–1,71 (m, 2H), 3.72 (t, J = 6.6 Hz, 2H), 3.83–3.87 (m, 2H), 3.95–3.98 (m, 2H), 4.36 (dq, J = 6.2 Hz, J = 6.7 Hz, 1H), 4.82 (t, J = 4.6 Hz), 5.94 (dq, J = 6.2 Hz, J = 1.7 Hz, 1H) ppm; 13C NMR (100 MHz, CDCl3): δ = 8.0, 12.6, 13.9, 19.1, 27.0, 31.9, 64.9, 68.9, 71.8, 100.7, 105.5, 145.7 ppm;

(E)-10-(1-Butoxypropoxy)dec-2-ene (5, C17H34O2)

B.p.: 118 °C (0.39 mbar); 1H NMR (400 MHz, CDCl3): δ = 0.86–0.97 (m, 9H), 1.23–1.44 (m, 10H), 1.51–1.66 (m, 6H), 1.92–2.04 (m, 2H), 3.37–3.43 (m, 2H), 3.53–3.63 (m, 2H), 4.39 (t, J = 5.7 Hz, 1H), 5.36–5.44 (m, 2H) ppm; 13C NMR (100 MHz, CDCl3): δ = 9.0, 13.9, 17.8, 19.4, 25.6, 26.3, 26.5, 27.0, 31.6, 31.9, 32.0, 32.6, 65.2, 65.5, 104.3, 124.5, 131.6 ppm.

(Z)-1-(1-Butoxypropoxy)octadec-9-ene (6, C25H50O2)

Colorless oil; 1H NMR (400 MHz, CDCl3): δ = 0.88 (t, J = 7.1 Hz, 3H), 0.91 (t, J = 7.7 Hz, 3H), 0.92 (t, J = 7.3 Hz, 3H), 1.26–1.40 (m, 26H), 1.52–1.66 (m, 4H), 1.94–2.05 (m, 4H), 3.37–3.44 (m, 2H), 3.52–3.64 (m, 2H), 4.39 (t, J = 5.7 Hz, 1H), 5.33–5.43 (m, 2H) ppm; 13C NMR (100 MHz, CDCl3): δ = 9.1, 13.9, 14.0, 19.4, 22.7, 25.8, 26.5, 27.17, 29.1, 29.2, 29.43, 29.43, 29.45, 29.6, 29.6, 29.6, 31.8, 32.0, 32.6, 65.2, 65.5, 104.2, 128.1, 128.9 ppm; HRMS (ESI+): calcd for C25H50O2Na [M + Na]+ 405.3708, found 405.3703.

[(1-Butoxypropoxy)methyl]benzene (7, C14H22O2)

B.p.: 98 °C (7 mbar); 1H NMR (300 MHz, CDCl3): δ = 0.93 (t, J = 7.3 Hz, 3H), 0.94 (t, J = 7.4 Hz, 3H), 1.34–1.47 (m, 2H), 1.52–1.63 (m, 2H), 1.66–1.75 (m, 2H), 3.46 (dt, J = 9.4, 6.5 Hz, 1H), 3.60 (dt, J = 9.4, 6.5 Hz, 1H), 4.52 (d, J = 11.8 Hz, 1H), 4.53 (t, J = 5.8 Hz, 1H), 4.64 (d, J = 11.8 Hz, 1H), 7.38–7.22 (m, 5H) ppm; 13C NMR (75 MHz, CDCl3): δ = 9.1, 13.9, 19.5, 26.4, 32.0, 65.2, 67.1, 103.8, 127.5, 127.7, 128.4, 138.6 ppm; GC–MS (70 eV): m/z (%) = 221 (5), 193 (24), 148 (18), 108 (20), 92 (20), 91 (100), 79 (20), 57 (23).

1-[1-(2,2,2-Trifluoroethoxy)propoxy]butane (8, C9H17F3O2)

B.p.: 66 °C (27 mbar); 1H NMR (400 MHz, CDCl3): δ = 0.91–0.95 (m, 6H), 1.34–1.44 (m, 2H), 1.52–1.59 (m, 2H), 1.61–1.68 (m, 2H), 3.44 (dt, J = 6.6, 9.4 Hz, 1H), 3.60–3.64 (m, 1H), 3.84 (q, J = 8.8 Hz, 1H), 3.85 (q, J = 8.8 Hz, 1H), 4.56 (t, J = 5.9 Hz, 1H) ppm; 13C NMR (100 MHz, CDCl3): δ = 8.7, 13.8, 19.3, 26.0, 31.7, 61.4, 65.9, 104.4, 124.2 (q, J = 277.8 Hz) ppm.

1-(1-tert-Butoxypropoxy)butane (9, C11H24O2)

B.p.: 65 °C (1.73 mbar); 1H NMR (300 MHz, CDCl3): δ = 0.91 (t, J = 7.5 Hz, 3H), 0.93 (t, J = 7.3 Hz, 3H), 1.24 (s, 9H), 1.33–1.45 (m, 2H), 1.51–1.67 (m, 4H), 3.42 (dt, J = 9.4, 6.6 Hz, 1H), 3.58 (dt, J = 9.4, 6.6 Hz, 1H), 4.39 (t, J = 5.8 Hz, 1H) ppm; 13C NMR (75 MHz, CDCl3): δ = 9.1, 13.9, 19.5, 26.5, 28.7, 32.1, 65.2, 74.8, 104.3 ppm.

1-(1-Butoxypropoxy)-3,7-dimethylocta-2,6-diene (10, C17H32O2)

Colorless oil; 1H NMR (400 MHz, CDCl3): δ = 0.81–0.83 (dd, J = 4.0 Hz, J = 2.5 Hz, 3H), 0.91 (t, J = 7.3 Hz, 3H), 1.25–1.29 (m, 2H), 1.36–1.40 (m, 2H), 1.51–1.56 (m, 2H), 1.58 (s, 3H), 1.66 (s, 6H), 1.99–2.12 (m, 4H), 3.55 (t, J = 6.6 Hz), 4.11 (d, J = 7.9 Hz), 4.43 (t, J = 5.7 Hz), 5.08 (t, J = 6.6 Hz), 5.34 (t, J = 7.9 Hz) ppm; 13C NMR (100 MHz, CDCl3): δ = 9.2, 11.5, 14.0, 14.4, 20.6, 22.7, 27.8, 29.2, 41.5, 62.0, 65.3, 103.7, 121.1, 124.2, 131.6, 139.8 ppm; HRMS (ESI+): calcd for C17H32O2Na [M + Na]+ 291.2295, found 291.2309.

1-[1-(1-Butoxypropoxy)propoxy]butane (11, C14H30O3)

B.p.: 74 °C (7 mbar); 1H NMR (400 MHz, CDCl3): δ = 0.91 (t, J = 7.4 Hz, 6H), 0.93 (t, J = 7.4 Hz, 6H), 1.34–1.44 (m, 4H), 1.51–1.66 (m, 8H), 3.42 (dt, J = 9.4, 6.6 Hz, 2H), 3.58 (dt, J = 9.4, 6.6 Hz, 2H), 4.39 (t, J = 5.8 Hz, 2H) ppm; 13C NMR (100 MHz, CDCl3): δ = 8.9, 13.7, 19.3, 26.4, 31.9, 65.0, 104.2 ppm.

1-(1,4-Dibutoxybutoxy)decane (12, C22H46O3)

Colorless oil; 1H NMR (400 MHz, CDCl3): δ = 0.86-0.95 (m, 9H), 1.27–1.41 (m, 18H), 1.51–1.68 (m, 10H), 3.37–3.44 (m, 6H), 3.54–3.61 (m, 2H), 4.48 (t, 1H, J = 5.4 Hz) ppm; 13C NMR (100 MHz, CDCl3): δ = 13.8, 13.8, 14.0, 19.4, 22.6, 25.0, 26.2, 29.3, 29.4, 29.5, 29.6, 29.8, 29.8, 30.2, 31.8, 31.8, 31.9, 65.2, 65.5, 70.4, 70.5, 102.9 ppm; HRMS (ESI+): calcd for C22H46O3Na [M + Na]+ 381.3339, found 381.3349.

(E)-10-(1,4-Dibutoxybutoxy)dec-2-ene (13, C22H44O3)

Colorless oil; 1H NMR (400 MHz, CDCl3): δ = 0.87–0.97 (m, 9H), 1.26–1.42 (m, 12H), 1.52–1.67 (m, 10H), 1.90–2.04 (m, 2H), 3.37–3.43 (m, 6H), 3.54–3.59 (m, 2H), 4.48 (t, J = 5.5 Hz, 1H), 5.37–5.42 (m, 2H) ppm; 13C NMR (100 MHz, CDCl3): δ = 13.9, 14.0, 17.9, 19.4, 19.5, 25.1, 26.3, 29.2, 29.4, 29.6, 30.0, 30.3, 31.9, 32.1, 32.6, 65.3, 65.6, 70.6, 70.7, 103.1, 124.6, 131.6 ppm.

References

Wuts PGM, Greene TW (2006) Greene’s protective groups in organic synthesis, 4th edn. Wiley, Weinheim

Ley SV, Polara A (2007) J Org Chem 72:5943

Bigora Lliossas J, Sato S, Bueno RC, Graupera E (2009) European patent EP 2050784

Dubois J, Iborra Chornet S, Corma Canos A, Velty AL (2009) European patent EP 2094820

Burdock GA, Fenaroli G (2004) Fenaroli’s Handbook of Flavor Ingredients, CRC Press, Boca Raton

Surburg H, Panten J (2006) Common fragrance and flavor materials: preparation, properties and uses. Wiley, Weinheim

Sivik MR (2002) United States Patent US 6395695 B1

Fischer J, Ganellin CR (2006) Analogue-based drug discovery. Wiley, Weinheim

Fujioka H, Okitsu T, Sawama Y, Murata N, Li R, Kita Y (2006) J Am Chem Soc 128:5930

Fujioka H, Okitsu T, Ohnaka T, Li R, Kubo O, Okamoto K, Sawama Y, Kita Y (2007) J Org Chem 72:7898

Chang B-H, Hanes RM (1988) United States Patent US 4743401

Chang B-H (1995) J Organomet Chem 492:31

Krompiec S, Penczek R, Kuźnik N, Małecki J, Matlengiewicz M (2007) Tetrahedron Lett 48:137

Krompiec S, Penczek R, Penkala M, Krompiec M, Rzepa J, Matlengiewicz M, Jaworska J, Baj S (2008) J Mol Catal A: Chem 290:15

Urbala M, Kuźnik N, Krompiec S, Rzepa J (2004) Synlett 7:1203

Kuźnik N, Krompiec S (2007) Coord Chem Rev 251:222

Krompiec S, Krompiec M, Penczek R, Ignasiak H (2008) Coord Chem Rev 252:1819

Krompiec S (1997) Izomeryzacja alkenów i ich funkcyjnie podstawionych pochodnych katalizowana kompleksami rutenu, Zesz Nauk Pol Śl, Gliwice

Pruchnik F (1993) Kataliza homogeniczna. PWN, Warszawa

Krompiec S, Kuźnik N, Krompiec M, Penczek R, Mrzigod J, Tórz A (2006) J Mol Catal A: Chem 253:132

Kwart H, Sarner SF, Slutsky J (1973) J Am Chem Soc 95:5234

Krompiec S, Antoszczyszyn M, Urbala M, Bieg T (2000) Pol J Chem 74:737

Krompiec S, Kuźnik N, Penczek R, Rzepa J, Mrowiec-Białoń J (2004) J Mol Catal A: Chem 219:29

Stephenson TA, Wilkinson G (1966) J Inorg Nucl Chem 28:945

Abel EW, Bennett MA, Wilkinson G (1959) J Chem Soc A 3178

Acknowledgments

This work was supported by The State Committee for Scientific Research, Project No. N N204 272237. Mateusz Penkala is a participant in UPGOW project, co-financed by the European Union within the European Social Fund.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Krompiec, S., Penkala, M., Kowalska, E. et al. Synthesis of unsymmetrical alkyl acetals via addition of primary alcohols to allyl ethers mediated by ruthenium complexes. Monatsh Chem 142, 1241–1247 (2011). https://doi.org/10.1007/s00706-011-0638-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-011-0638-8