Abstract

New alternating fluorene–thiophene copolymers are introduced bearing polar ethylene glycol-carboxylate functionalities on the thiophene ring to achieve enhanced solubility in polar solvents. Suzuki polycondensation was applied to synthesize a set of three polymers with differing lengths of the ethylene glycol side-chains. The polymers are thermally stable up to temperatures of 300 °C. Solutions of the polymers in CHCl3 show an absorption maximum at approximately 397 nm and a luminescence maximum of 472 nm in solutions with quantum yield of 30%. The highest occupied molecular orbital (HOMO) and lowest unoccupied molecular orbital (LUMO) levels have been determined to be at −5.7 and −2.6 eV, respectively.

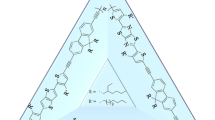

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

During the last two decades, conjugated polymers have been in the focus of polymer and materials scientists due to their interesting chemical and physical properties and their various applications in the area of organic electronics [1, 2], e.g., in organic light-emitting devices (OLEDs) [3, 4], organic thin-film transistors [5], sensor applications [6], and polymer photovoltaics [7, 8]. Among the broad variety of polymers synthesized to date, polyfluorenes are some of the most prominent polymers, and because of their blue emission and high fluorescence quantum yield combined with good thermal and chemical stability, they are especially interesting materials for OLEDs [9–13]. In addition, copolymers of fluorenes with other arylene monomers are easily accessible, and the band gap and other electrooptical properties can be tuned over a broad range by the choice of proper co-monomers [3, 14–17]. In this regard, fluorene–arylene copolymers are discussed in all aspects of applications for conjugated polymers [18–21].

Suzuki polycondensation (SPC) is one of the methods of choice for synthesis of polyfluorenes and copolymers, as it is a versatile and simple method to obtain polyarylenes and especially alternating copolymers [4]. A comprehensive overview on the occasion of the 20th anniversary of SPC was published by Sakamoto et al. [22] last year.

State-of-the-art organic electronic devices very often exhibit a multilayer structure with different organic layers stacked on each other, e.g., hole conducting layers, light-emitting layer, etc. Consequently, it is necessary to deposit different organic layers on top of each other. To keep an all solution-based process for device assembly, use of orthogonal solvents is advantageous, which in turn needs polymers with orthogonal solubilities. In contrast to the electrooptical properties of fluorene copolymers, which are primarily determined by the chemical structure of the backbone, the solubility of these polymers is mainly a result of the chosen side-chain, e.g., the introduction of long alkyl and branched side-chains for apolar solvents, or ionic side-groups for protic and polar solvents [23, 24].

In this contribution we focus on the synthesis of a set of new alternating 9,9-dioctylfluorene thiophene copolymers with carboxy(ethylene glycol) side-chains on the thiophene ring to obtain polymers possessing all the positive optoelectronic characteristics of such polymers and in addition enhanced solubility in polar solvents. Starting from 2,5-dibromothiophene-3-carboxylic acid, the monomers were prepared by esterification using ethyl-ethylene glycol, ethyl-bisethylene glycol, as well as ethyl-trisethylene glycol as alcohols. The polymers were characterized by nuclear magnetic resonance (NMR) spectroscopy, Fourier-transform infrared (FTIR) spectroscopy, thermal analysis, and gel permeation chromatography (GPC). In addition, their solubility was investigated using a set of solvents with different polarity indices. The optical and electrochemical properties were analyzed by optical absorption and emission spectroscopy, as well as by cyclic voltammetry.

Results and discussion

Synthesis and characterization

The general synthetic routes towards the monomers are outlined in Scheme 1. The new ethylene glycol 2,5-dibromothiophene-3-carboxylate monomers, 2-ethoxyethyl 2,5-dibromothiophene-3-carboxylate (1), 2-(2-ethoxyethoxy)ethyl 2,5-dibromothiophene-3-carboxylate (2), and 2-[2-(2-ethoxyethoxy)ethoxy]ethyl 2,5-dibromothiophene-3-carboxylate (3) were synthesized following a literature method [25]. After bromination of thiophene-3-carboxylic acid (4) with Br2, the intermediate 2,5-dibromothiophene-3-carboxylic acid (5) was reacted with oxalylchloride. Reaction of the acid chloride (6) with the corresponding ethylene glycol monoethylether and pyridine as base afforded 1 (38%), 2 (36%), and 3 (35%). The chemical structures were verified by 1H NMR and 13C NMR spectroscopy.

For the synthesis of the polymers poly-[9,9-dioctylfluorene-alt-(2-ethoxyethyl thiophene-3-carboxylate)] (7), poly-[9,9-dioctylfluorene-alt-[2-(2-ethoxyethoxy)ethyl thiophene-3-carboxylate]] (8), and poly-[9,9-dioctylfluorene-alt-[2-[2-(2-ethoxyethoxy)ethoxy]ethyl thiophene-3-carboxylate]] (9), a general Suzuki coupling polymerization was applied, as shown in Scheme 2 [26]. Polymer 7 was synthesized using 1 and 9,9-dioctylfluorene-2,7-bis-(trimethylborate) (10) and tetrakis(triphenylphospine)-palladium(0) [Pd(PPh3)4] as catalyst in a mixture of toluene and aqueous sodium carbonate solution (2 M) at 85 °C for 2 days. Polymers 8 and 9 were prepared by the same procedure, using 2 and 3, respectively. All three polymers were obtained in good yields of 73–90% as green powders.

The chemical structures were verified by 1H NMR and IR spectroscopy. The number-average molecular weights (M n) of polymers 7, 8, and 9 were determined by GPC using a polystyrene standard to be 8,600 g/mol (M w/M n = 1.7), 9,900 g/mol (M w/M n = 1.7), and 10,200 g/mol (M w/M n = 2.2), respectively. The GPC results are summarized in Table 1. In the case of 7, low-molecular-weight oligomers can be removed using Soxhlet extraction with acetone as solvent, resulting in a polymer with M n = 17,200 g/mol. In addition the molecular weight distribution is narrowed down to a value M w/M n of 1.2. This procedure cannot be applied for 8 and 9, as both polymers are fairly soluble in hot acetone.

The thermal stability of the polymers was evaluated under helium atmosphere by thermogravimetric analysis (TGA). The polymers possess good thermal stability as there was no weight loss detectable until 300 °C, as shown in Fig. 1. Polymer 7 showed 5% weight loss at 373 °C (8 at 357 °C and 9 at 387 °C), which is caused by a decomposition of the side-groups. The thermally induced phase-transition behavior of the polymers was investigated with differential scanning calorimetry (DSC) in nitrogen atmosphere, but only very weak signals could be detected. Additionally the signals weakened with increasing length of the polyglycol side-group. This is a sign for decreasing crystallinity with increasing length. All three polymers showed one endothermal peak at heating at around 100 °C (7 119 °C, 8 95 °C, 9 92 °C).

The glycol side-groups should lead to better solubility in polar solvents. Therefore, we investigated the solubility of polymers 7, 8, and 9 in solvents of different polarities. For these experiments, 2 mg polymer was mixed with 1 cm3 solvent, and, if the polymer was not dissolved at ambient temperature, heated to the boiling point of the solvent. The results are summarized in Table 2. The solvents are listed according to the polarity index of Snyder [27] with two exceptions; for chlorobenzene and dichlorobenzene, the values were taken from Burdick and Jackson [28]. All three polymers were well soluble in apolar solvents such as toluene (polarity index 2.3), as well as in “standard” solvents such as methylene chloride (3.4), chloroform (3.4–4.4), tetrahydrofuran (THF) (4.2), and cyclohexanone (4.5). As expected, the polymers with longer polyglycol side-group (8 and 9) showed better solubility in polar as well as protic solvents. Both polymers 8 and 9 were soluble in hot acetone, and partly soluble in hot ethanol and isopropyl alcohol. Remarkably, all three polymers were soluble in hot dimethylformamide (DMF) (6.4).

Optical properties

UV–Vis absorption and photoluminescence (PL) emission spectra of the polymers were measured both in solution (CHCl3) and as thin film. All three polymers gave practically identical spectra, as shown in Fig. 2. In solution they showed an absorption maximum at 397 nm. This maximum is slightly red-shifted in comparison with a pure poly-(fluorene), e.g., poly-2,7-(9,9-dioctylfluorene) in chloroform (λ max = 385 nm) [29], because of the thiophene unit in the copolymer. The value varies between 386 nm for a poly-[(hexyl 2,5-thiophene-3-carboxylate)-2,7-(9,9-dihexylfluorene)] (A) and 412 nm for poly-[(2,5-thiophene)-2,7-(9,9-dihexylfluorene)] (B) [30].

The absorption of the polymers in thin films is red-shifted by 10 nm (λ max = 407 nm). This shift might be attributed to improved intermolecular π–π interactions or planarization of the backbone in the film [31]. The additional broad peak found in all spectra is caused by interference fringes of the thin film. By casting thinner or thicker films this peak shifts or even completely vanishes. The optical band gaps, E g, of 7–9 were estimated from the onset of absorption of the UV–Vis spectrum of the polymer solution. Values of E g = 2.7 eV for all polymers were obtained. These values are in good agreement with data published for polymers A and B by Pal et al. [30] and showed that the optical properties are almost unaffected by the side-chains.

Figure 3 shows the photoluminescence spectra of the chloroform solution. The PL emission spectra showed a maximum at 472 nm and a shoulder at around 500 nm. The fluorescence quantum yields (Φ) of the polymers in chloroform were estimated by comparison with a quinine sulfate standard (ca. 1 × 10−5 M solution in 0.5 M H2SO4, ΦSt = 0.55). The measurement was accomplished according to the literature [32]. All three polymers showed PL quantum yield of approximately 0.3.

All UV–Vis absorption and PL emission maxima of the polymers are listed in Table 3, together with their optical band gaps and PL quantum efficiencies.

Electrochemical properties

Cyclic voltammograms (CVs), shown in Fig. 4, on drop-cast polymer films were conducted in acetonitrile using a platinum disk as working electrode, a platinum wire as counterelectrode, and Ag/Ag+ as reference electrode. Tetrabutylammonium tetrafluoroborate was used as supporting electrolyte and the ferrocene/ferrocenium (Fc/Fc+) couple as a calibrant [33]. The onset potentials of oxidation (E onset,ox) and reduction (E onset,red) were determined from the intersection of the two tangents drawn at the rising current and baseline charging current of the CV traces.

The ionization potentials (I P) and electron affinities (E A), which correlate to the HOMO and LUMO level of the polymers, were calculated from the onset of oxidation (E onset,ox) and reduction (E onset,red) according to the empirical relationship proposed by de Leeuw et al. [34].

The electrochemical band gaps \( \left( {E_{g}^{\text{ec}} } \right) \) derive from the difference between the ionization potential (I P) and the electron affinity (E A) [35, 36].

The HOMO and LUMO levels for the different polymers are presented in Table 4. The electrochemical properties of 7, 8, and 9 are very similar, thus the variations in the side-chains do not cause a noticeable difference of the electronic behavior between the polymers. For all three polymers, the HOMO and LUMO levels are approximately the same at around −5.7 and −2.6 eV, respectively. The electrochemical band gap (approx. 3.1 eV) is significantly higher than the optical band gap; however, this phenomenon can be explained by an interface barrier between the polymer film and the electrode surface [36].

The HOMO levels are in good agreement with literature reports of a very similar polymer [30] bearing a hexyl carboxylate side-chain. However, the LUMO levels are significantly lower in our case, leading to a higher electrochemical band gap. This difference might be due to a different measurement setup, as we measured CVs of polymer films and not of a solution of the polymer in CH2Cl2.

Conclusions

In this contribution we have shown that introduction of glycol side-groups in the thiophene units of poly-fluorene-alt-thiophene copolymers leads to polymers which are readily soluble in a variety of solvents ranging from apolar toluene to polar DMF. Especially 8 and 9 with longer ethylene glycol side-chains are already soluble in polar and protic solvents such as hot acetone, isopropyl alcohol, and ethanol. In addition, the optical properties and thermal stability are not affected by these side-groups and are comparable to other polyfluorene–thiophene polymers.

Experimental

All chemicals were purchased from commercial sources and used without further purification. CH2Cl2 was distilled over CaH2, THF was distilled over Na and subsequently over K, and toluene was distilled over Na. All solvents were degassed with argon. All experiments were carried out under inert atmosphere in a glove box or using Schlenk techniques.

1H NMR and 13C NMR spectra were recorded on a 300 MHz Bruker Avance III spectrometer and were referenced to Si(CH3)4. Solvent residual peaks were used for referencing the NMR spectra to the corresponding values given in literature [37]. FTIR spectra were recorded with a PerkinElmer Spectrum One instrument (spectral range between 4,000 and 450 cm−1). All FTIR spectra of the samples were recorded in transmission mode (films on KBr discs). UV–Vis spectra were collected using a Shimadzu UV-1800 spectrometer. Fluorescence spectra were recorded on a Hitachi F-7000 fluorescence spectrometer equipped with a red-sensitive photomultiplier R 928 from Hamamatsu.

Molecular weights of the polymers were determined by GPC using the following arrangement: Merck Hitachi L6000 pump, a Polymer Standard Service precolumn, 2 PLgel separation columns (5 μm MIXED C, 7.5 × 300 mm), and a Waters 401 differential refractometer detector. Polystyrene standards purchased from Polymer Standard Service were used for calibration. Combined DSC/TGA measurements were performed with a simultaneous thermal analyzer STA 449 C Jupiter from Netsch Gerätebau GmbH (crucibles: aluminum) at heating rate of 10 °C/min in He flow (50 cm3/min). DSC measurements were carried out on a PerkinElmer Pyris Diamond under nitrogen flow of 20 cm3/min and heating rate of 10 °C/min. Glass-transition temperatures (T g) from the second heating run were read as the midpoint of change in heat capacity. Cyclic voltammograms on drop-cast polymer films were recorded using an Autolab PGSTAT128N potentiostat/galvanostat in a three-electrode cell with acetonitrile under argon gas protection with scan rate of 100 mV/s. All measurements were carried out at room temperature (25 ± 2 °C). A platinum disk was used as working electrode, a platinum wire as counterelectrode, and Ag/Ag+ as reference electrode. Tetrabutylammonium tetrafluoroborate (n-Bu4NBF4, 0.1 M) was used as supporting electrolyte and the ferrocene/ferrocenium (Fc/Fc+) couple as a calibrant according to IUPAC recommendation [38].

Synthesis

Caution: For the preparative work, hazardous chemicals and solvents were used. Reactions must be carried out in a fume hood, and protective clothes and goggles must be used.

2,5-Dibromothiophene-3-carboxylic acid (5)

The acid 5 was prepared as described [25], but yielded 5 in only 41% yield compared with 84% given there. Obtained analytical data were identical to published values.

General procedure for compounds 1, 2, and 3 (modified from Ref. [25])

Substance 5 (1.00 g, 3.50 mmol) was dissolved in 100 cm3 dry CH2Cl2, 0.6 cm3 oxalyl chloride (6.96 mmol) was added, and the resulting mixture was stirred overnight at room temperature. The solvent was removed and dried under vacuum to give 6. The acid chloride was dissolved in 50 cm3 dry THF, and 0.8 cm3 pyridine (10.49 mmol) followed by ethylene glycol monoethyl ether (5.25 mmol) were added. The resulting mixture was stirred overnight. The reaction mixture was concentrated under reduced pressure, and the residue was partitioned between CH2Cl2 and 10% aqueous HCl. The organic layer was dried over Na2SO4 and concentrated under reduced pressure to give a crude product, which was purified by column chromatography to afford the monomers as pale-yellow oils.

2-Ethoxyethyl 2,5-dibromothiophene-3-carboxylate (1, C9H10Br2O3S)

2-Ethoxyethanol (0.5 cm3, 5.25 mmol) was used as alcohol. Purification by column chromatography (cyclohexane/ethyl acetate = 10/1) yielded 1 (478 mg, 38%). 1H NMR (CDCl3): δ = 7.37 (s, 1H, H4), 4.41 (t, 2H, H1′), 3.73 (t, 2H, H2′), 3.56 (q, 2H, H1″), 1.22 (t, 3H, H2″) ppm; 13C NMR (CDCl3): δ = 160.9 (C=O), 131.9 (C4), 131.7 (C3), 119.6 (C2), 111.5 (C5), 68.3 (C2′), 66.8 (C1″), 64.5 (C1′), 15.3 (C2″) ppm.

2-(2-Ethoxyethoxy)ethyl 2,5-dibromothiophene-3-carboxylate (2, C11H14Br2O4S)

Diethylene glycol monoethyl ether (0.7 cm3, 5.25 mmol) was used as alcohol. Purification by column chromatography (cyclohexane/ethyl acetate = 5/1) and flash chromatography (cyclohexane/ethyl acetate = 1/1) yielded 2 (508 mg, 36%). 1H NMR (CDCl3): δ = 7.37 (s, 1H, H4), 4.43 (t, 2H, H1′), 3.81 (t, 2H, H2′), 3.68 (m, 2H, H1″), 3.60 (m, 2H, H2″), 3.52 (q, 2H, H1″′), 1.22 (t, 3H, H2″′) ppm; 13C NMR (CDCl3): δ = 160.8 (C=O), 131.9 (C4), 131.7 (C3), 119.6 (C2), 111.5 (C5), 70.9 (C1″), 70.0 (C2″), 69.1 (C2′), 66.9 (C1″′), 64.4 (C1′), 15.3 (C2″′) ppm.

2-[2-(2-Ethoxyethoxy)ethoxy]ethyl 2,5-dibromothiophene-3-carboxylate (3, C13H18Br2O5S)

Triethylene glycol monoethyl ether (0.9 cm3, 5.25 mmol) was used as alcohol. Purification by column chromatography (cyclohexane/ethyl acetate = 3/1) and flash chromatography (cyclohexane/ethyl acetate = 1/3) yielded 3 (539 mg, 35%). 1H NMR (CDCl3): δ = 7.36 (s, 1H, H4), 4.13 (t, 2H, H1′), 3.79 (t, 2H, H2′), 3.67–3.57 (m, 8H, H1″, H2″, H1″′, H2″′), 3.51 (q, 2H, H1″″), 1.20 (t, 3H, H2″″) ppm; 13C NMR (CDCl3): δ = 160.8 (C=O), 131.9 (C4), 131.7 (C3), 119.6 (C2), 111.5 (C5), 70.9–70.8 (C1″, C2″, C1″′), 70.0–69.1 (C2′, C2″′), 66.9 (C1″″), 64.4 (C1′), 15.3 (C2″″) ppm.

General procedure: Suzuki coupling polymerization

The phase transfer catalyst Aliquat 336 (0.1 eq) was dissolved in a mixture of 1.7 cm3 2 M aqueous sodium carbonate (3.46 mmol) and 8 cm3 anhydrous toluene. The solution was degassed for 30 min. Substance 10 (1.0 eq) and 2,5-dibromothiophene 1–3 (1.0 eq) were added. Tetrakis(triphenylphosphine)palladium (0.01 eq) was added to the mixture in argon atmosphere. The reaction mixture was stirred and heated to 85 °C for 48 h. An excess of 10 (0.01 eq) and bromobenzene (0.1 eq) were added for end-capping. After further stirring and heating for 12 h, the reaction mixture was cooled to room temperature and added slowly to a vigorously stirred mixture consisting of 100 cm3 methanol and 5.6 cm3 1 N aqueous HCl. The polymer was collected by filtration and purified by reprecipitation from methanol.

Poly-[9,9-dioctylfluorene-alt-(2-ethoxyethyl thiophene-3-carboxylate)] (7, (C38H50O3S) n )

Polymer 7 was synthesized using the general Suzuki coupling procedure starting from 150.0 mg 1 (0.42 mmol) as thiophene monomer. A part of the polymer was further purified by Soxhlet extraction in acetone for 2 days to yield a green solid. Yield (before Soxhlet extraction) 181 mg (73%); 1H NMR (CDCl3): δ = 7.84–7.55 (m, 7H, aromatic), 4.38 (s, 2H, H1′), 3.63 (s, 2H, H2′), 3.50 (q, 2H, H1″), 2.05 (s, 4H, Hoct1), 1.24–1.12 (m, 23H, H2″, Hoct2–6), 0.81 (s, 10H, Hoct7, Hoct8) ppm; IR (KBr): \( \bar{v} \) = 2,954 (s), 2,926 (s), 2,854 (s), 1,724 (s), 1,608 (w), 1,538 (w), 1,463 (m), 1,419 (w), 1,377 (w), 1,261 (m), 1,203 (m), 1,124 (m), 882 (w), 819 (m), 801 (m), 522 (w) cm−1.

Poly-[9,9-dioctylfluorene-alt-[2-(2-ethoxyethoxy)ethyl thiophene-3-carboxylate]] (8, (C40H54O4S) n )

Polymer 8 was synthesized using the general Suzuki coupling procedure starting from 219.4 mg 2 (0.55 mmol) as thiophene to yield a light-green solid. Yield 265 mg (76%); 1H NMR (CDCl3): δ = 7.84–7.55 (m, 7H, aromatic), 4.39 (s, 2H, H1′), 3.71 (s, 2H, H2′), 3.59 (m, 4H, H1″, H2″), 3.52 (q, 2H, H1″′), 2.05 (s, 4H, Hoct1), 1.24–1.12 (m, 23H, H2″′, Hoct2–6), 0.81 (s, 10H, Hoct7, Hoct8) ppm; IR (KBr): \( \bar{v} \) = 2,954 (s), 2,926 (s), 2,854 (s), 1,724 (s), 1,608 (w), 1,538 (w), 1,463 (m), 1,419 (w), 1,376 (w), 1,350 (w), 1,263 (m), 1,204 (m), 1,124 (m), 1,018 (w), 820 (m), 752 (m) cm−1.

Poly-[9,9-dioctylfluorene-alt-[2-[2-(2-ethoxyethoxy)ethoxy]ethyl thiophene-3-carboxylate]] (9, (C42H58O5S) n )

Polymer 9 was synthesized using the general Suzuki coupling procedure starting from 237.7 mg 3 (0.53 mmol) as thiophene to yield a light-green solid. Yield 332 mg (91%); 1H NMR (CDCl3): δ = 7.84–7.54 (m, 7H, aromatic), 4.38 (s, 2H, H1′), 3.70–3.58 (m, 10H, H2′, H1″, H2″, H1″′, H2″′), 3.51 (q, 2H, H1″″), 2.05 (s, 4H, Hoct1), 1.26–1.12 (m, 23H, H2″″, Hoct2–6), 0.81 (s, 10H, Hoct7, Hoct8) ppm; IR (KBr): \( \bar{v} \) = 2,954 (s), 2,925 (s), 2,853 (s), 1,723 (s), 1,609 (w), 1,538 (w), 1,463 (m), 1,376 (w), 1,350 (w), 1,264 (m), 1,204 (m), 1,125 (m), 1,038 (w), 940 (w), 820 (m), 777 (w), 756 (w) cm−1.

References

Roncali J (2007) Macromol Rapid Commun 28:1761

Dodabalapur A (2006) Mater Today 9:24

Grimsdale AC, Chan KL, Martin RE, Jokisz PG, Holmes AB (2009) Chem Rev 109:897

Akcelrud L (2003) Prog Polym Sci 28:875

Allard S, Forster M, Souharce B, Thiem H, Scherf U (2008) Angew Chem Int Ed 47:4070

Thomas SW, Joly GD, Swager TM (2007) Chem Rev 107:1339

Dennler G, Scharber MC, Brabec CJ (2009) Adv Mater 21:1323

Cheng Y-J, Yang S-H, Hsu C-S (2009) Chem Rev 109:5868

Scherf U, List EJW (2002) Adv Mater 14:477

Zhao Q, Liu S-J, Huang W (2009) Macromol Chem Phys 210:1580

Neher D (2001) Macromol Rapid Commun 22:1365

Scherf U, Neher D (2008) In: Advances in polymer science, Vol 212, Springer, Berlin

Tsoi WC, Charas A, Cadby AJ, Khalil G, Adawi AM, Iraqi A, Hunt B, Morgado J, Lidzey DG (2008) Adv Funct Mater 18:600

Inganäs O, Zhang F, Andersson MR (2009) Acc Chem Res 42:1731

Leclerc M (2001) J Polym Sci A Polym Chem 39:2867

Kappaun S, Horner S, Kelterer A-M, Waich K, Grasse F, Graf M, Romaner L, Niedermair F, Müllen K, Grimsdale AC, Saf R, List EJW, Zojer E, Slugovc C (2008) Macromol Chem Phys 209:2122

Winfield JM, Van Vooren A, Park M-J, Hwang D-H, Cornil J, Kim J-S, Friend RH (2009) J Chem Phys 131:035104

Abbel R, Schenning APHJ, Meijer EW (2009) J Polym Sci A Polym Chem 47:4215

Inganäs O, Svensson M, Zhang F, Gadisa A, Persson NK, Wang X, Andersson MR (2004) Appl Phys A 79:31

Levermore PA, Jin R, Wang X, de Mello JC, Bradley DDC (2009) Adv Funct Mater 19:950

McNeill CR, Greenham NC (2009) Adv Mater 21:3840

Sakamoto J, Rehahn M, Wegner G, Schlüter AD (2009) Macromol Rapid Commun 30:653

Burrows HD, Tapia MJ, Fonseca SM, Valente AJM, Lobo VMM, Justino LLG, Qiu S, Pradhan S, Scherf U, Chattopadhyay N, Knaapila M, Garamus VM (2009) ACS Appl Mater Interf 1:864

Knaapila M, Almásy L, Garamus VM, Pearson C, Pradhan S, Petty MC, Scherf U, Burrows H-D, Monkman AP (2006) J Phys Chem B 110:10248

Kim D-S, Ahn KH (2008) J Org Chem 73:6831

Lim E, Jung B-J, Shim H-K (2003) Macromolecules 36:4288

Snyder LR (1978) J Chromatogr Sci 16:223

Louisiana State University Macromolecular Studies Group, polarity index. http://macro.lsu.edu/howto/solvents/Polarity%20index.htm. Accessed December 2009

Wang R, Wang W-Z, Yang G-Z, Liu T, Yu J, Jiang Y (2008) J Polym Sci A Polym Chem 46:790

Pal B, Yen W-C, Yang J-S, Su W-F (2007) Macromolecules 40:8189

Surin M, Sonar P, Grimsdale AC, Müllen K, Lazzaroni R, Leclère P (2005) Adv Funct Mater 15:1426

Horiba JY, A guide to recording fluorescence quantum yields. http://www.horiba.com/fileadmin/uploads/Scientific/Documents/Fluorescence/quantumyieldstrad.pdf. Accessed October 2009

Pommerehne J, Vestweber H, Guss W, Mahrt RF, Bässler H, Porsch M, Daub J (1995) Adv Mater 7:551

De Leeuw DM, Simenon MMJ, Brown AR, Einerhand REF (1997) Synth Met 87:53

Pei J, Yu W-L, Huang W, Heeger AJ (2000) Macromolecules 33:2462

Chen Z-K, Huang W, Wang L-H, Kang E-T, Chen BJ, Lee CS, Lee ST (2000) Macromolecules 33:9015

Gottlieb HE, Kotlyar V, Nudelman A (1997) J Org Chem 62:7512

Gritzner G (1990) Pure Appl Chem 62:1839

Acknowledgments

The authors thank the Austrian Science Fund (FWF): N903-NAN within the Austrian NanoInitiative (Research Project Cluster 900), the Christian Doppler Research Association (CDG), and the Federal Ministry for Economy, Family and Youth (BMWFJ) for financial support.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Ziegler, E., Pein, A., Fischereder, A. et al. Synthesis and characterization of alternating fluorene–thiophene copolymers bearing ethylene glycol side-chains. Monatsh Chem 142, 193–200 (2011). https://doi.org/10.1007/s00706-010-0440-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00706-010-0440-z