Abstract

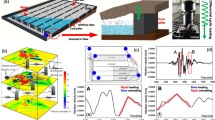

Acoustic emission (AE) and particle flow code (PFC3D) are utilized to characterize microcracking nature in mode-I fracture of coal with strong bursting liability. The microcracks are represented by AE moment tensor (MT), which corresponds to displacement discontinuities involving opening/closing and sliding motions. The microcracking source parameters, including shear/tensile type, volume, orientation, motion, and magnitude, are calculated by minimizing the errors between the analytical and measured displacements, with an imposed constraint. Then, the detailed fracture processes, including microcracking source mechanisms and energy dissipation during coal tensile failure, are analyzed using both experimental and numerical approaches. The results show that the time-varying of crack mode angle and decomposed crack volume suggest a mixed-mode mechanisms locally with both normal and tangential displacements for microcracks. However, the orientations of microcracks with bigger magnitude are almost parallel to the direction of the crack propagation path, and their movement directions are mainly along the direction of the maximum principal stress, which is compatible with the expected fracture mechanism of mode-I opening globally. The dissipated energy and crack opening displacement obtained from AE inversion are approximately consistent with results calculated from energy release rate G and opening displacement measured using DIC, respectively. A new AE MT simulation method, based on particle motion, is developed using PFC3D to verify the reliability of the above-mentioned microcracking characterization results. The mechanical properties as well as AE responses (including AE rate, magnitude distribution, spatial location, and MT) from PFC3D numerical simulation are in good agreement with the experimental results, which reinforces the reliability the microcracking characterization results from AE inversion and simulation. Due to the tortuous crack propagation path and the inhomogeneity between grains, the maximum principal stress and resultant displacement coexists both on the normal and tangential of the inclined crack surface. Under the combined action of tensile and shear stress, the normal and tangential motion displacement components along the crack plane are generated, respectively, resulting in mixed-mode microcrack. This research provides a new approach for characterizing the microcracks in loaded rock/coal, which can deepen the understanding of meso-process and mechanism during rock/coal fracture.

Highlights

-

Microcracks are represented by acoustic emission moment tensor subjected to displacement discontinuity.

-

A new method for acoustic emission simulation is developed using particle flow code to verify test results.

-

Time–space–energy evolution process and focal-mechanism of microcracks are analyzed.

-

Meso-mechanism of mixed-mode microcracks during coal tensile failure is explained.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Aki K, Richards PG (2002) Quantitative seismology. University Science Books, Sausalito

Asem P, Wang XR, Chen H, Labuz JF (2021) On tensile fracture of a brittle rock. Int J Rock Mech Min Sci 144:104823

Carpinteri A, Xu J, Lacidogna G, Manuello A (2012) Reliable onset time determination and source location of acoustic emissions in concrete structures. Cement Concr Compos 34(4):529–537

Carvalho FCS, Labuz JF (2002) Moment tensor of acoustic emissions in shear faulting under plane-strain compression. Tectonophysics 356(1–3):199–211

Chang SH, Lee CI (2004) Estimation of cracking and damage mechanisms in rock under triaxial compression by moment tensor analysis of acoustic emission. Int J Rock Mech Min Sci 41(7):1069–1086

Chen L, Wang J, Zong HZ, Liu J, Su R, Guo YH, Jin YX, Chen WM, Ji RL, Zhao HG, Wang XY, Tian X, Luo H, Zhang M (2015) A new rock mass classification system Q(HLW) for high-level radioactive waste disposal. Eng Geol 190:33–51

Ding Z, Feng XJ, Wang EY, Wei QL, Zhao X, Hu QJ (2023) Acoustic emission response and evolution of pre-cracked coal in the meta-instability stage under graded loading. Eng Geol 312:106930

Elsworth D, Spiers CJ, Niemeijer AR (2016) Understanding induced seismicity. Science 354(6318):1380–1381

Forbes B, Vlachopoulos N, Diederichs MS, Hyett AJ, Punkkinen A (2020) An in situ monitoring campaign of a hard rock pillar at great depth within a Canadian mine. J Rock Mech Geotech Eng 12(3):427–448

Ge MC (2003) Analysis of source location algorithms: part II. Iterative methods. J Acoust Emiss 21:29–51

Graham CC, Stanchits S, Main IG, Dresen G (2010) Comparison of polarity and moment tensor inversion methods for source analysis of acoustic emission data. Int J Rock Mech Min Sci 47(1):161–169

Grigoli F, Cesca S, Rinaldi AP, Manconi A, Lopez-Comino JA, Clinton JF, Westaway R, Cauzzi C, Dahm T, Wiemer S (2018) The November 2017 Mw 5.5 Pohang earthquake: a possible case of induced seismicity in South Korea. Science 360(6392):1003–1036

Hanks TC, Kanamori H (1979) A moment magnitude scale. J Geophys Res Solid Earth 84:2348–2350

Hazzard JF, Young RP (2002) Moment tensors and micromechanical models. Tectonophysics 356(1):181–197

He MC, Miao JL, Feng JL (2010) Rock burst process of limestone and its acoustic emission characteristics under true-triaxial unloading conditions. Int J Rock Mech Min Sci 47(2):286–298

Hu X, Duan K (2008) Size effect and quasi-brittle fracture: the role of FPZ. Int J Fract 154:3–14

Ishida T, Labuz JF, Manthei G, Meredith PG, Nasseri MHB, Shin K, Yokoyama T, Zang A (2017) ISRM suggested method for laboratory acoustic emission monitoring. Rock Mech Rock Eng 50(3):665–674

Itasca Consulting Group Inc (2018) PFC (Particle Flow Code) Version 6.0. Minneapolis

Kao CS, Carvalho FCS, Labuz JF (2011) Micromechanisms of fracture from acoustic emission. Int J Rock Mech Min Sci 48(4):666–673

Kong B, Wang EY, Li ZH, Wang XR, Liu J, Li N (2016) Fracture mechanical behavior of sandstone subjected to high-temperature treatment and its acoustic emission characteristics under uniaxial compression conditions. Rock Mech Rock Eng 49(12):4911–4918

Labuz JF, Biolzi L (1991) Class I vs class II stability: a demonstration of size effect. Int J Rock Mech Min Sci Geomech Abstr 28(2/3):199–205

Li N, Wang EY, Ge MC, Sun ZY (2014) A nonlinear microseismic source location method based on simplex method and its residual analysis. Arab J Geosci 7(11):4477–4486

Lin Q, Labuz JF (2013) Fracture of sandstone characterized by digital image correlation. Int J Rock Mech Min Sci 60:235–245

Liu JP, Li YH, Xu SD, Xu S, Jin CY, Liu ZS (2015) Moment tensor analysis of acoustic emission for cracking mechanisms in rock with a pre-cut circular hole under uniaxial compression. Eng Fract Mech 135:206–218

Liu T, Lin BQ, Yang W (2017) Mechanical behavior and failure mechanism of pre-cracked specimen under uniaxial compression. Tectonophysics 712:330–343

Liu QS, Liu Q, Pan YC, Liu XW, Kong XX, Deng PH (2018) Microcracking mechanism analysis of rock failure in diametral compression tests. J Mater Civil Eng 30(6):04018082

Liu B, Zhang D, Li X, Li JC (2022) Seismic response of underground structure–soil–aboveground structure coupling system: current status and future prospects. Tunn Undergr Space Technol 122:104372

Lisjak A, Grasselli G (2014) A review of discrete modeling techniques for fracturing processes in discontinuous rock masses. J Rock Mech Geotech Eng 6(4):301–314

Maity D, Ciezobka J (2019) Using microseismic frequency-magnitude distributions from hydraulic fracturing as an incremental tool for fracture completion diagnostics. J Pet Sci Eng 176:1135–1151

Muralidhara S, Prasad BKR, Eskandari H, Karihaloo BL (2010) Fracture process zone size and true fracture energy of concrete using acoustic emission. Constr Build Mater 24(4):479–486

Ohtsu M (1991) Simplified moment tensor analysis and unified decomposition of acoustic emission source: application to in situ hydrofracturing test. J Geophys Res Solid Earth 96(4):6211–6221

Ohtsu M (1995) Acoustic emission theory for moment tensor analysis. Res Nondestruct Eval 6(3):169–184

Ortlepp WD (2001) The behaviour of tunnels at great depth under large static and dynamic pressures. Tunn Undergr Space Technol 16(1):41–48

Petružálek M, Jechumtálová Z, Kolář P, Adamova P, Svitek T, Sileny J, Lokajicek T (2018) Acoustic emission in a laboratory: mechanism of microearthquakes using alternative source models. J Geophys Res Solid Earth 123(6):4965–4982

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41(8):1329–1364

Reinecker J, Gutmanis J, Foxford A, Cotton L, Dalby C, Law R (2021) Geothermal exploration and reservoir modelling of the United Downs deep geothermal project, Cornwall (UK). Geothermics 97:102226

Rice JR (1968) Mathematical analysis in the mechanics of fracture. In: Liebowitz H (ed) Fracture: an advanced treatise (Vol. 2, mathematical fundamentals). Academic Press, New York

Rice JR (1980) Elastic wave emission from damage processes. J Nondestruct Eval 1(4):215–224

Scruby CB, Baldwin GR, Stacey KA (1985) Characterisation of fatigue crack extension by quantitative acoustic emission. Int J Fract 28(4):201–222

Shah K, Labuz JF (1995) Damage mechanisms in stressed rock from acoustic emission. J Geophys Res Solid Earth 100(8):15527–15539

Wang XR, Liu XF, Wang EY, Li XL, Zhang X, Zhang C, Kong B (2017) Experimental research of the AE responses and fracture evolution characteristics for sand-paraffin similar material. Constr Build Mater 132:446–456

Wang XR, Wang EY, Liu XF (2019) Damage characterization of concrete under multi-step loading by integrated ultrasonic and acoustic emission techniques. Constr Build Mater 221:678–690

Wang XR, Wang EY, Liu XF (2021a) Failure mechanism of fracture rock and associated acoustic behaviors under different loading rates. Eng Fract Mech 247:107674

Wang XR, Wang EY, Liu XF (2021b) Micromechanisms of coal fracture: insights from quantitative AE technique. Theor Appl Fract Mech 114:103000

Wang XR, Asem PY, Chen H, Labuz JF (2021c) Microcracking in tensile fracture of a brittle rock. Eng Fract Mech 251:107789

Wang S, Li LP, Cheng S, Yang JY, Jin H, Gao S, Wen T (2021d) Study on an improved real-time monitoring and fusion prewarning method for water inrush in tunnels. Tunn Undergr Space Technol 112:103884

Wang YC, Tang CA, Tang LX, Zhang SC, Li LM, Li YB, Duan WS (2022) Microseismicity characteristics before and after a rockburst and mechanisms of intermittent rockbursts in a water diversion tunnel. Rock Mech Rock Eng 55:341–361

Wang H, Liu XF, Wang XR, Zhou X, Xie H, Cai DK, Gu PX (2023) Stress-induced AE varying characteristics in distinct lithologies subjected to uniaxial compression. Eng Frac Mech 286:109266

Xie YC, Wu XN, Hou ZM, Li ZY, Luo JS, Lueddeke CT, Huang LC, Wu L, Liao JX (2023) Gleaning insights from German energy transition and large-scale underground energy storage for China’s carbon neutrality. Int J Min Sci Technol 33(5):529–553

Yfantis G, Pytharouli S, Lunn RJ, Carvajal HEM (2021) Microseismic monitoring illuminates phases of slope failure in soft soils. Eng Geol 280:105940

Zhou X, Liu XF, Wang XR, Liu YB, Xie H, Du PF (2022) Acoustic emission characteristics of coal failure under triaxial loading and unloading disturbance. Rock Mech Rock Eng 56(2):1043–1061

Zietlow WK, Labuz JF (1998) Measurement of the intrinsic process zone in rock using acoustic emission. Int J Rock Mech Min Sci 35:291–299

Funding

This work is supported by the National Key R&D Program of China (2022YFE0128300), the National Natural Science Foundation of China (Grant No. 52204249 and 52227901), and the independent research project of State Key Laboratory for Fine Exploration and Intelligent Development of Coal Resources, CUMT (SKLCRSM23X005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Liu, X., Wang, E. et al. Microcracking Characterization in Tensile Failure of Hard Coal: An Experimental and Numerical Approach. Rock Mech Rock Eng (2024). https://doi.org/10.1007/s00603-024-03827-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00603-024-03827-4