Abstract

Identification of preferential seepage channels for a large-scale underground water-sealed oil storage cavern is of great importance for controlling groundwater seepage and ensuring water-sealing performance. In this study, a new approach to identifying preferential seepage channels in the surrounding rock of the underground water-sealed oil storage cavern is proposed, focusing on the spatial distribution and connectivity of microfractures obtained from microseismic monitoring in the surrounding rock masses during cavern construction. The focal mechanism and the spatial occurrence of microfractures are revealed through inversion and analysis of the microseismic moment tensor. By adopting the graph traversal method, the spatial connectivity of microfractures is determined and preferential seepage channels are identified. An underground water-sealed oil storage cavern in Jinzhou, China, is selected as a case study. Five preferential seepage channels, which originate from the water curtain borehole and the surrounding rock masses between the oil storage caverns, and extend downwards along microfracture clusters are identified. The feasibility and validity of the proposed method are verified by the water supply data in the water curtain borehole and field survey. The research results can provide some reference for seepage channel detection, water-sealing performance evaluation and grouting design of large-scale underground water-sealed oil storage caverns.

Highlights

-

The formation of preferential seepage channel is accompanied by the spatial connectivity of microfractures.

-

Preferential seepage channels can be identified using microseismicity and pore pressure data in rocks.

-

The microfractures caused by excavation-induced unloading are mainly tensile cracks in underground oil storage caverns.

-

The occurrence of microfracture around the water curtain tunnel differs from that near the oil storage cavern.

Similar content being viewed by others

Data availability

The data are not publicly available due to privacy.

Abbreviations

- \({\varvec{U}}\) :

-

Matrix of displacements

- \({\varvec{M}},\boldsymbol{ }{M}_{ij}\) :

-

Moment tensor and its component

- \({\varvec{G}}\) :

-

Green’s function

- \(\rho\) :

-

Density

- \(r\) :

-

Distance between the seismic source and the sensor

- \({v}_{P},{ v}_{S}\) :

-

P wave velocity and S wave velocity

- \(\gamma\), \(\varphi\), \(\theta\) :

-

Three components of the source-sensor ray coordinate system in the global coordinate system

- \({M}_{1}, \text{ }{ M}_{2},\text{ } {M}_{3}\) :

-

Three eigenvalues of moment tensor

- \({{\varvec{E}}}^{\text{ISO}}, \text{ }{{\varvec{E}}}^{\text{DC}}, \text{ }{{\varvec{E}}}^{\text{CLVD}}\) :

-

Moment tensor bases

- \({M}^{ISO},\text{ }{M}^{DC} ,\text{ }{M}^{CLVD}\) :

-

Magnitudes of the isotropic component, double-couple component and the compensated linear vector dipole component

- \({P}_{DC}\) :

-

Proportion of the double-couple component

- \(\overrightarrow{{{\varvec{e}}}_{1}}\), \(\overrightarrow{{{\varvec{e}}}_{3}}\) :

-

Eigenvectors corresponding to the maximum and minimum eigenvalues

- \(\overrightarrow{{\varvec{n}}}\) :

-

Normal vector of the fracture surface

- \(R\) :

-

Radius of a circular fracture surface

- \({K}_{c}\) :

-

Seismic source model constant

- \({f}_{0}\) :

-

Corner frequency

References

Aki K, Richards PG (2002) Quantitative seismology, 2nd edn. University Science Books, Sausalito

Åberg B (1977) Prevention of gas leakage from unlined reservoirs in rock. In: The first international symposium on storage in excavated rock caverns, ROCKSTORE 77, Stockholm, 5–8 September 1977

Baig A, Urbancic T (2010) Microseismic moment tensors: a path to understanding frac growth. Lead Edge 29(3):320–324

Benardos AG, Kaliampakos DC (2005) Hydrocarbon storage in unlined rock caverns in Greek limestone. Tunn Undergr Space Technol 20:175–182

Chen Z, Ma C, Li T, He C (2022) Experimental investigation of the failure mechanism of deep granite under high seepage water pressure and strong unloading effect. Acta Geotech 17:5009–5030

Dershowitz WS, Einstein HH (1988) Characterizing rock joint geometry with joint system models. Rock Mech Rock Eng 21(1):21–51

Einstein HH, Locsin JZ (2012) Modeling rock fracture intersections and application to the Boston area. J Geotech Geoenviron 138(11):1415–1421

Feignier B, Young RP (1992) Moment tensor inversion of induced microseisnmic events: evidence of non-shear failures in the −4 < M < −2 moment magnitude range. Geophys Res Lett 19(14):1503–1506

Ge M (2003) Analysis of source location algorithms: part I. Overview and non-iterative methods. J Acoust Emis 21(1):14–28

Gilbert F (1971) Excitation of the normal modes of the earth by earthquake sources. Geophys J Int 22(2):223–226

Goodall DC, Aberg B, Brekke TL (1988) Fundamental of gas containment in unlined rock caverns. Rock Mech Rock Eng 21:235–258

Grosse CU, Finck F (2006) Quantitative evaluation of fracture processes in concrete using signal-based acoustic emission techniques. Cem Concr Compos 28(4):330–336

Hamberger U (1991) Case history: blowout at an LPG storage cavern in Sweden. Tunn Undergr Sp Tech 6(1):119–120

Kim T, Lee KK, Ko KS, Chang HW (2000) Groundwater flow system inferred from hydraulic stresses and heads at an underground LPG storage cavern site. J Hydrol 236(3):165–184

Kiyoyama S (1990) The present state of underground crude oil storage technology in Japan. Tunn Undergr Sp Tech 5(4):343–349

Knopoff L, Randall MJ (1970) The compensated linear-vector dipole: a possible mechanism for deep earthquakes. J Geophys Res 75(26):4957–4963

Lee C, Song J (2003) Rock engineering in underground energy storage in Korea. Tunn Undergr Sp Tech 18(5):467–483

Li Z, Wang K, Wang A, Liu H (2009) Experimental study of water curtain performance for gas storage in an underground cavern. J Rock Mech Geotech 1(1):89–96

Li S, Wang Z, Ping Y, Zhou Y, Zhang L (2014) Discrete element analysis of hydro-mechanical behavior of a pilot underground crude oil storage facility in granite in China. Tunn Undergr Sp Tech 40:75–84

Li Z, Lu B, Zou J, Xu B, Zhang Z (2016) Design and operation problems related to water curtain system for underground water-sealed oil storage caverns. J Rock Mech Geotech 8(5):689–696

Li Y, Chen Y, Zhang G, Liu Y, Zhou C (2017) A numerical procedure for modeling the seepage field of water-sealed underground oil and gas storage caverns. Tunn Undergr Sp Tech 66:56–63

Li ZQ, Xue YG, Liang JY, Qiu DH, Su MX, Kong FM (2020) Performance assessment of the water curtain system: a monitoring system in an underground water-sealed oil reservoir in China. Bull Eng Geol Environ 79:3635–3648

Lin F, Ren F, Luan H, Ma G, Chen S (2016) Effectiveness analysis of water-sealing for underground LPG storage. Tunn Undergr Sp Tech 51:270–290

Lindblom UE (1994) History and present status of hydrocarbon storage in excavated rock caverns. Society of Petroleum Engineers, Delft

Liu H, Qiao L, Wang S, Li W, Liu J, Wang Z (2021) Quantifying the containment efficiency of underground water-sealed oil storage caverns: method and case study. Tunn Undergr Sp Tech 110:103797

Lorén A, Hallbeck L, Pedersen K, Abrahamsson K (2001) Determination and distribution of diesel components in igneous rock surrounding underground diesel storage facilities in Sweden. Environ Sci Technol 35(2):374–378

Ma K, Tang CA, Wang LX et al (2016) Stability analysis of underground oil storage caverns by an integrated numerical and microseismic monitoring approach. Tunn Undergr Sp Tech 54:81–91

Ma C, Jiang Y, Li, T (2019) Gravitational search algorithm for microseismic source location in tunneling: performance analysis and engineering case study. Rock Mech Rock Eng 52:3999–4016

Ma K, Tang CA, Liang ZZ, Zhuang DY, Zhang QB (2017) Stability analysis and reinforcement evaluation of high-steep rock slope by microseismic monitoring. Eng Geol 218:22–38

Mendecki AJ (1997) Seismic monitoring in mine. Champman & Hall Press, London

Ming H, Feng X, Chen B, Zhang C (2013) Analysis of rockburst mechanism for deep tunnel based on moment tensor. Rock Soil Mech 34(1):163–172

Moberg SH (1977) Storage of heavy fuel oil in rock caverns during three decades. In: Proceedings of the 1st International symposium on storage in excavated rock caverns, Stockholm, 5–8 September 1977

Ohtsu M (1991) Simplified moment tensor analysis and unified decomposition of acoustic emission source: application to in situ hydrofracturing test. J Geophys Res 96(B4):6211–6221

Ohtsu M (1995) Acoustic emission theory for moment tensor analysis. Res Nondestruct Eval 6(3):169–184

Ren F, Ma G, Wang Y, Fan L (2016) Pipe network model for unconfined seepage analysis in fractured rock masses. Int J Rock Mech Min 88:183–196

Shi L, Zhang B, Wang L, Wang H, Zhang H (2018) Functional efficiency assessment of the water curtain system in an underground water-sealed oil storage cavern based on time-series monitoring data. Eng Geol 239:79–95

Shi L, Zhang B, Wang H, Zhang H, Peng Z, Li J (2019) Investigation on the causes of abnormal increase of water inflow in underground water-sealed storage system. Tunn Undergr Sp Tech 87:174–186

Song K, Yan E, Gao L, Liang J (2014) Influence of anisotropic permeability of rockmass on stability of underground oil storage caverns. Chin J Rock Mech Eng 33(S2):3803–3809

Sun J, Zhao Z (2010) Effects of anisotropic permeability of fractured rock masses on underground oil storage caverns. Tunn Undergr Sp Tech 25(5):629–637

Tang C (1997) Numerical simulation of progressive rock failure and associated seismicity. Int J Rock Mech Min 34(2):249–261

Tang CA, Tham LG, Lee PKK, Yang TH, Li LC (2002) Coupled analysis of flow, stress and damage (FSD) in rock failure. Int J Rock Mech Min 39(4):477–489

Trifu C, Angus D, Shumila V (2000) A fast evaluation of the seismic moment tensor for induced seismicity. B Seismol Soc Am 90(6):1521–1527

Wang Z, Li S, Qiao L (2015) Assessment of hydro-mechanical behavior of a granite rock mass for a pilot underground crude oil storage facility in China. Rock Mech Rock Eng 48(6):2459–2472

Wang Z, Li W, Qiao L, Liu J, Yang J (2018a) Hydraulic properties of fractured rock mass with correlated fracture length and aperture in both radial and unidirectional flow configurations. Comput Geotech 104:167–184

Wang Z, Li W, Bi L, Qiao L, Liu R, Liu J (2018b) Estimation of the REV size and equivalent permeability coefficient of fractured rock masses with an emphasis on comparing the radial and unidirectional flow configurations. Rock Mech Rock Eng 51(5):1457–1471

Xiao Y, Feng X, Hudson JA, Chen B, Feng G, Liu J (2016) ISRM suggested method for in situ microseismic monitoring of the fracturing process in rock masses. Rock Mech Rock Eng 49(1):343–369

Xu NW, Tang CA, Li LC et al (2011) Microseismic monitoring and stability analysis of the left bank slope in Jinping first stage hydropower station in Southwestern China. Int J Rock Mech Min 48(6):950–963

Yang T, Tang C, Tan Z, Zhu W, Feng Q (2007) State of the art of inrush models in rock mass failure and development trend for prediction and forecast of groundwater inrush. Chin J Rock Mech Eng 26(2):268–277

Yu C, Deng SC, Li HB, Li JC, Xia X (2013) The anisotropic seepage analysis of water-sealed underground oil storage caverns. Tunn Undergr Sp Tech 38:26–37

Zhao J, Bergh-Christensen J (1996) Construction and utilization of rock caverns in Singapore part D: two proposed cavern schemes. Tunn Undergr Sp Tech 11(1):85–91

Zhao H, Chen J (2005) Searching for seepage path of 3D network in fractured rock masses. Chin J Rock Mech Eng 24(4):622–627

Zhao Y, Yang T, Zhang P, Xu H, Zhou J, Yu Q (2019) Method for generating a discrete fracture network from microseismic data and its application in analyzing the permeability of rock masses: a case study. Rock Mech Rock Eng 52:3133–3155

Zhuang DY, Tang CA, Liang ZZ, Ma K, Wang SY, Liang JZ (2017) Effects of excavation unloading on the energy-release patterns and stability of underground water-sealed oil storage caverns. Tunn Undergr Sp Tech 61:122–133

Acknowledgements

This research was supported by the National Natural Science Foundation of China (grant nos. 42007262, 51974055, 42122052), the Joint Fund of Natural Science Basic Research Program of Shanxi Province (Grant No. 2021JLM-11), the Fund of China Petroleum Technology and Innovation (grant no. 2020D-5007-0302) and Yunnan Fundamental Research Projects (grant no. 202001AT070150).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix

Pore water pressure in the surrounding rock masses of the underground water-sealed storage caverns after excavation obtained by numerical simulation.

Numerical Model and Boundary Conditions

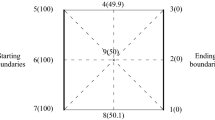

As the length along the cavern axis is much greater than the other two directions, the problem can be simplified into a plane strain problem. Therefore, a typical cavern structure model (Fig. 5) consisting of oil storage caverns 1N and 1S is established to simulate and analyze the seepage field of underground water-sealed caverns during construction. The curtain system is composed of 2 water curtain tunnels (WCTs), 2 horizontal water curtain boreholes (HWCBs) and 2 vertical water curtain boreholes (VWCBs). The horizontal curtain borehole has a diameter of 100 mm and a length of 50 m, while the vertical curtain borehole has a diameter of 100 mm and a length of 58 m. During construction, the water curtain tunnels were not filled with water, while a water pressure of 0.4 MPa was maintained in the horizontal and vertical curtain boreholes so as to ensure the operation state of the curtain system.

The rock layers (Fig. 5) below the groundwater table and the cavern structure are selected to simulate the pore water pressure and seepage vectors in the surrounding rocks after cavern excavation by the F-RFPA2Dmethod. The F-RFPA2D (Tang et al. 2002) was developed on the basis of the RFPA method (Tang 1997), by applying the principle of seepage-stress-damage coupling. It can not only be applied to simulate the seepage characteristics of brittle rocks, but also can be used for numerical analysis of the seepage field and the pore pressure field around rock structures.

The numerical model has a dimension of 276 m (width) × 170 m (height), and is divided into 187,860 elements. According to field survey and packer tests, the mechanical and seepage parameters of the surrounding rocks are determined as listed in Table 4. As for the mechanical boundary condition, the bottom is fixed in the vertical direction while the top is a free boundary. A horizontal in situ stress of 4 MPa is applied on the left and right boundaries so as to simulate the in situ stress on the caverns. As for the seepage boundary, the surrounding rocks are considered saturated and the top is a permeable boundary; a constant water head is applied on the left, right and bottom boundaries, which is determined according to the hydrostatic pressure. Zero water head is applied at the water curtain tunnels and the oil storage caverns. A constant water head of 0.4 MPa is maintained in the horizontal and vertical water curtain boreholes.

Simulation Results

Figure 10 shows the numerical results of pore water pressure distribution, where the higher the gray level, the lower the pore water pressure. The right figure shows the vector diagrams of seepage field, where the line length indicates the seepage velocity. After excavation, obvious groundwater depression cones are formed around the water curtain tunnels and the oil storage caverns. The seepage vectors point to the water curtain tunnel and the oil storage caverns, respectively. This is consistent with the calculation results obtained by Song et al. (2014). All the increased seepage vectors point to the oil storage caverns, indicating that the seepage volume will increase in the oil storage caverns with a seepage volume for one cavern of 350 m3/d and the direction of seepage vectors is the preferential seepage direction of groundwater.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, K., Zhuang, D., Argilaga, A. et al. A New Approach to Identifying Preferential Seepage Channels for Underground Water-Sealed Oil Storage Cavern During Construction. Rock Mech Rock Eng 56, 6395–6410 (2023). https://doi.org/10.1007/s00603-023-03384-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-023-03384-2