Abstract

Matrix shrinkage/swelling induced by gas sorption can be a major geomechanical driver for coalbed methane reservoir stress depletion and gas transport enhancement under in situ reservoir conditions. The pressure-dependent three-dimensional (3-D) coal matrix shrinkage/swelling is of obvious interest for investigating the mechanical failures and gas transport behaviors of coal. An integrated sorption and matrix shrinkage system was employed for simultaneously measuring the gas sorption capacity and 3-D anisotropic swelling/shrinkage strains. The sorbing methane gas and non-sorbing helium gas were used as the flooding fluids on two coals. The high heterogeneity and anisotropy features in micro- to macro- scale of coals were confirmed using FESEM-EDS imaging and elemental analysis. To quantify the 3-D anisotropic characteristics in directional swelling strains, rosette strain gauges were employed. The 3-D principal strains for the two coals were computed through combining the proposed strain transformation model and the visualized cleat coordinate system established via the reconstructed 3-D coal structure using the X-ray CT images. For helium injection, coals were in compression and the maximum compression strain in the newly established cleat system can be up to ~ – 0.11% and ~ – 0.10% for samples S1 and S2 at pressure of 1664.35 psi, respectively. The maximum principal strain in dilation for coals S1 and S2 due to methane injection can be up to ~ 0.21% and ~ 0.149%, respectively, at pressure of 2279.37 psi. The pressure- or methane content- dependent anisotropic degree based on the actual three-dimensional principal strains in the cleat coordinate system was calculated and discussed. The results will provide a comprehensive modeling framework to evaluate sorption-induced swelling effects under in situ complex boundary conditions.

Highlights

-

3D swelling strains of coal induced by gas sorption are determined.

-

Micro- to macro- scale heterogeneity and anisotropy of coals are confirmed.

-

3D principle swelling strains are modeled in the cleat coordinate system.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon request.

References

Cui X, Bustin RM (2005) Volumetric strain associated with methane desorption and its impact on coalbed gas production from deep coal seams. Am Assoc Pet Geol Bull 89:1181–1202

Day S, Fry R, Sakurovs R (2008) Swelling of Australian coals in supercritical CO2. Int J Coal Geol 74:41–52

Espinoza DN, Vandamme M, Pereira J et al (2014) Measurement and modeling of adsorptive – poromechanical properties of bituminous coal cores exposed to CO 2: adsorption, swelling strains, swelling stresses and impact on fracture permeability. Int J Coal Geol 134–135:80–95. https://doi.org/10.1016/j.coal.2014.09.010

Gallagher N, Wise G (1981) A theoretical analysis of the properties of median filters. IEEE Trans Acoust 29:1136–1141

Harpalani S, Chen G (1995) Estimation of changes in fracture porosity of coal with gas emission. Fuel 74:1491–1498

Harpalani S, Schraufnagel RA (1990) Shrinkage of coal matrix with release of gas and its impact on permeability of coal. Fuel 69:551–556. https://doi.org/10.1016/0016-2361(90)90137-F

Hou X, Liu S, Li G et al (2021) Quantifying and modeling of in situ sress evolutions of coal reservoirs for helium, methane, nitrogen and CO2 depletions. Rock Mech Rock Eng 54:3701–3719. https://doi.org/10.1007/s00603-021-02511-1

Jaeger GC (1969) Fundamentals of rock mechanics. Chapman and Hall Ltd and Science Paperbacks, London

Karacan CÖ (2003) Heterogeneous sorption and swelling in a confined and stressed coal during CO2 injection. Energy Fuels 17:1595–1608. https://doi.org/10.1021/ef0301349

Laubach SE, Marrett RA, Olson IE, Scott AR (1998) Characteristics and origins of coal cleat: a review. Int J Coal Geol 35:175–207. https://doi.org/10.1016/S0166-5162(97)00012-8

Levine JR (1996) Model study of the influence of matrix shrinkage on absolute permeability ofcoal bed reservoirs. In: Gayer R, Harris T (eds) Coalbed methane and coal geology, vol 109. Geological Society Special Publication, London, pp 197–212

Liu S, Harpalani S (2013) A new theoretical approach to model sorption-induced coal shrinkage or swelling. Am Assoc Pet Geol Bull 97:1033–1049. https://doi.org/10.1306/12181212061

Liu S, Harpalani S (2014) Evaluation of in situ stress changes with gas depletion of coalbed methane reservoirs. J Geophys Res Solid Earth. 119:6263–6276

Liu J, Chen Z, Elsworth D et al (2011) Interactions of multiple processes during CBM extraction: a critical review. Int J Coal Geol 87:175–189. https://doi.org/10.1016/j.coal.2011.06.004

Liu J, Peach CJ, Spiers CJ (2016a) Anisotropic swelling behaviour of coal matrix cubes exposed to water vapour: effects of relative humidity and sample size. Int J Coal Geol 167:119–135. https://doi.org/10.1016/j.coal.2016.09.011

Liu J, Spiers CJ, Peach CJ, Vidal-Gilbert S (2016b) Effect of lithostatic stress on methane sorption by coal: theory vs. experiment and implications for predicting in-situ coalbed methane content. Int J Coal Geol 167:48–64. https://doi.org/10.1016/j.coal.2016.07.012

Liu S, Wang Y, Harpalani S (2016c) Anisotropy characteristics of coal shrinkage/swelling and its impact on coal permeability evolution with CO2 injection. Greenh Gases Sci Technol 6: 615–632. https://doi.org/10.1002/ghg

Liu J, Fokker PA, Spiers CJ (2017) Coupling of swelling, internal stress evolution, and diffusion in coal matrix material during exposure to methane. J Geophys Res Solid Earth 122:844–865. https://doi.org/10.1002/2016JB013322

Liu A, Liu S, Wang G, Sang G (2020a) Modeling of coal matrix apparent strains for sorbing gases using a transversely isotropic approach. Rock Mech Rock Eng 53:4163–4181. https://doi.org/10.1007/s00603-020-02159-3

Liu T, Liu S, Lin B et al (2020b) Stress response during in-situ gas depletion and its impact on permeability and stability of CBM reservoir. Fuel 266:11703. https://doi.org/10.1016/j.fuel.2020.117083

Liu A, Liu S, Liu P, Harpalani S (2021) The role of sorption-induced coal matrix shrinkage on permeability and stress evolutions under replicated in situ condition for CBM reservoirs. Fuel 294:120530. https://doi.org/10.1016/j.fuel.2021.120530

Lu M, Connell L (2016) Coal failure during primary and enhanced coalbed methane production — theory and approximate analyses. Int J Coal Geol 154–155:275–285. https://doi.org/10.1016/j.coal.2016.01.008

Lu M, Connell LD (2020) Coal seam failure during primary/enhanced gas production: How failure develops in fields. Int J Coal Geol 221:103432. https://doi.org/10.1016/j.coal.2020.103432

Moffat W (1955) Sorption by coal of methane at high pressures. Fuel 34:449–462

Pan Z, Connell LD (2007) A theoretical model for gas adsorption-induced coal swelling. Int J Coal Geol 69:243–252. https://doi.org/10.1016/j.coal.2006.04.006

Pan Z, Connell LD (2011) Modelling of anisotropic coal swelling and its impact on permeability behaviour for primary and enhanced coalbed methane recovery. Int J Coal Geol 85:257–267. https://doi.org/10.1016/j.coal.2010.12.003

Pan Z, Connell LD (2012) Modelling permeability for coal reservoirs: a review of analytical models and testing data. Int J Coal Geol 92:1–44. https://doi.org/10.1016/j.coal.2011.12.009

Reucroft PJ, Sethuraman AR (1987) Effect of pressure on carbon dioxide induced coal swelling. Energy Fuels 1:72–75

Sang G, Liu S (2021) Carbonate caprock–brine–carbon dioxide interaction: alteration of hydromechanical properties and implications on carbon dioxide leakage. SPE J 26:2780–2792. https://doi.org/10.2118/201353-pa

Saurabh S, Harpalani S (2019) Anisotropy of coal at various scales and its variation with sorption. Int J Coal Geol 201:14–25. https://doi.org/10.1016/j.coal.2018.11.008

Shi J, Durucan S (2005) A model for changes in coalbed permeability during primary and enhanced methane recovery. SPE Res Eval Eng 8:291–299

Wang K, Zang J, Wang G, Zhou A (2014) Anisotropic permeability evolution of coal with effective stress variation and gas sorption: Model development and analysis. Int J Coal Geol 130:53–65. https://doi.org/10.1016/j.coal.2014.05.006

Zang J, Ge Y, Wang K (2020) The principal permeability tensor of inclined coalbeds during pore pressure depletion under uniaxial strain conditions: developing a mathematical model, evaluating the influences of featured parameters, and upscaling for CBM recovery. J Nat Gas Sci Eng 74:103099. https://doi.org/10.1016/j.jngse.2019.103099

Zhang R, Liu S, He L et al (2020) Characterizing anisotropic pore structure and its impact on gas storage and transport in coalbed methane and shale gas reservoirs. Energy Fuels 34:3161–3172. https://doi.org/10.1021/acs.energyfuels.0c00109

Zhao Y, Song H, Liu S et al (2019) Mechanical anisotropy of coal with considerations of realistic microstructures and external loading directions. Int J Rock Mech Min Sci 116:111–121. https://doi.org/10.1016/j.ijrmms.2019.03.005

Zhou X, Liu S, Zhang Y (2021) Permeability evolution of fractured sorptive geomaterials: a theoretical study on coalbed methane reservoir. Rock Mech Rock Eng 54:3507–3525. https://doi.org/10.1007/s00603-021-02404-3

Acknowledgements

This work was financially supported by the Open Fund Research Project Supported by State Key Laboratory of Strata Intelligent Control and Green Mining Co-founded by Shandong Province and the Ministry of Science and Technology under Contract No. SICGM202206. We acknowledge Dr. Kai Wang from China University of Mining and Technology (Beijing) for his contribution in the visualization of the original manuscript.

Funding

The work of Ang Liu was supported by the State Key Laboratory of Strata Intelligent Control and Green Mining co-founded by Shandong Province and the Ministry of Science and Technology, under Grant No. SICGM202206.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Experimental Procedure for Synchronous Gas Sorption and Matrix Swelling Measurements

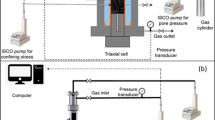

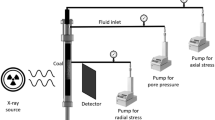

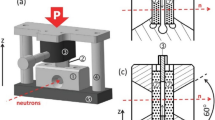

Approximately 150 g coal powders were loaded into the powder sample cell and the cubic coal sample was placed into the cubic sample cell prior to gas injections (Fig.

19). Pressure-dependent gas sorption and sorption-induced directional swelling strains can be monitored and estimated using the recorded pressures and strains. For the matrix swelling test, we initially opened all the valves and vacuumed the whole experimental system for residual air removal. Then, the reference cell was pressurized through opening valve 3 and shutting off valve 1, valve 2, and valve 4. When the pressure in reference cell reached p1 indicated by pressure transducer 3, we shut off valve 3 and waited for the pressure stabilization. Then, we opened valve 1, the gas was dosed to cubic sample cell from reference cell with its pressure decreases from p1 to p2, which was recorded by pressure transducer 3. At this stage, both the reference cell and cubic sample cell stabilized at the same pressure p2, which can be indicated by pressure transducers 1 and 3. Subsequently, valve 1 was closed and the cubic sample cell was isolated as a closed system with testing pressure of p2 (pressure transducer 1). The stabilized pressure p2 at different stages was defined as the stage-based equilibrium pressures for matrix swelling tests. Till then, the pressure in reference cell was still p2. Then, we started to operate the adsorption test. After closing valves 1, the reference cell and powder sample cell separated by valve 2 were established as a traditional volumetric-based sorption measurement system. Since the reference cell was stabilized at pressure p2, the total amount of gas molecules in reference cell was known. We opened valve 2, a portion of gas molecules in reference cell was dosed into powder samples cell. We kept valve 2 open till the pressure stabilized at p3 in both reference cell and powder sample cell, which are indicated by pressure transducers 2 and 3. The final stabilized pressure p3 was used as the gas pressure for this stage. The stabilized pressures p3 at different stages were defined as the stage-based equilibrium pressures for adsorption tests. Because gas sorption in power coal sample is quicker than the strain equilibrium on cubic sample in cubic sample cell, we waited for at least 3 days for each pressure step. To complete all the testing program, we repeated all the steps for each pressure until the final pressure was achieved. The recorded pressures and strains were used for data analyses.

Appendix B: Modeling Analysis

2.1 Determination of Principal Strains on Coal from Strain Rosettes

Various techniques have been implemented to measure the state of strain on a plane for rocks under both unconstrained and constrained conditions. These techniques, primarily involving strain gauges or displacement extensometers, depend on measured normal strains in various directions. In this study, the \({45}^{^\circ }\)-rectangular strain rosette was employed to determine the state of strain at any given coal surficial plane. The question then arises to use the measured three angular normal strains to identify the principal strains and the directions. As illustrated in Fig.

Strain transformation diagram: (a) on a test surface, the grid of a rectangular rosette was installed at the arbitrary angle \(\varphi\) from the major principal axis; (b) axes of the rectangular rosette superimposed on Mohr’s circle for strain. Determined from the directional strains on the plane at the directions of \(\varphi\), \(\varphi +{45}^{^\circ }\), and \(\varphi +{90}^{^\circ }\), the maximum and minimum normal strains (i.e., \({\varepsilon }_{P}\) and \({\varepsilon }_{Q}\)) can be determined based on Eqs. (1) to (3). Except in the case in which \(x\) or \(y\) is a principal direction, these two subsidiary principal strains will not correspond to two of the actual three-dimensional principal strains. In other words, the angle \(\gamma\) from the \(x\)-axis defines the rotation degree of principal strain/stress from the coordinate system showing the actual three-dimensional principal strains. If \(\gamma =\varphi\), the calculated principal strain directions are coaxial with the actual principal directions

20, the strain transformation from principal strains can be determined using rectangular strain gage rosette (Fig. 20a) and then recalling strain-transformation relationship with the aid of strain Mohr’s circle (Fig. 20b).

At any angle \(\varphi\) from the major principal axis, the angles in Mohr’s circle double the normal strains, and thus, the normal strains at three arbitrary directions measured from three grids in rectangular rosette can be expressed as

where \({\varepsilon }_{\varphi }\), \({\varepsilon }_{\varphi +{45}^{^\circ }}\), and \({\varepsilon }_{\varphi +{90}^{^\circ }}\) are the measured directional strains, dimensionless; \({\varepsilon }_{P}\) and \({\varepsilon }_{Q}\) are the maximum and minimum normal strains, dimensionless; \(\varphi\) is the acute angle from the principal axis to the Grid 1, as shown in Fig. 20a.

In terms of the three measured strains (i.e.,\({\varepsilon }_{\varphi }\), \({\varepsilon }_{\varphi +{45}^{^\circ }}\) and \({\varepsilon }_{\varphi +{90}^{^\circ }}\)), the unknown quantities \({\varepsilon }_{P}\), \({\varepsilon }_{Q}\), and \(\varphi\), can be obtained by solving the Eqs. (1)–(3) simultaneously, which can be expressed as

If positive, the physical direction of the angle \(\varphi\) given by Eq. (5) is counterclockwise. If negative, it is clockwise. Since \(\mathrm{tan}2\varphi =\mathrm{tan}(2\varphi +{90}^{^\circ })\), the calculated angle \(\varphi\) can refer to either principal axis, and hence, the identification in Eq. (5) was represented as \({\varphi }_{P,Q}\). This ambiguity can readily be solved by application of the following criteria: (a) if \({\varepsilon }_{\varphi }>{\varepsilon }_{\varphi +{90}^{^\circ }}\), then \({\varphi }_{P,Q}={\varphi }_{P}\); (b) if \({\varepsilon }_{\varphi }<{\varepsilon }_{\varphi +{90}^{^\circ }}\), then \({\varphi }_{P,Q}={\varphi }_{Q}\); (c) if \({\varepsilon }_{\varphi }={\varepsilon }_{\varphi +{90}^{^\circ }}\) and \({\varepsilon }_{\varphi }<{\varepsilon }_{\varphi +{45}^{^\circ }}\), then \({\varphi }_{P,Q}={\varphi }_{P}=-{45}^{^\circ }\); (d) if \({\varepsilon }_{\varphi }={\varepsilon }_{\varphi +{90}^{^\circ }}\) and \({\varepsilon }_{\varphi }>{\varepsilon }_{\varphi +{45}^{^\circ }}\), then \({\varphi }_{P,Q}={\varphi }_{Q}={45}^{^\circ }\); (e) if \({\varepsilon }_{\varphi }={\varepsilon }_{\varphi +{45}^{^\circ }}={\varepsilon }_{\varphi +{90}^{^\circ }}\), then \({\varphi }_{P,Q}\) is indeterminate (equal biaxial strain).

Under hydrostatic pressure condition, there is no shear stress and the directions exhibiting the maximum and minimum normal strains \({\varepsilon }_{P}\) and \({\varepsilon }_{Q}\) are regarded as coaxial to two of the actual three-dimensional principal directions. Using the strain transformation relation, the directional strains at any arbitrary directions can be expressed as

where \({\varepsilon }_{{P}^{^{\prime}}}\), \({\varepsilon }_{{Q}^{^{\prime}}}\) and \({\varepsilon }_{{{P}^{^{\prime}}Q}^{^{\prime}}}\) are the plane strains at arbitrary directions;\(\theta\) is the angle between the targeted plane and the principal directions, which is defined as positive in the counterclockwise direction.

Based on Eqs. (6)–(8), the directional strains on each of the orthogonal surfaces at arbitrary directions can be computed and quantified.

2.2 Determination of Principal Strains at the Matrix Coordinate System Using Strain Gage Rosettes

Based on the tensors of Young’s moduli and Poisson’s ratios, the anisotropic elastic properties of bulk coal can be depicted. By applying Hooke’s law (Jaeger 1969; Pan and Connell 2011), the isothermal anisotropy strains induced by mechanical compression can be written as

where \({\varepsilon }_{c\_i}\) is the apparent strain solely attributed to the mechanical compression with the subscript \(i\) represents the \(i\) -component stress; \({\sigma }_{i}\)(\({\sigma }_{j}\)) (\(i,j=x,y,z\)) represents the i-component effective stress; \({E}_{i}\) (\({E}_{j}\)) (\(i,j=x,y,z\)) and \({v}_{ji}\) (\(i=x,y,z\)) are the directional Young’s moduli and Poisson’s ratios, respectively.

In an orthorhombic symmetry system, the relationships between the principal stresses and strains can be derived as (Liu et al. 2020a)

Taking the derivative of Eq. (10) with respect to gas pressure, it gives the directional matrix compressibility

From Eq. (11), it shows that the difference in directional swelling/shrinkage strain with gas injection/depletion under unconstrained condition is controlled by the intrinsic elastic properties, such as Young’s modulus and Poisson’s ratio.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, A., Liu, S., Xia, K. et al. Characterizing Anisotropic Swelling Strains of Coal Using Combined Rosette Strain Gauge and CT-Scans. Rock Mech Rock Eng 56, 5405–5426 (2023). https://doi.org/10.1007/s00603-023-03348-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-023-03348-6